Patents

Literature

41results about How to "Stable back pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

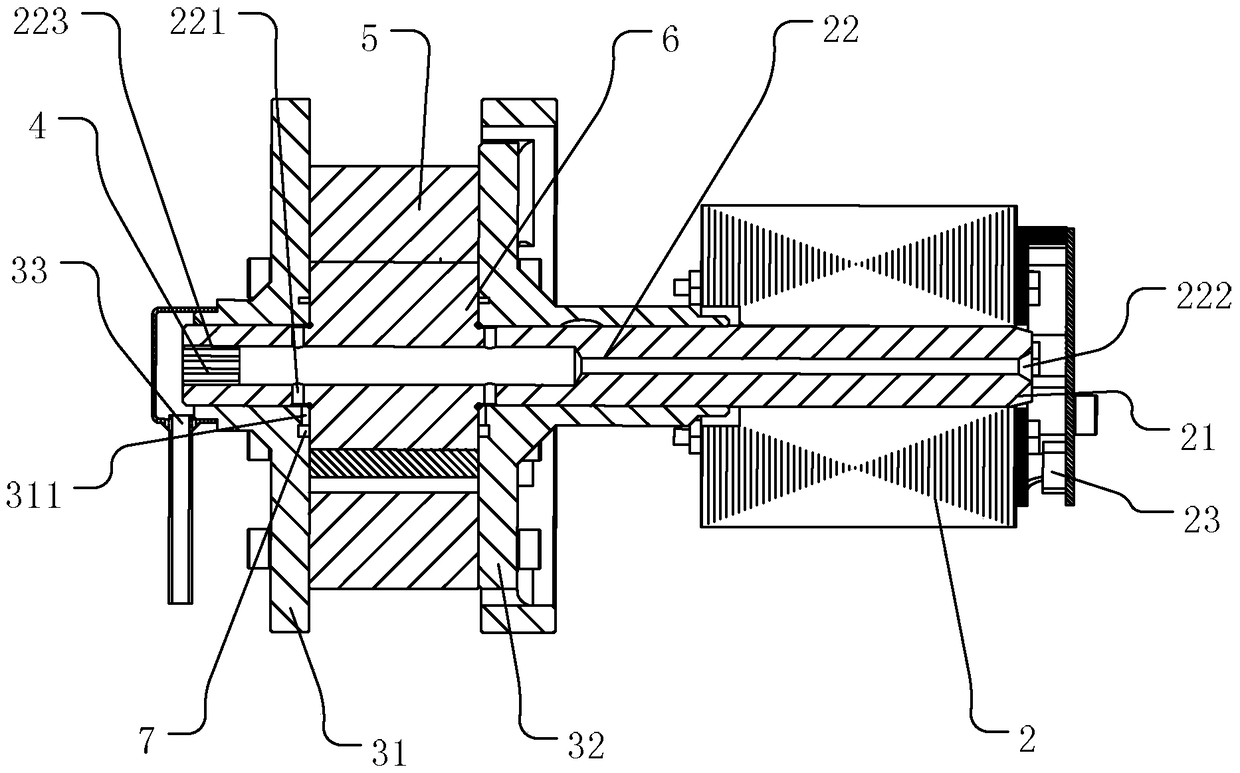

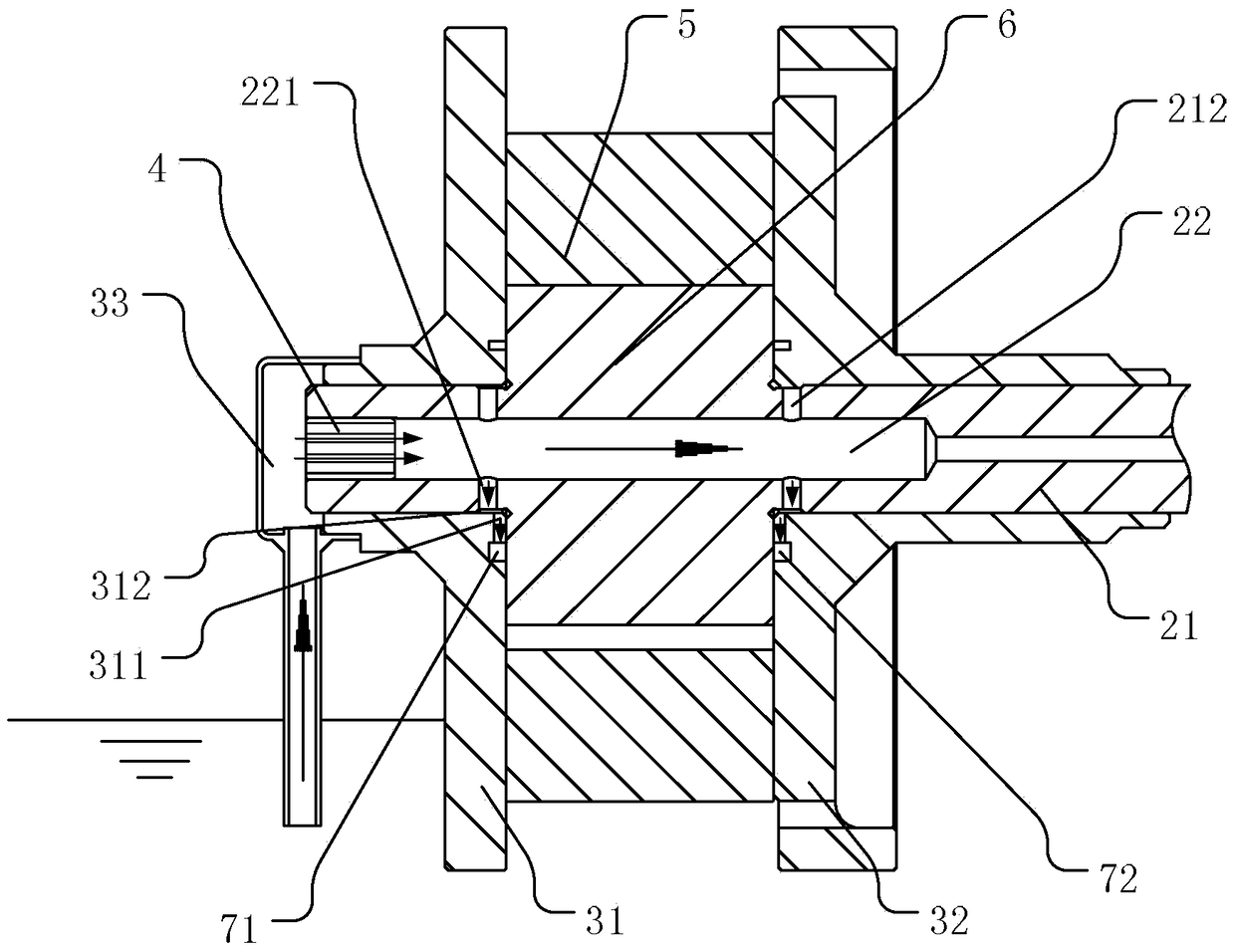

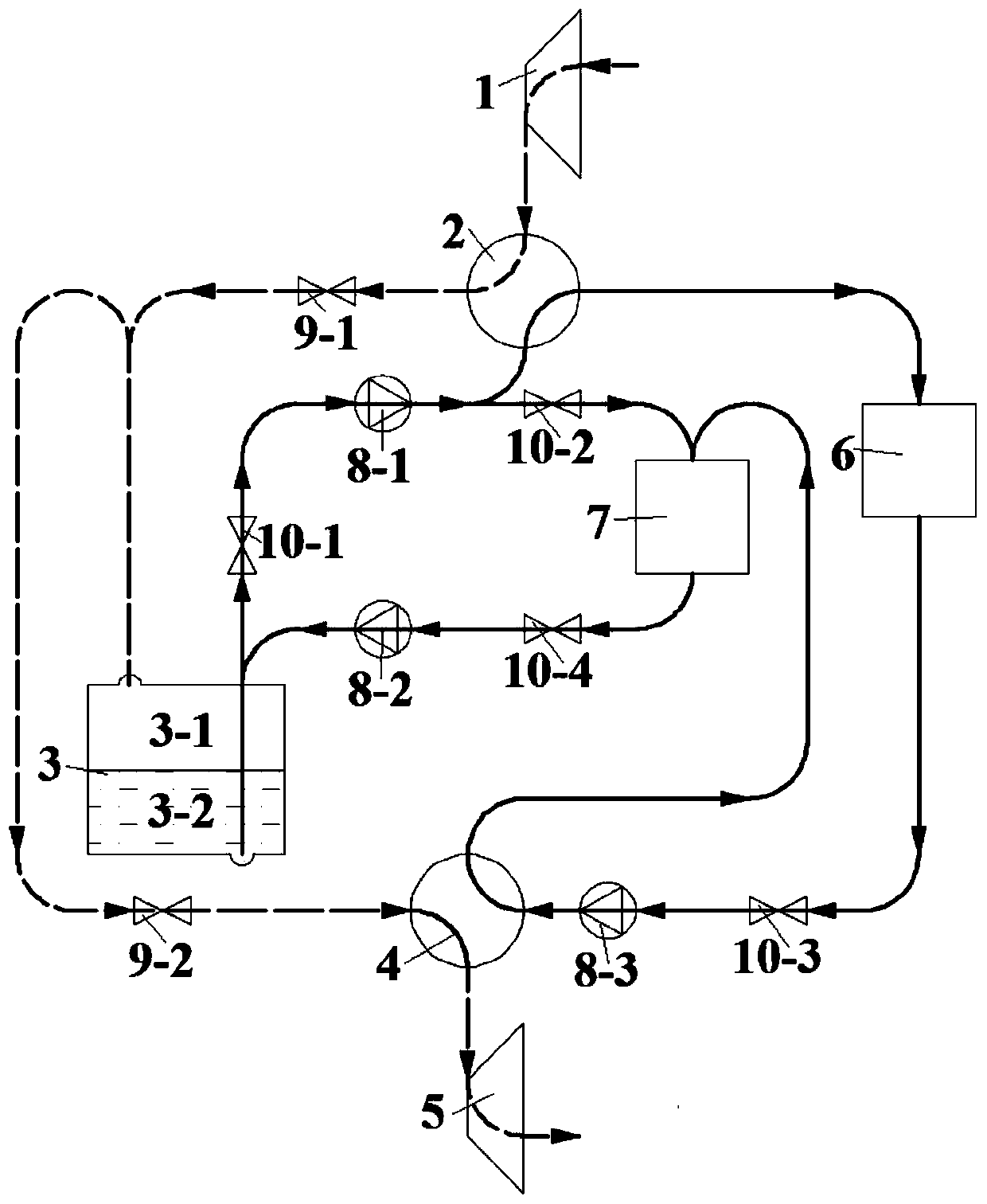

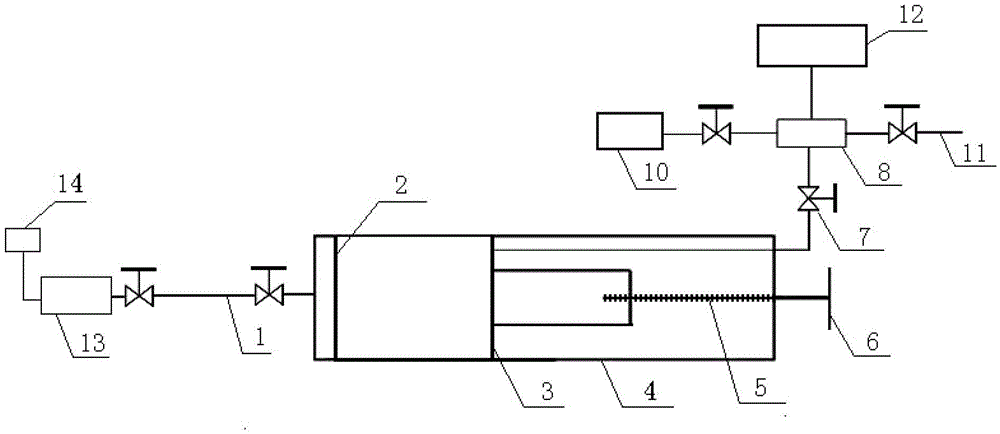

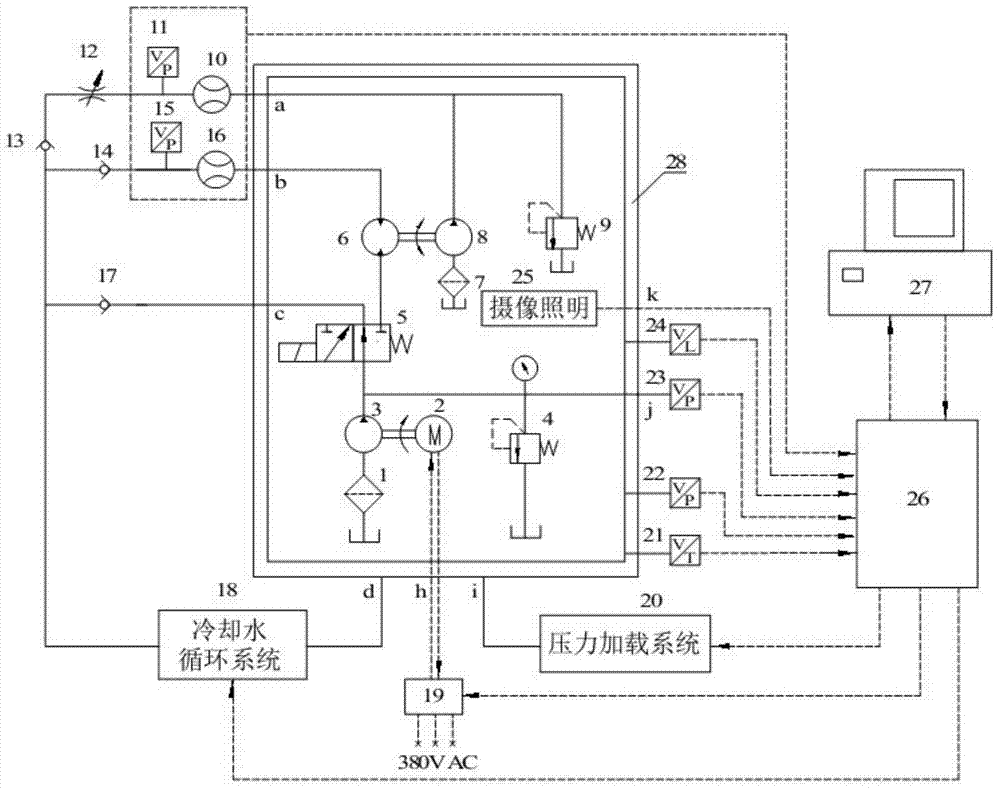

Performance test device and test method for seawater hydraulic motor under deep-sea high-back-pressure environment

ActiveCN105443503AStable back pressureAvoid mixingFluid-pressure actuator testingHigh pressureSeawater

