Horizontal array for overlong single-wall carbon nano-tube, preparation method and reaction device

A single-walled carbon nanotube, horizontal technology, applied in the field of nanomaterials research, can solve the problems of slow growth and instability of carbon nanotubes, and achieve the effects of high Young's modulus, high current density, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

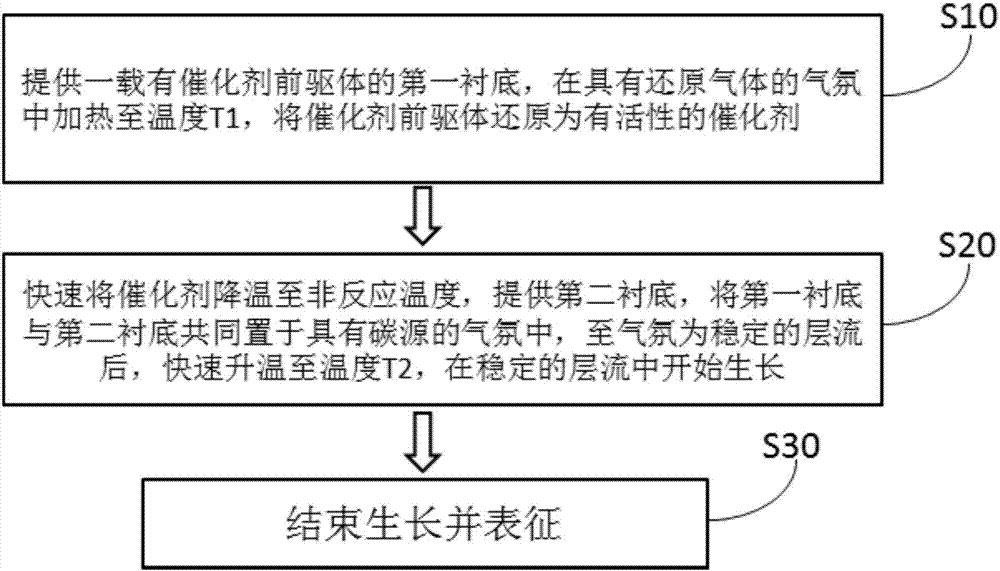

[0101] figure 1 A schematic flowchart showing a method for preparing a horizontal array of ultra-long single-walled carbon nanotubes according to an embodiment of the present invention. Generally, the method for preparing a horizontal array of ultra-long single-walled carbon nanotubes includes the following steps,

[0102] S10 provides a first substrate 25 carrying a catalyst precursor 41 , and heats it to a temperature T1 in an atmosphere with a reducing gas to reduce the catalyst precursor 41 to an active catalyst 411 .

[0103] S20 quickly reduce the temperature of the first substrate 25 and the catalyst 411 to the non-reaction temperature, provide the second substrate 26, and place the second substrate 26 and the first substrate 25 carrying the active catalyst 411 together In the atmosphere with a carbon source, after the atmosphere is a stable laminar flow, the temperature is rapidly raised to the growth temperature T2, and grown at the temperature T2 to obtain a horizon...

Embodiment 1

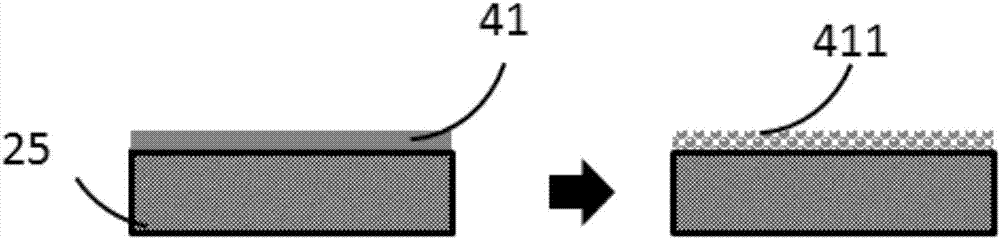

[0160] Step 1: Spray ferric chloride anhydrous ethanol dispersion on the polished surface of the N-type single crystal silicon wafer containing a 500nm thermal oxide layer after polishing, and dry it at room temperature to form a catalyst precursor 41 film 411. This implementation In the example, the size of the first substrate 25 is 1cm×1cm, and the preferred concentration of the dispersion is 0.1mM (10 -4 mol / L), the spray volume is 10μL / cm 2 .

