Improved preparation method for zinc/copper acrylate resin

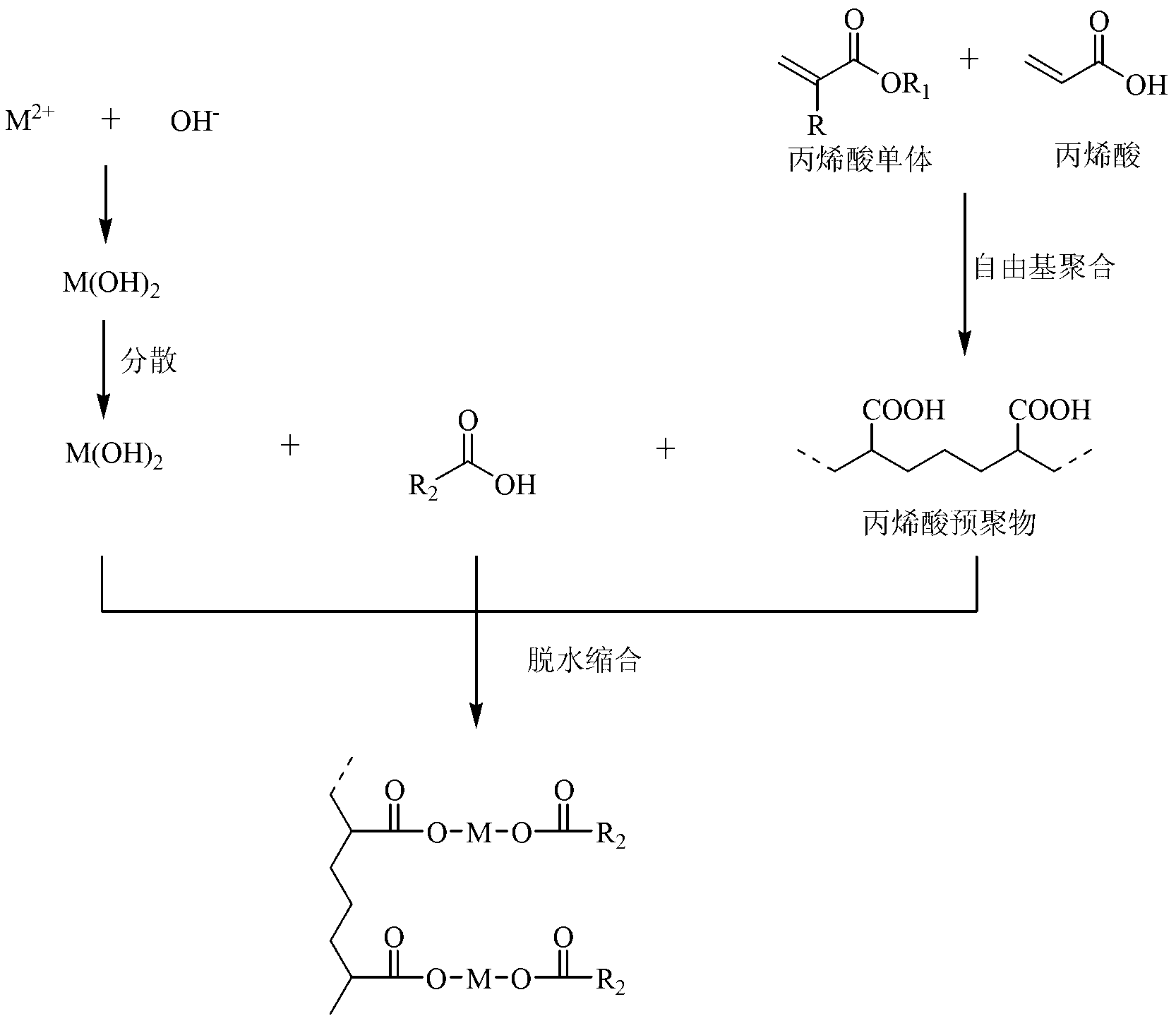

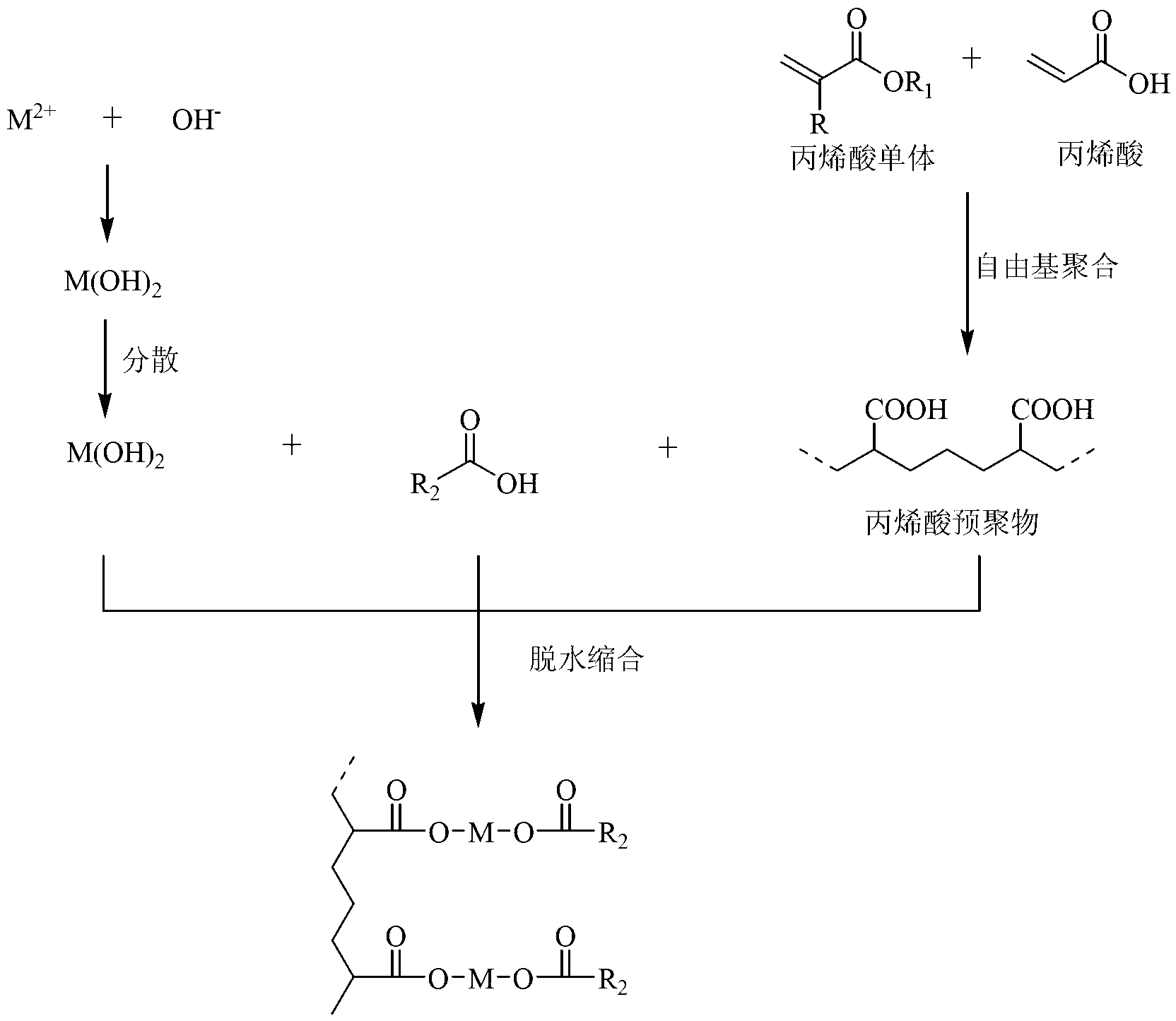

A technology of acrylic zinc and copper resin, which can be used in biocide-containing paints, antifouling/underwater coatings, coatings, etc., and can solve the problems of poor repeatability of antifouling effect, low stability of acrylic zinc/copper resin, and agglomeration. , to achieve the effect of inhibiting adhesion and growth, shortening reaction time, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Preparation of zinc hydroxide

[0043] Add 32.2g of sodium hydroxide to a solution containing 2.5ml of ethanol, 0.5ml of acetone, and 97ml of water, stir continuously until the sodium hydroxide is completely dissolved, use 0.2g of sodium hexametaphosphate as a dispersant, and fully Stir for 0.5 hour, slowly add 100ml of 4.0mol / L zinc nitrate dropwise until the pH of the solution becomes neutral. Insulate and disperse for 1 hour, vacuum filter, wash with 100ml of distilled water for 3 times, drain, and dry at 80°C for 12 hours.

