Green and environment-friendly antifouling paint for fishing boats, and fouling-panel testing method

A green, environmentally friendly, antifouling paint technology, applied in antifouling/underwater paints, paints containing biocides, devices for coating liquids on surfaces, etc. stability issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

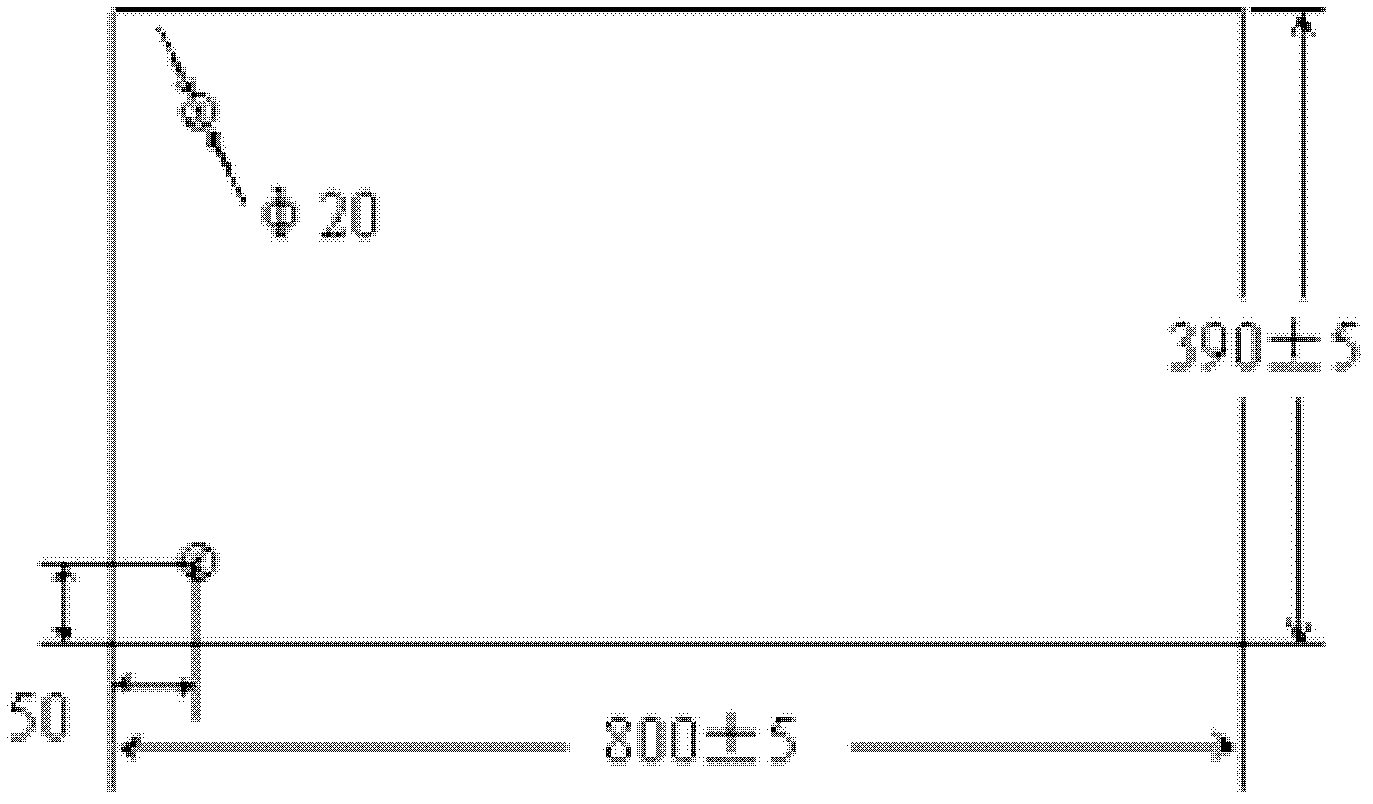

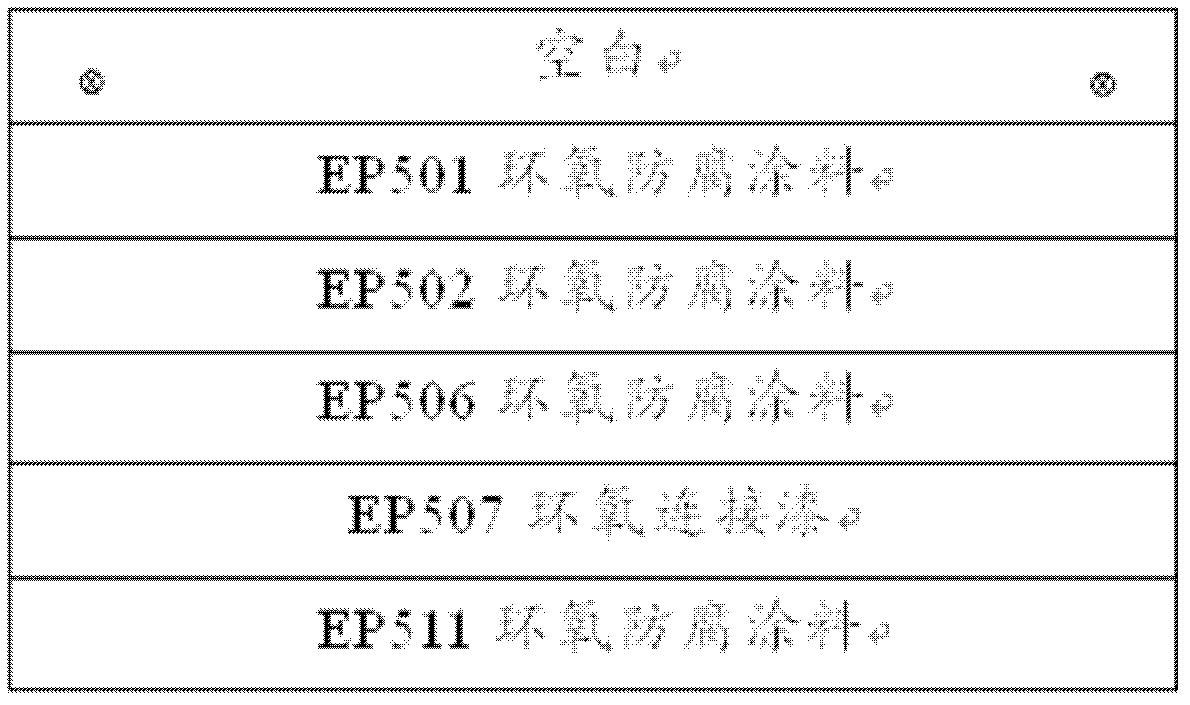

[0052] Embodiment 1: the shallow sea immersion test method of the fishing boat antifouling paint model of the present invention

[0053] The test sample for the shallow sea immersion test is made of PVC sheet, with a length of 800 mm, a width of 390 mm, a thickness of 5 mm, and a drilling diameter of 20 mm. image 3 , respectively apply 4 kinds of surface anti-corrosion paint, epoxy connecting paint and white space along the long side and horizontal width. After drying at room temperature for 24 hours, if attached Figure 4 Apply 6 anti-fouling paints and blanks in the longitudinal direction, and use a polyethylene rope with a diameter of 8 mm to pass through the drilled hole and tie it in knots. After drying for 24 hours, conduct a shallow sea immersion test (underwater test).

