Polymer dispersed liquid crystal (PDLC) membrane preparation method and PDLC membrane

A technology for dispersing liquid crystals and polymers, applied in liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of performance improvement limitations, single mesh structure, strong irritation, etc., to improve electro-optical properties, low viscosity, Low volatility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Mix the polymerizable monomer and the liquid crystal according to the mass ratio of 3:7, wherein the mass ratio of each monomer of the polymerizable monomer is LMA:HPMA:PEGDA200:TTMP=2:3:4:1, and add the polymerizable monomer 5% UV photoinitiator 1173 by volume, the liquid crystal material used is nematic liquid crystal SLC 1717 that matches the refractive index of the selected polymerizable monomer; after stirring evenly, pour the mixed system into two plates In a liquid crystal cell made of indium tin oxide (ITO) conductive glass, the thickness between the two pieces of ITO conductive glass that controls the liquid crystal cell is about 20 μm; at a temperature of 273K, the filled liquid crystal cell has a wavelength of 365nm , the light intensity is 10mW / cm 2 Under the ultraviolet light, irradiate 10min, promptly obtain the PDLC thin film of embodiment 1.

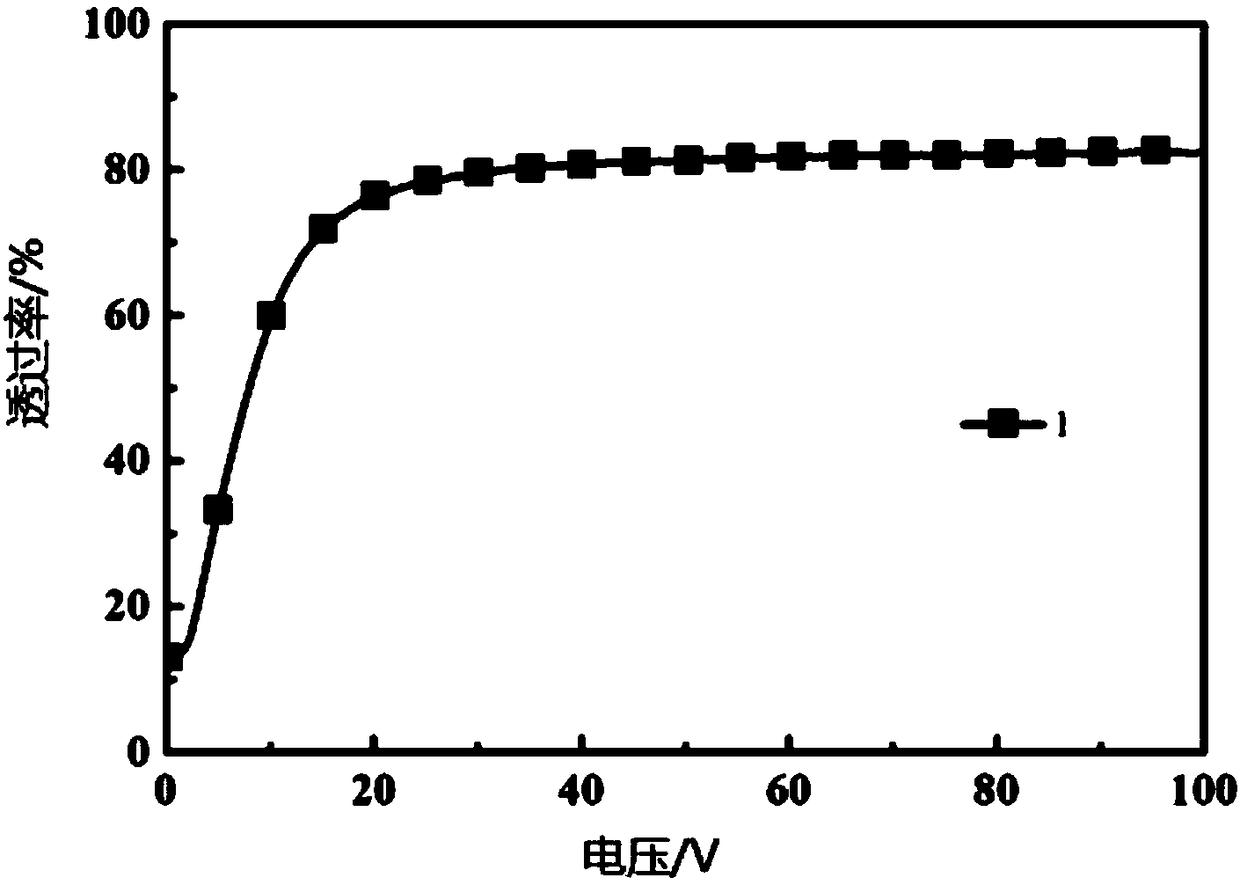

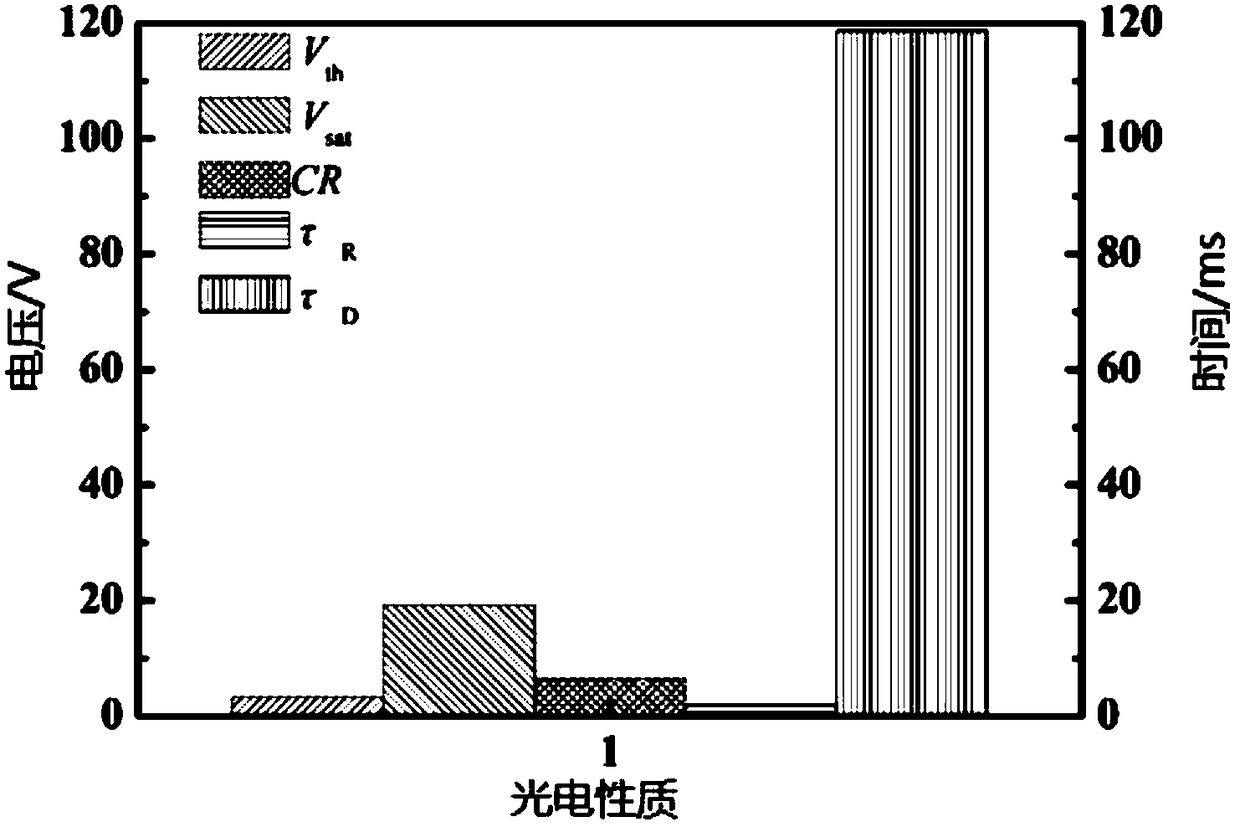

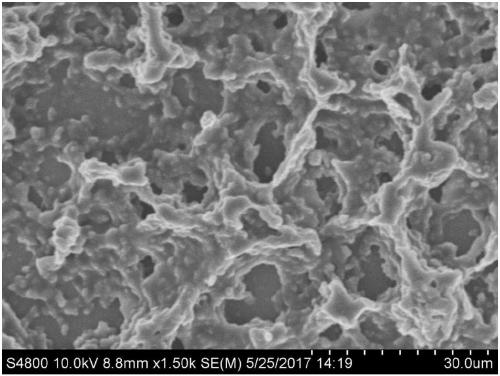

[0056] The experimental results show that: due to the low liquid crystal content, the formed polymer network ha...

Embodiment 2

