Solid electrolyte thin film and preparation method and ion device thereof

A solid electrolyte and thin film technology, which is applied in hybrid capacitor electrolytes, hybrid capacitor electrodes, gaseous chemical plating, etc., can solve the problem of LiPON ion conductance is difficult to significantly improve, achieve stable performance, improve conductivity, and a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the solid electrolyte film disclosed by the invention comprises the following steps:

[0034] Step 1: Use LiHMDS as the lithium source, TMPO as the phosphorus source, TBS as the silicon source, TTIP as the titanium source, and H 2 S is used as the sulfur source, nitrogen plasma is used as the nitrogen source, and ozone is used for the decomposition reaction of metal organic compounds; a capacitive plasma generator is used to generate N 2 Plasma; ozone generator produces O 3 .

[0035] Step 2: Heat the lithium source LiHMDS to 60-65°C, and heat the phosphorus source TMPO to 45-50°C, so that the lithium source LiHMDS, the phosphorus source TMPO, the silicon source TBS, the titanium source TTIP, and the sulfur source H 2 Precursor sources such as S and ozone can be vaporized and volatilized at room temperature 20°C and low pressure; select the corresponding precursor source according to the reaction program, and use high-purity argon as the carr...

Embodiment 1

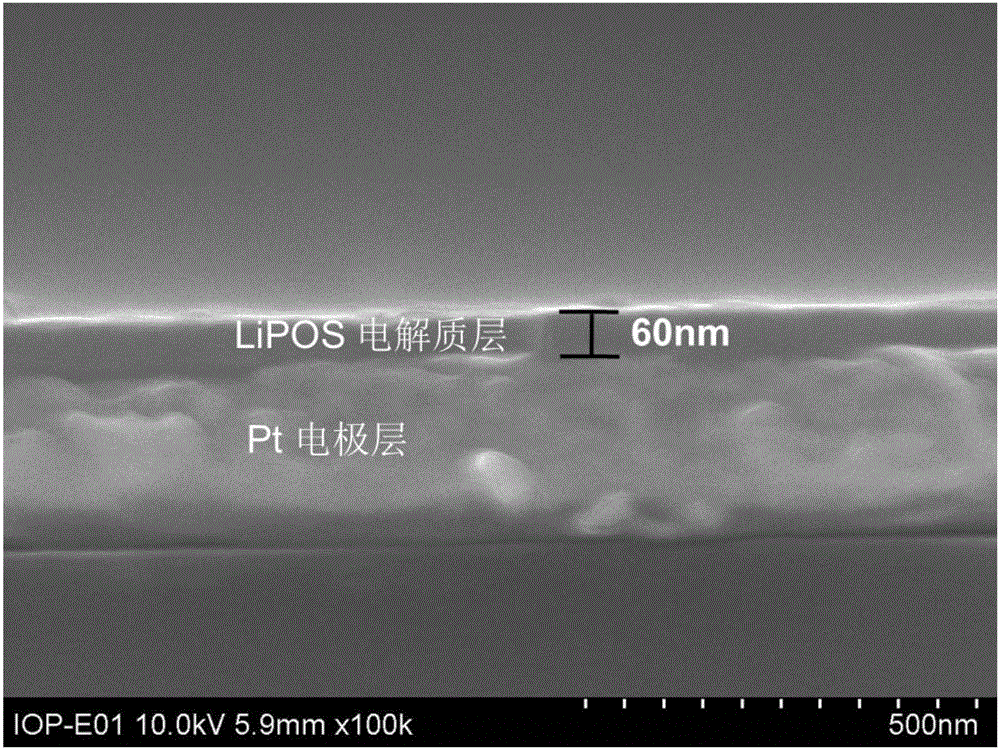

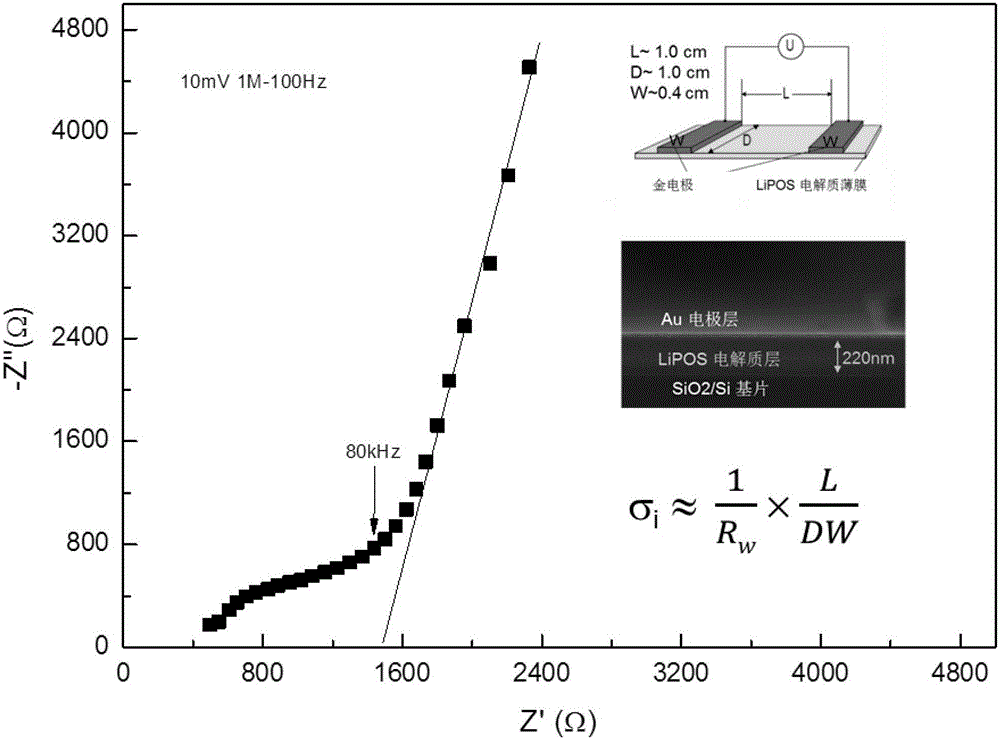

[0042] ALD technology prepares mixed composite thin film LiPOS, the characteristics of its preparation process: heating lithium source LiHMDS to 60 ℃, heating phosphorus source TMPO to 50 ℃. Use high-purity argon 200mm 3 The flow rate of / S is used as the carrier gas, the supply volume of lithium source