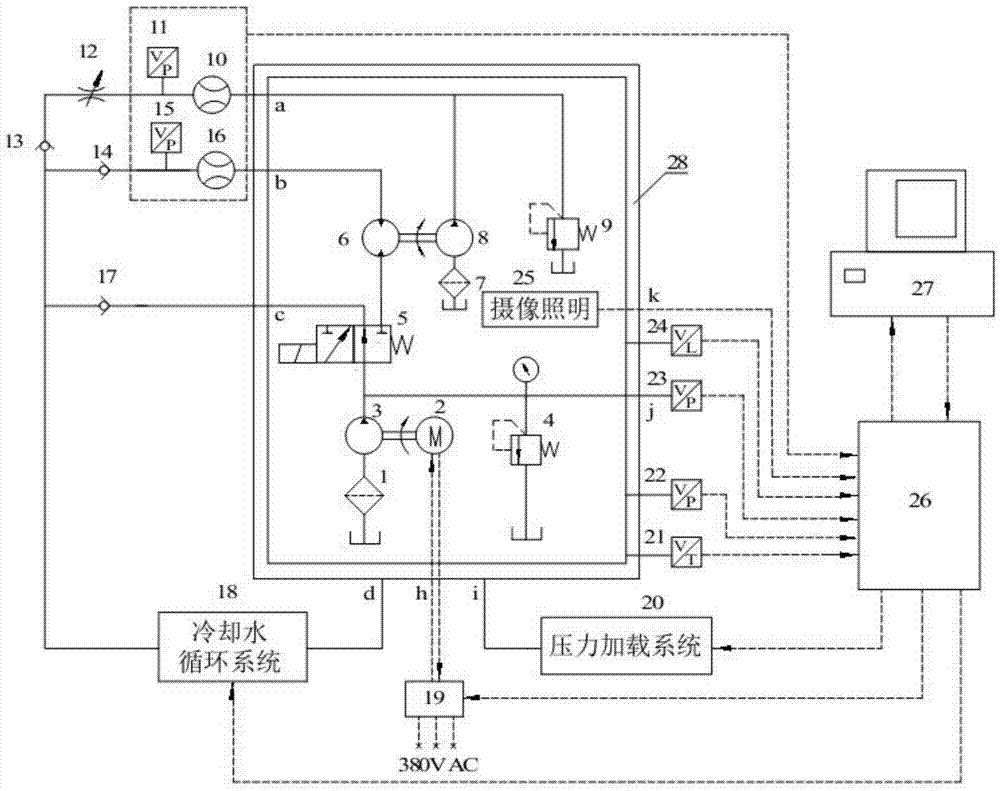

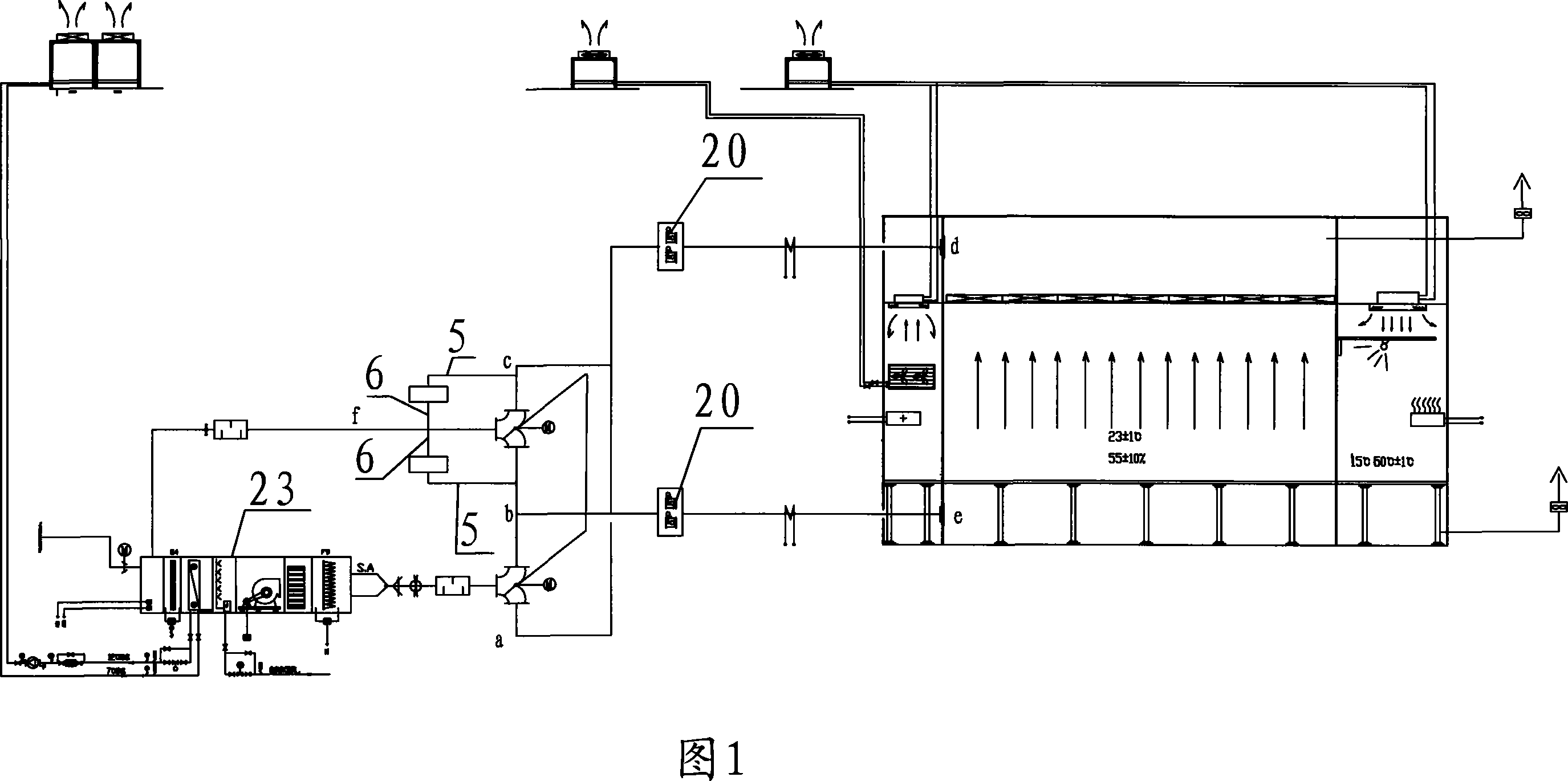

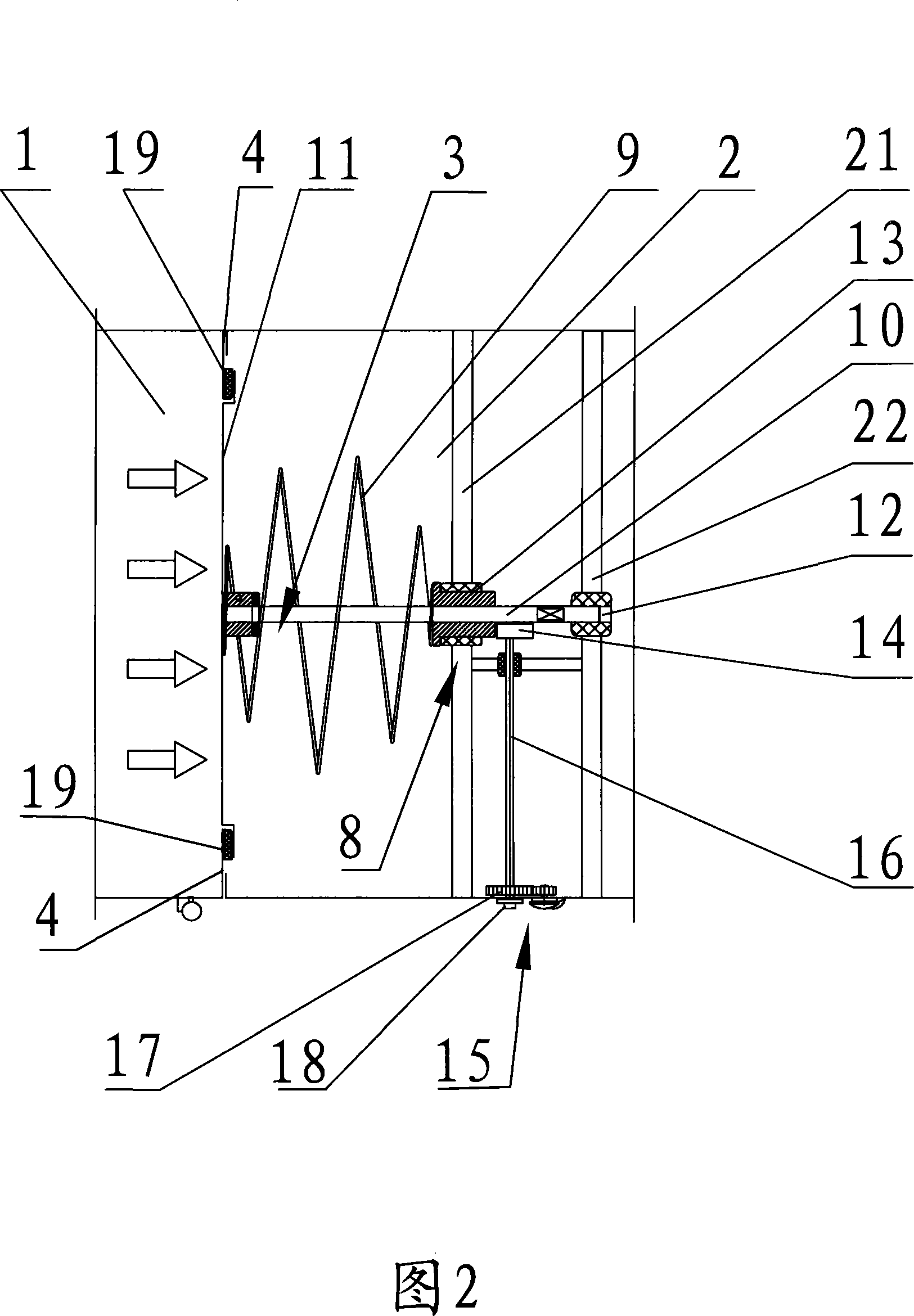

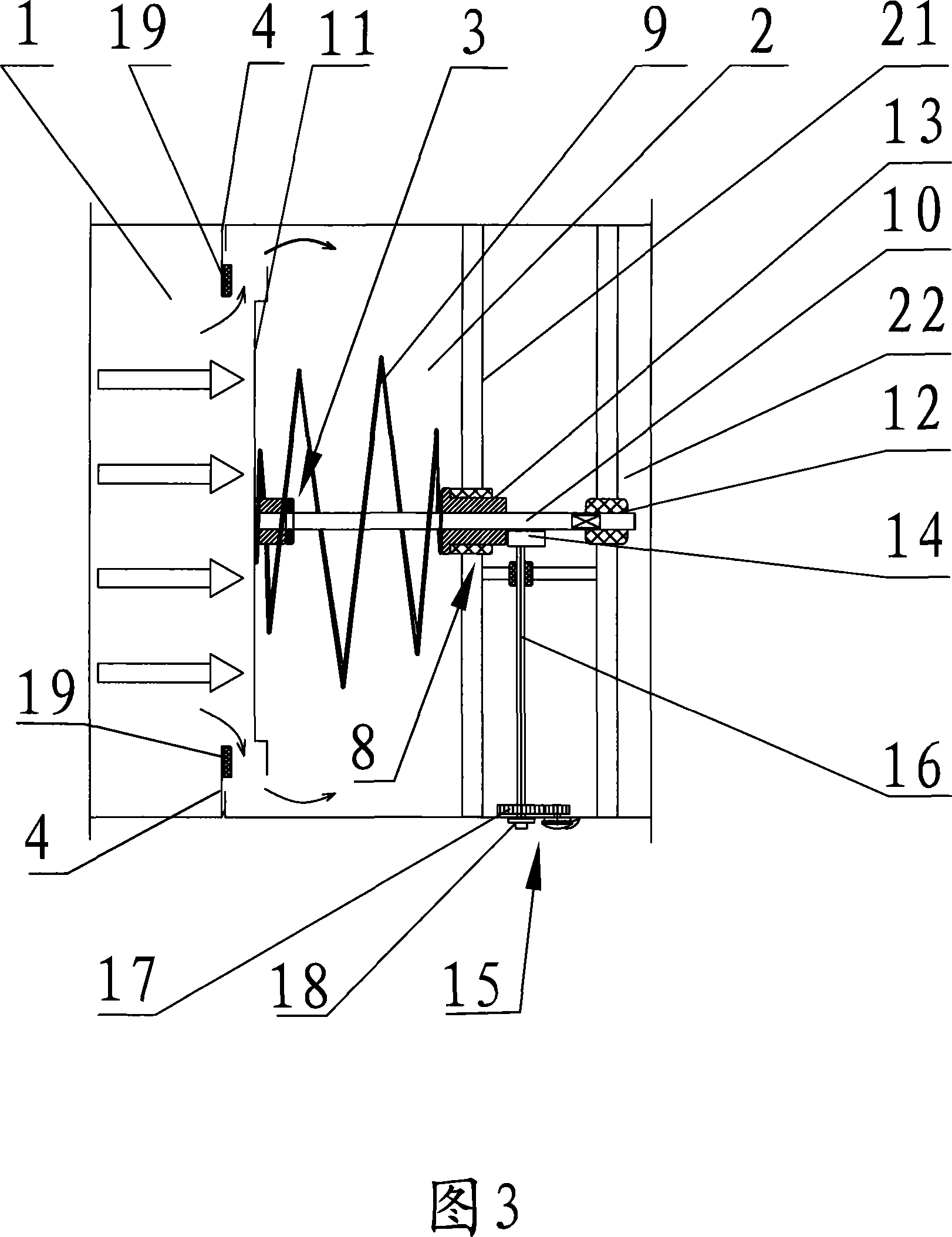

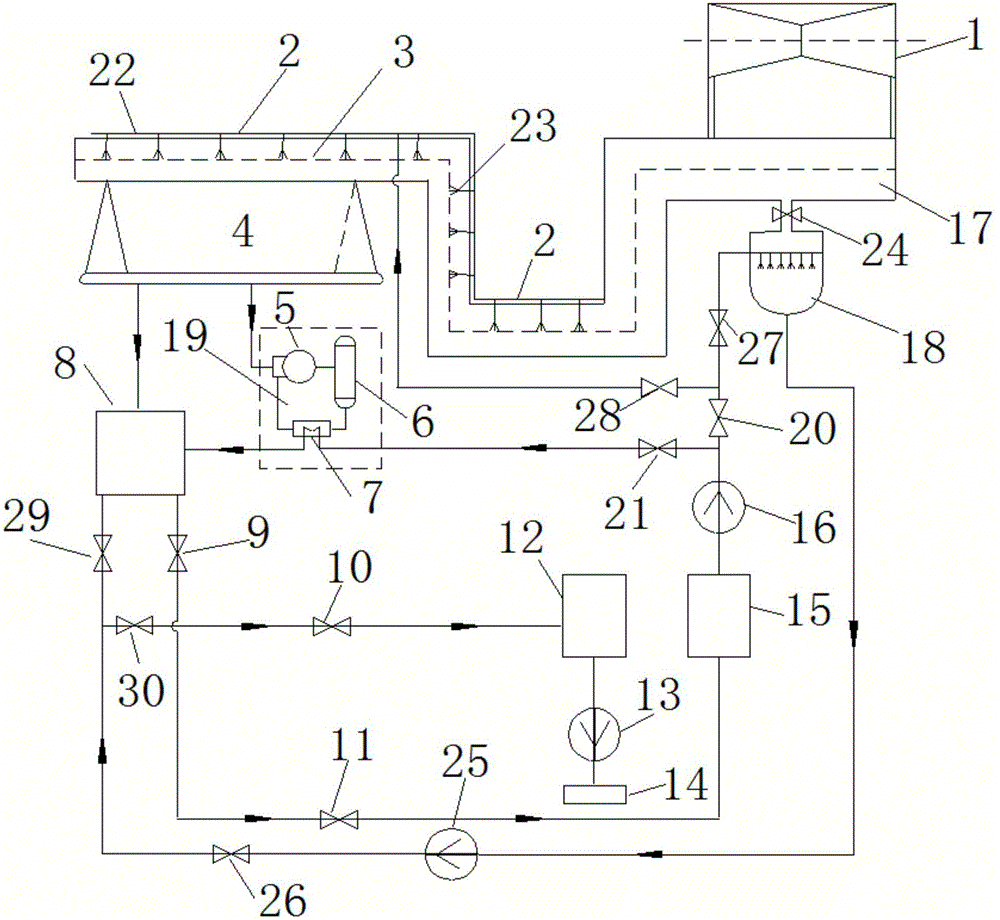

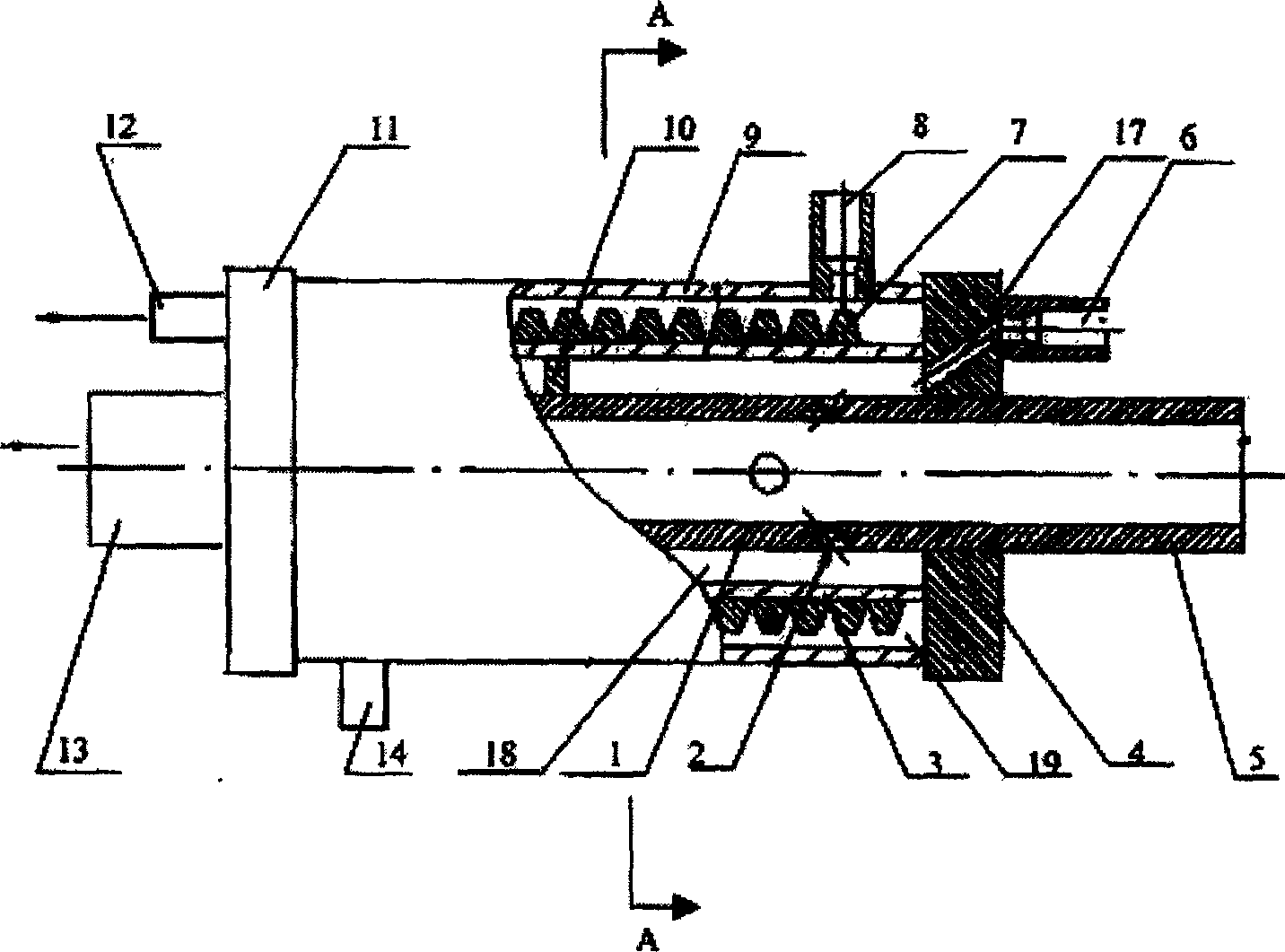

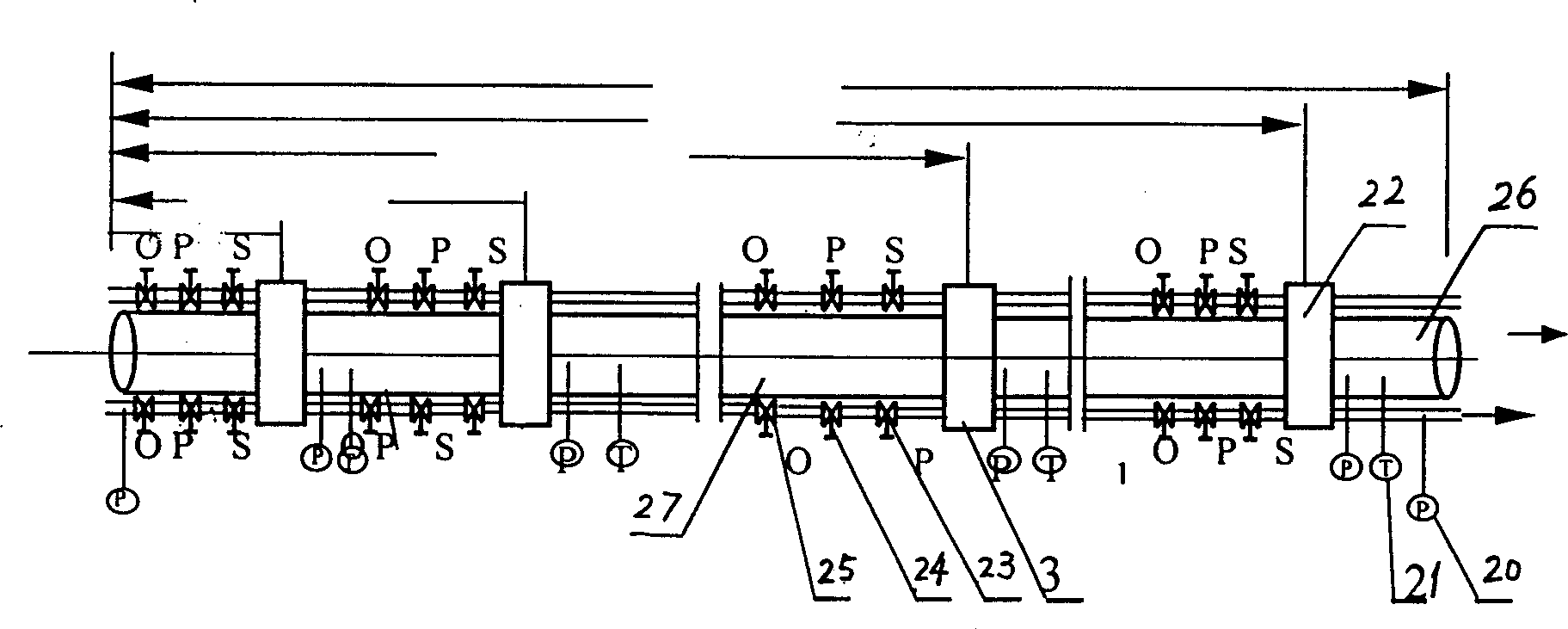

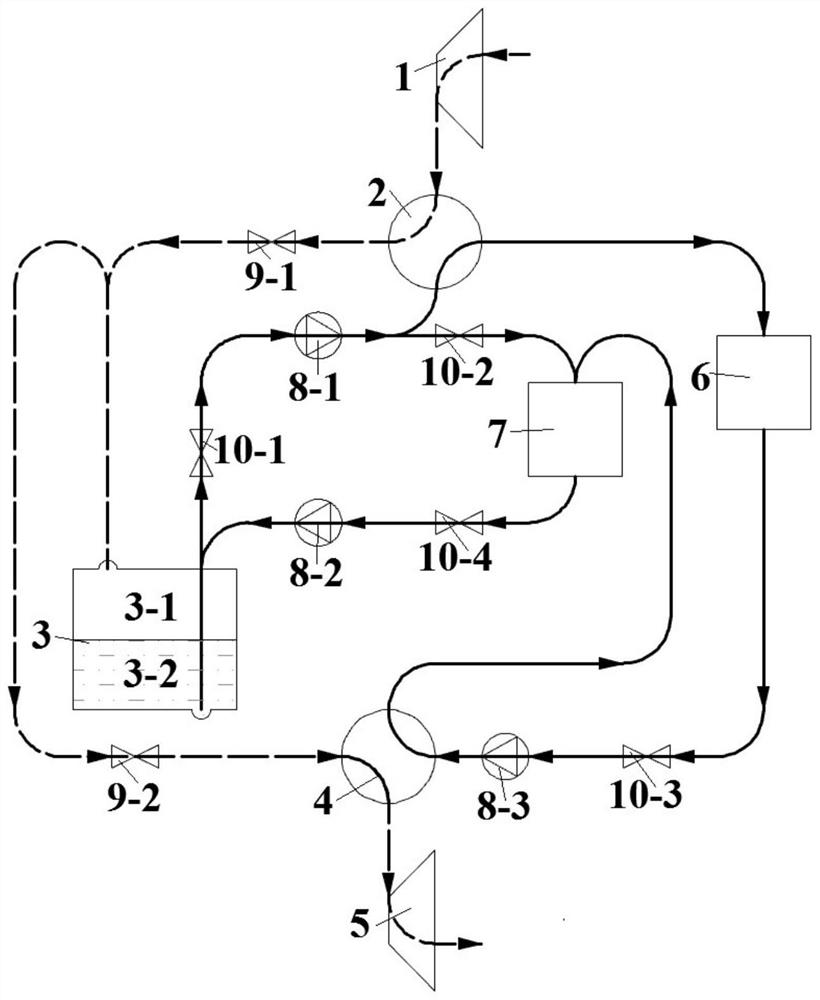

The invention discloses a performance test device and a performance test method for a seawater hydraulic motor under a deep-sea high-back-pressure environment. The performance test device mainly comprises a seawater hydraulic motor test system, a monitoring control system, a deep-sea simulation cabin, a pressure loading system and a circulating water cooling system, wherein the deep-sea simulation cabin provides back pressure required to bear while working under different water-depth environments for performance test of the tested seawater hydraulic motor by virtue of the pressure loading system; test load of the tested seawater hydraulic motor is freely regulated by virtue of a high-pressure flow control valve mounted in the circulating water cooling pipeline; and the circulating water cooling pipeline can effectively avoid rising the water temperature in the cabin due to heat generated by the seawater hydraulic motor operated under load, the motor and the like. The method can simulate the back pressure environment at a set ocean depth and can realize performance test for the seawater hydraulic motor, is simple to operate, easy to realize, not only overcomes the technical difficulty of lowering the seawater hydraulic motor into great-depth deep sea, but also can accurately obtain performance parameters of the seawater hydraulic motor.

