Fuel cell hydrogen ejector and hydrogen circulating system thereof

A fuel cell and ejector technology, applied in fuel cells, fuel cell additives, electrical components, etc., to achieve the effect of less pipeline connections, fewer leakage points, and increased flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

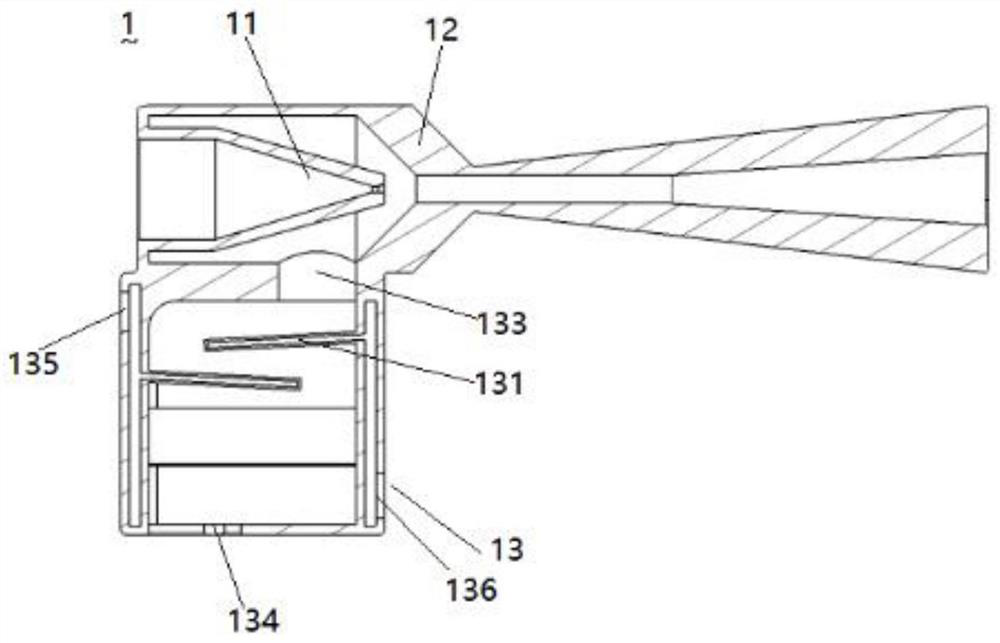

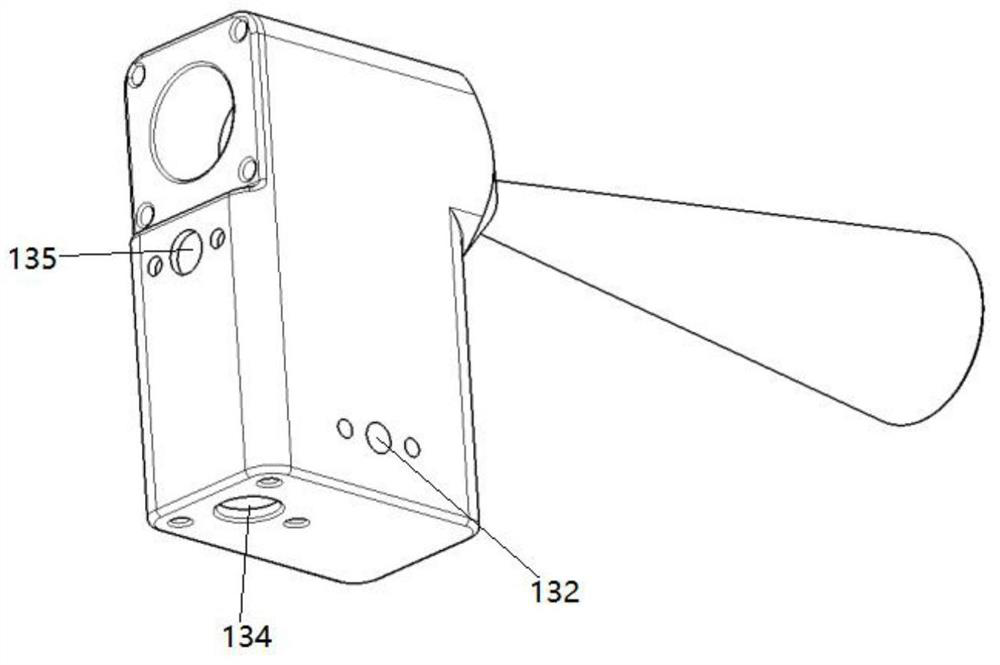

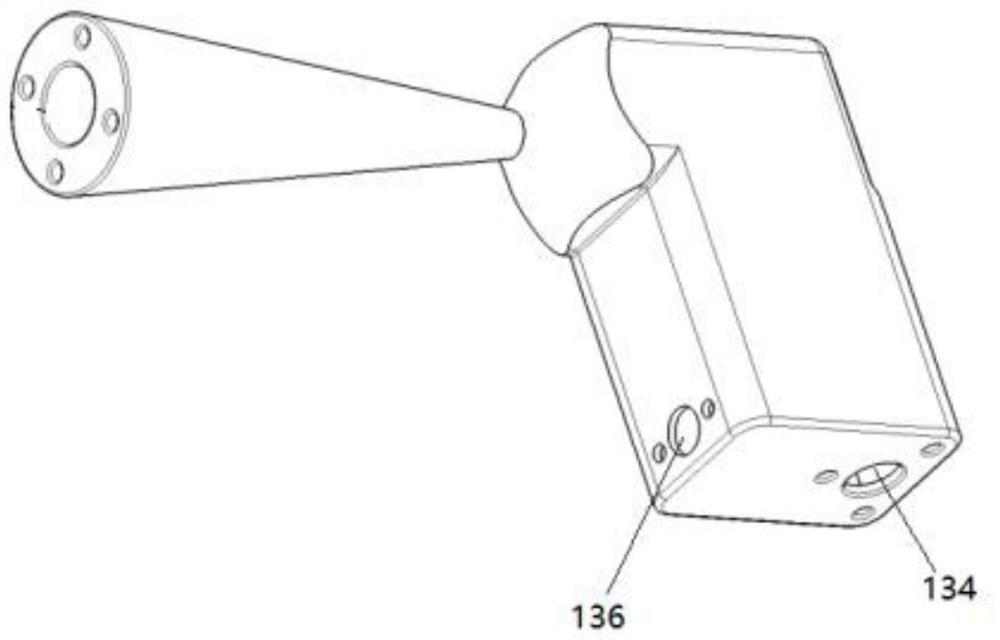

[0035] Such as figure 1 As shown, a fuel cell hydrogen ejector includes a nozzle 11, an ejector main body 12 and a control main body 13; the ejector main body 12 includes a suction chamber, a mixing chamber and a diffusion chamber arranged in sequence; one side of the suction chamber is provided with There is a primary inlet for the inflow of high-pressure hydrogen, and a mixed gas outlet for the outflow of the mixed gas is provided on one side of the diffusion chamber; the nozzle 11 is located in the suction chamber; the control body 13 is provided with a refrigerant channel and a mixed cooling channel; the refrigerant channel is used for refrigerant Circulation; the mixed cooling channel is used for heat exchange and cooling of the high-temperature hydrogen-water vapor mixture discharged from the stack 2 and the refrigerant; the mixed cooling channel communicates with the suction chamber.

[0036] In actual use, the ejector main body 12 is arranged horizontally, and a nozzle...

Embodiment 2

[0047] On the basis of Example 1, such as Figure 4 As shown, the hydrogen circulation system with the fuel cell hydrogen injector 1 includes the hydrogen injector 1 and the electric stack 2; the mixed gas outlet of the hydrogen injector 1 is connected to the electric stack 2 through the first pipeline; The hydrogen inflow inlet 132 is connected to the cell stack 2 through a second pipeline; a third pipeline connected externally between the outlet 135 and the inlet 136 of the refrigerant passage.

[0048] In a certain embodiment, the primary inflow port is externally connected with a fourth pipeline; the fourth pipeline is provided with a pressure control valve 6; the third pipeline is provided with a compressor 3, a condenser 4 and a throttle valve 5; the drain port 134 There is a drain valve.

[0049] In a certain embodiment, the compressor 3 , the condenser 4 and the throttle valve 5 are arranged in sequence along the fluid flow direction.

[0050] In actual use, the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com