Slow release type biological anti-fouling paint

A biological antifouling and biological antifouling agent technology, applied in antifouling/underwater coatings, rubber derivative coatings, epoxy resin coatings, etc., can solve the problems of short life, toxicity, high cost, and improve the antifouling period , low cost, and the effect of improving the antifouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of Vegetable Tannin Microcapsules

[0026] Preparation of water phase: add gelatin to water, heat and stir in a water bath at 70°C to dissolve, and make a gelatin solution with a concentration of 25% (w / v), adjust the pH value to about 3 with 10% (v / v) acetic acid solution, add appropriate amount of Tween -20 to make the concentration 2% (v / v), then add an appropriate amount of vegetable tannin to make the concentration 6% (w / v), stir and emulsify to obtain the water phase;

[0027] Preparation of the oil phase: add an appropriate amount of Span-80 to the soybean oil to make the concentration 4% (v / v), stir and mix at a high speed to obtain the oil phase;

[0028] Microencapsulation process: Take an appropriate amount of oil phase, emulsify and stir with a high-speed emulsifying homogenizer or an electric mixer in a water bath at 75°C for about 15 minutes, then adjust the speed of the high-speed emulsifying homogenizer or electric mixer to an appropriate spe...

Embodiment 2

[0030] Preparation of tea polyphenol microcapsules

[0031] Preparation of water phase: add gelatin to water, heat and stir in a water bath at 70°C to dissolve, and make a gelatin solution with a concentration of 25% (w / v), adjust the pH value to about 3 with 10% (v / v) acetic acid solution, add appropriate amount of Tween -20 to make the concentration 2% (v / v), then add an appropriate amount of tea polyphenols to make the concentration 6% (w / v), stir and emulsify to obtain the water phase;

[0032] Preparation of the oil phase: add an appropriate amount of Span-80 to the soybean oil to make the concentration 4% (v / v), stir and mix at a high speed to obtain the oil phase;

[0033]Microencapsulation process: Take an appropriate amount of oil phase, emulsify and stir with a high-speed emulsifying homogenizer or an electric mixer in a water bath at 75°C for about 15 minutes, then adjust the speed of the high-speed emulsifying homogenizer or electric mixer to an appropriate speed, ...

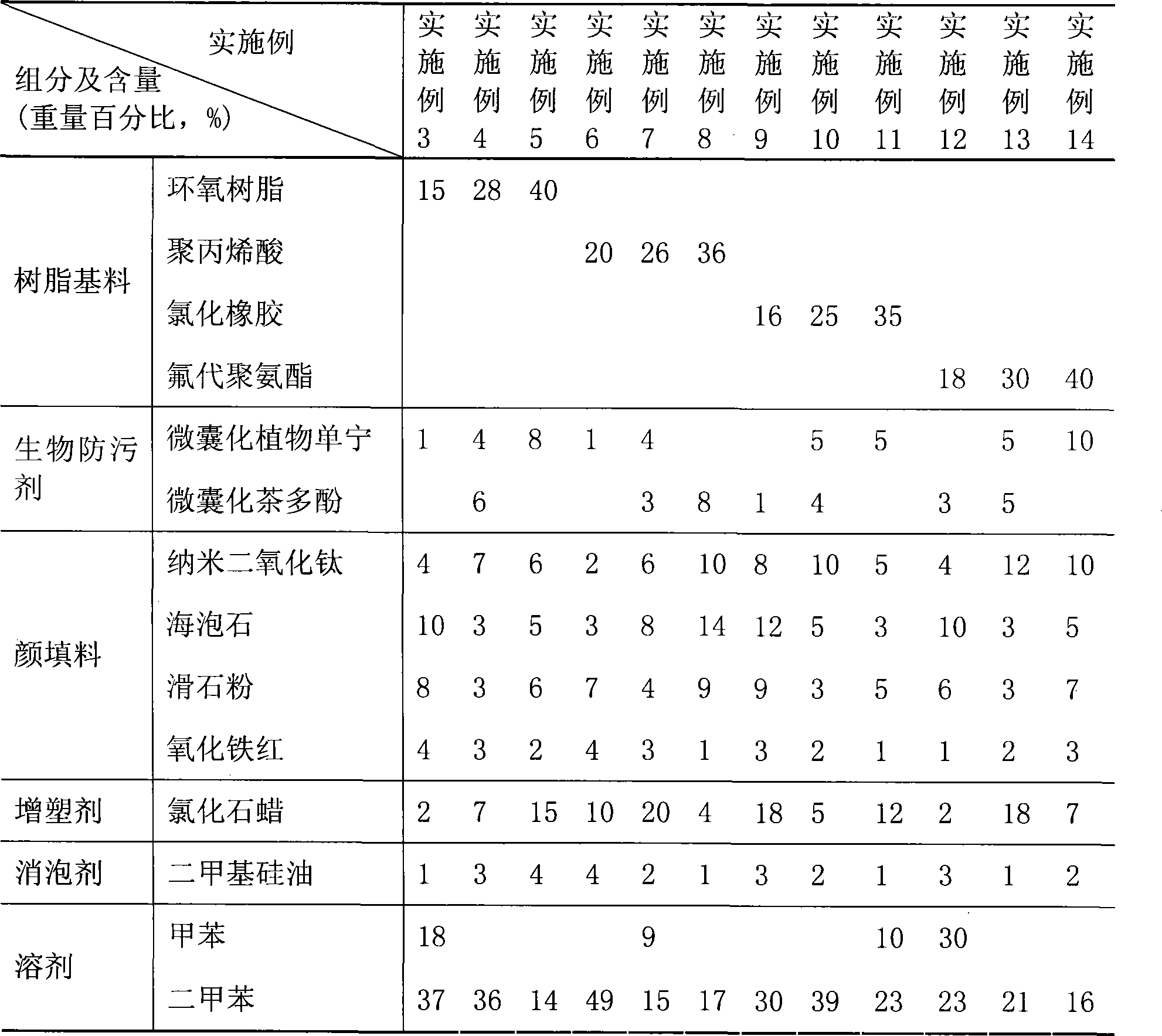

Embodiment 3~14

[0035] Table 1 Embodiment 3~14 components and weight percentage

[0036]

[0037] The antifouling coatings of the above-mentioned prepared examples 3 to 14 are evenly applied to the 45 # and hang the steel plate in simulated seawater to measure the release rate of plant tannins or tea polyphenols, the results are shown in Table 2:

[0038] Table 2 Release rate of bio-antifouling agent from coating

[0039] Release rate (μg.m-2.d-1)

[0040] 10 days

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com