Owner:BEIJING UNIV OF TECH

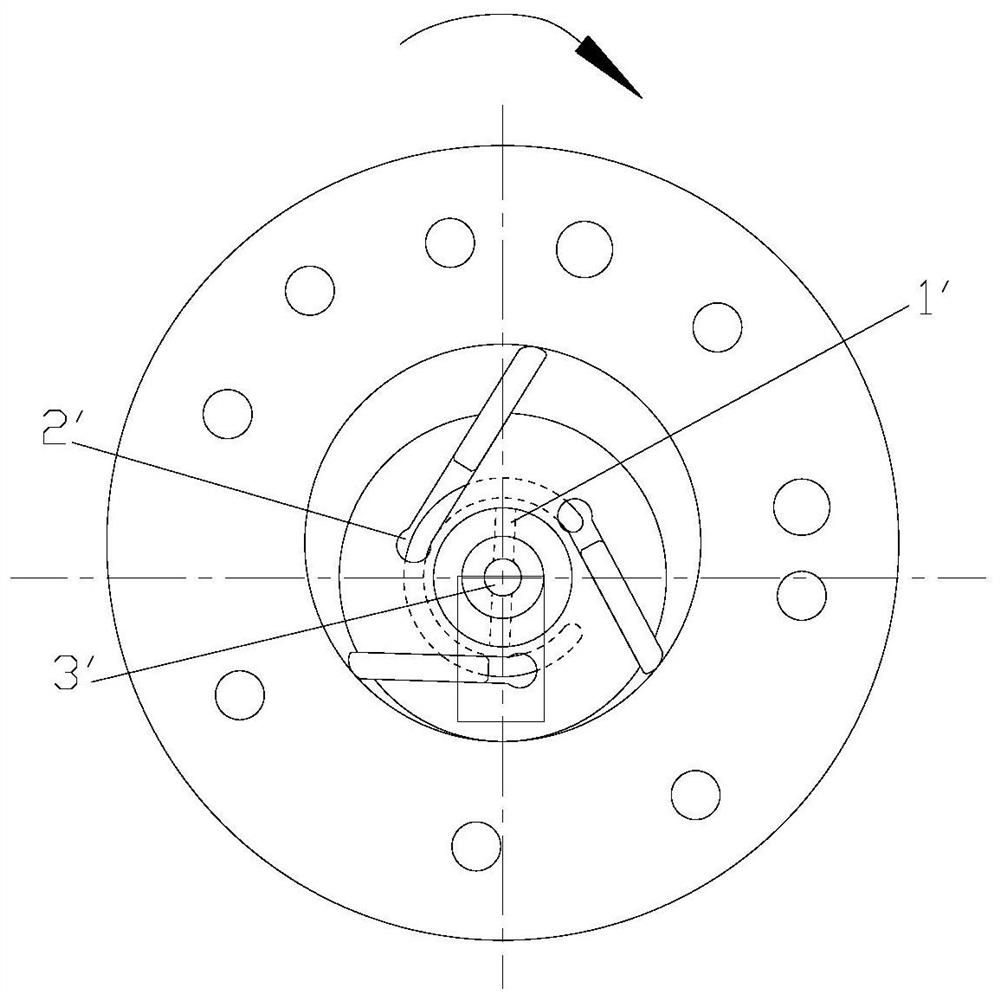

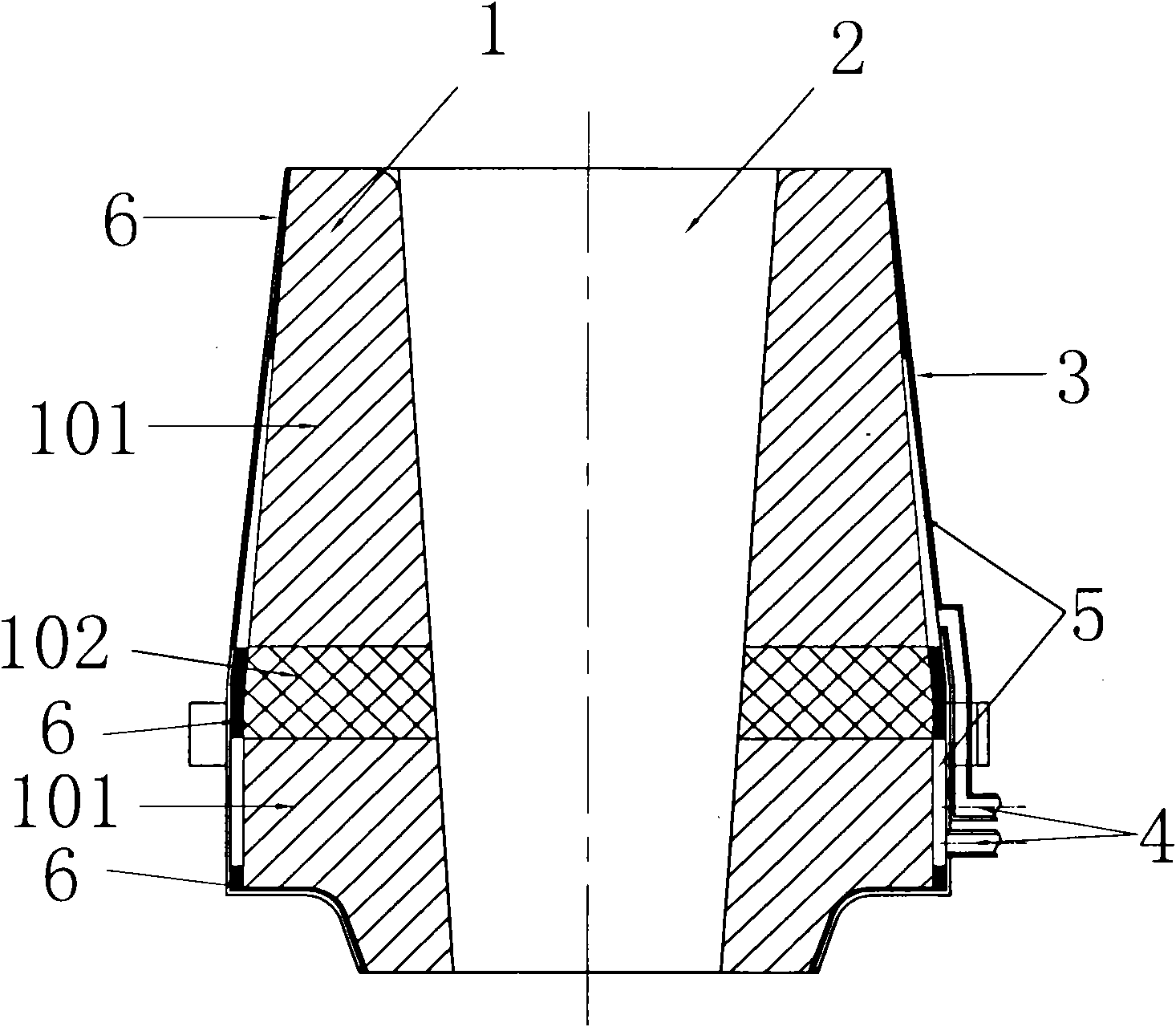

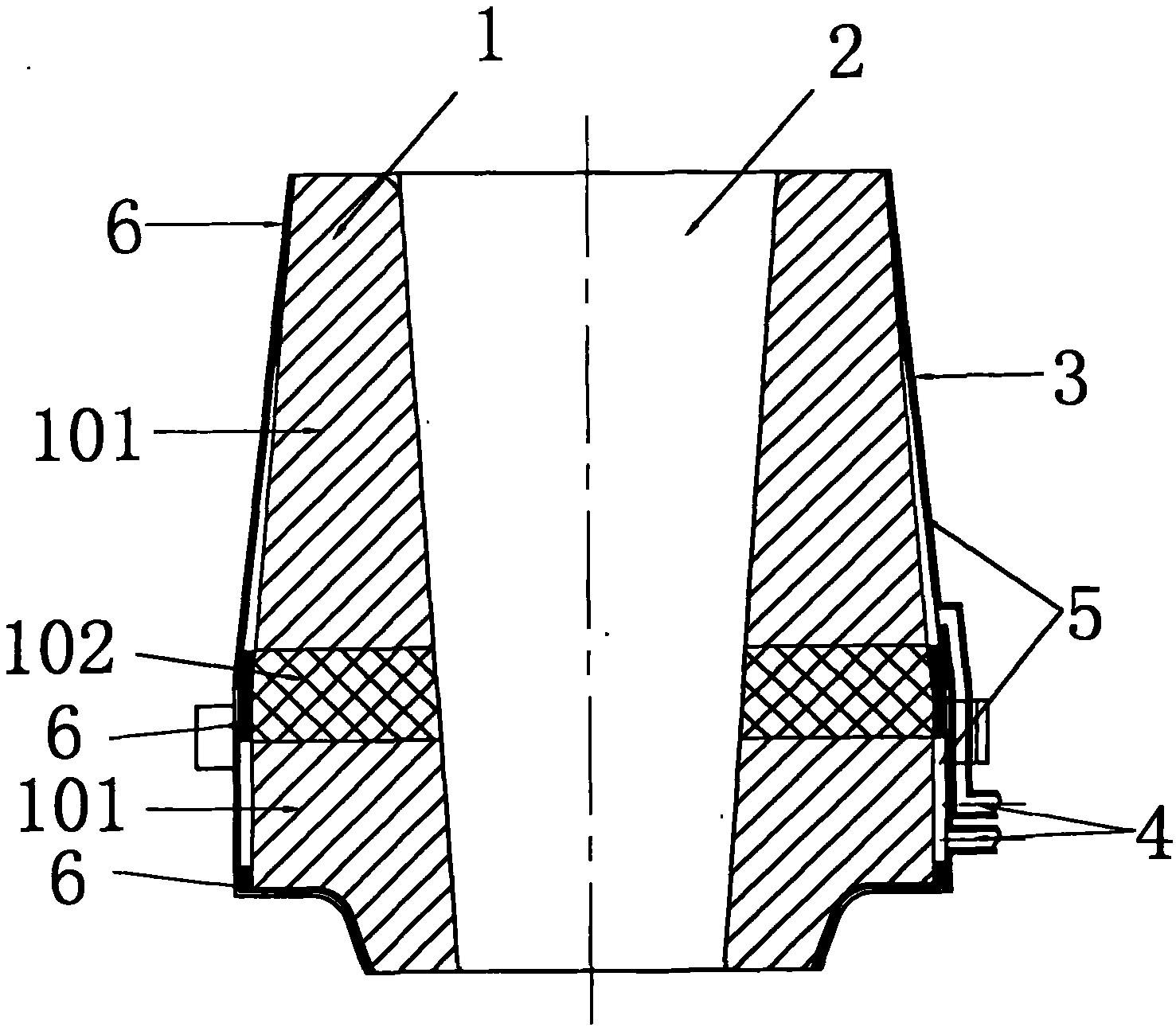

Slide vane compressor

ActiveCN105402125AStable back pressureReduce the cross-sectional areaRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsPetroleum engineering

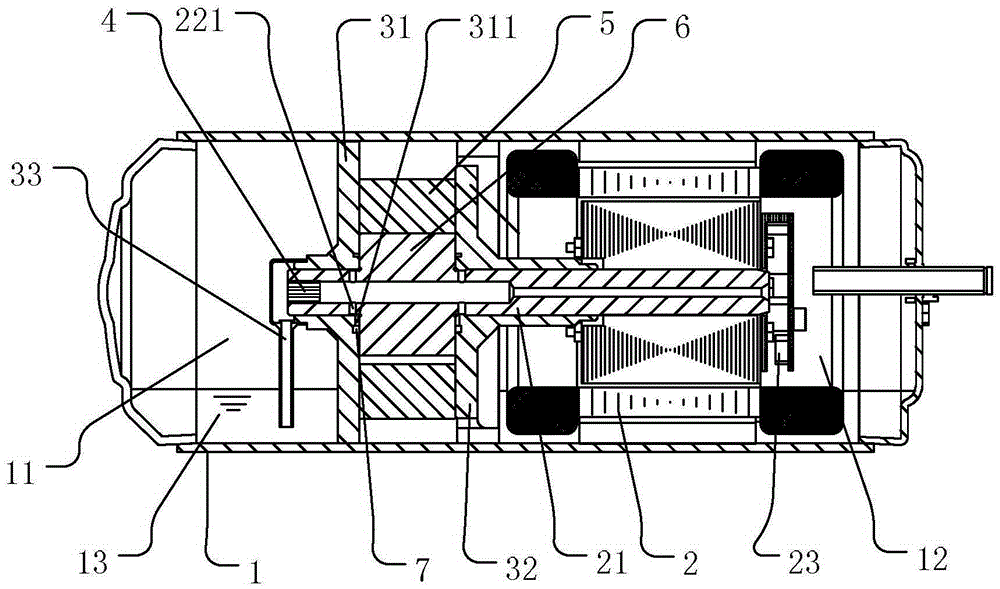

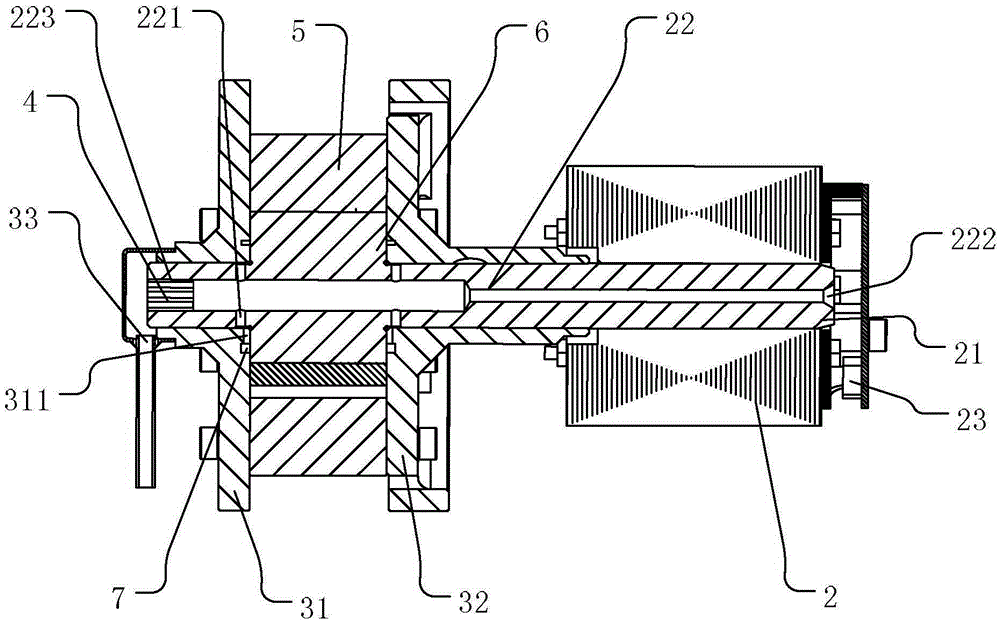

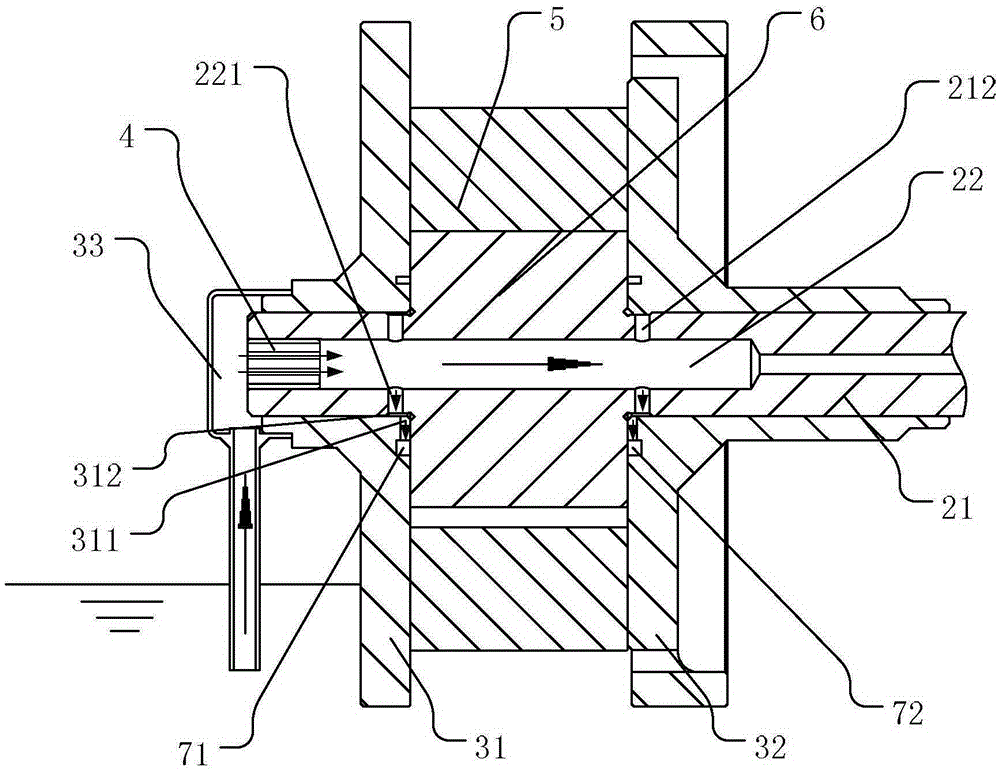

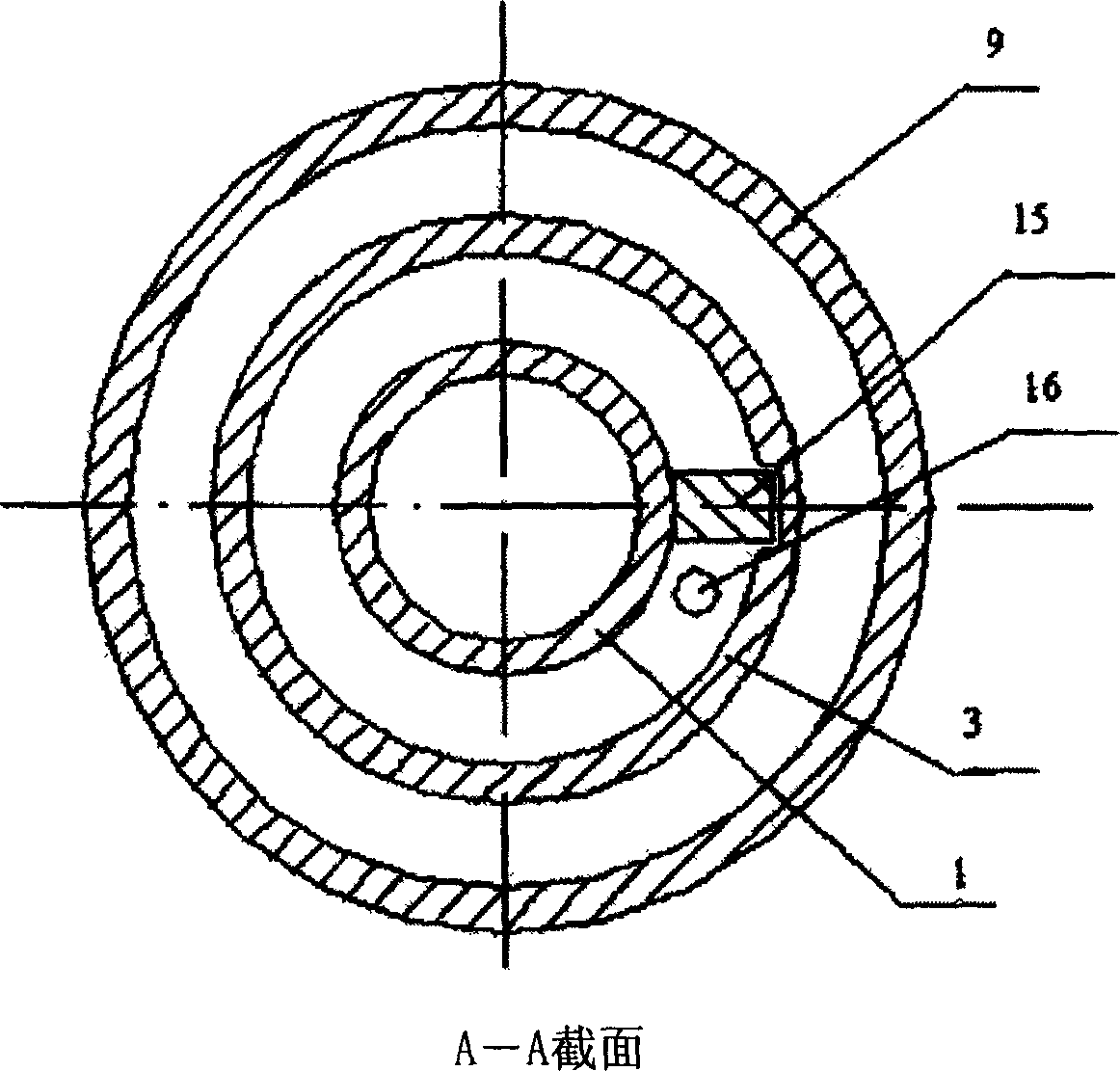

The invention aims at providing a slide vane compressor. The problem that backpressure oil supplying of an existing slide vane compressor is not stable is mainly solved. According to the technical scheme, negative pressure is generated in a main oil way in a spindle through a fan, and then an upper oil tube assembly is used for pumping oil from an oil pool; a backpressure oil tank is communicated with the main oil way, and the main oil way supplies pressure oil to the backpressure oil tank. Through the arrangement, oil supplying of the backpressure oil tank is more stable and reliable.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