[0161] Step 2: The first substrate 25 carrying the directly deposited catalyst precursor 41 is oxidized at a high temperature in a muffle furnace to form a processed catalyst precursor 41, such as figure 2 As shown, in this embodiment, the treatment temperature is preferably 800° C., and the treatment time is preferably 5 minutes.

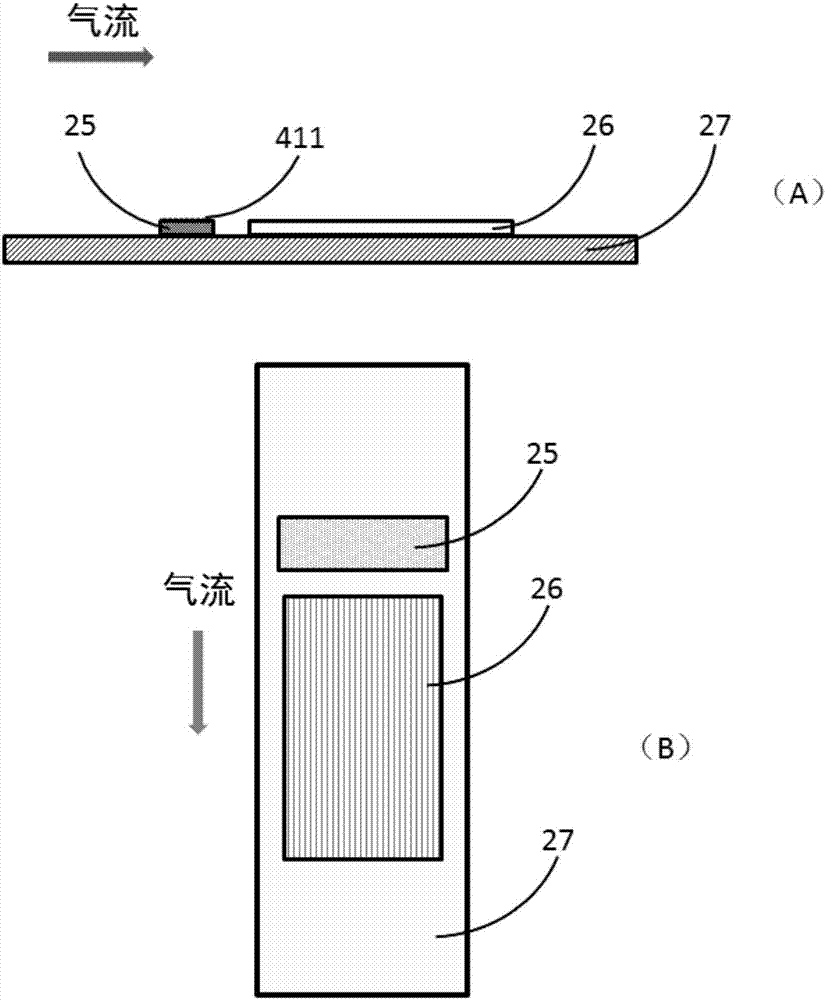

[0162] Step 3: Place the cleaned second substrate 26 and the first substrate 25 carrying the treated catalyst precursor 41 on the base 27 at the same time, as image 3 (A) and 3(B).

[0163] In the ...

specific Embodiment 1

[0194] In the specific embodiment 1, the positions of the heating device 22 and the cooling device 23 are kept fixed, and the reaction chamber 21 is moved to quickly switch the first substrate 25 and the three second substrates 26 between the reaction zone 221 and the non-reaction zone 231 . In this embodiment, the position of the reaction chamber 21 is kept fixed, and the heating device 22 is moved, so that the first substrate 25 and the three second substrates 26 can be quickly switched between the reaction zone 221 and the non-reaction zone 231, achieving the same Specific Example 1 has the same preparation effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com