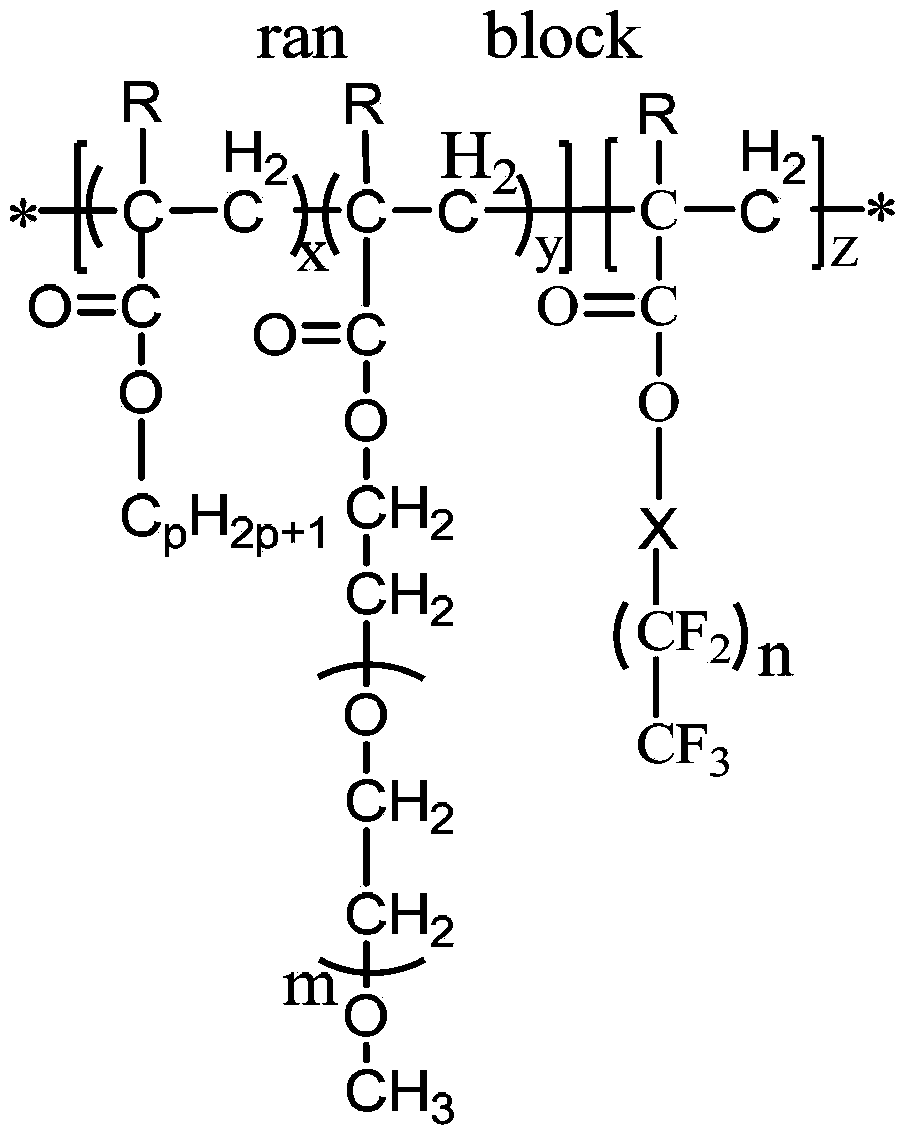

Amphiphilic fluorine-containing block copolymer resin, and preparation method and application thereof

A block copolymer and amphiphilic technology, which is applied in the field of amphiphilic fluorine-containing block copolymer resin and its preparation, to achieve superior chemical stability, simple preparation process, and good antifouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

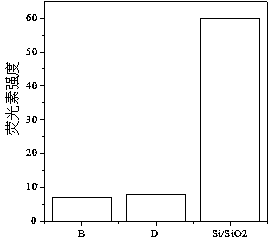

Examples

Embodiment 1

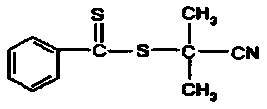

[0026] (1) Under a nitrogen atmosphere, add 0.21g of RAFT reagent, 7.5g of polyethylene glycol methyl ether acrylate, 0.5g of methyl acrylate, 0.04g of AIBN, and 12g of anisole into a 100ml three-necked flask. At a temperature of 60° C., react for 5 hours, and precipitate to obtain a macromolecular chain transfer agent.

[0027] (2) Then take 0.8g of macromolecular chain transfer agent, add 0.92g of perfluorosulfonamidoethyl acrylate, 0.006g of AIBN, and 5.17g of butyl acetate, and react at a temperature of 70°C for 10 hours to obtain amphiphilic fluorine-containing Block copolymer resins.

Embodiment 2

[0029] (1) Under a nitrogen atmosphere, add 0.80g of RAFT reagent, 5g of polyethylene glycol methyl ether methacrylate, 15g of methyl acrylate, 0.10g of AIBN, and 55g of phenylene ether into a 100ml three-necked flask. At a temperature of 70° C., react for 4 hours, and precipitate to obtain a macromolecular chain transfer agent.

[0030] (2) Then take 1.6g of macromolecular chain transfer agent, add 2.0g of perfluorosulfonamidoethyl methacrylate, 0.01g of AIBN, and 10.2g of butyl acetate, and react at a temperature of 80°C for 10 hours to obtain amphiphilic Fluorinated block copolymer resin.

Embodiment 3

[0032] (1) Under a nitrogen atmosphere, add 0.63g of RAFT reagent, 3.82g of polyethylene glycol methyl ether methacrylate, 10.8g of methyl acrylate, 0.09g of AIBN, and 43.5g of anisole into a 100ml three-necked flask. At a temperature of 80° C., react for 4 hours, and precipitate to obtain a macromolecular chain transfer agent.

[0033] (2) Then take 1.2g of macromolecular chain transfer agent, add 1.8g of perfluorosulfonamidoethyl methacrylate, 0.009g of AIBN, and 9.5g of butyl acetate, and react at a temperature of 90°C for 8 hours to obtain amphiphilic Fluorinated block copolymer resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com