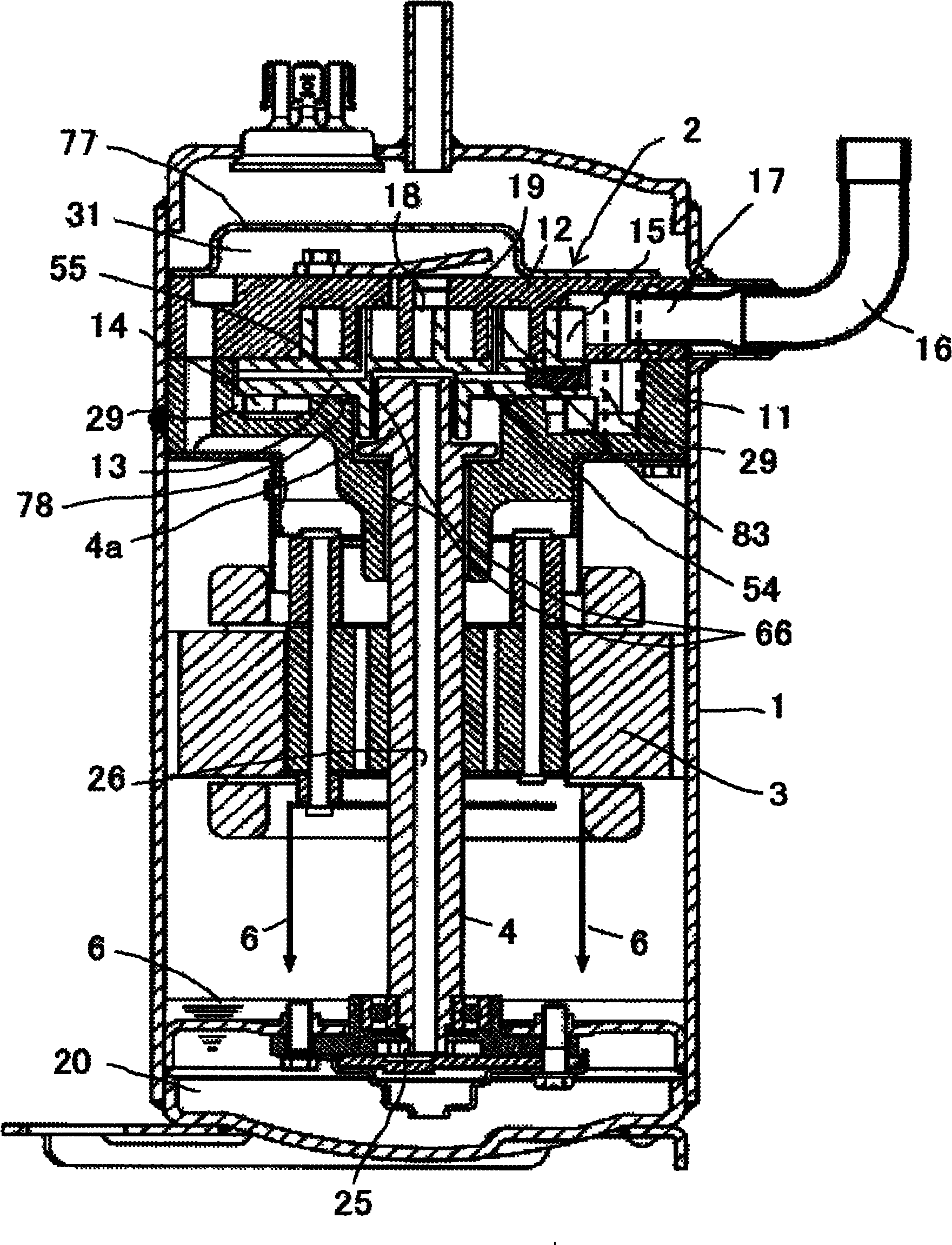

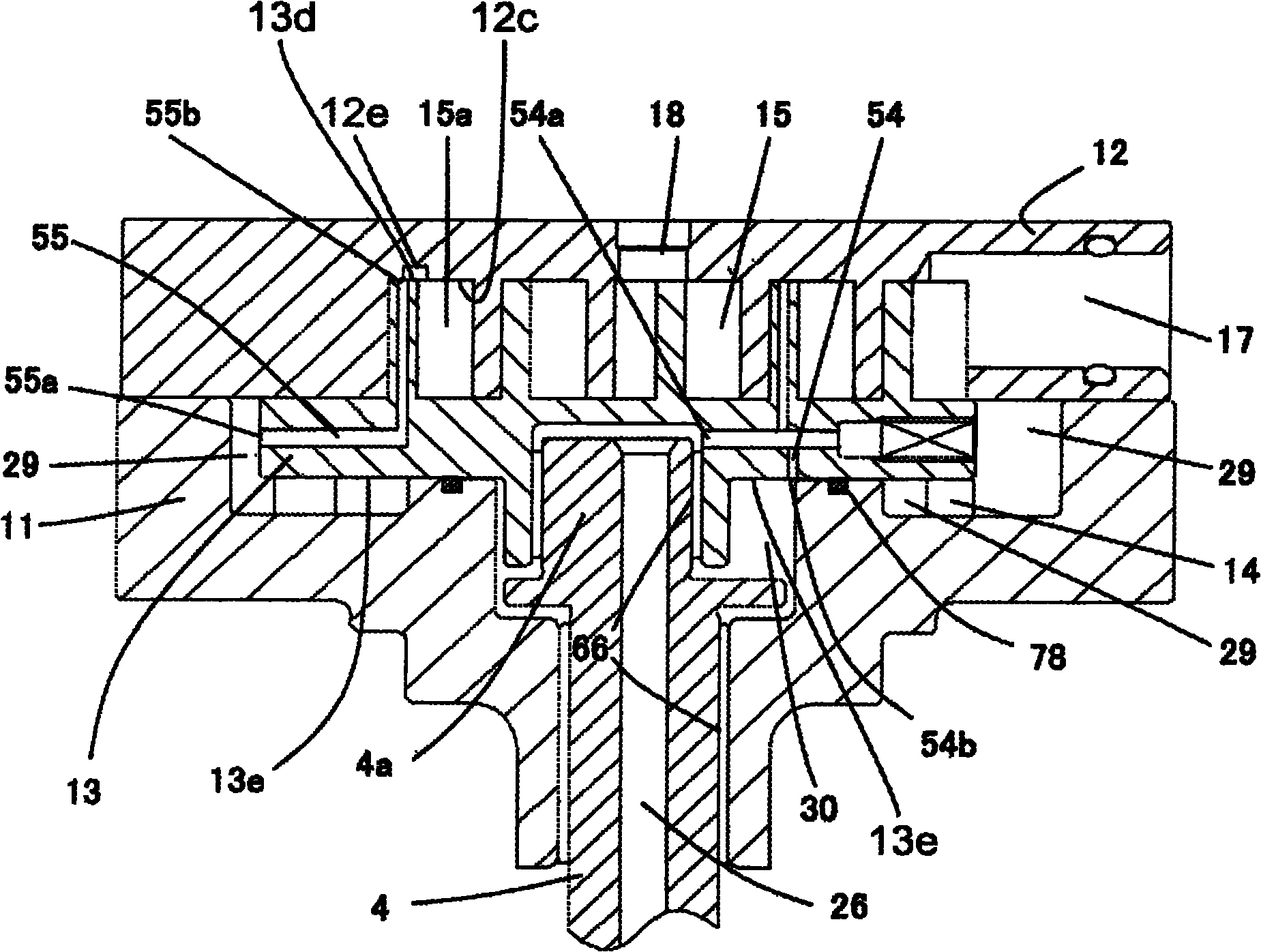

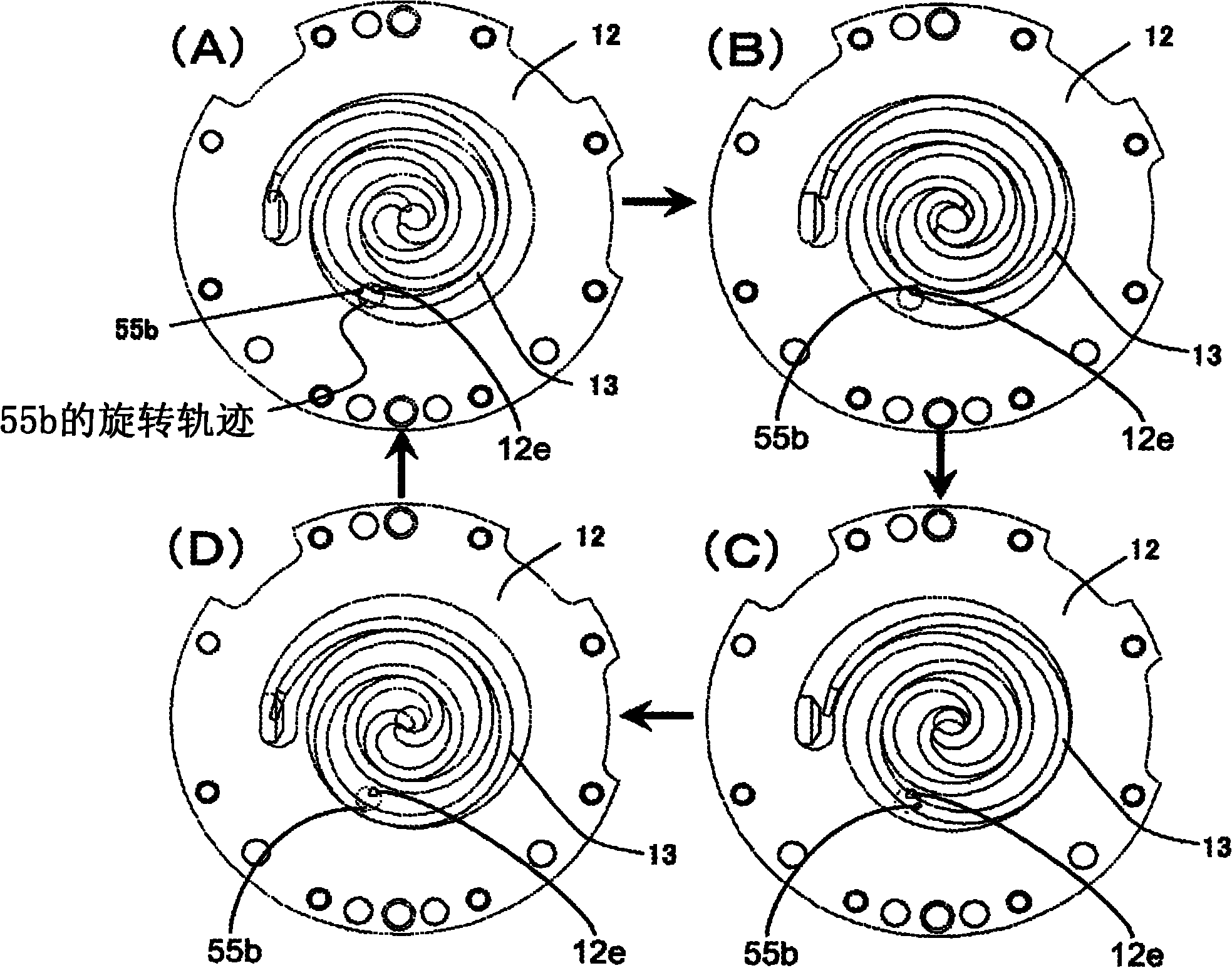

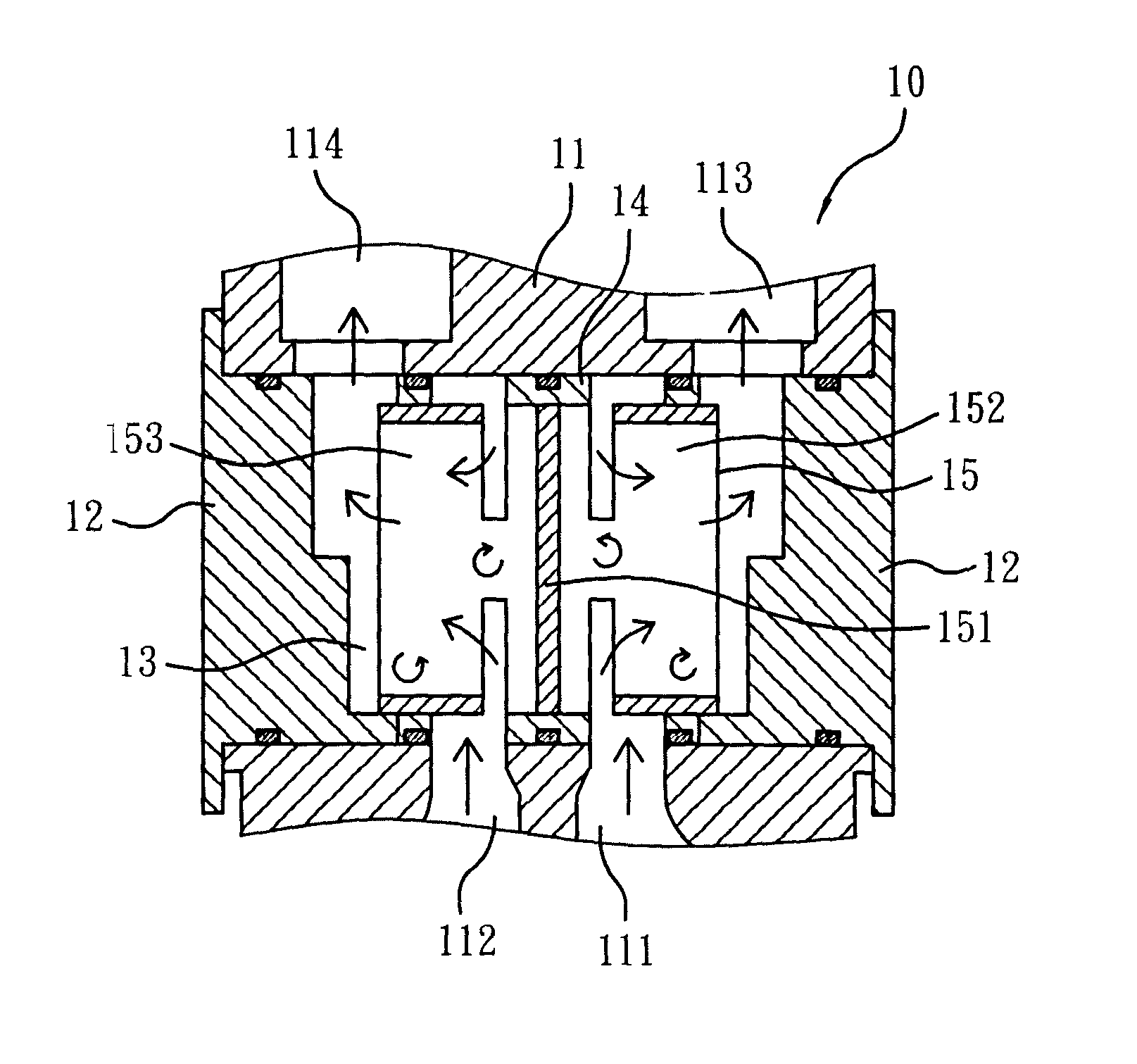

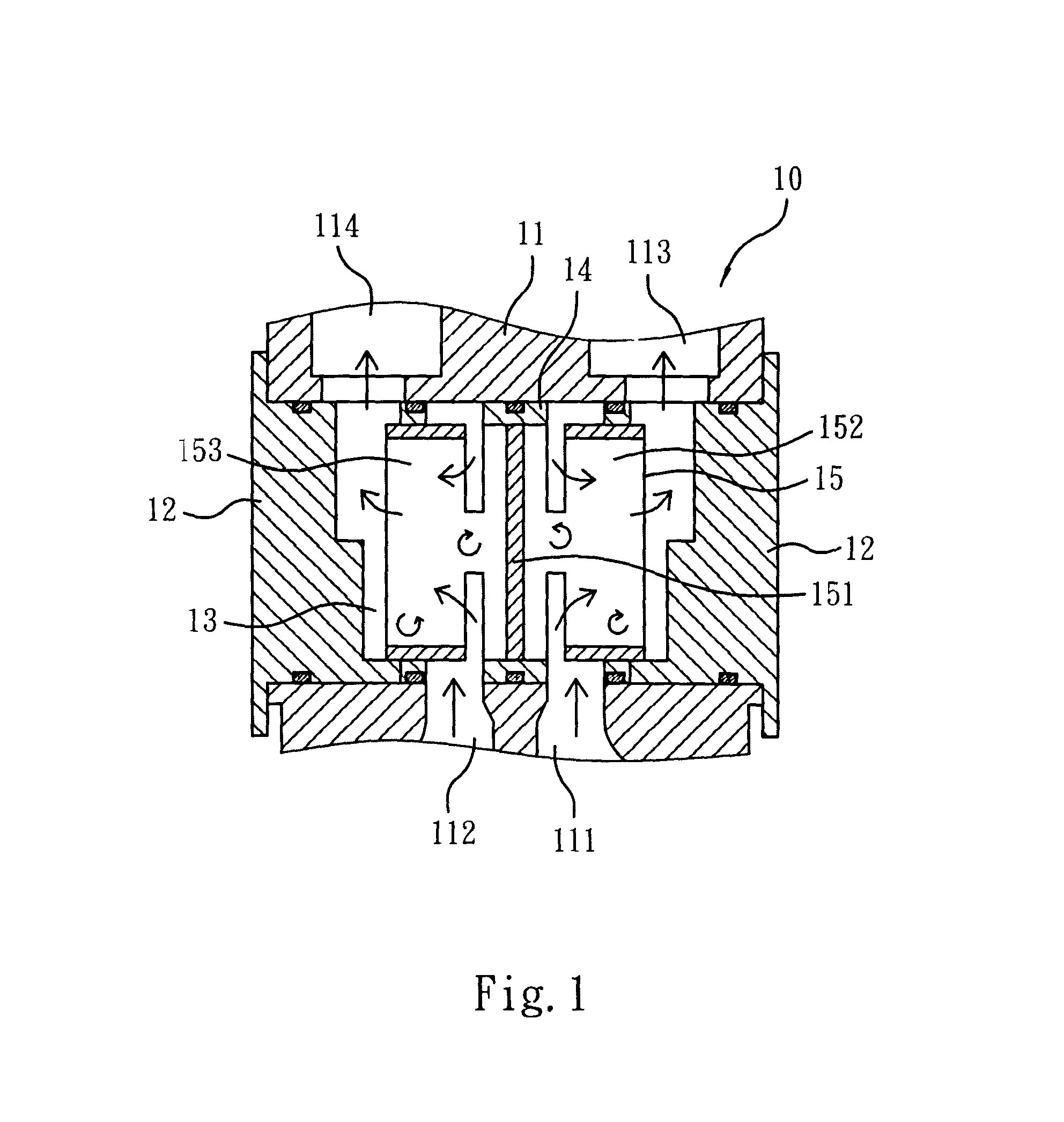

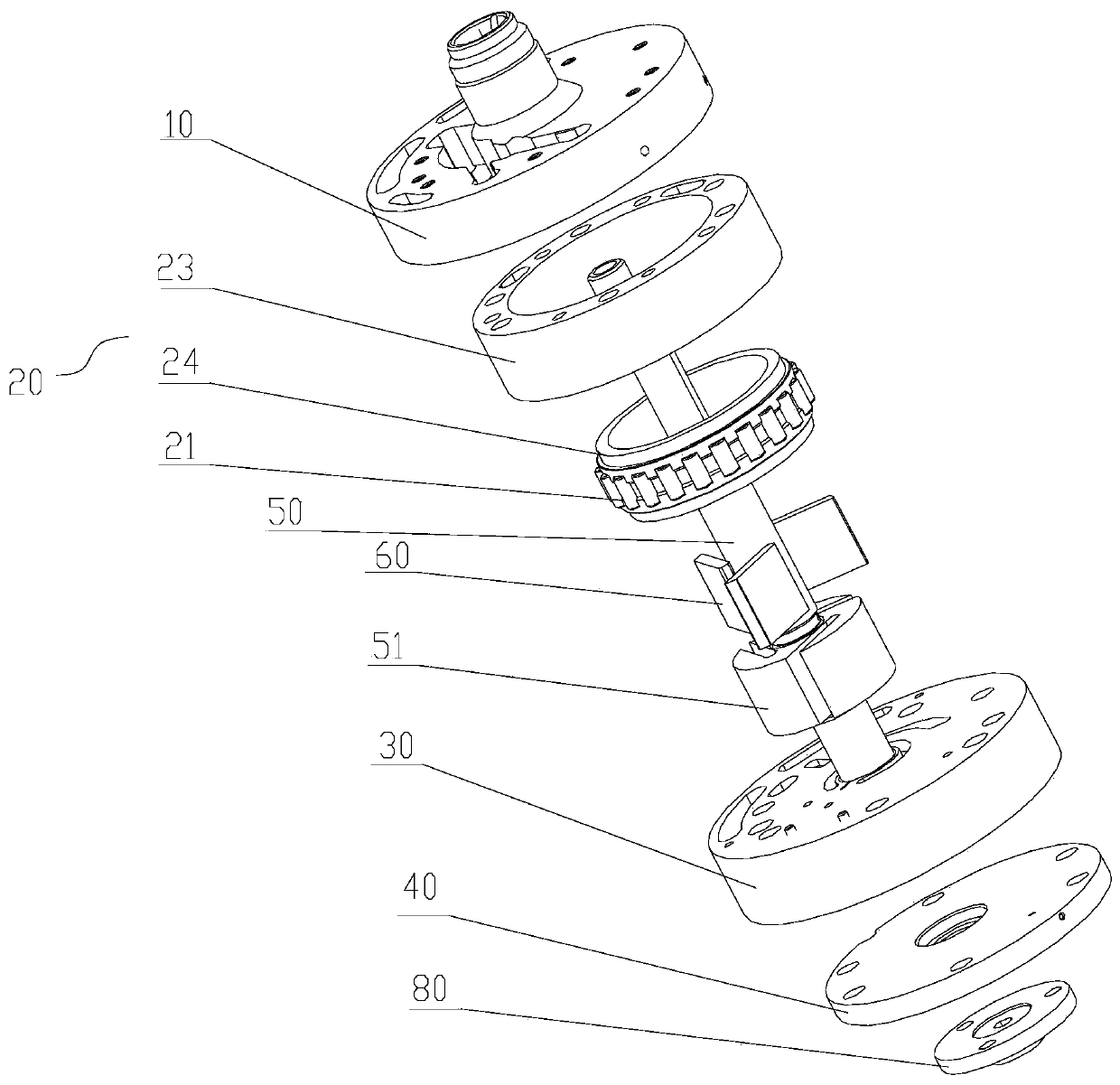

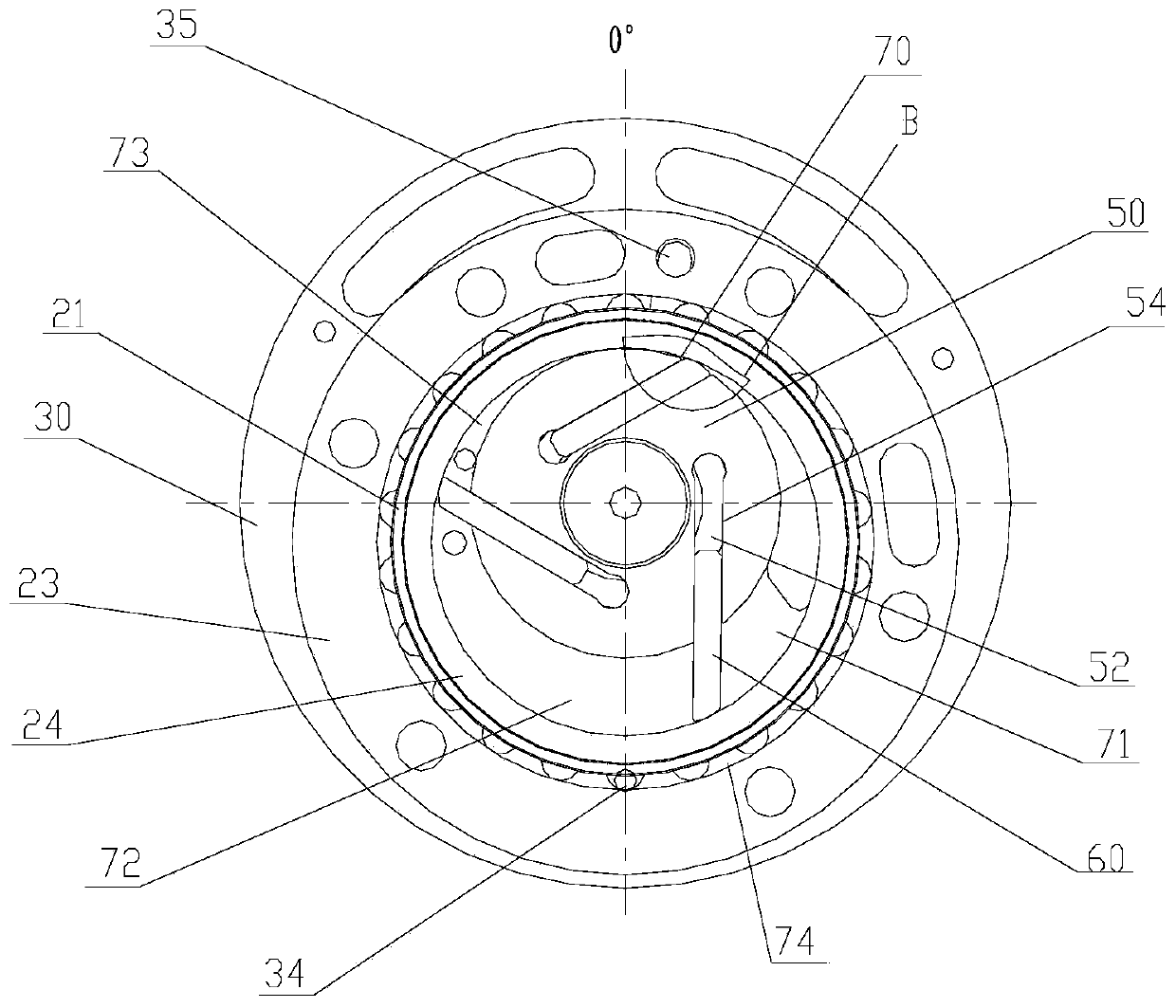

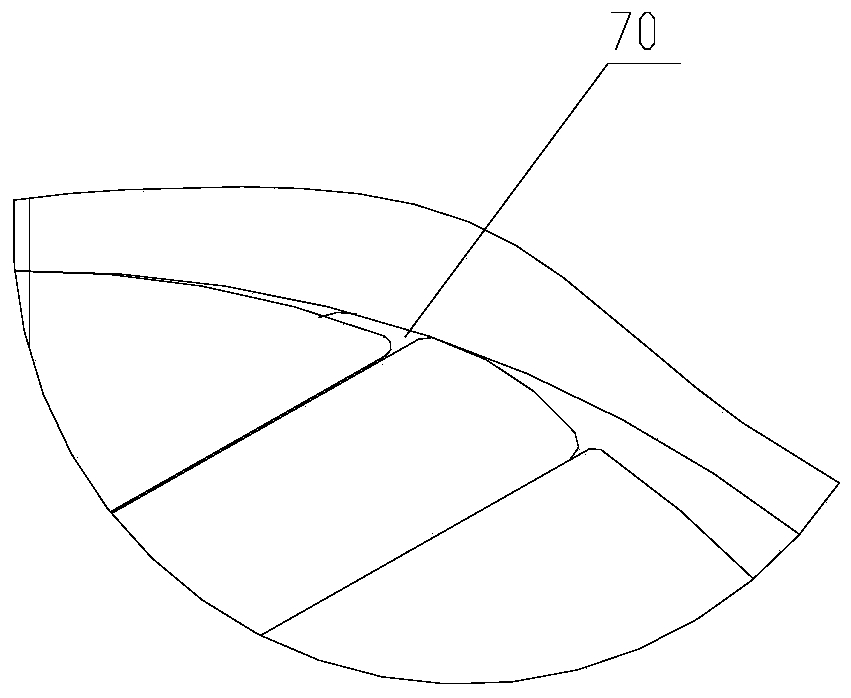

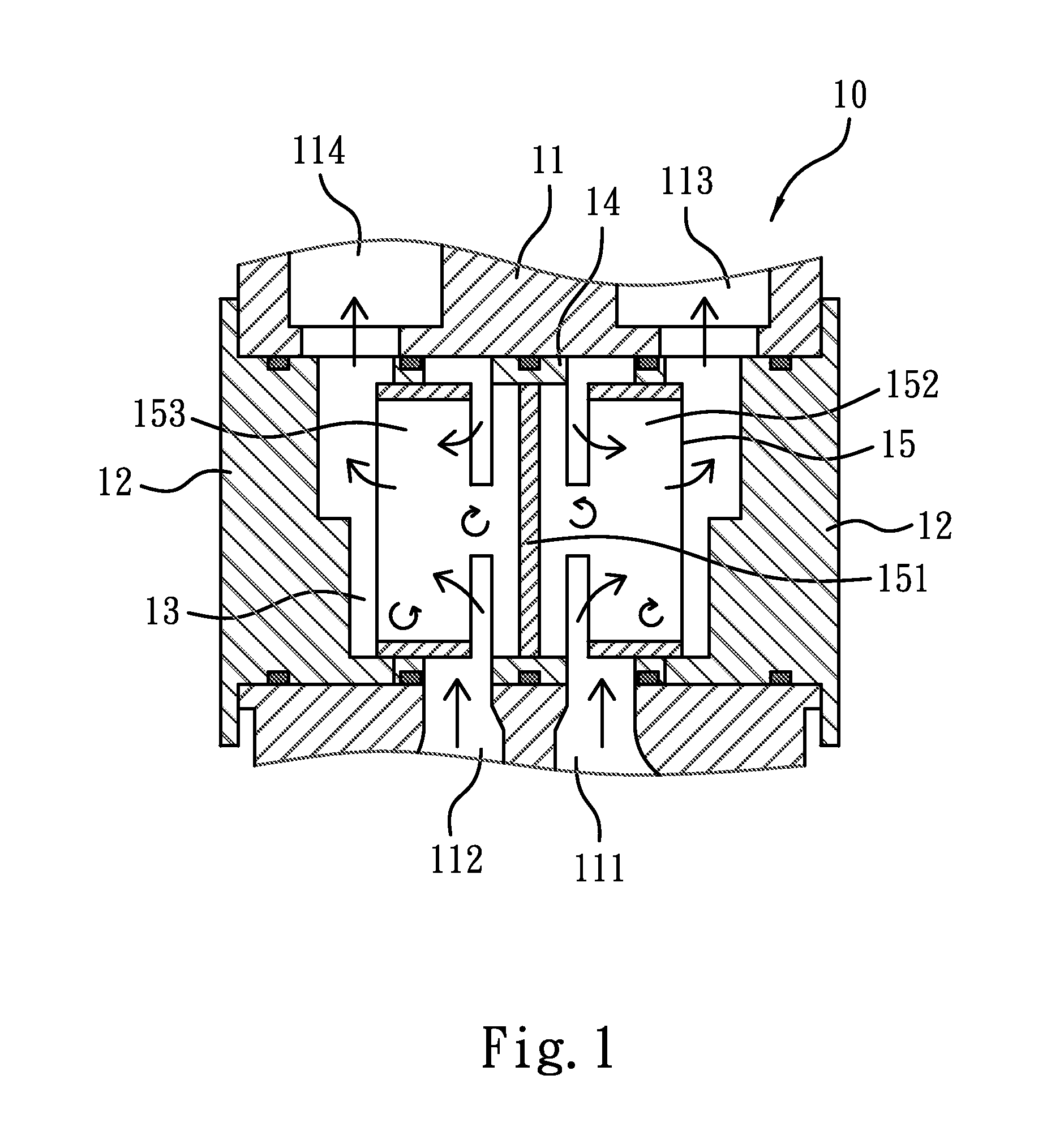

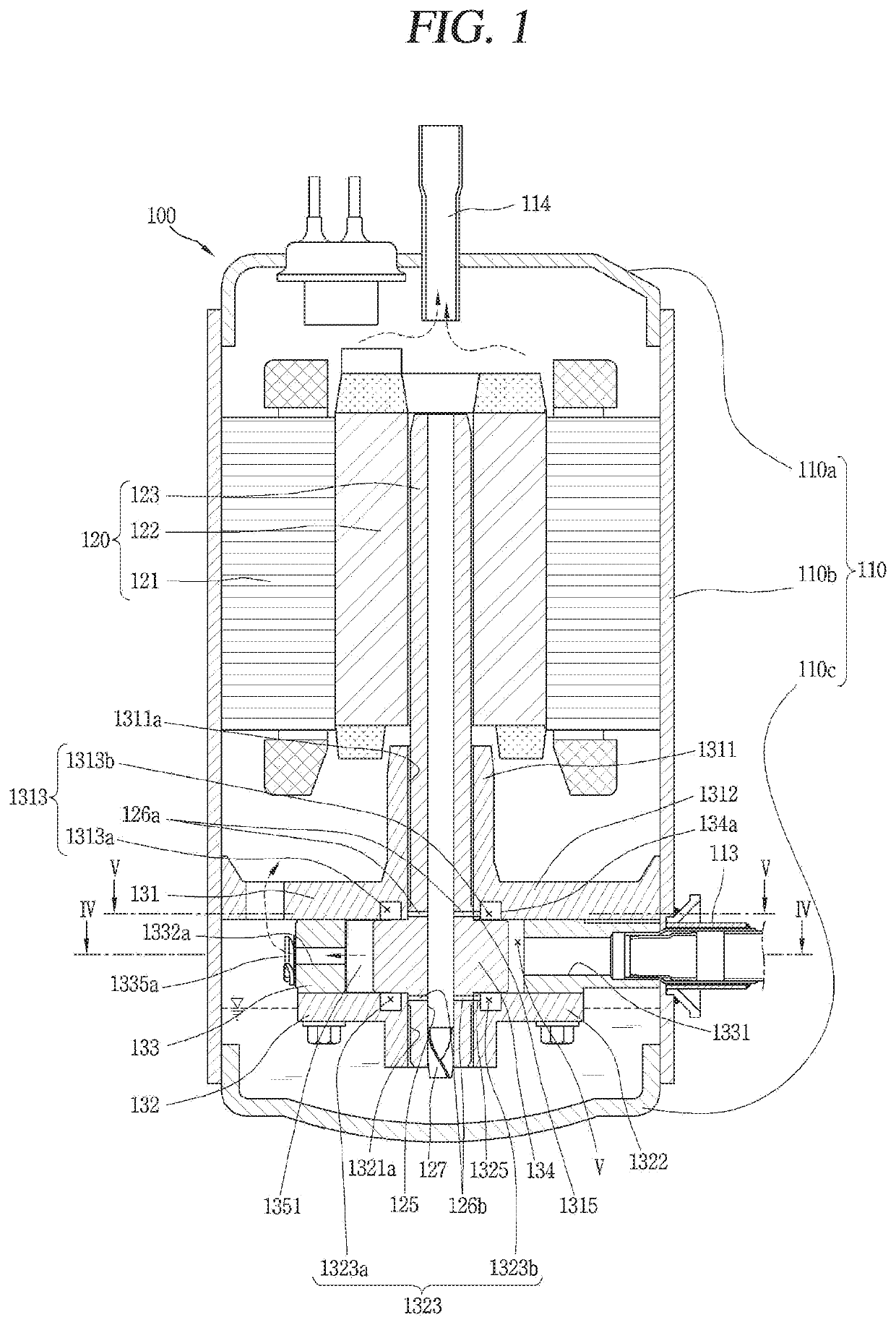

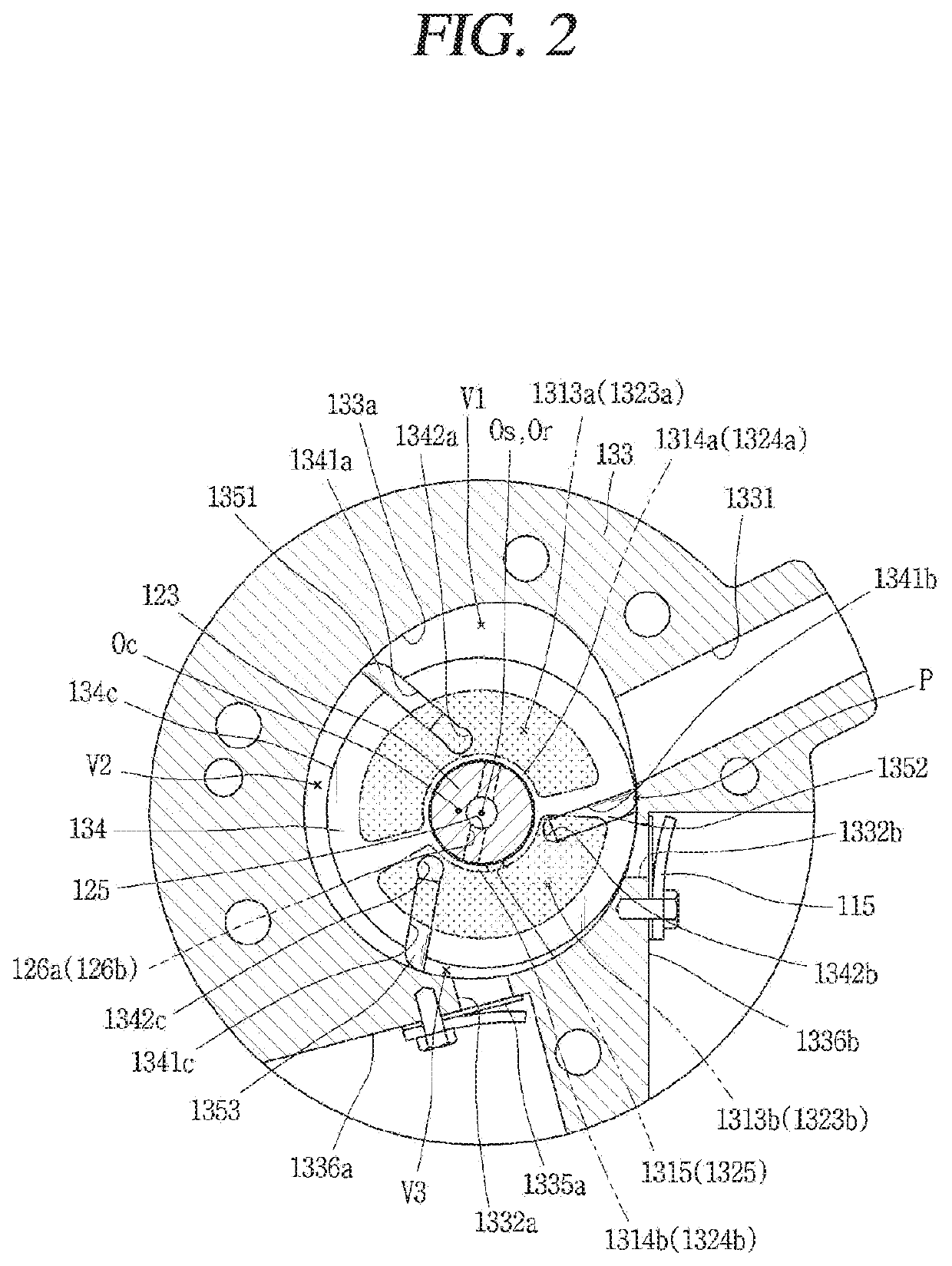

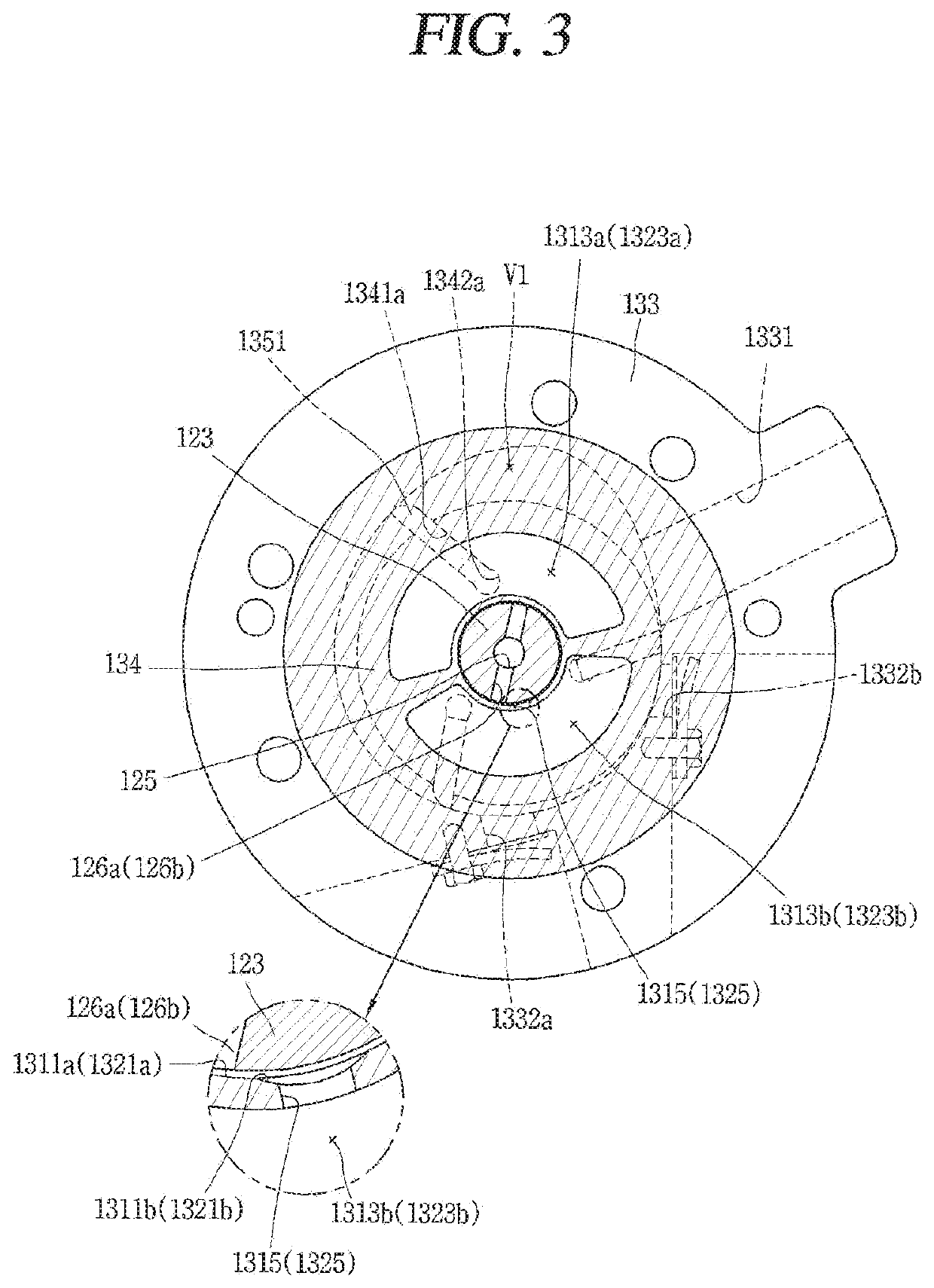

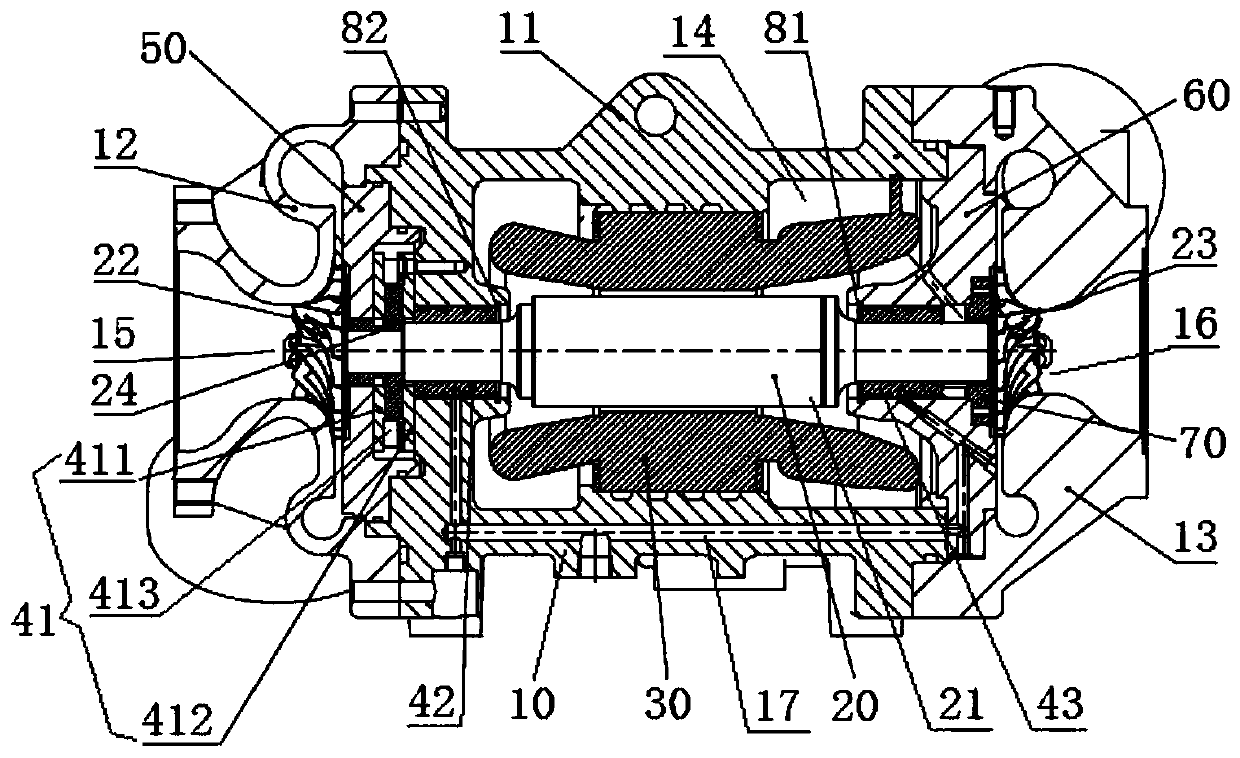

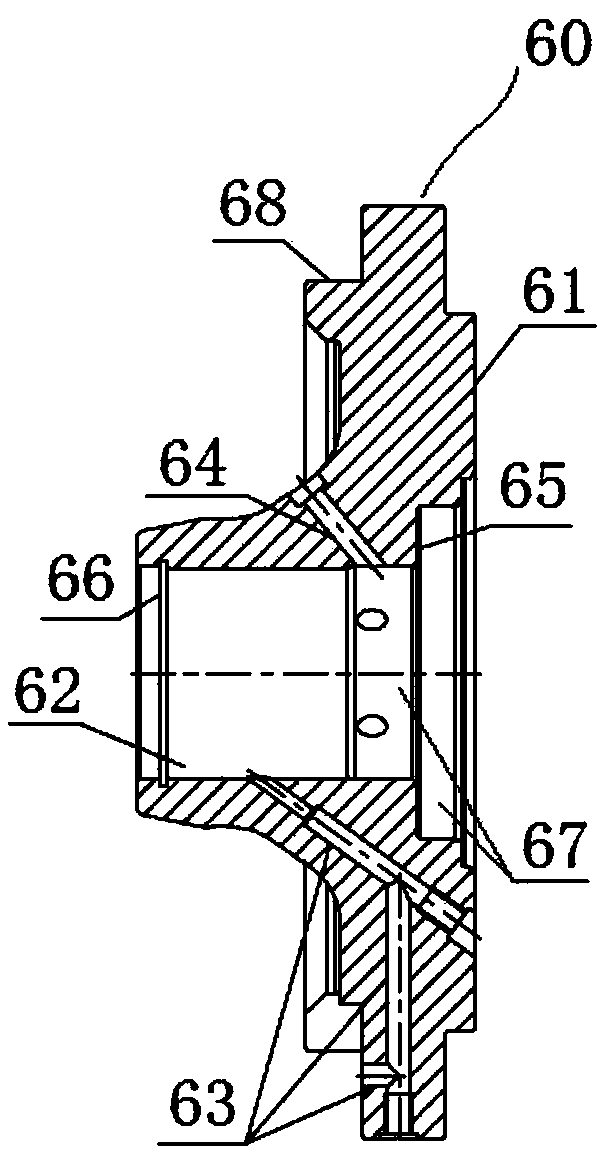

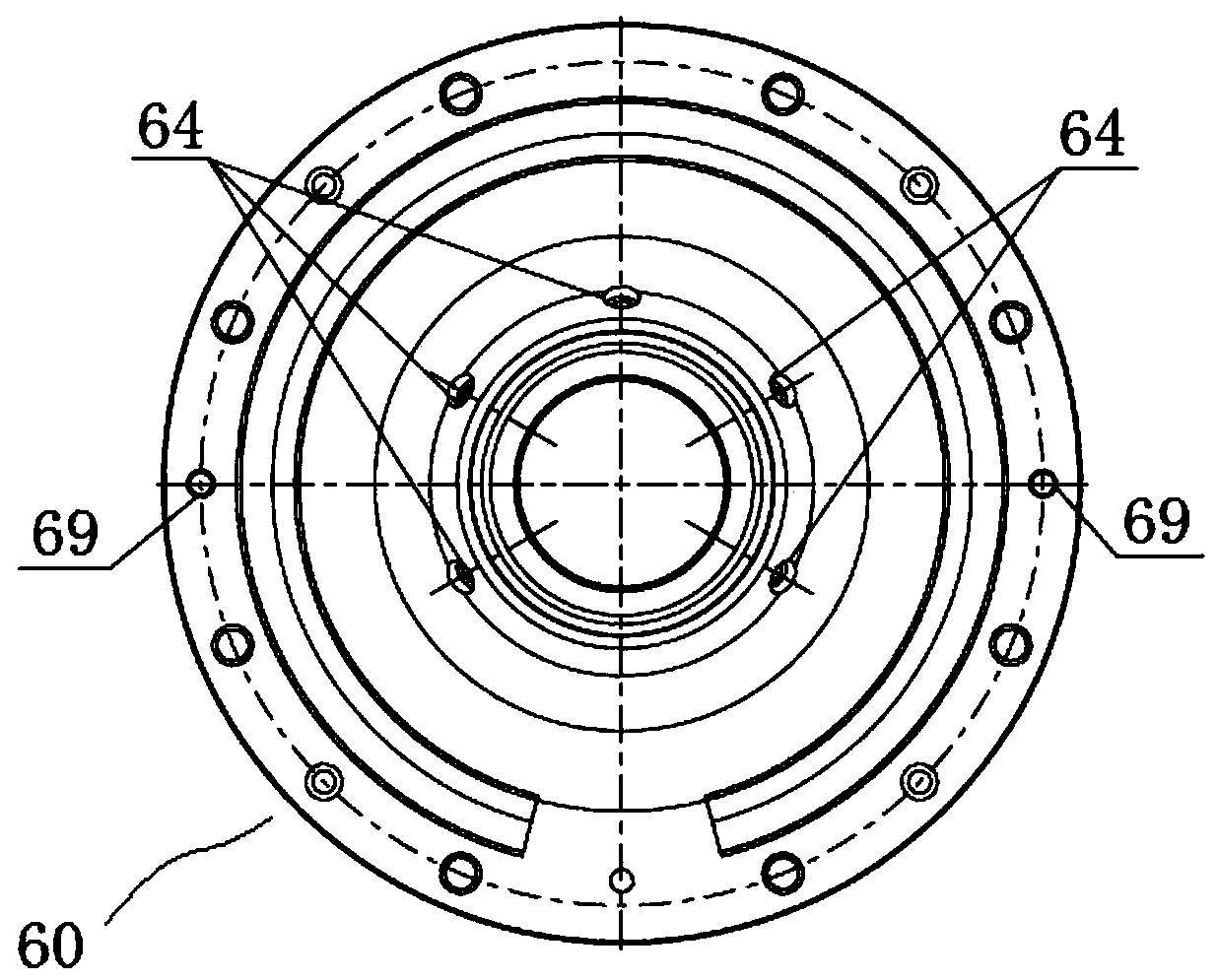

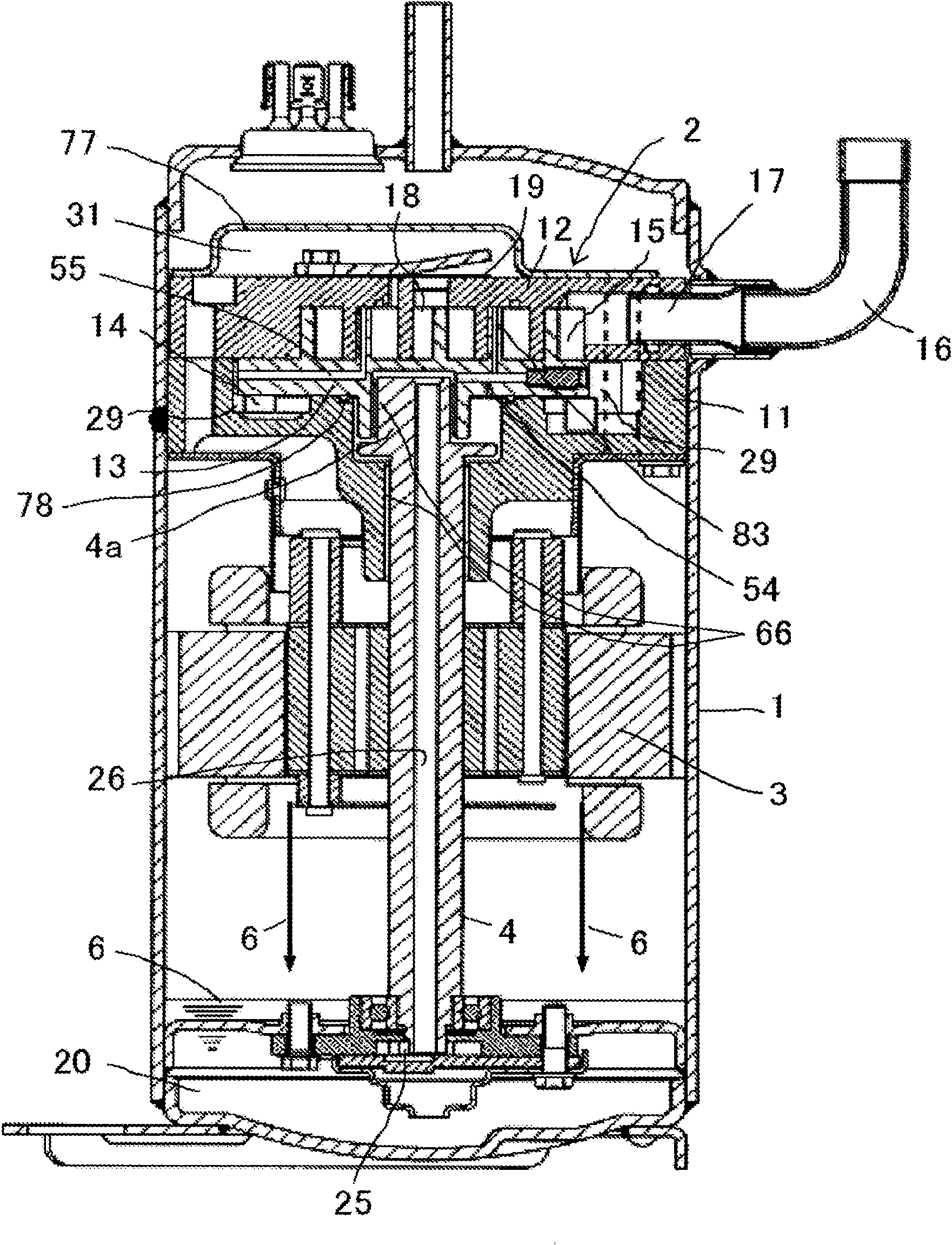

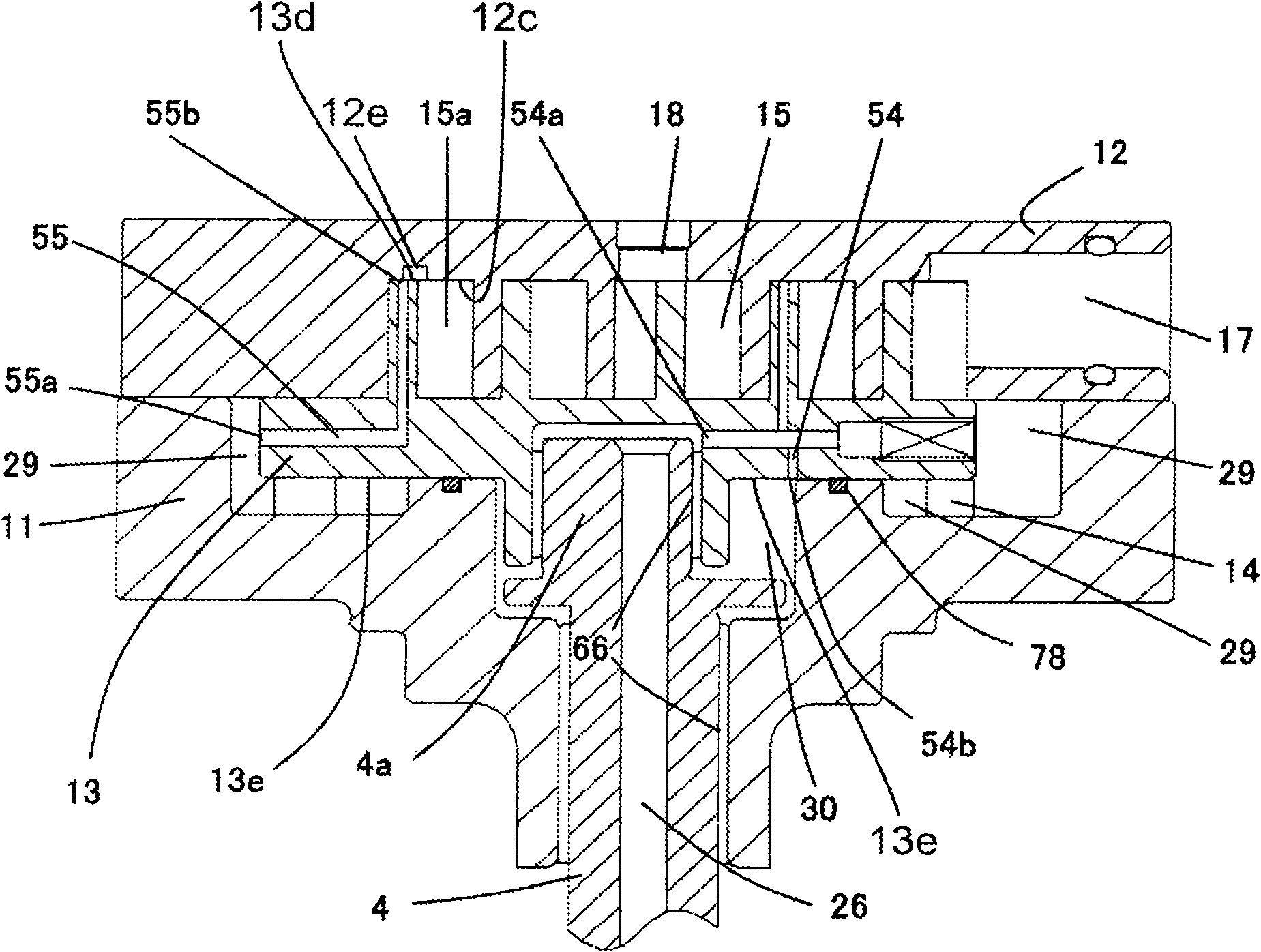

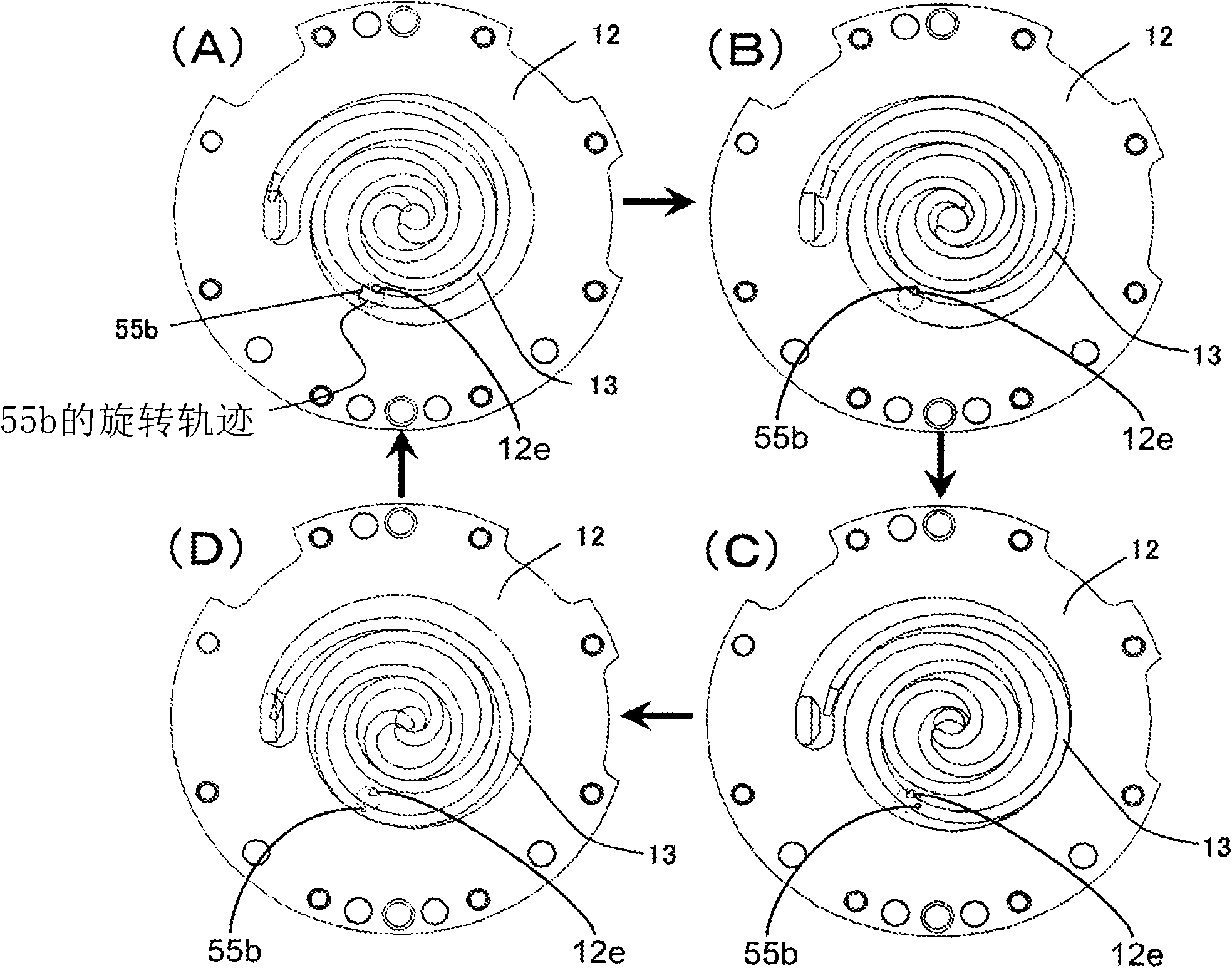

Scroll compressor

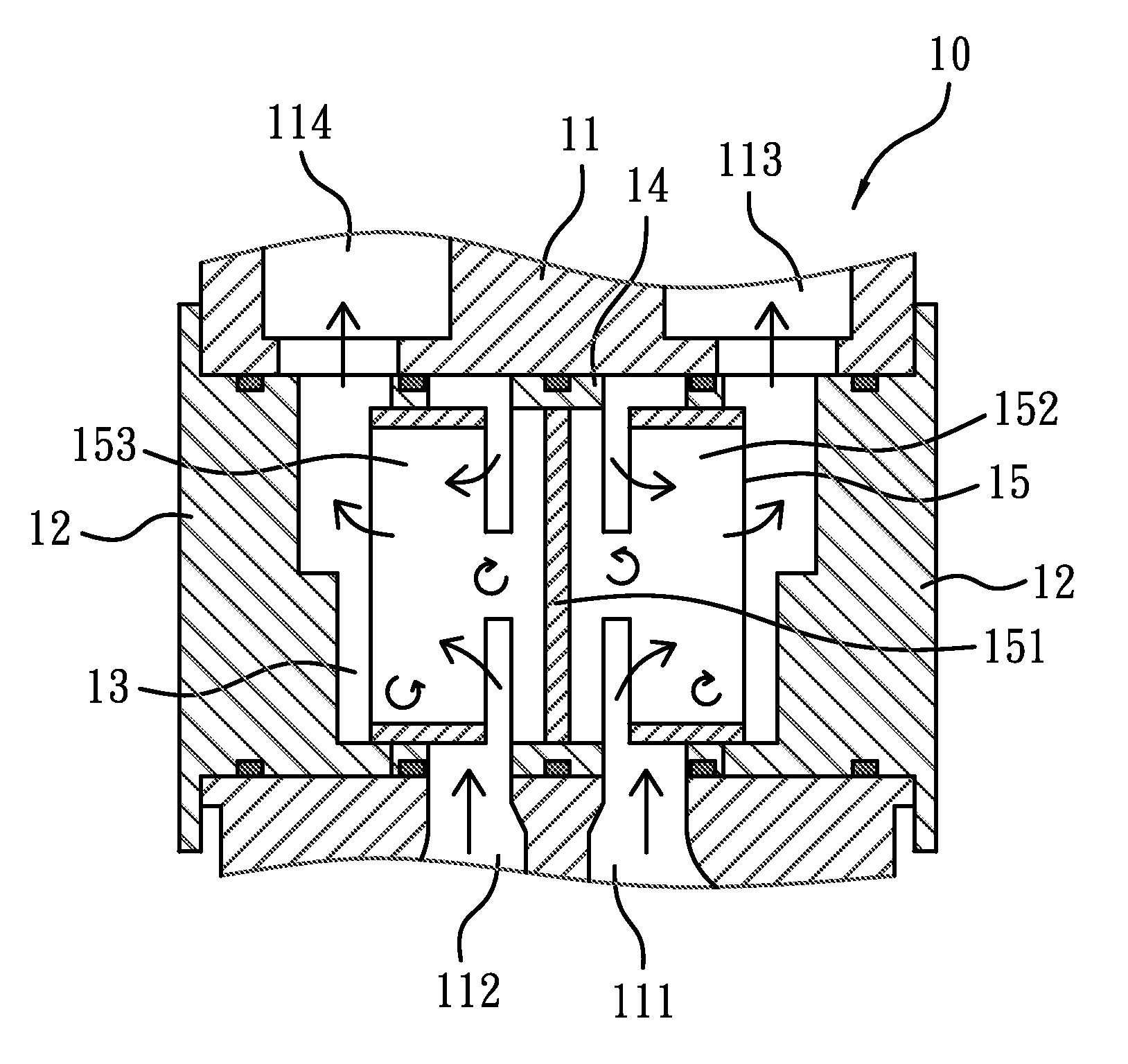

ActiveCN102016319AAvoid back pressureStable back pressureRotary piston pumpsRotary piston liquid enginesBack pressureEngineering

A scroll compressor in which timing of communication between a high-pressure region and a back pressure chamber and timing of communication between the back pressure chamber and a compression chamber are controlled to prevent excessive back pressure, allowing application of stable back pressure. As a result, the scroll compressor has high efficiency and high reliability. The scroll compressor has a first route (54) for intermittently interconnecting a high-pressure region (30) and a back pressure chamber (29), and also has a second route (55) for intermittently interconnecting the back pressure chamber (29) and a compression chamber (15).

Owner:PANASONIC CORP

A sliding vane compressor

ActiveCN105402125BStable back pressureReduce the cross-sectional areaRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsOil tank

