Method for preparation of zinc or copper containing acrylic acid resin

The technology of acrylic resin and organic acid is applied in the field of preparation of acrylic resin containing zinc or copper, which can solve the problems of gender variation, shell distortion, damage to the marine ecological environment and marine aquaculture, etc., and achieves short reaction time and low cost. , the effect of easy control of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

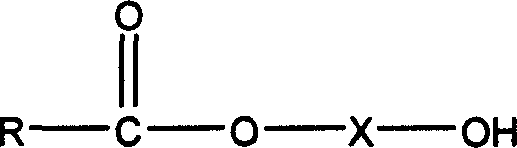

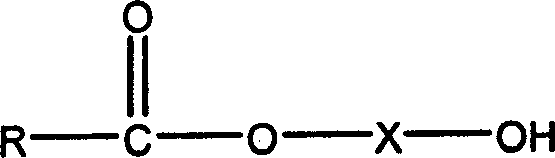

Image

Examples

Embodiment Construction

[0006] 1, the preparation of basic zinc benzoate

[0007] Weigh 5.7 g of zinc chloride, 1.7 g of sodium hydroxide, and 6.1 g (0.042 mol) of sodium benzoate at a molar ratio of 1:1:1, respectively. Dissolve the weighed sodium benzoate and sodium hydroxide successively in 400ml of deionized water, slowly drop the solution of 5.7g of zinc chloride and 200ml of deionized water into it under high-speed stirring, and generate white turbidity, pH The value is about 7, and after being washed with deionized water several times, it is suction-filtered and dried to obtain basic zinc benzoate.

[0008] 2. Preparation of carboxyl-containing acrylic resin

[0009] Add 600ml of a mixed solution of toluene and n-butanol with a weight ratio of 4:1 into a four-necked round-bottomed flask equipped with a stirring device, a condenser, and a thermometer, raise the temperature to 80°C, and then drop the mixed solution within 3 hours. In the monomer mixture of 60g acrylic acid, 80g methyl methacry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com