Marine life corrosion-resistant ceramic coating and preparation method thereof

A bio-corrosion and ceramic coating technology, applied in coatings, metal material coating processes, fusion spraying and other directions, can solve the problems of non-friction, non-sea biological corrosion and anti-fouling coatings, etc., to achieve low cost, high efficiency Anti-corrosion performance of marine organisms, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

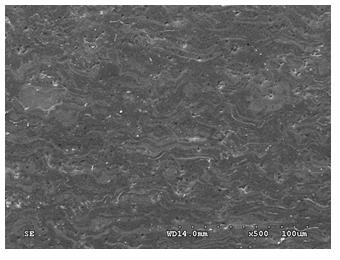

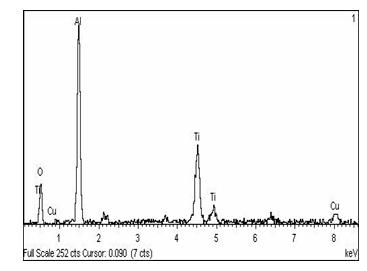

[0034] In order to prepare Al which is resistant to marine corrosion 2 o 3 -13%TiO 2 The first embodiment of the present invention will be described by taking the ceramic coating as an example.

[0035] Al in particle size 5-0 μm 2 o 3 -13%TiO 2 In the ceramic powder, CuO powder with a particle size of 5-5 μm is added. CuO powder accounts for 4% by volume of the mixed powder. Agglomerated and granulated by spray drying equipment, sintered, spheroidized, crushed and sieved to obtain composite ceramic powder with a particle size of 10-45 μm.

[0036]Put the stainless steel workpiece in acetone for ultrasonic cleaning for 15-0 minutes, and use 20-70 mesh corundum sand to roughen the surface of the workpiece after wiping with alcohol. Dry the composite ceramic powder and the 45-00 μm sprayed bonding transition layer with Ni-20%Cr alloy powder at 60°C-50°C, and then put the dried powder into the powder feeder.

[0037] Supersonic plasma spraying is used to bond the transiti...

Embodiment 2

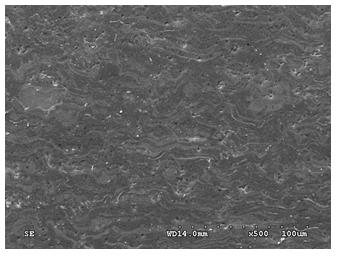

[0040] The following is to prepare Cr which is resistant to marine corrosion 2 o 3 -SiO 2 -TiO 2 A ceramic coating is taken as an example to describe the second embodiment of the present invention.

[0041] In Cr with a particle size of 5-25 μm 2 o 3 -SiO 2 -TiO 2 In the ceramic powder, CuO powder with a particle size of 5-15 μm is added. CuO powder accounts for 5% by volume of the mixed powder. Agglomerated and granulated by spray drying equipment, sintered, spheroidized, crushed and sieved to obtain composite ceramic powder with a particle size of 20-45 μm.

[0042] Put the stainless steel workpiece in acetone for ultrasonic cleaning for 15-30 minutes, and use 20-70 mesh corundum sand to roughen the surface of the workpiece after wiping with alcohol. Dry the composite ceramic powder and the 45-100 μm spray-coated bonding transition layer with Ni-20%Cr alloy powder at 60°C-150°C, and then put the dried powder into the powder feeder.

[0043] The bonding transition l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com