The invention aims at providing a slide vane compressor. The problem that backpressure oil supplying of an existing slide vane compressor is not stable is mainly solved. According to the technical scheme, negative pressure is generated in a main oil way in a spindle through a fan, and then an upper oil tube assembly is used for pumping oil from an oil pool; a backpressure oil tank is communicated with the main oil way, and the main oil way supplies pressure oil to the backpressure oil tank. Through the arrangement, oil supplying of the backpressure oil tank is more stable and reliable.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

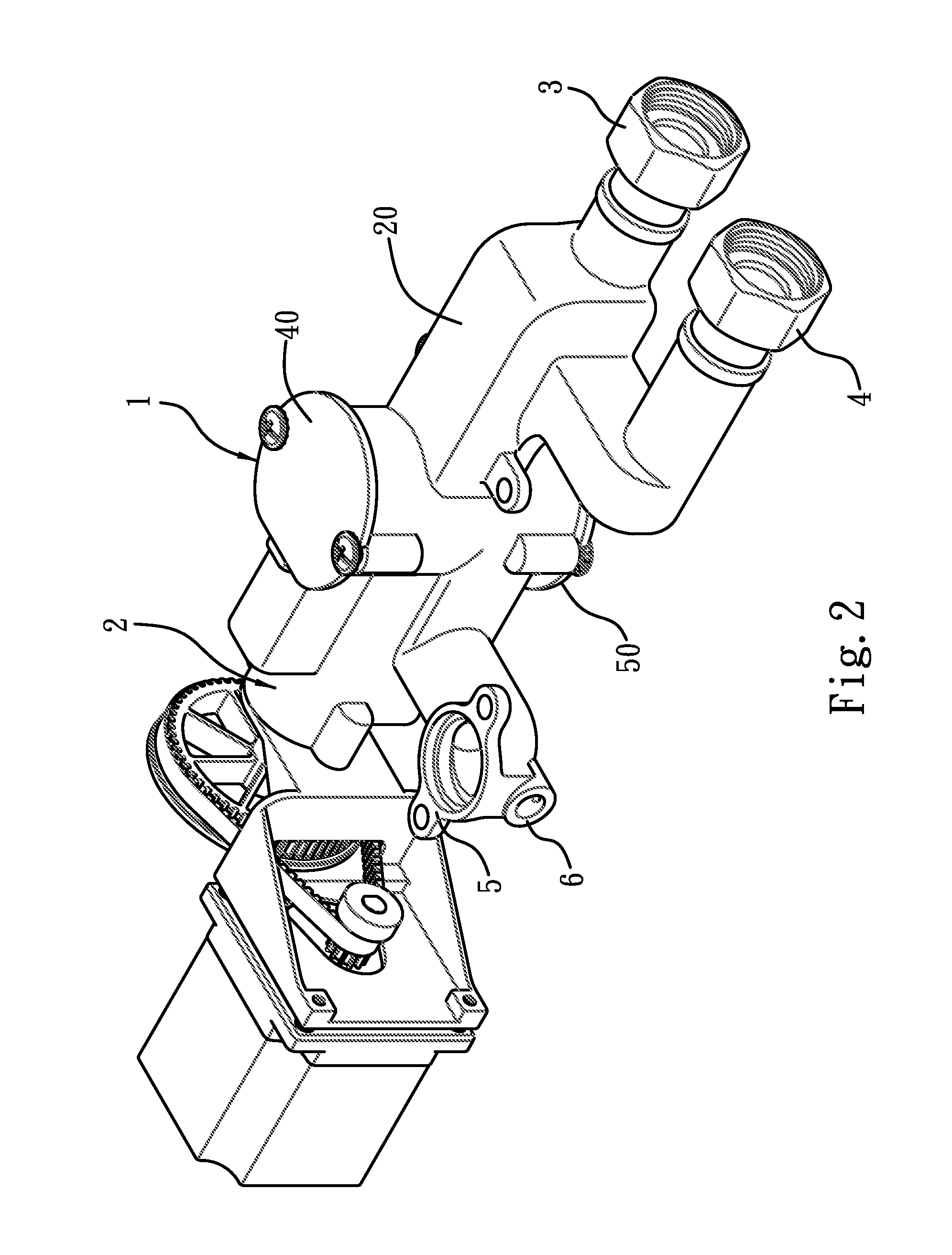

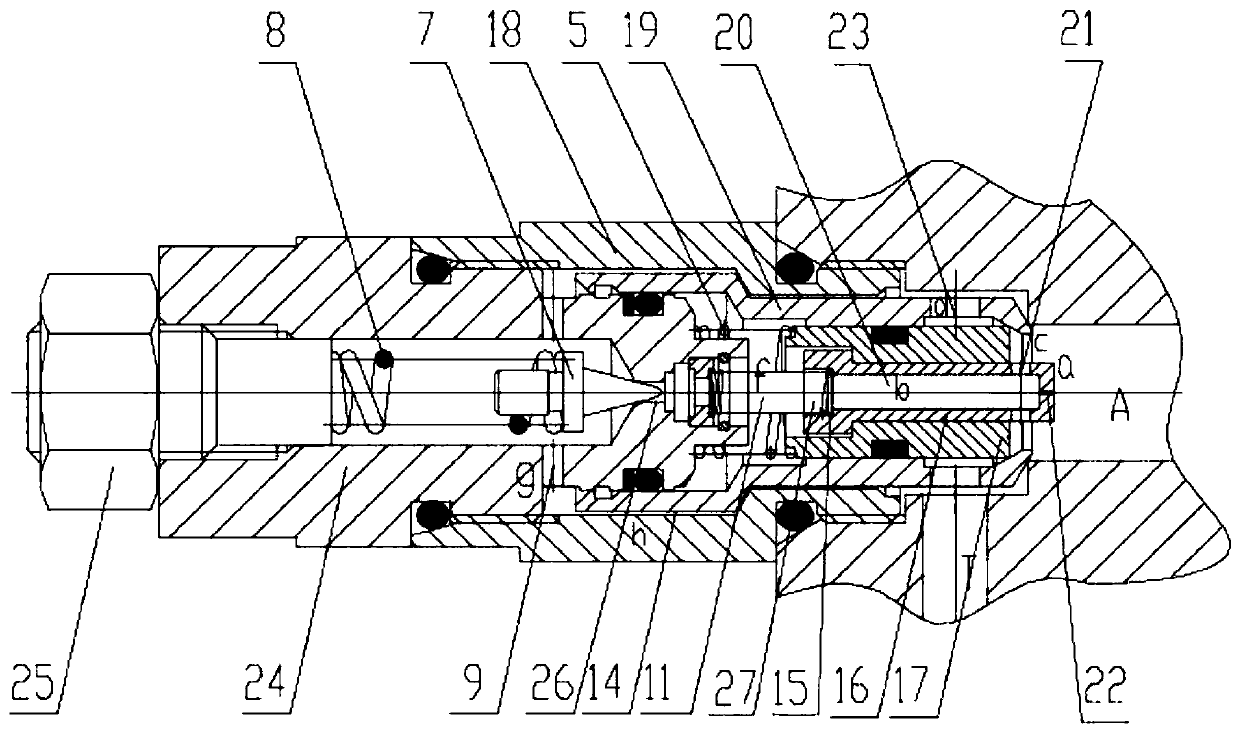

Pressure balance valve

InactiveUS8408231B2Speed up the flowAdd temperature control functionTemperatue controlMultiple way valvesTemperature controlEngineering

A temperature controlling valve contains a body including a cylindrical chamber, a first opening, a second opening, a first inflow channel, and a second inflow channel; a sleeve member retained in the chamber and including at least one first orifice and second orifice; a first cover to close the first opening; a second cover applied to close the second opening; a valve core fitted into the sleeve member, wherein the first cover includes a first projected portion with a first guide tunnel; the first guide tunnel includes a first axial flowing section and a first longitudinal flowing section; the first projected portion includes a first circular back pressure fence; the second cover includes a second projected portion with a second guide tunnel; the second guide tunnel includes a second axial flowing section and a second longitudinal flowing section; the second projected portion includes a second circular back pressure fence.

