Nickel-based brazing material for brazed diamond tool and preparation method thereof

A technology of diamond tools and brazing material, which is applied in the field of nickel-based brazing material for brazing diamond tools and its preparation, and can solve problems such as degradation and thermal alteration of diamonds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the formula of the present embodiment is by weight percentage, and concrete composition is as follows:

[0023] Si: 8.0%, Cr: 16.5%, C: 0.6%, Fe: 8.0%, B: 3.5%, and the balance is Ni.

[0024] (1) batching is carried out according to the proportioning ratio of above-mentioned composition design;

[0025] (2) In the medium frequency induction furnace, put C into the bottom of the furnace, put Ni, Fe and Cr blocks on it, when the above blocks are melted, put Si and B, and melt at 1520 ° C ~ 1560 ° C;

[0026] (3) Under the conditions of 850Kg pressure, 120L / min flow rate and 1560°C, the above-mentioned melt was atomized by high-pressure water. Laser particle size D of powder after atomization 50 It is about 30 microns (through a -200 mesh sieve), and the oxygen content is controlled within 450ppm.

[0027] The above-mentioned high-pressure water atomization equipment is a small-scale experimental equipment.

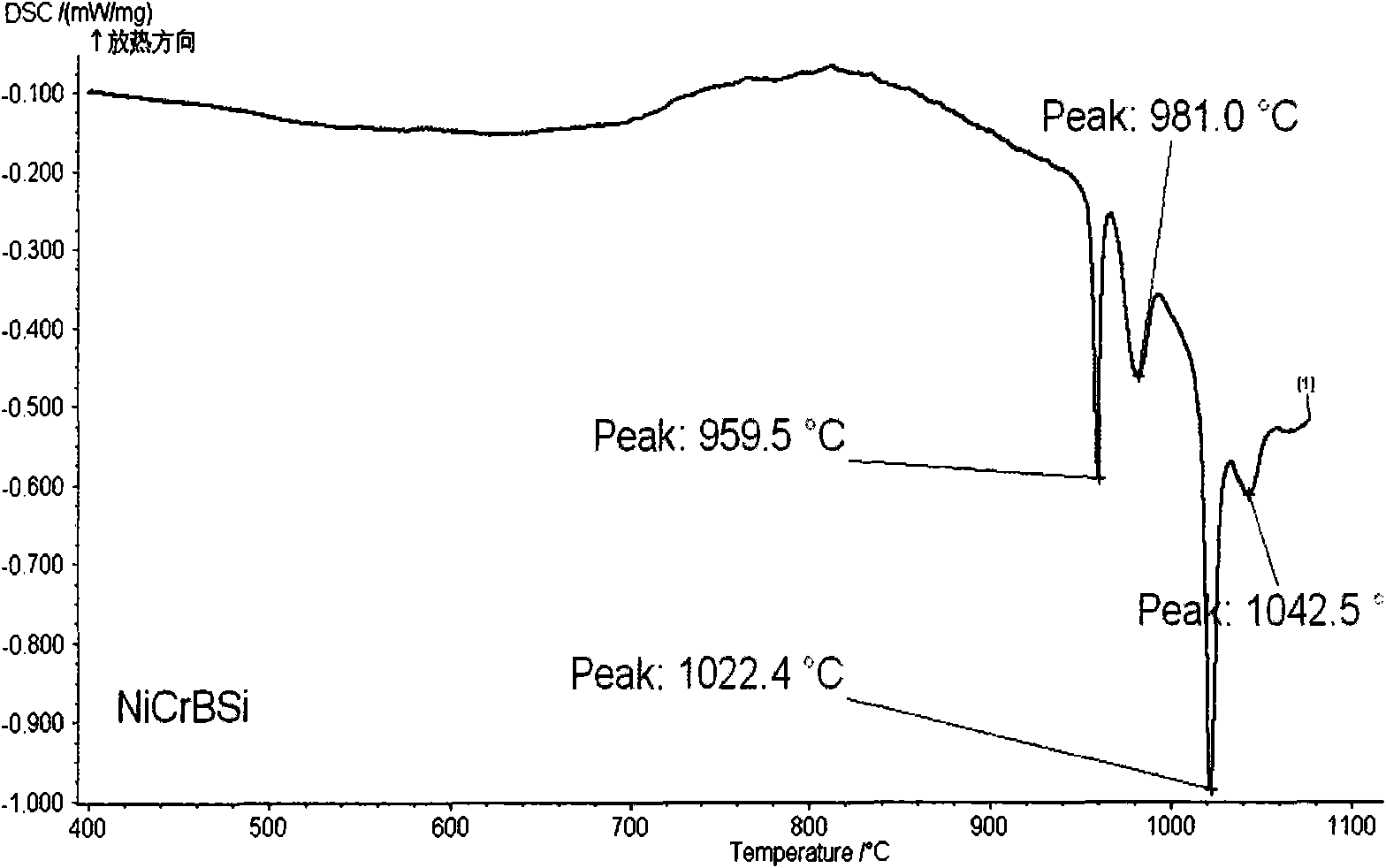

[0028] figure 1 It is the DSC curve of this ...

Embodiment 2

[0030] The formula of the present embodiment is by weight percentage, and concrete composition is as follows:

[0031] Si: 2.5%, Cr: 5.5%, C: 0.5%, Fe: 2.5%, P: 3.0%, and the balance is Ni.