Embodiment 2

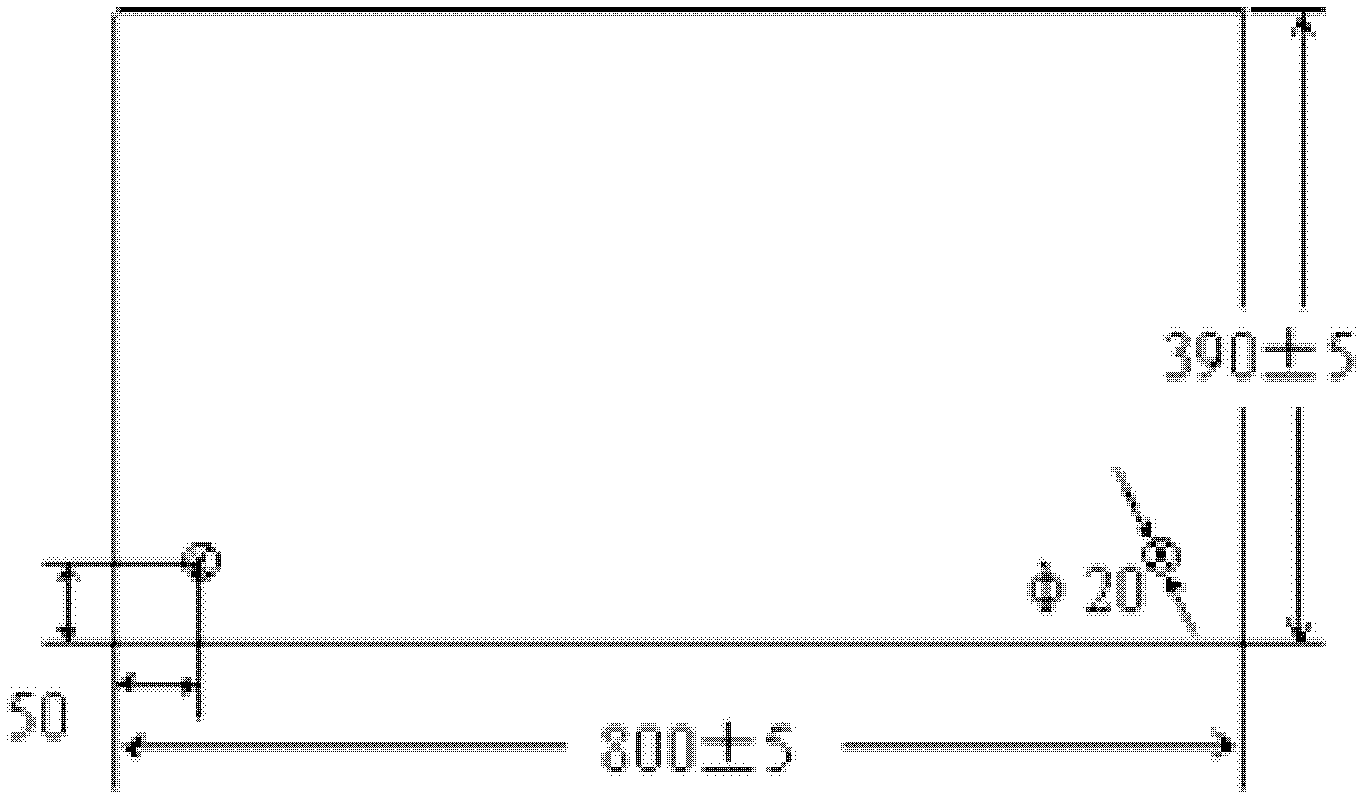

[0054] Embodiment 2: the shallow sea immersion test method of the fishing boat antifouling paint model of the present invention

[0055] The test sample for the shallow sea immersion test is made of PVC sheet, with a length of 800 mm, a width of 390 mm, a thickness of 5 mm, and a drilling diameter of 20 mm. Figure 5 , coating 2 kinds of anti-corrosion paints and blanks on the surface of different materials along the long side and equal width respectively, and coating 20 kinds of antifouling paints and contrast coatings along the long side and equal width (attached Image 6 ), and use a polyethylene rope with a diameter of 8mm to pass through the drill hole and tie it in knots. After 24 hours of drying, perform a shallow sea immersion test (underwater test).

Embodiment 3

[0056] Embodiment 3: the fishing boat antifouling paint sample shallow sea immersion test method of the present invention

[0057] The test sample for the shallow sea immersion test is made of PVC sheet, with a length of 800mm, a width of 390mm, a thickness of 5mm, and a drilled hole diameter of 20mm. Figure 7 , respectively apply 2 kinds of anti-corrosion paints and blanks on the surface of different materials along the long side and horizontal width, after drying at room temperature for 24 hours, apply 16 kinds of antifouling paints vertically, and leave blanks on the left and right upper corners (attached Figure 8 ), and use a polyethylene rope with a diameter of 8mm to pass through the drill hole and tie it in knots. After 24 hours of drying, perform a shallow sea immersion test (underwater test).

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com