Anti-fouling paint composition

A technology of antifouling coatings and compositions, applied in the direction of antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems that the antifouling ability needs to be improved, and achieve good antifouling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

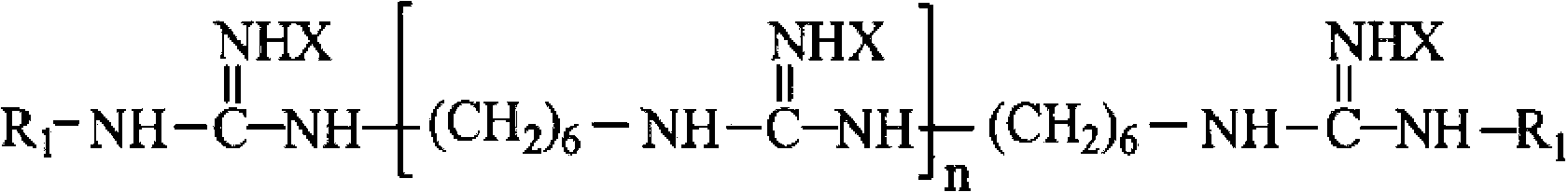

Method used

Image

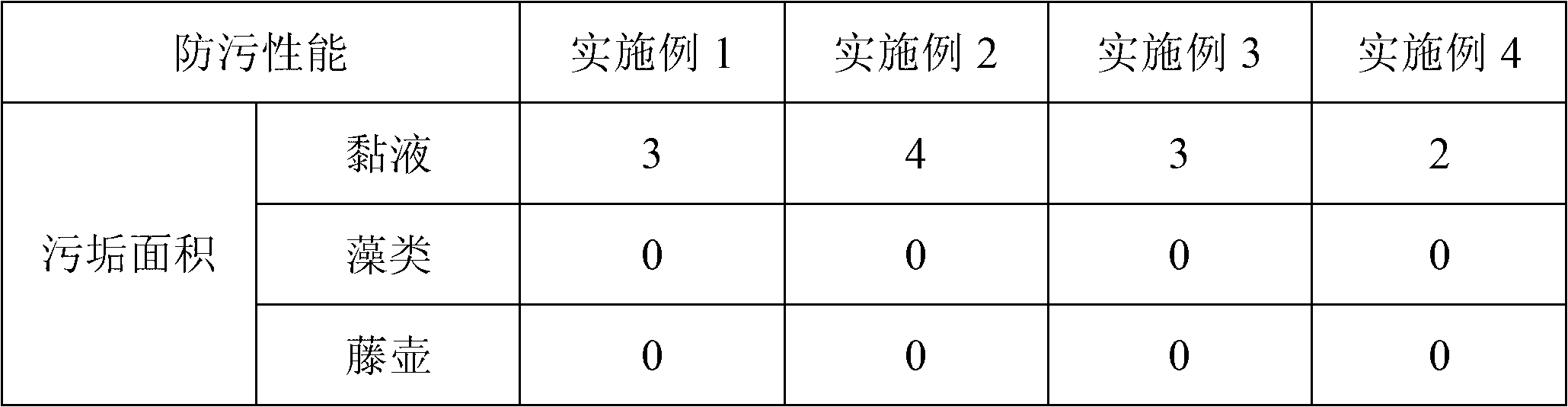

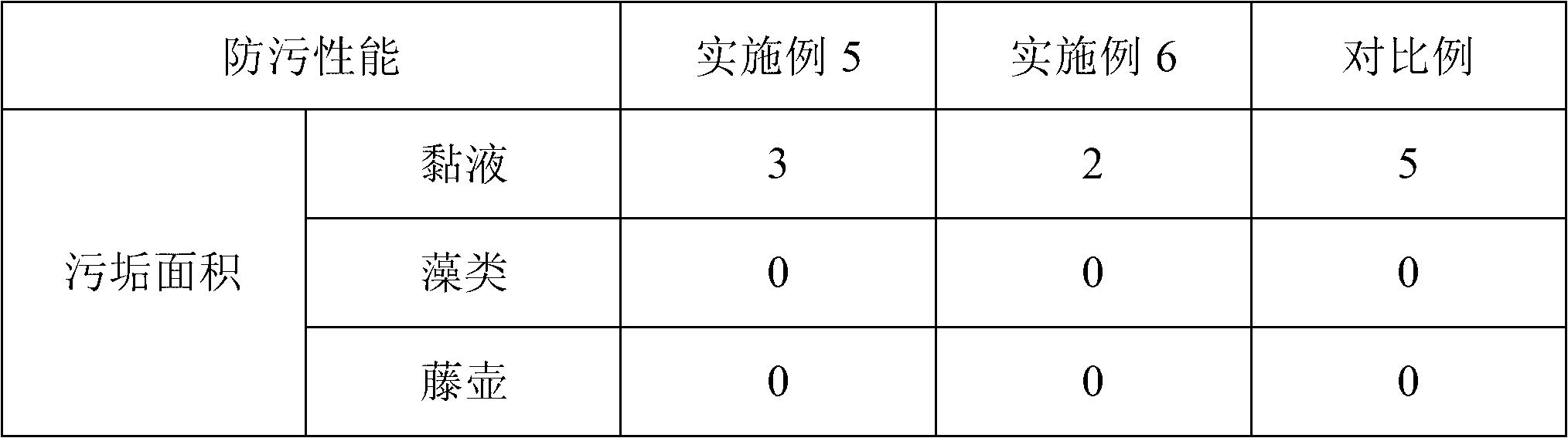

Examples

Embodiment 1

[0025]1 part by weight of polytetrafluoroethylene and 4 parts by weight of polyether-modified siloxane were completely dissolved in a mixed solvent of 3 parts by weight of toluene and acetone (v:v=1:1). Then 5 parts by weight of zinc oxide was added thereto, and dispersed twice with a sand mill. Add 1 part by weight of a leveling agent to the resulting dispersion mixture, and stir at 1500 rpm for 30 minutes with a high-speed disperser. Finally, the remaining 2 parts by weight of the mixed solvent was added thereto and stirred to obtain an antifouling coating composition.

Embodiment 2

[0027] 20 parts by weight of polyvinylidene fluoride and 5 parts by weight of polydimethylsiloxane were completely dissolved in 15 parts by weight of ethyl acetate solvent. Then 1 part by weight of titanium oxide was added thereto, and dispersed twice with a sand mill. 3 parts by weight of a leveling agent was added to the obtained dispersion mixture, and stirred at 1500 rpm for 30 minutes with a high-speed disperser. Finally, the remaining 5 parts by weight of the solvent was added thereto and stirred to obtain an antifouling coating composition.

Embodiment 3

[0029] 7.5 parts by weight of polychlorotrifluoroethylene and 7.5 parts by weight of polyester-modified siloxane were completely dissolved in a mixed solvent of 20 parts by weight of chloroform and butanone (v:v=1:1). Then 10 parts by weight of zinc oxide was added thereto and dispersed twice with a sand mill. 5 parts by weight of a leveling agent was added to the obtained dispersion mixture, and stirred at 1500 rpm for 30 minutes with a high-speed disperser. Finally, the remaining 5 parts by weight of the mixed solvent was added thereto and stirred to obtain an antifouling coating composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com