New method for preparing nitrogen doped graphene

A technology of nitrogen-doped graphene and organic ligands, which is applied in the field of graphene, can solve the problems of nitrogen content and distribution position uncertainty, and achieve the effects of convenient operation, simple preparation process and high electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

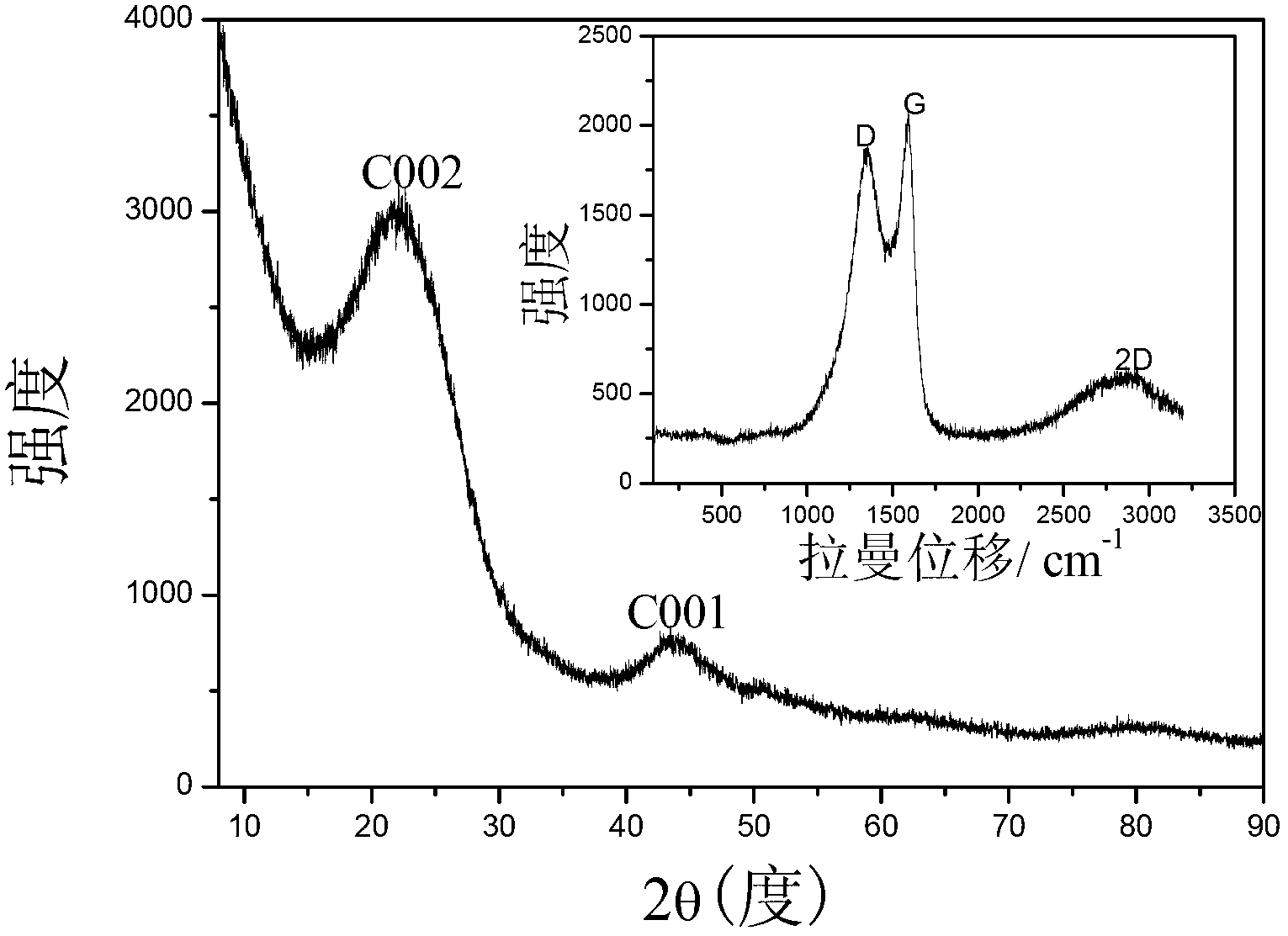

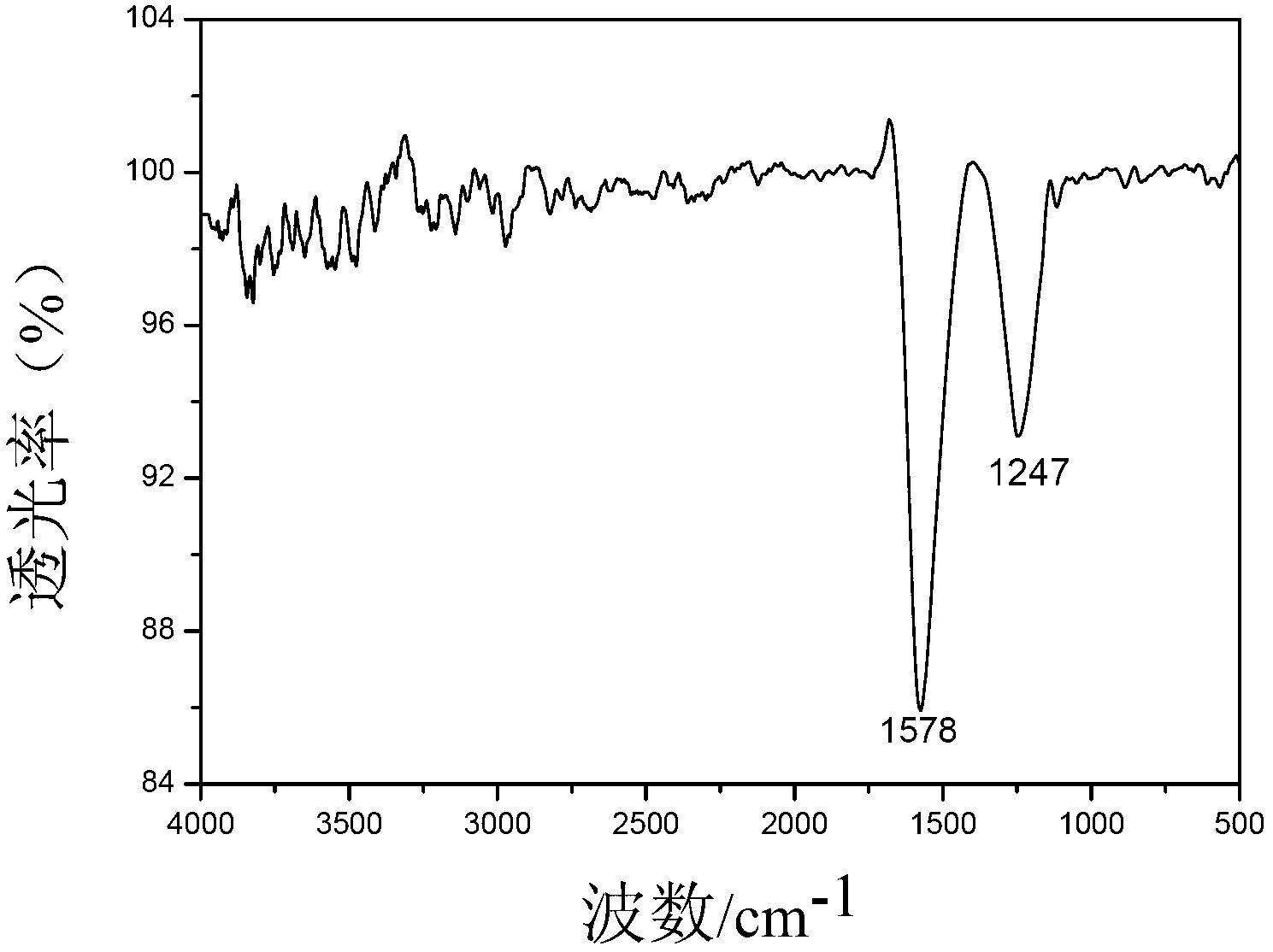

Embodiment 1

[0048] The first step: Add 4.908mmol of bis(1,5-cyclooctadiene) nickel and 4.908mmol of 2,2′‐bipyridine into a round bottom flask, then add 78ml of purified DMF, and then add 4.908mmol of 1,5-Cyclooctadiene, stir the mixture until completely dissolved. 0.942 mmol of organic ligand TBT was added to the purple solution obtained above. React at 95°C for 8 hours. After the solution was cooled to room temperature, 29.9 ml of concentrated hydrochloric acid was added to the dark purple solution, and the color of the solution became light green and transparent. The solution was filtered and washed with 5×19.5 ml of chloroform, 5×19.5 ml of tetrahydrofuran and 5×19.5 ml of deionized water, respectively. Transfer to a vacuum oven and dry at 200°C for 7 hours to obtain COP-4 solid powder.

[0049] Step 2: Put the covalent organic polymer COP-4 with a mass of 0.05g in a tube furnace. Before heating up the tube furnace, vacuumize it first, and then pass in an inert gas. Then rise from ...