[0032] Powder preparation method is with embodiment 1.

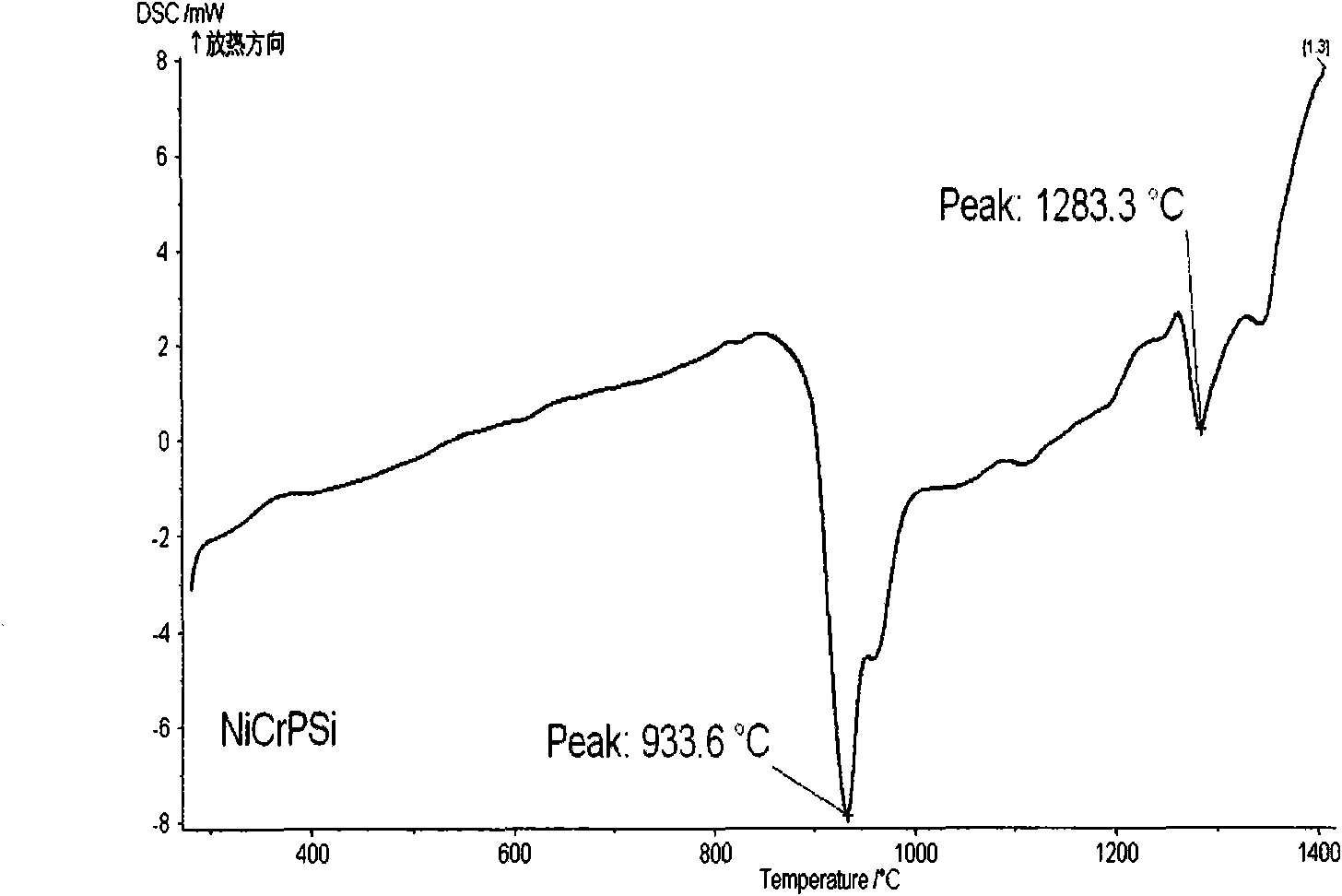

[0033] figure 2 It is the DSC curve of this composition Ni-Cr-P, and the test instrument is produced by the American NETZSCH company. The solid-liquid phase temperature ranges from 933.6°C to 1283.3°C, which obviously does not meet the design requirements.

Embodiment 3

[0035] The formula of the present embodiment is by weight percentage, and concrete composition is as follows:

[0036] Si: 2.5%, Cr: 4.5%, C: 0.5%, Fe: 2.5%, P: 2.5%, B: 1.5%, and the balance is Ni.

[0037] (1) batching is carried out according to the proportioning ratio of above-mentioned composition design;

[0038] (2) In the medium frequency induction furnace, put C into the bottom of the furnace, put Ni, Fe and Cr blocks on it, and when the above blocks are melted, put Si, B and P, and melt at 1520 ° C to 1560 ° C;

[0039] (3) Under the conditions of 500Kg pressure, 140L / min flow rate and 1560°C, the above-mentioned melt was atomized by high-pressure water. Laser particle size D of powder after atomization 50 The size is about 20 microns (through -200 mesh sieve), the oxygen content is controlled within 650ppm, and the bulk ratio is 2.47g / cm 3 , no mobility.

[0040] The above-mentioned high-pressure water atomization equipment is a small-scale experimental equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com