[0044] 2) Preparation of Acrylic Prepolymer

[0045] In a 500ml three-necked round-bottomed flask equipped with stirring, condenser, and constant pressure dropping funnel, add 100g of mixed solvent (the mass ratio of xylene to n-butanol is 4:1), 80°C, 400r / min, dropwise within 3h Complete 100 g of acrylic acid monomer mixture (23 g of acrylic acid, 31 g of methyl methacrylate, 41 g of butyl acrylate) containing 4 g of azobisisobutyronitrile...

Embodiment 2

[0053] Unlike Example 1, the preparation of copper hydroxide:

[0054] Add 32.2g of sodium hydroxide to a solution containing 2.5ml of ethanol, 0.5ml of acetone, and 97ml of water, and stir continuously until the sodium hydroxide is completely dissolved. Use 0.2g of sodium hexametaphosphate as a dispersant, and fully stir at 500r / min at 40C After 0.5 hour, slowly add 100 ml of 4.0 mol / L copper hydroxide dropwise until the pH of the solution becomes neutral. Insulate and disperse for 1 hour, vacuum filter, wash with 100ml of distilled water for 3 times, drain, and dry at 80°C for 12 hours.

[0055] The operation example of other steps is the same as Example 1, promptly obtains acrylic acid copper antifouling paint, and the results are shown in Table 1.

Embodiment 3

[0057] Unlike Example 1, the preparation of copper hydroxide:

[0058] Add 32.0g of sodium hydroxide to a solution containing 2.0ml of ethanol, 1.0ml of methyl ethyl ketone, and 97ml of water, stir continuously until the sodium hydroxide is completely dissolved, use 0.2g of polyacrylamide as a dispersant, and stir fully at 40°C at 500r / min After 0.5 hour, 100ml of 4.0mol / L zinc chloride was slowly added dropwise until the pH of the solution became neutral. Insulate and disperse for 1 hour, vacuum filter, wash with distilled water until no chloride ions can be detected, drain, and dry at 80°C for 12 hours.

[0059] The operation example of other steps is the same as Example 1, promptly obtains zinc acrylic acid antifouling paint, and the result of hanging board is shown in Table 1.

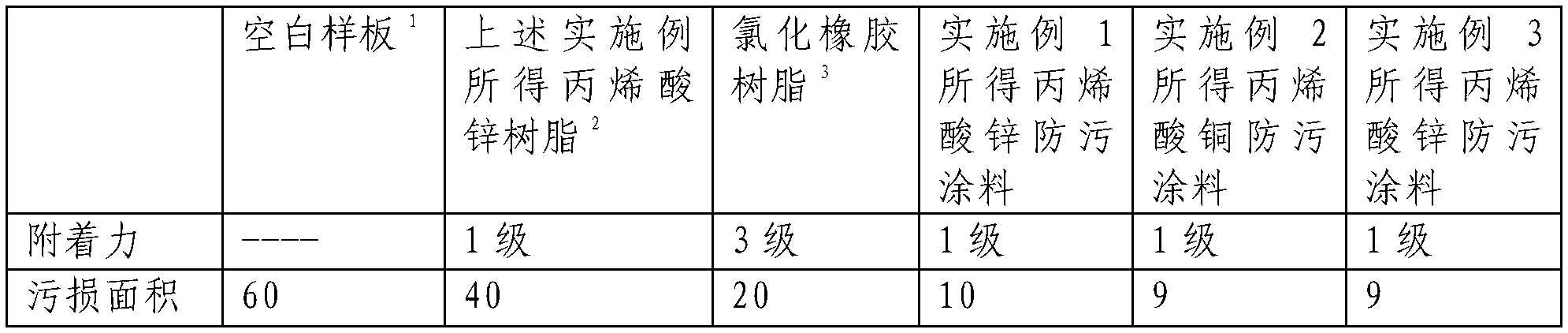

[0060] Table 1 Performance comparison of improved zinc acrylate / copper resin antifouling coatings

[0061]

[0062] Note: 1. The blank sample is not coated with marine antifouling paint except...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com