Embodiment 2

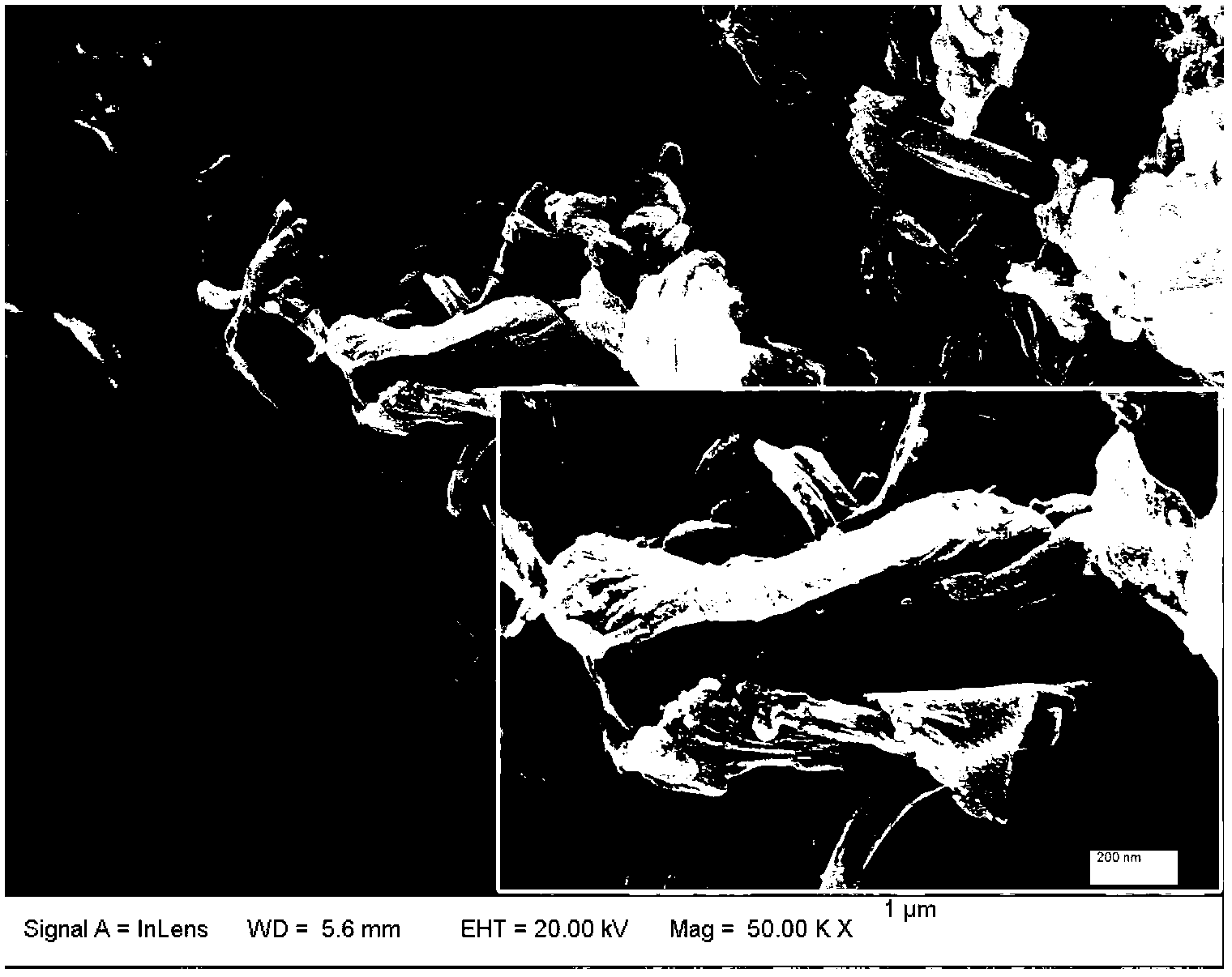

[0054] The preparation method and experimental conditions are basically the same as in Example 1, except that the organic ligand used is TBP, that is, the carbonized material is C-COP-P. Such as Figure 5 Shown are the Raman spectra and scanning electron micrographs of the products. From the scanning electron microscope image, it can be seen that the material is a mixture of spherical particles and rod-like structures, but it can be seen that the rod-like structures are curled from layered structures. The positions and intensities of the peaks in the Raman spectrum are consistent with the structure of nitrogen-doped graphene.

Embodiment 3

[0056] The preparation method and experimental conditions are basically the same as in Example 1, except that the organic ligand used is TBTT, that is, the carbonized material is C-COP-T. Such as Figure 6 Shown is a scanning electron micrograph of the product. It can be seen from the figure that the prepared material has a uniform structure and mainly exists in a layered structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com