Metal processing device for coating on bonding copper wire

A technology for metal processing and bonding copper wire, which is applied to the device, coating, and electrical components that apply liquid to the surface. and other problems to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

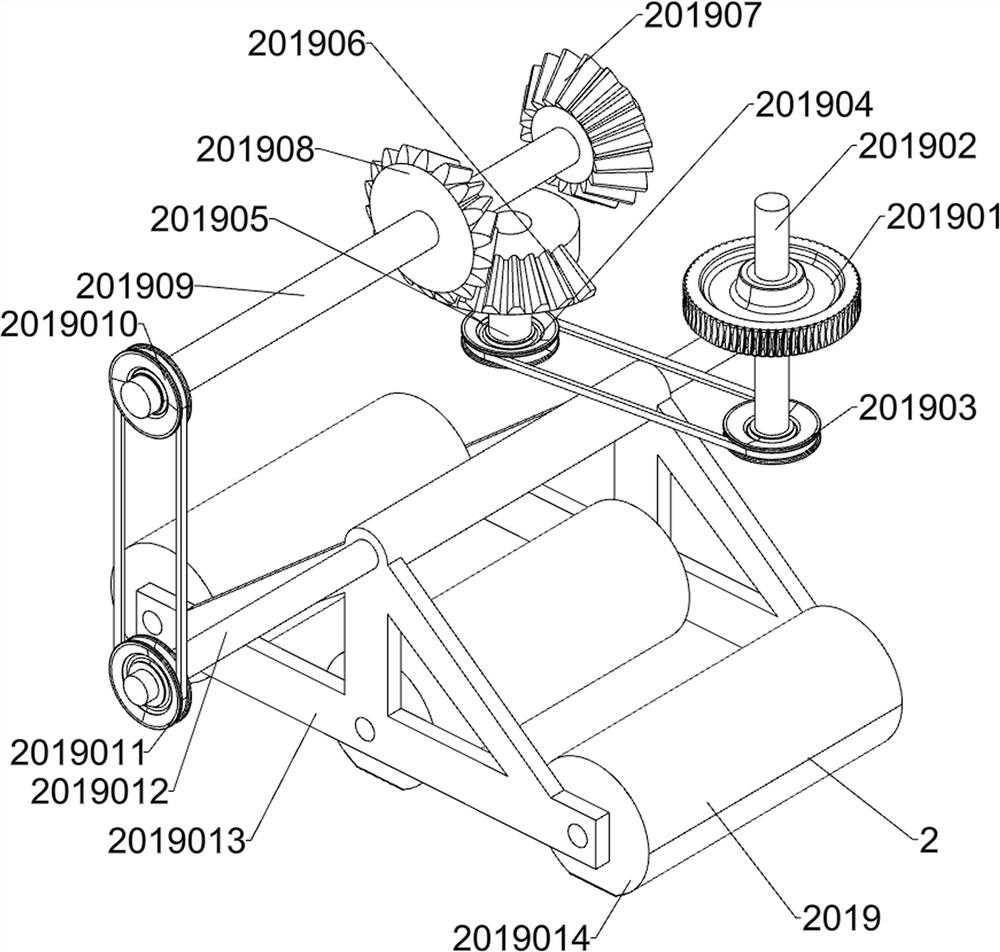

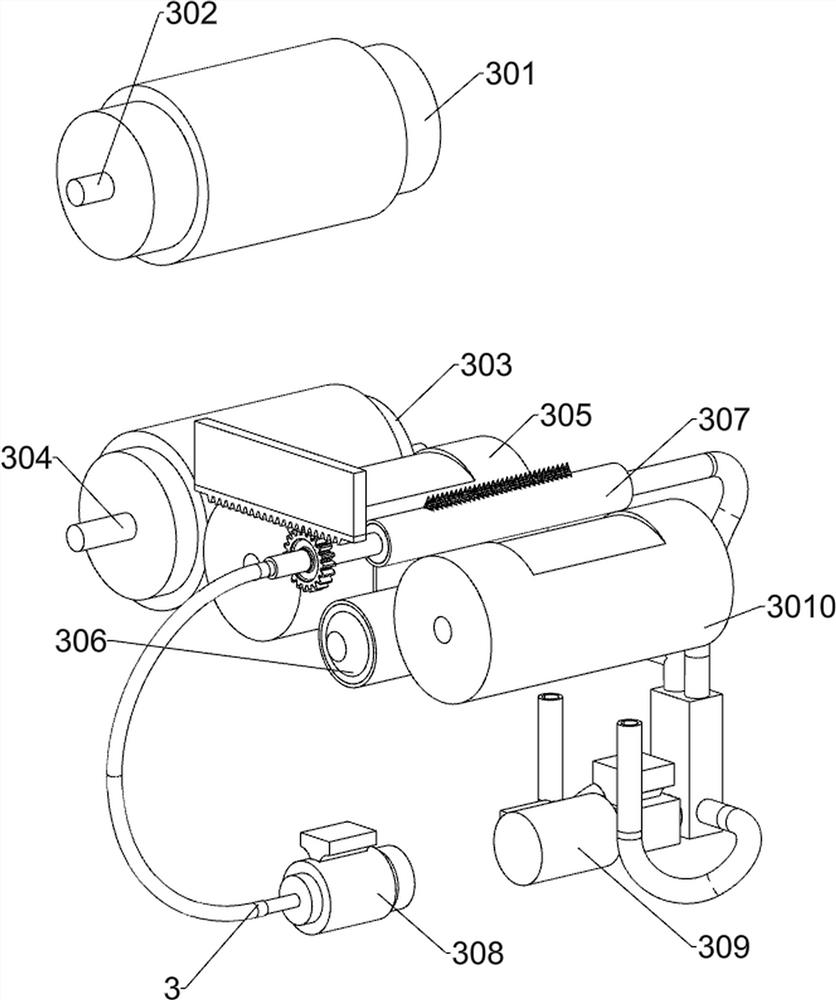

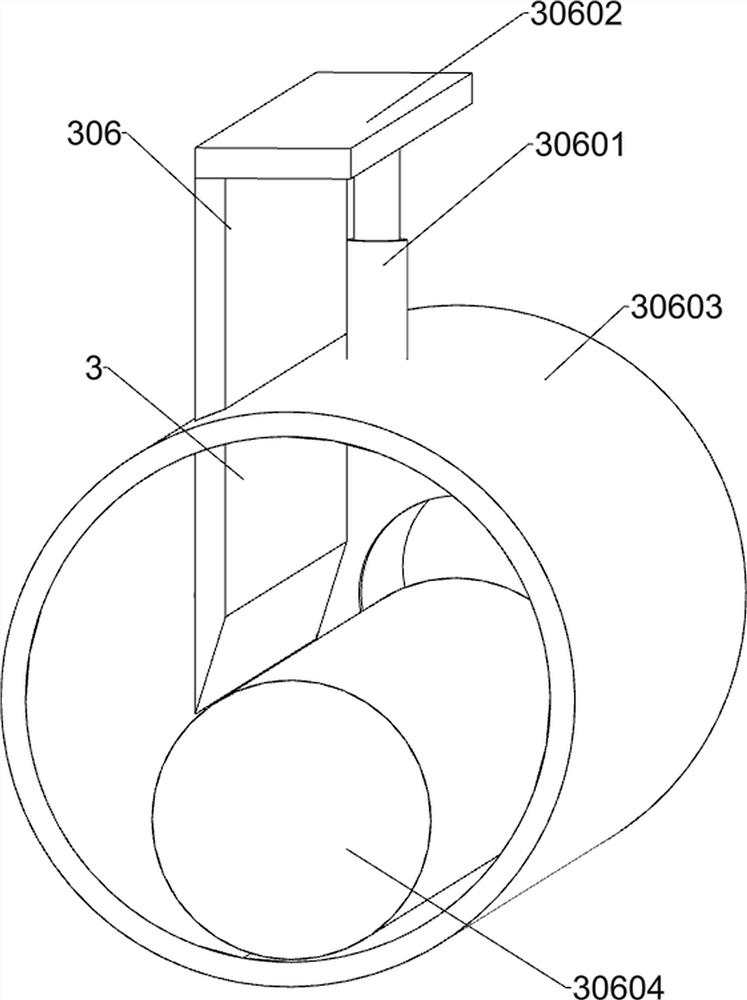

[0032] Metal processing apparatus for coating on bonded copper wire, such as Figure 1-9 As shown, including the chassis 1, the rocking type friction unit 2, the coating unit 3, the winding unit 4, the control screen 5, and the coating box 6; the chassis 1 is connected to the rocking friction unit 2; the chassis 1 and the coated The cloth unit 3 is connected; the chassis 1 is connected to the winding unit 4; the chassis 1 is connected to the control screen 5; the bottom frame 1 is connected to the coating box 6; the rocking friction unit 2 is connected to the winding unit 4; The wound unit 4 is provided with a coating unit 3 on the side of the winding unit 4; the winding unit 4 is provided with a coating box 6.

[0033] When using, the metal processing apparatus of the bonded copper wire is placed to the position to be used, then the external power source is applied, and then the chassis 1 is placed in a stationary position, and the device is controlled by the control screen 5; fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com