[0058] Mix the polymerizable monomer and liquid crystal according to the mass ratio of 1:1, wherein the mass ratio of each monomer of the polymerizable monomer is LMA:HPMA:PEGDA200:TTMP=2:3:4:1, and add the polymerizable monomer 5% by mass of UV photoinitiator 651, the liquid crystal material used is nematic liquid crystal SLC 1717 that matches the refractive index of the selected polymerizable monomer; after stirring evenly, pour the mixed system into two coated In a liquid crystal cell made of indium tin oxide (ITO) conductive glass, the thickness between the two pieces of ITO conductive glass that controls the liquid crystal cell is about 20 μm; at a temperature of 273K, the filled liquid crystal cell is The light intensity is 10mW / cm 2 Under the ultraviolet light, irradiate 10min, promptly obtain the PDLC thin film of embodiment 2.

[0059] The experimental results show that: due to the high content of liquid crystals, the formed polymer network has a smaller mesh, and th...

Embodiment 3

[0061] The polymerizable monomer and the liquid crystal are mixed according to a mass ratio of 1:1, wherein the mass ratio of each monomer of the polymerizable monomer is LMA:HPMA:PEGDA200:TTMP=14:21:10:5, and the proportion of the polymerizable monomer is added 3% by volume of UV photoinitiator 651, the liquid crystal material used is nematic liquid crystal SLC 1717 that matches the refractive index of the selected polymerizable monomer; after stirring evenly, pour the mixed system into two plated In a liquid crystal cell made of indium tin oxide (ITO) conductive glass, the thickness between the two pieces of ITO conductive glass that controls the liquid crystal cell is about 10 μm; at a temperature of 273K, the filled liquid crystal cell has a wavelength of 365nm , the light intensity is 10mW / cm 2 Under the ultraviolet light, irradiate 10min, promptly obtain the PDLC thin film of embodiment 3.

[0062] The experimental results show that: due to the lower content of the cros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com