Nitrogen-doped graphite-loaded phosphorus-doped molybdenum carbide nanowire electrocatalytic hydrogen production catalyst and preparation method thereof

A technology of molybdenum carbide and phosphorus doping, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of difficult to highly uniformly disperse ultrafine nanostructured structures, excessive strength, etc., and achieve uniform distribution and improved conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1, put 2 mmol of aniline and 0.1 mmol of phytic acid into a beaker, add 10 ml of deionized water and stir for 30 minutes, then let it stand for 10 minutes; Aqueous ammonium persulfate solution was allowed to stand at room temperature for 12 hours, and then washed with deionized water for 4 times for use. The above-mentioned washed solid product was placed in 40 g of ammonium molybdate aqueous solution with a mass concentration of 5.8%, and reacted at 50° C. for 6 hours. After the reaction, the above suspension was centrifuged and dried to obtain MoO x -Phytic acid-polyaniline (MoO x -PA-PANI) precursor.

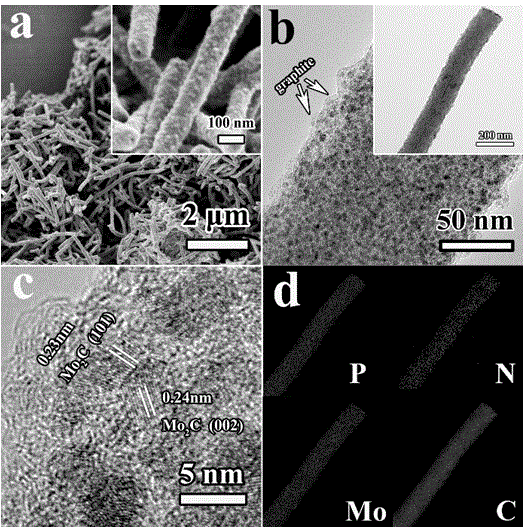

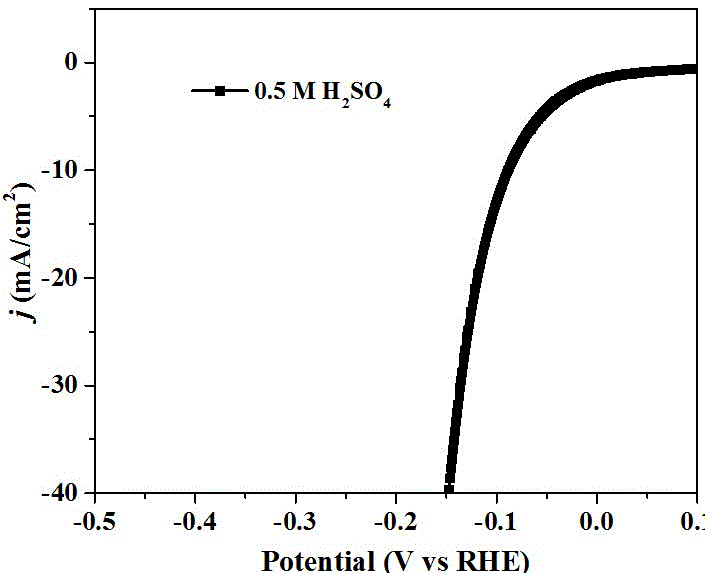

[0025] Put the above precursor in a tube furnace, under the protection of argon, program the temperature to 850 ° C for 5 hours, and control the heating rate at 2 ° C / min, then the phosphorus-doped molybdenum carbide supported by nitrogen-doped graphite can be prepared Nanowire electrocatalytic hydrogen production catalyst. Such as figure 1 Shown: Hyperd...

Embodiment 2

[0030] Example 2, put 2 mmol of aniline and 0.2 mmol of phytic acid in a beaker, add 10 ml of deionized water and stir for 30 minutes, then let it stand for 10 minutes; Aqueous ammonium persulfate solution was allowed to stand at room temperature for 12 hours, and then washed with deionized water for 4 times for use. The above-mentioned washed solid product was placed in 40 g of ammonium molybdate aqueous solution with a mass concentration of 5.8%, and reacted at 45°C for 6 hours. After the reaction, the above suspension was centrifuged and dried to obtain MoO x -Phytic acid-polyaniline (MoO x -PA-PANI) precursor.

[0031] Put the above precursor in a tube furnace, under the protection of argon, program the temperature to 850°C for carbonization for 5 hours, and control the heating rate at 2°C / min, to prepare the phosphorus-doped molybdenum carbide nanowires supported by nitrogen-doped graphite Electrocatalytic hydrogen production catalyst.

[0032] The electrochemical tes...

Embodiment 3

[0034] Example 3, put 2 mmol of aniline and 0.15 mmol of phytic acid into a beaker, add 10 ml of deionized water and stir for 30 minutes, then let it stand for 10 minutes; Aqueous ammonium persulfate solution was allowed to stand at room temperature for 12 hours, and then washed with deionized water for 4 times for use. The above-mentioned washed solid product was placed in 40 g of ammonium molybdate aqueous solution with a mass concentration of 5.8%, and reacted at 50° C. for 6 hours. After the reaction, the above suspension was centrifuged and dried to obtain MoO x -Phytic acid-polyaniline (MoO x -PA-PANI) precursor.

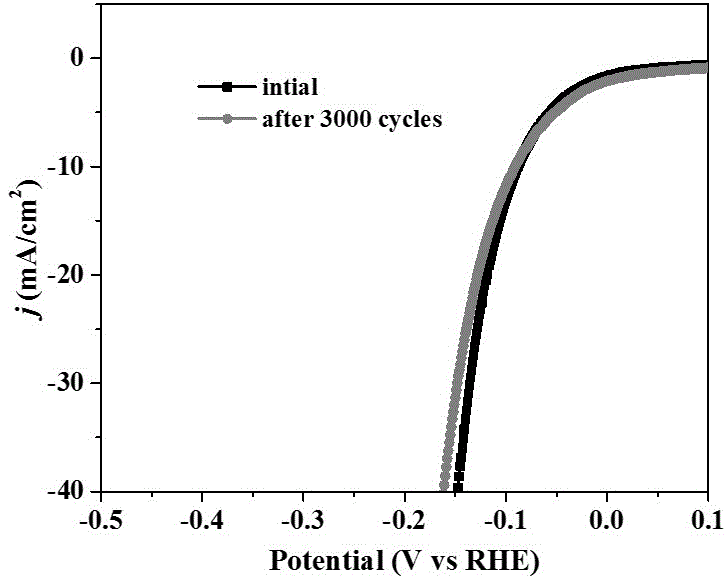

[0035] Put the above precursor in a tube furnace, under the protection of argon, program the temperature to 850°C for carbonization for 5 hours, and control the heating rate at 2°C / min, to prepare the phosphorus-doped molybdenum carbide nanowires supported by nitrogen-doped graphite The electrochemical test of the nitrogen-doped graphite supported phosphoru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com