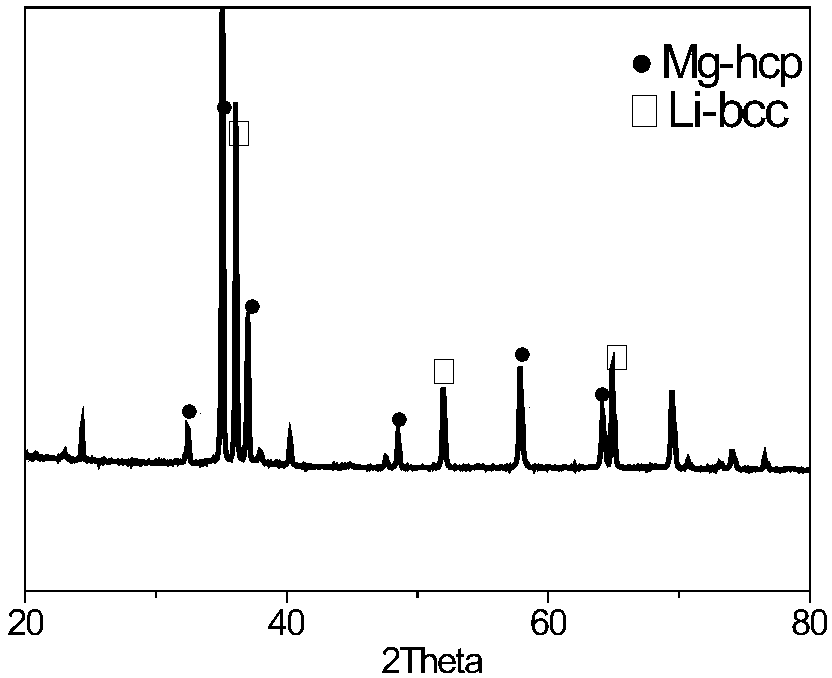

High-strength low-density hcp+bcc dual-structure magnesium-lithium alloy bar and preparation method thereof

A magnesium-lithium alloy and low-density technology, which is applied in the field of high-strength and low-density hcp+bcc double-structure magnesium-lithium alloy rods and its preparation, can solve the problems of limiting the application value of magnesium-lithium alloys and low alloy strength, and achieve improved purity The effect of improving alloy yield, improving alloy strength, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A high-strength and low-density hcp+bcc double-structure magnesium-lithium alloy rod, the raw materials of which are as follows by weight percentage: the chemical composition and weight percentage of the magnesium-lithium alloy are: Li: 8.8%, Al: 5.7%, Zn: 1.9%, 0.5% %Y, inevitable Ca, Fe, Cu, Ni and other impurity elements, the total amount is less than 0.2%, of which Fe≤0.04%, Ca≤0.03%. The rest is Mg.

[0032] Dry each raw material at 200±5°C for 30 minutes, then place the pure magnesium ingot in a smelting furnace and raise the temperature to 720±5°C. After the metal magnesium is completely melted, a magnesium melt is formed, and then the dried Mg-Y is placed in the middle The alloy, pure aluminum and pure zinc are placed in the magnesium melt in sequence, and the covering agent is sprayed to cover the surface of the magnesium melt, and the temperature is controlled at 720°C and stirred;

[0033] Under the condition of feeding protective gas, the temperature of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com