LiHMDS for each reaction is 5 μl, the supply volume of phosphorus source TMPO is 10 μl, and the supply volume of H 2 S gas supply flow rate 20mm 3 / S. The reaction time between lithium source LiHMDS and phosphorus source TMPO is 1 second, and the argon gas is purged for 1 second; lithium source LiHMDS and H 2 The reaction time of S gas is 500 milliseconds each time, and the high-purity argon gas is purged for 1 second. The ambient atmosphere of the ALD reaction chamber is high-purity argon, the temperature is controlled at 220°C, and the air pressure is 10mBar.

[0043] After 10 reactions of lithium source LiHMDS and phosphorus source TMPO, the lithium source LiHMDS and H ...

Embodiment 2

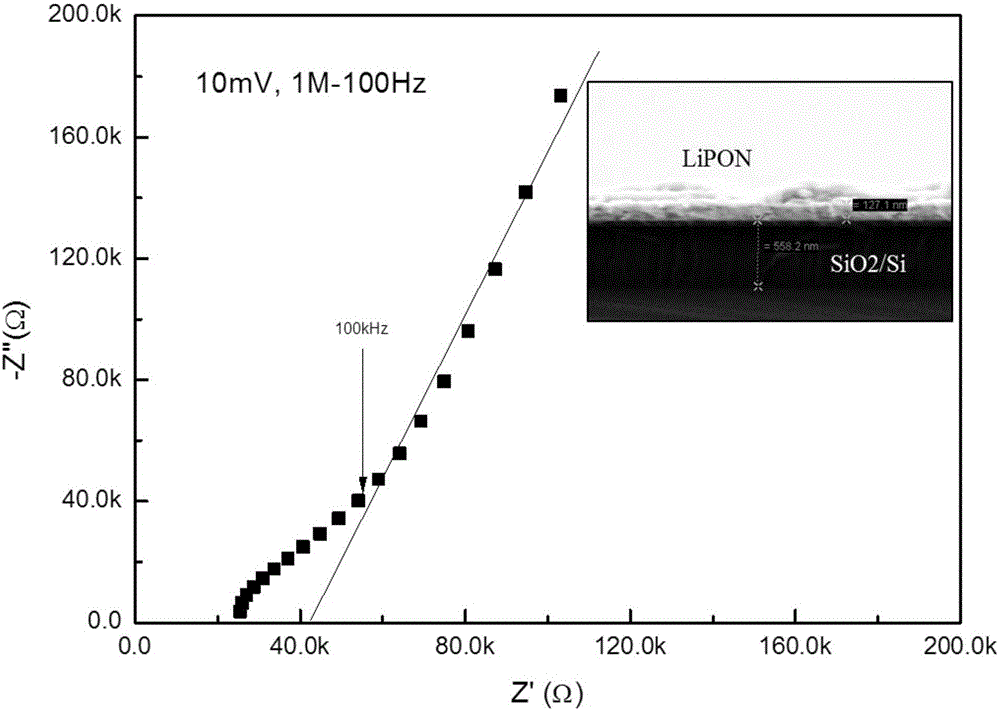

[0045] ALD technology prepares mixed composite thin film LiPON, and its preparation process features: heating lithium source LiHMDS to 65 ° C, heating phosphorus source TMPO to 45 ° C. Use high-purity argon 200mm 3The flow rate of / S is used as the carrier gas, and the supply volume of lithium source LiHMDS for each reaction is 5 μl, and the supply volume of phosphorus source TMPO is 10 μl, N 2 Gas supply flow rate 25mm 3 / S, plasma generator power 60W. The reaction time between lithium source LiHMDS and phosphorus source TMPO is 1 second, and argon gas is purged for 1 second; the time for each reaction between lithium source LiHMDS and nitrogen plasma is 2 seconds, and high-purity argon gas is purged for 1 second. The ambient atmosphere of the ALD reaction chamber is high-purity argon, the temperature is controlled at 220°C, and the air pressure is 20mBar.

[0046] After 10 reactions of lithium source LiHMDS and phosphorus source TMPO, lithium source LiHMDS reacts with nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com