Owner:GLOBE UNION INDAL

Compressed air energy storage system and storage method

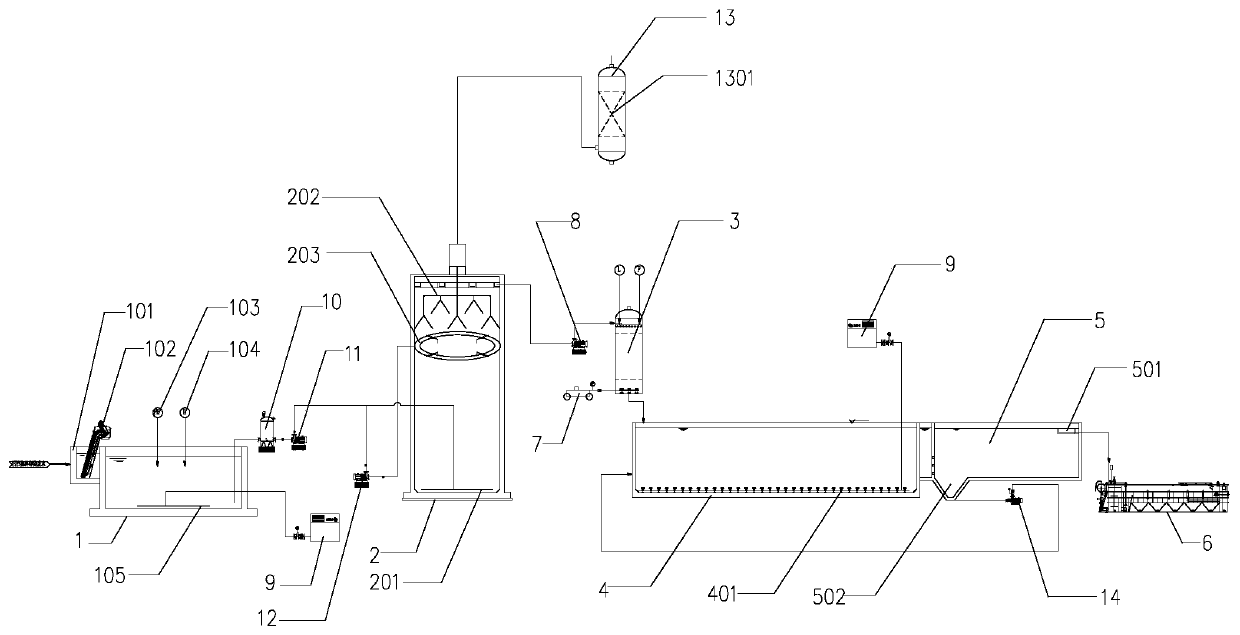

ActiveCN111412126AStable pressureStable back pressurePositive displacement pump componentsSteam engine plantsThermal energy storageHeat balance

The invention relates to the technical field of energy storage, and discloses a compressed air energy storage system and an energy storage method. The compressed air energy storage system comprises anair compressor, a heat exchanger, a gas storage, an air expansion, a heat regenerator and a heat accumulator. An air outlet of the air compressor communicates with a gas-phase space of the gas storage through a first heat exchanging pipeline of the heat exchanger, the gas-phase space is further connected with an inlet of the air expansion through a third heat exchanging pipeline of the heat regenerator, a heat storage medium space of the gas storage is connected with an inlet of the heat accumulator through a second heat exchanging pipeline of the heat exchanger, and an outlet of the heat accumulator is connected to the heat storage medium space through a fourth heat exchanging pipeline of the heat regenerator. According to the energy storage method of the energy storage system, energy-releasing storage is combined with a heat energy storage system, the gas storage, the heat exchanger, the heat accumulator and the heat regenerator are used for forming a heat regenerative cycle, internal heat balance and pressure balance of the compressed air energy storage system can be simultaneously realized, and the conditions of variable backpressure operation of the air compressor becoming and sliding pressure operation of the air expansion are avoided.

