Catalyst for ozone catalytic oxidation treatment of chemical wastewater and preparation method of catalyst

A technology for ozone catalytic oxidation and chemical wastewater, applied in catalyst activation/preparation, special compound water treatment, oxidized water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

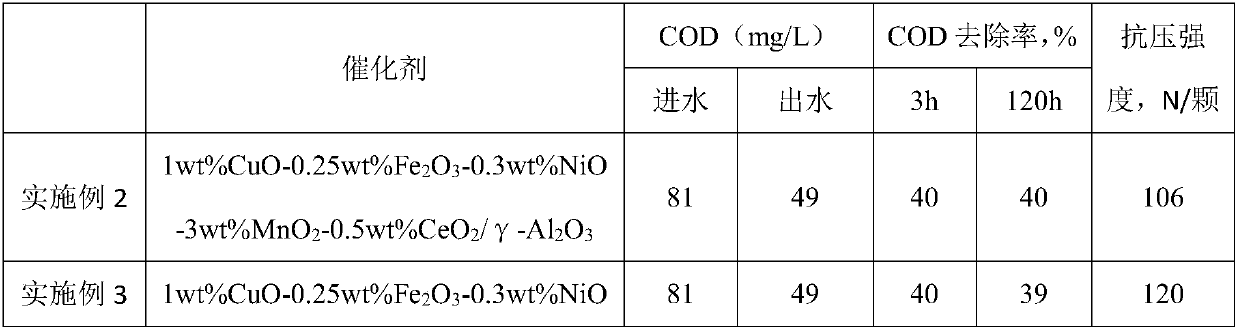

Examples

Embodiment 1

[0073] Embodiment 1 Carrier Water Absorption Measurement

[0074] Weigh the carrier γ-Al 2 o 3 Particles 50g (m, accurate to 0.01g); put them into a beaker, add water to immerse, stir continuously, use a funnel to separate the water from the sample after 1h, let it stand for 10min, and then weigh the sample after absorbing water (m1, accurate to 0.01g) . Calculate the water absorption rate (Y, %) of the carrier according to formula (1).

[0075] Carrier γ-Al in the embodiment of the present invention 2 o 3 The water absorption rate of the particles is 55.0%, that is, every 100g carrier (γ-Al 2 o 3 ) The amount of completely absorbed water is 55ml.

Embodiment 2

[0076] Embodiment 2 catalyst preparation

[0077] 1. Weigh 380g carrier γ-Al 2 o 3 ,spare.

[0078] 2. The water absorption rate Y of the carrier measured according to Example 1 is 55%, and it is converted according to the volume of every 1g of water as 1ml. Therefore, the water absorption rate of the carrier is 55ml per 100g of the catalyst carrier. The volume of the solution weighed by equal-volume impregnation of the pretreated carrier is 380×55 / 100=209ml.

[0079] 3. Preparation of dipping solution

[0080] Get part deionized water, add successively 50% manganese nitrate aqueous solution (49.4g), ferric nitrate nonahydrate (5.1g), nickel nitrate hexahydrate (4.7g), cerium nitrate hexahydrate (5.3g), copper nitrate trihydrate ( 12.2g) was stirred for 30 minutes to dissolve the solid completely, then added deionized water until the total volume of the mixed solution was 209ml, and made an impregnating solution (i.e. copper-iron-manganese-nickel-cerium salt impregnating s...

Embodiment 3

[0090] Embodiment 3 catalyst preparation

[0091] Steps 1 and 2 are identical to Embodiment 2;

[0092] 3. Preparation of dipping solution

[0093] Get part of deionized water, add manganese acetate tetrahydrate (33.8g), ferric nitrate nonahydrate (5.1g), nickel acetate tetrahydrate (4.0g), cerium acetate (4.5g), copper acetate monohydrate (10g) successively, Stir for 30 minutes to dissolve the solid completely, then add deionized water until the total volume of the mixed solution is 209ml, and make an impregnation solution (i.e. copper-iron-manganese-nickel-cerium salt impregnation solution), for subsequent use, wherein the impregnation solution The mass of copper acetate converted to copper oxide (CuO), the mass of ferric nitrate converted to iron oxide (Fe 2 o 3 ), the mass of nickel acetate converted to nickel oxide (NiO), the mass of manganese acetate converted to manganese oxide (MnO 2 ) mass, cerium acetate converted to cerium oxide (CeO 2 ) to the total amount of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com