Owner:TSINGHUA UNIV

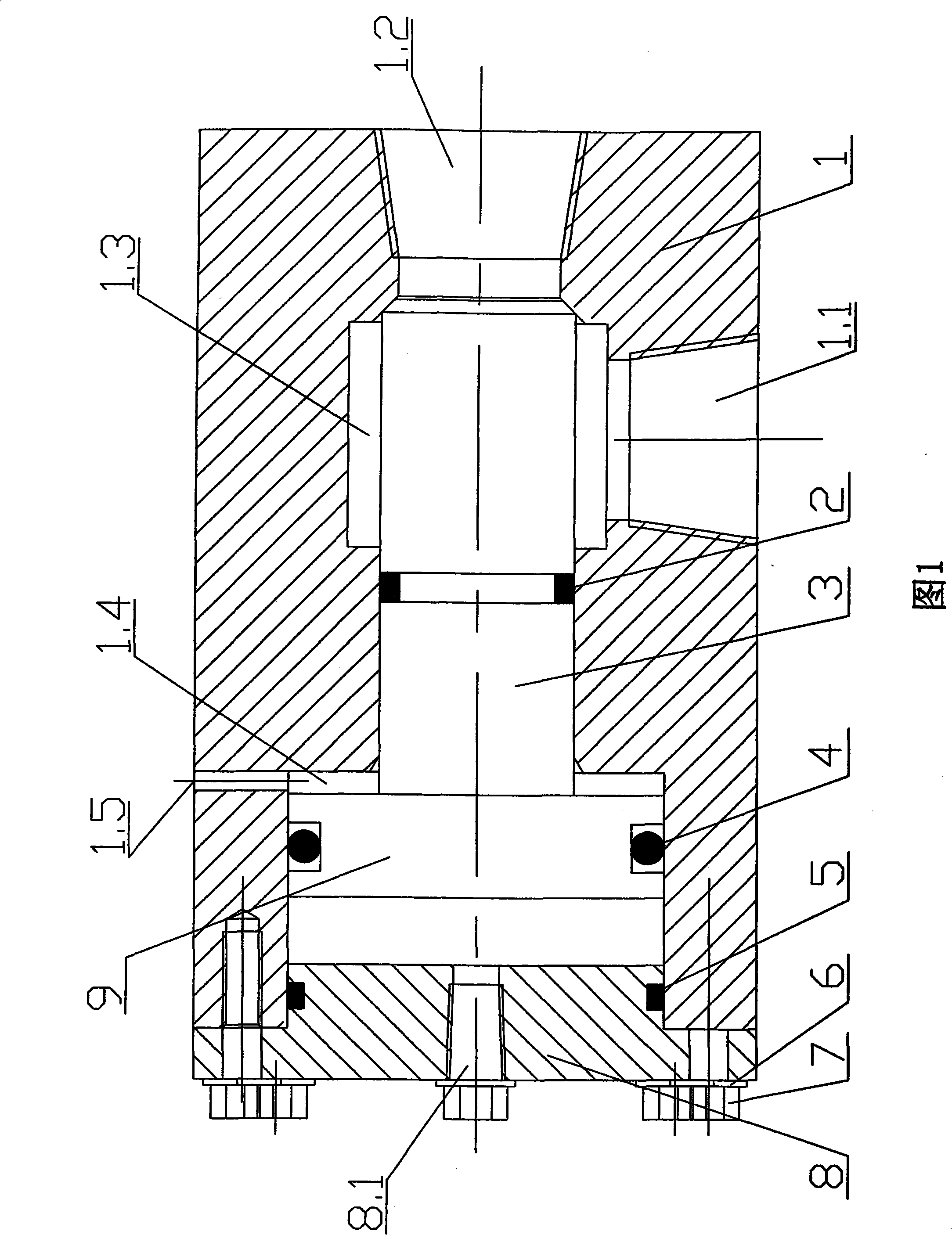

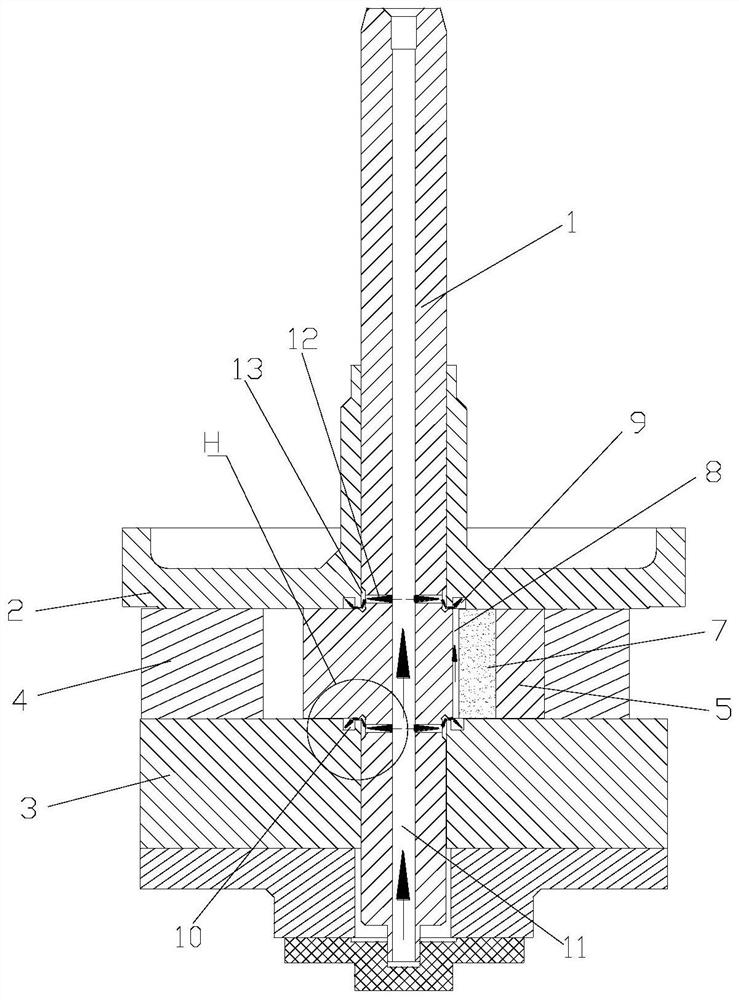

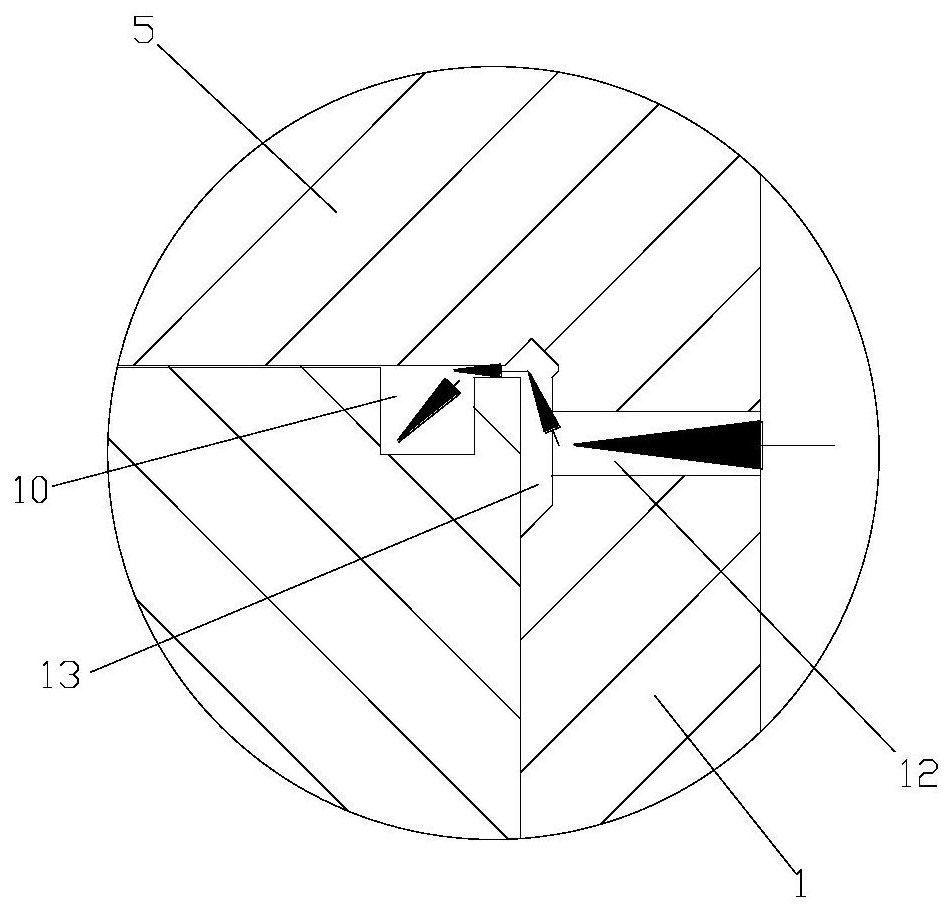

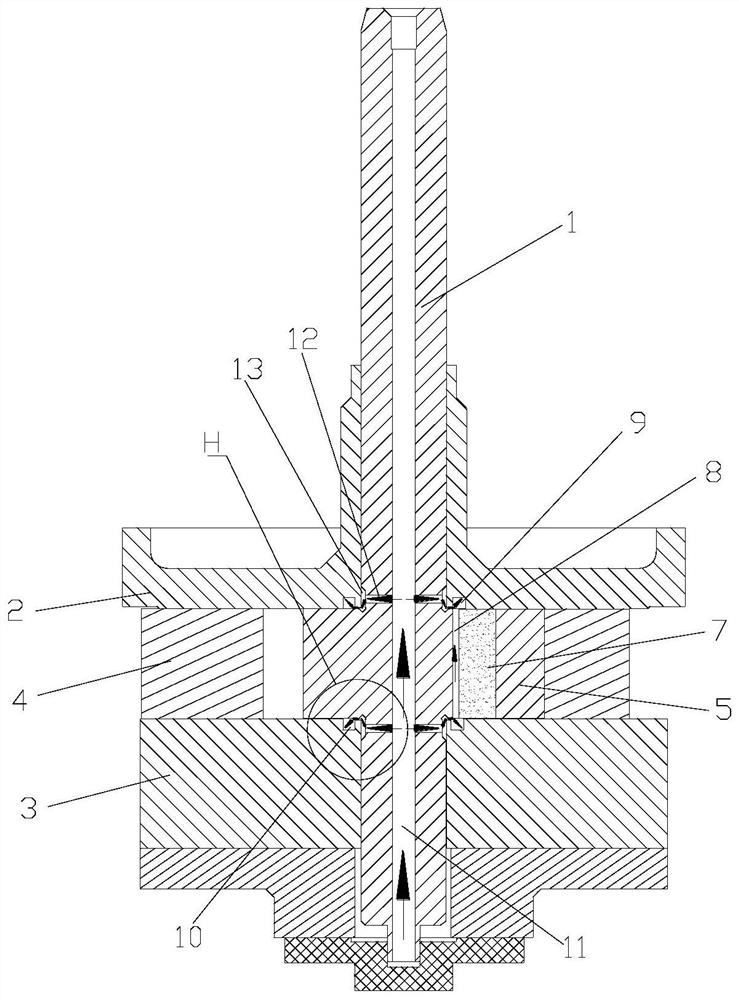

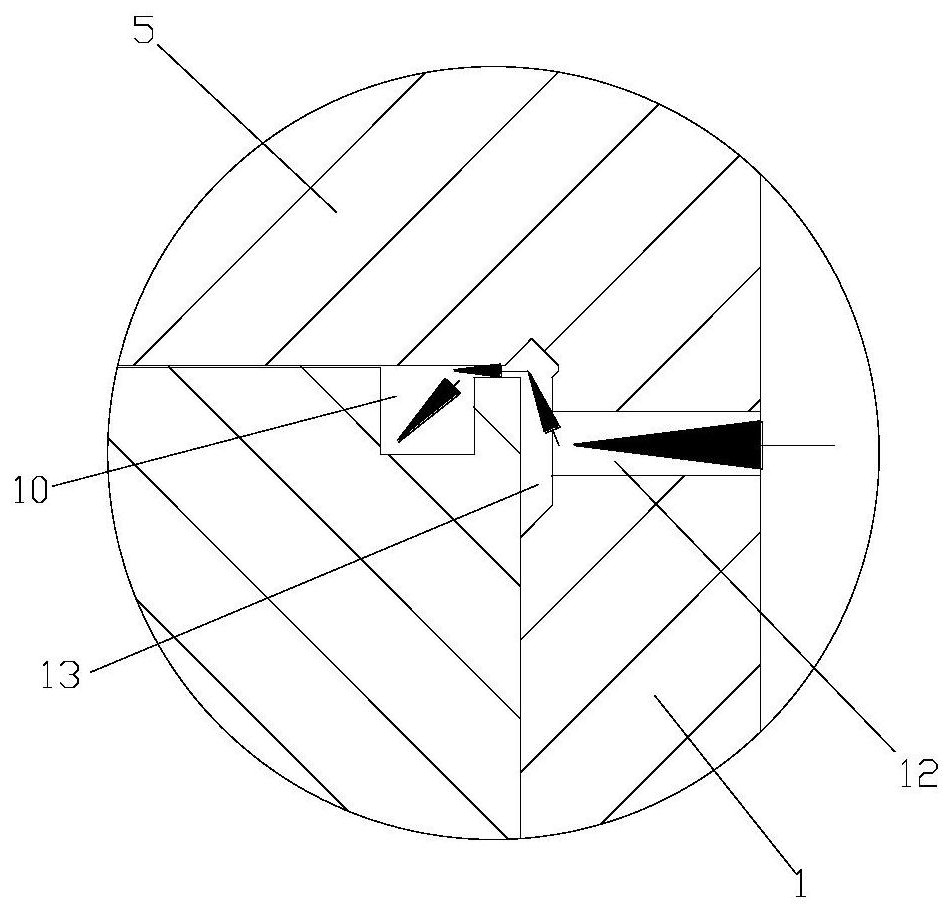

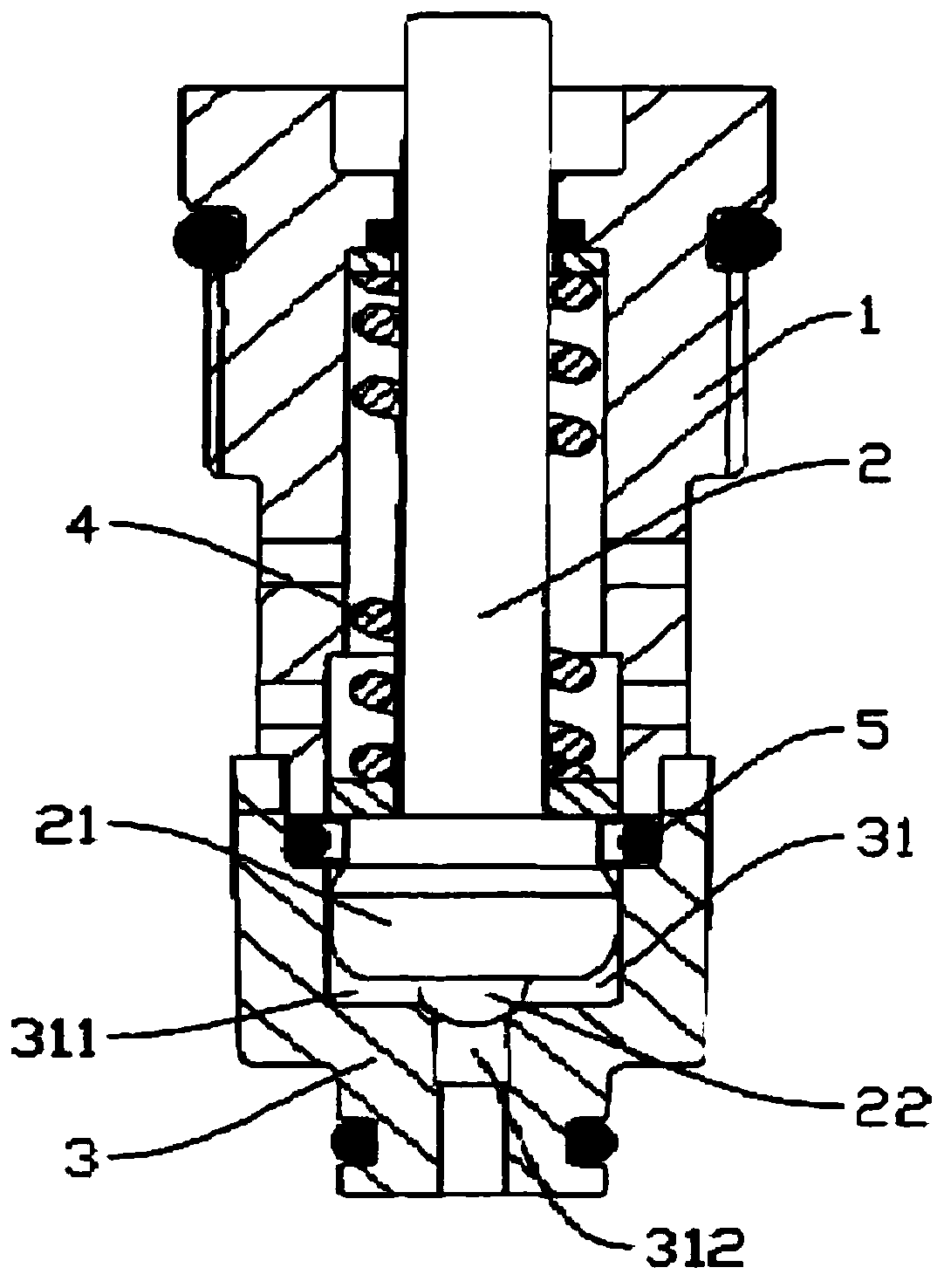

New-type finalized vulcanizer overflow control valve

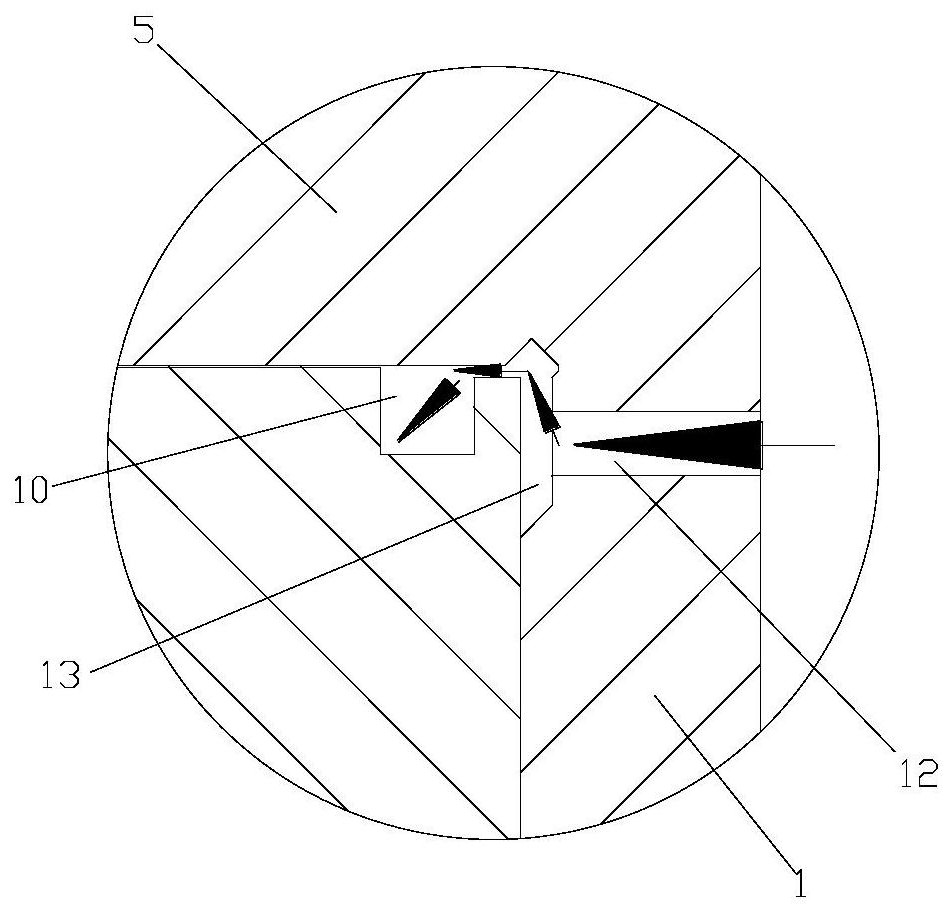

The invention relates to a novel excess flow valve of a tire forming vulcanizer, which is mainly used for controlling water coming in or out a water cylinder of the tire forming vulcanizer. The novel excess flow valve comprises a valve body (1), a piston (9), a cylinder rod (3) and a valve cover (8). The valve body (1) has an integrated structure, a piston hole (1.4) and a cylinder rod hole (1.3) are axially formed on the center of the valve body (1), an O-shaped sealing ring I is embedded between the cylinder rod (3) and the cylinder rod hole (1.3), an O-shaped sealing ring II is arranged between the piston (9) and the piston hole (1.4), one side of the valve body (1) is provided with a water outlet (1.1), one end of the valve body is provided with a water inlet (1.2), the other end of the valve body (1) is provided with the valve cover (8), an air inlet (8.1) is axially arranged on the center of the valve cover (8), the other side of the valve body (1) is provided with an air outlet (1.5), the valve cover (8) and the valve body (1) are fixedly connected, an O-shaped sealing ring III (5) is embedded between the hole walls of the valve cover (8) and the piston hole of the valve body (1) to seal. The novel excess flow valve has the advantages of small volume, light weight, good sealing performance and good closing performance.

Owner:徐慕贤

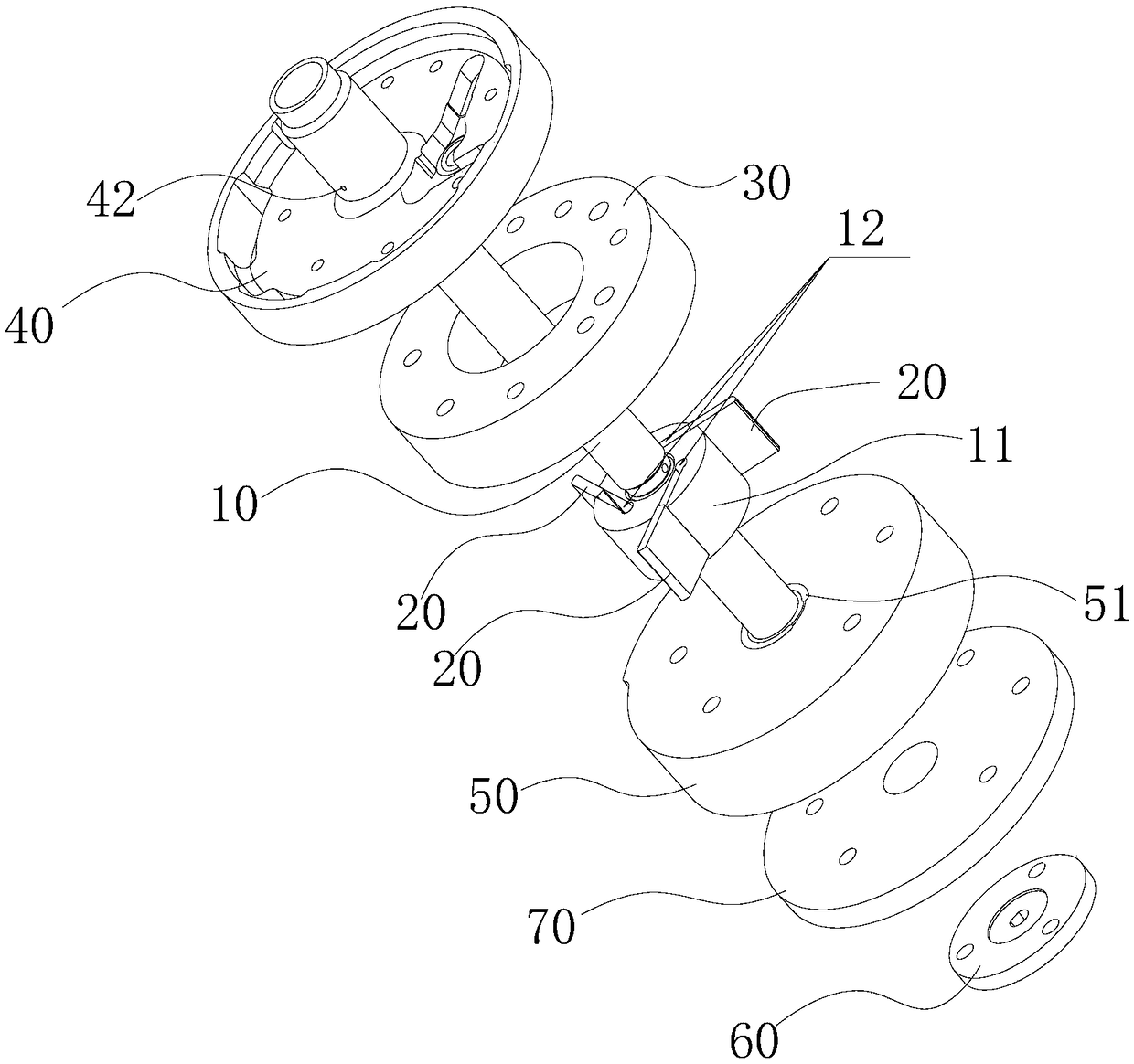

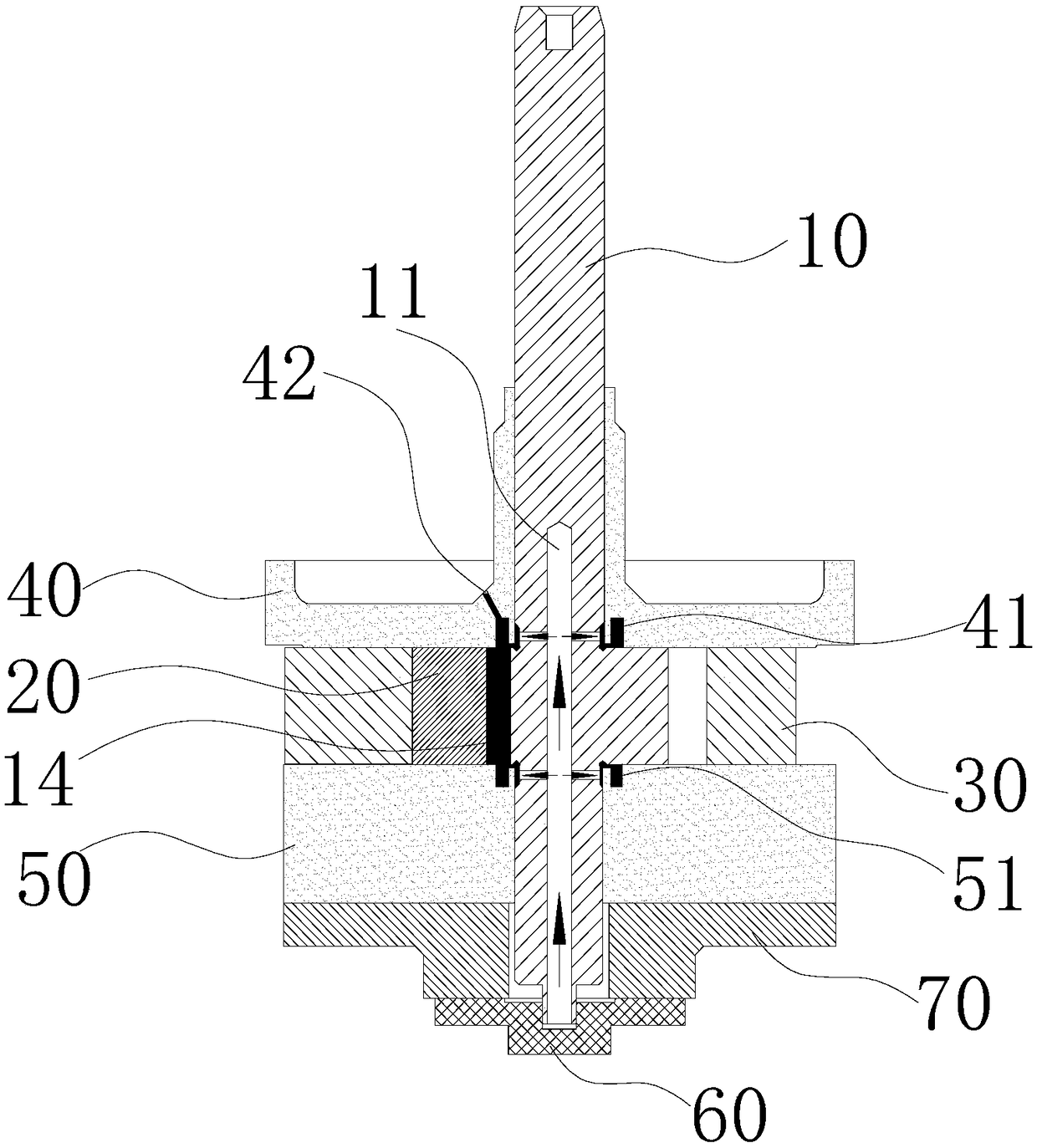

Compressor pump body, compressor and air conditioner

PendingCN108757454AImprove operational reliabilityAvoid situations where the oil level is lower than the upper surface of the slideRotary piston pumpsRotary piston liquid enginesGas compressorFlange

The invention provides a compressor pump body, a compressor and an air conditioner. The compressor pump body comprises a main shaft, an air cylinder, an upper flange and an air pull structure. A center portion is arranged on the main shaft, and sliding piece grooves and a lubricating oil conveying channel are formed in the center portion. The air cylinder sleeves the periphery of the center portion. The upper flange sleeves the main shaft and is located on the upper end face of the air cylinder, a first back pressure groove which communicates with the sliding piece grooves is formed in the upper flange, and the conveying channel communicates with the first back pressure groove. The air pull structure is arranged on the upper flange to exhaust the gas in the first back pressure groove to the exterior of the compressor pump body. By the adoption of the compressor pump body, the situation that the oil level of lubricating oil is lower than the upper surfaces of sliding pieces can be avoided, the states that the back pressure of each sliding piece is stable, and the fluctuation is low can be guaranteed, and the operating reliability of the compressor pump body and the compressor with the compressor pump body can be improved.

Owner:GREE ELECTRIC APPLIANCES INC

Steam turbine condenser and operating method thereof

InactiveCN109139148AAchieve recyclingSimple organizationFeed water supplySteam useEngineeringBevel gear

The invention discloses a steam turbine condenser and an operating method thereof. The steam turbine condenser comprises a condensation box and a gear mechanism arranged in the condensation box. A first rotating cavity with an opening being rightward is arranged at the middle bottom of a second bevel gear of the condensation box. A second rotating cavity located on the upper side of the first rotating cavity is arranged in the condensation box. A third rotating cavity located on the upper side of the second rotating cavity is arranged in the condensation box. Fourth rotating cavities located on the upper side of the third rotating cavity are arranged in the condensation box in bilateral symmetry. Fifth rotating cavities located on the inner sides of the fourth rotating cavities are arranged in the condensation box in bilateral symmetry. A sixth rotating cavity located on the upper sides of the fourth rotating cavities is arranged in the condensation box. A first liquid storage cavity located on the lower side of the sixth rotating cavity is arranged in the condensation box. A condensation cavity located on the lower side of the first liquid storage cavity is arranged in the condensation box. A second liquid storage cavity located on the right side of the first rotating cavity is arranged in the condensation box.

Owner:钟莹莹

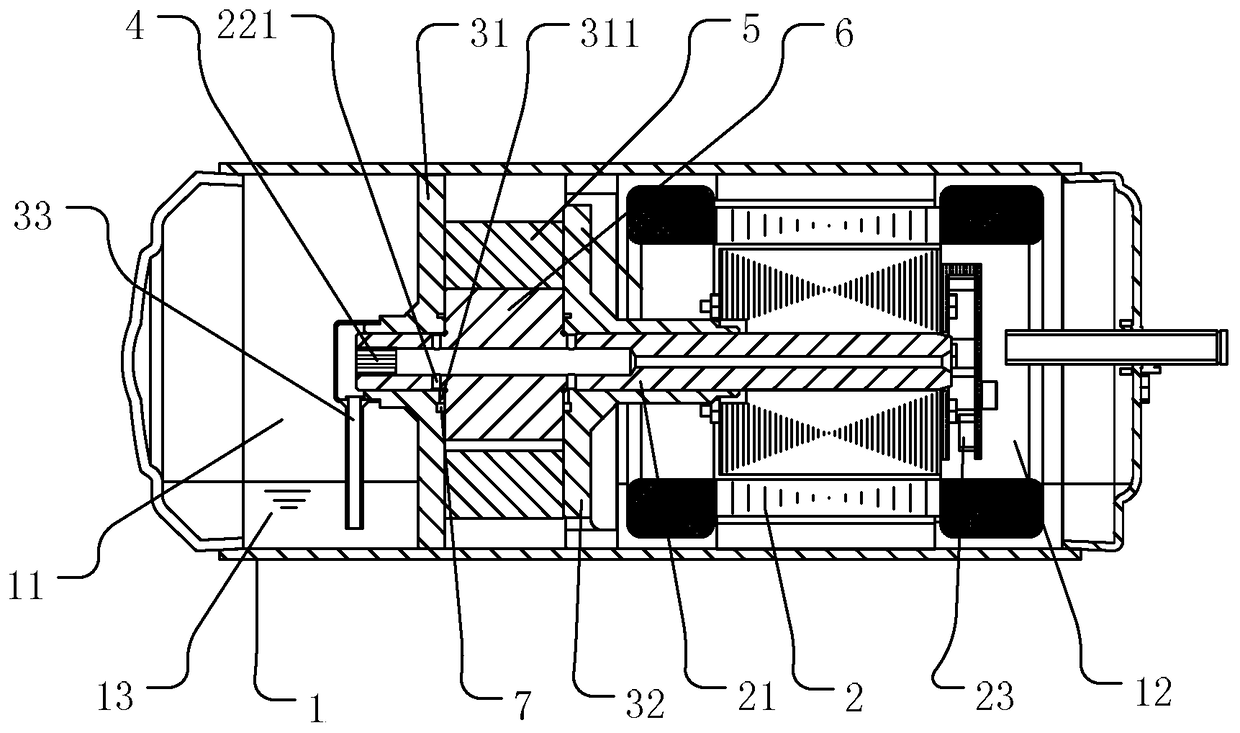

Pump body unit, compressor and air conditioning device

PendingCN109737065AStable back pressureLighting and heating apparatusRotary piston pumpsLubricationEngineering

The invention provides a pump body unit, a compressor and an air conditioning device. The pump body unit comprises a first structural body, a rolling bearing assembly, a second structural body, a third structural body and a main shaft. The main shaft penetrates through the first structural body, the rolling bearing assembly, the second structural body and the third structural body. The pump body unit comprises multiple lubricating oil lines. The multiple lubricating oil lines at least include the first lubricating oil line, the second lubricating oil line and the third lubricating oil line. The first lubricating oil line penetrates through the second structural body, a sliding sheet backpressure chamber of a rotor structure of the main shaft, a third structural body, the second structuralbody and a rolling body of the rolling bearing assembly. The second lubricating oil line penetrates through the sliding sheet backpressure chamber of the rotor structure of the main shaft, and a firstdecompression groove of the first structural body. The third lubricating oil line penetrates through the sliding sheet backpressure chamber of the rotor structure of the main shaft, the first structural body, and the rolling body of the rolling bearing assembly. With the pump body unit, the compressor and the air conditioning device, the problem that lubricating oil lines in a pump body unit in the prior art cannot meet the requirements of a pump body for lubrication is effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

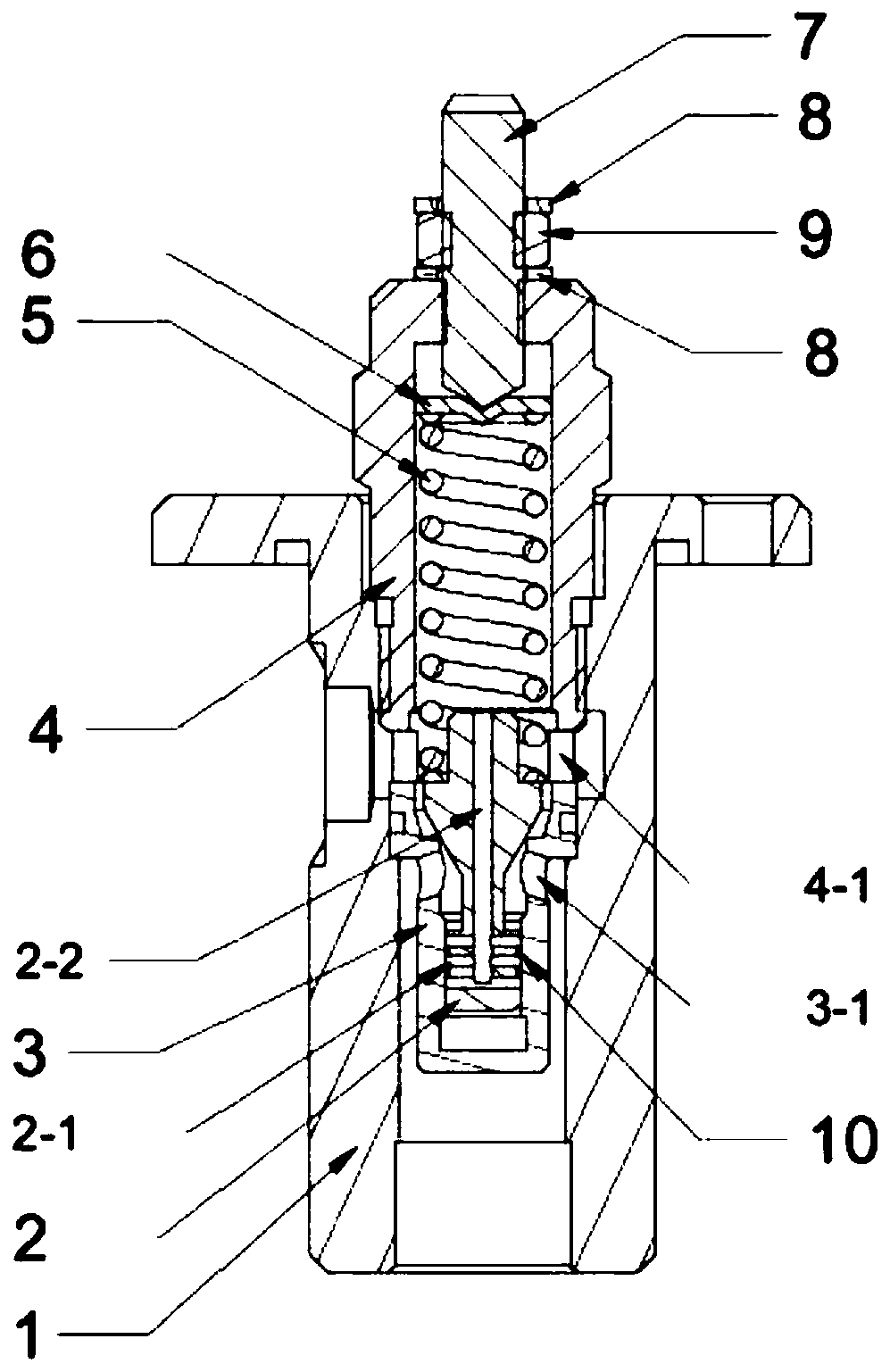

Fixed pressure by-pass valve device for air quantity control system

InactiveCN101235920AStable pressureStable back pressureEqualizing valvesSafety valvesVariable air volumeAir volume

The invention relates to a constant pressure by-pass valve device for wind control. A wind inlet cavity and a wind outlet cavity are arranged in the device, a valve core is glidingly disposed in the device which is equipped with a valve seat, and the wind inlet cavity and the wind outlet cavity are respectively positioned on bilateral sides of the valve seat. When closed, the valve core seals the valve seat, and when opened, the valve core disengages from the valve seat, and the wind inlet cavity and the wind outlet cavity are communicated. Additionally a regulating mechanism is disposed in the device, which is used for adjusting the compressing force that the valve core pushes against the valve seat, when pressure in pipe is larger than the pre-compression force that the valve core pushes against the valve seat, the valve core disengages from the valve seat, and the device can automatically discharge excess wind by-passing in the system from a return air pipe or an air discharging pipe. The constant pressure by-pass valve device can stabilize constant pressure by-pass valve device, avoid generation and enlargement of 'breathe type' pressure oscillation, simultaneously the device provides a stable back pressure for a constant air volume valve and a variable air volume valve at the end, and increases the actual usage accuracy.

Owner:JIANGSU SUZHOU PURIFICATION TECH

Pressure balance valve

InactiveUS20120167999A1Speed up the flowAdd temperature control functionTemperatue controlMultiple way valvesTemperature controlEngineering

A temperature controlling valve contains a body including a cylindrical chamber, a first opening, a second opening, a first inflow channel, and a second inflow channel; a sleeve member retained in the chamber and including at least one first orifice and second orifice; a first cover to close the first opening; a second cover applied to close the second opening; a valve core fitted into the sleeve member, wherein the first cover includes a first projected portion with a first guide tunnel; the first guide tunnel includes a first axial flowing section and a first longitudinal flowing section; the first projected portion includes a first circular back pressure fence; the second cover includes a second projected portion with a second guide tunnel; the second guide tunnel includes a second axial flowing section and a second longitudinal flowing section; the second projected portion includes a second circular back pressure fence.

Owner:GLOBE UNION INDAL

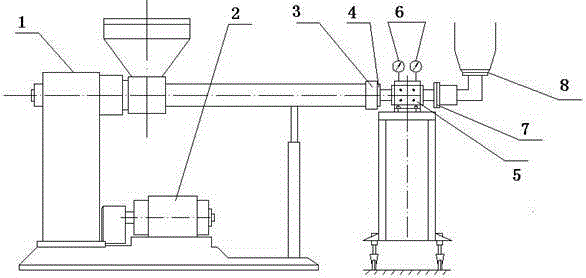

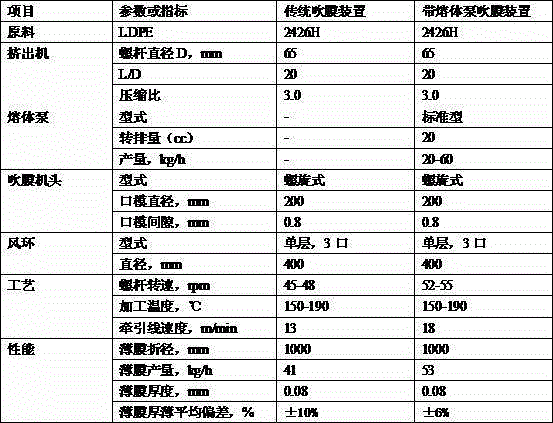

Blown film device with melt pump

The invention discloses a blown film device with a melt pump. The device comprises an extruder, a motor, a splitter plate, an extruder connecting body, a melt pump assembly, a pressure sensor, a machine head connecting body and a film blowing machine head, wherein the melt pump assembly serves as the core of the blown film device provided by the invention, the blown film device comprises a support, a gear pump, a mounting plate, a universal coupling, a speed reducer and a motor. The melt pump assembly is connected with the extruder through the extruder connecting body, and is connected with the film blowing machine head through the machine head connecting body, the pressure sensor is mounted at the top of the melt pump assembly, the splitter plate is mounted at the outlet of the extruder and connected with the extruder connecting body, the motor is connected with the extruder, and power is provided for the entire device. The device can stable a plasticizing process, lower the melting temperature, improve product yield and quality, and further prolong the service life of the extruder.

Owner:YIXING GUANGHUI PACKAGE +1

Two-way energy storage and coal consumption reduction system for thermal power generating unit

ActiveCN106224020ARelieve pressureIncrease vacuumMachines/enginesEngine componentsThermal energy storageEngineering

The invention relates to a two-way energy storage and coal consumption reduction system for a thermal power generating unit. The two-way energy storage and coal consumption reduction system comprises a jet condenser. The top end of the jet condenser communicates with an exhaust pipeline. The bottom of the jet condenser communicates with a condensed water tank and a heat storage tank. The heat storage tank communicates with a regenerative system of a steam turbine. The bottom of the condensed water tank communicates with a cold storage tank. The cold storage tank is connected with multiple nozzles arranged in the jet condenser through a pipeline sequentially provided with a circulating cooling water pump, a third regulating valve and a sixth regulating valve. The cold storage tank communicates with a cooling and mixing device communicating with the exhaust pipeline through another pipeline sequentially provided with the circulating cooling water pump, a third regulating valve and a seventh regulating valve. The two-way energy storage and coal consumption reduction system has the beneficial effects that the design is reasonable, the pressure in the air-cooling condenser is lowered effectively, the vacuum of the unit in the operating process is improved, the operating economy of the unit is improved, the operating safety and reliability of a steam turbine unit are improved, the fatigue loss of a steam turbine rotor is reduced, the service life of the rotor is prolonged, and on the premise of meeting the safe operation of the unit, energy saving and emission reduction are truly achieved.

Owner:BEIJING NORTH SANHE ENERGY TECH

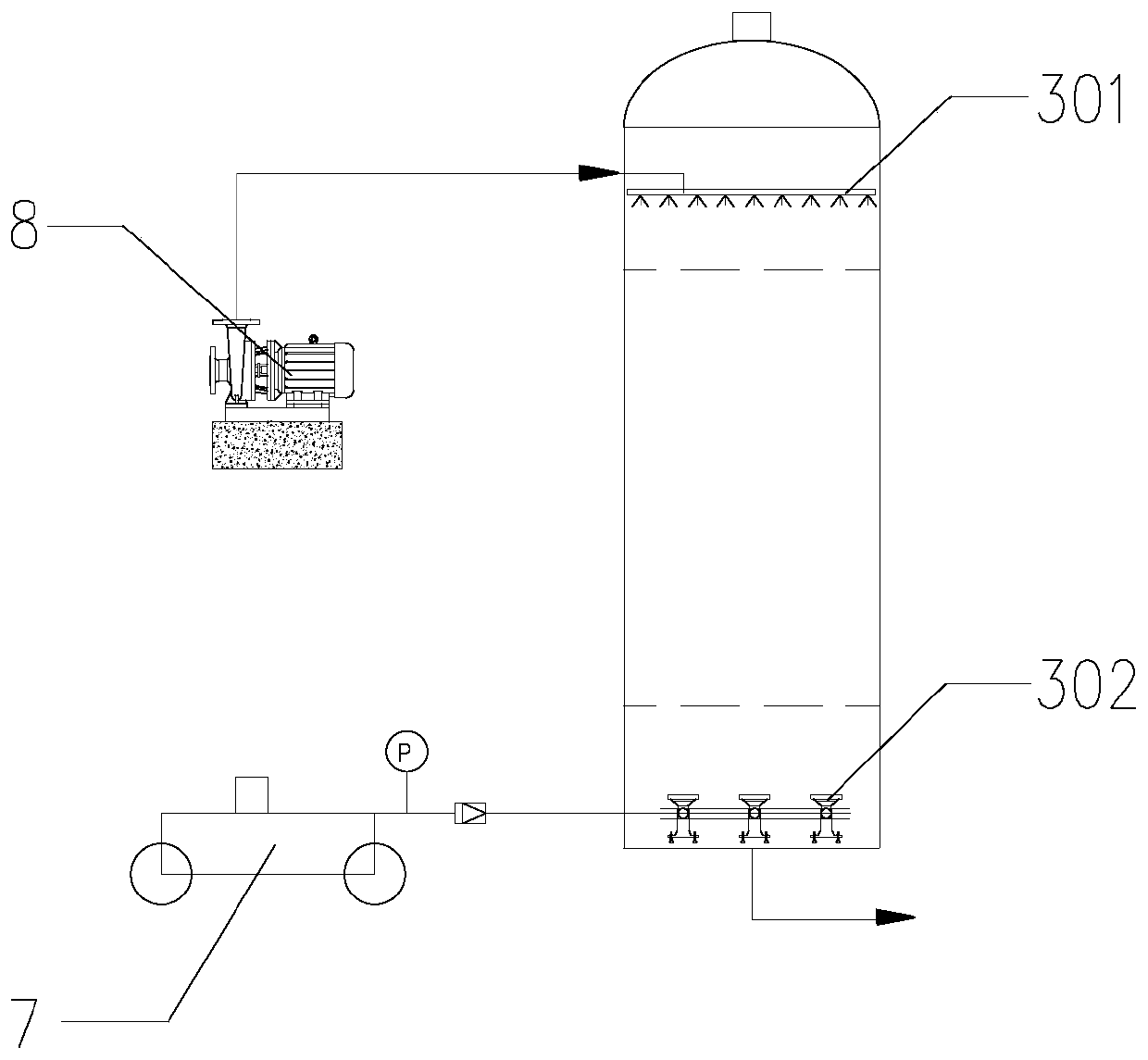

Reactive dye printing and dyeing wastewater treatment system

PendingCN111233251ANothing producedImprove efficiencyWater contaminantsTreatment involving filtrationTreatment pondProcess engineering

The invention relates to the technical field of sewage treatment. The invention discloses a reactive dye printing and dyeing wastewater treatment system. The system comprises a wastewater regulating tank, an anaerobic reactor, a high-pressure air desulfurization device, an aerobic biochemical tank, a secondary sedimentation tank and a physicochemical treatment tank which are sequentially connectedthrough pipelines, wherein a high-pressure spraying device is arranged at the top of the high-pressure air desulfurization device, a micro air floatation releaser connected with an air compressor positioned outside the high-pressure air desulfurization device is arranged at the bottom of the high-pressure air desulfurization device, a booster pump is arranged between the anaerobic reactor and thehigh-pressure air desulfurization device, one end of the booster pump is connected with the anaerobic reactor, and the other end is connected with the high-pressure spraying device. Sulfur ions generated in anaerobic reaction can be rapidly removed through the high-pressure air desulfurization device, biotoxicity is avoided, high-pressure air can be excessively added, desulfurization is thorough,the operation cost is low, no extra sludge is generated, and the reaction speed is high; and the high-pressure air desulfurization device can also change the anaerobic environment of the wastewater into the aerobic environment in advance, so that subsequent aerobic biochemical treatment is facilitated.

Owner:杭州乐升环保工程有限公司

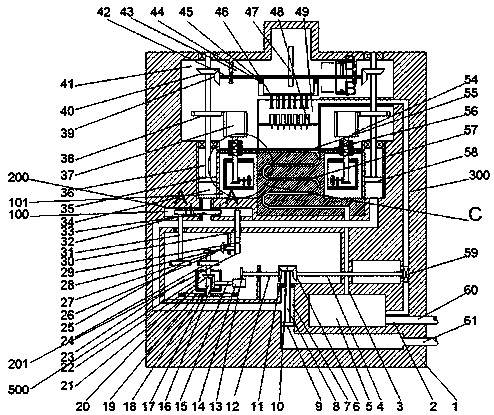

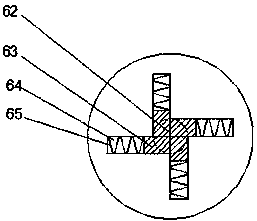

Vane rotary compressor

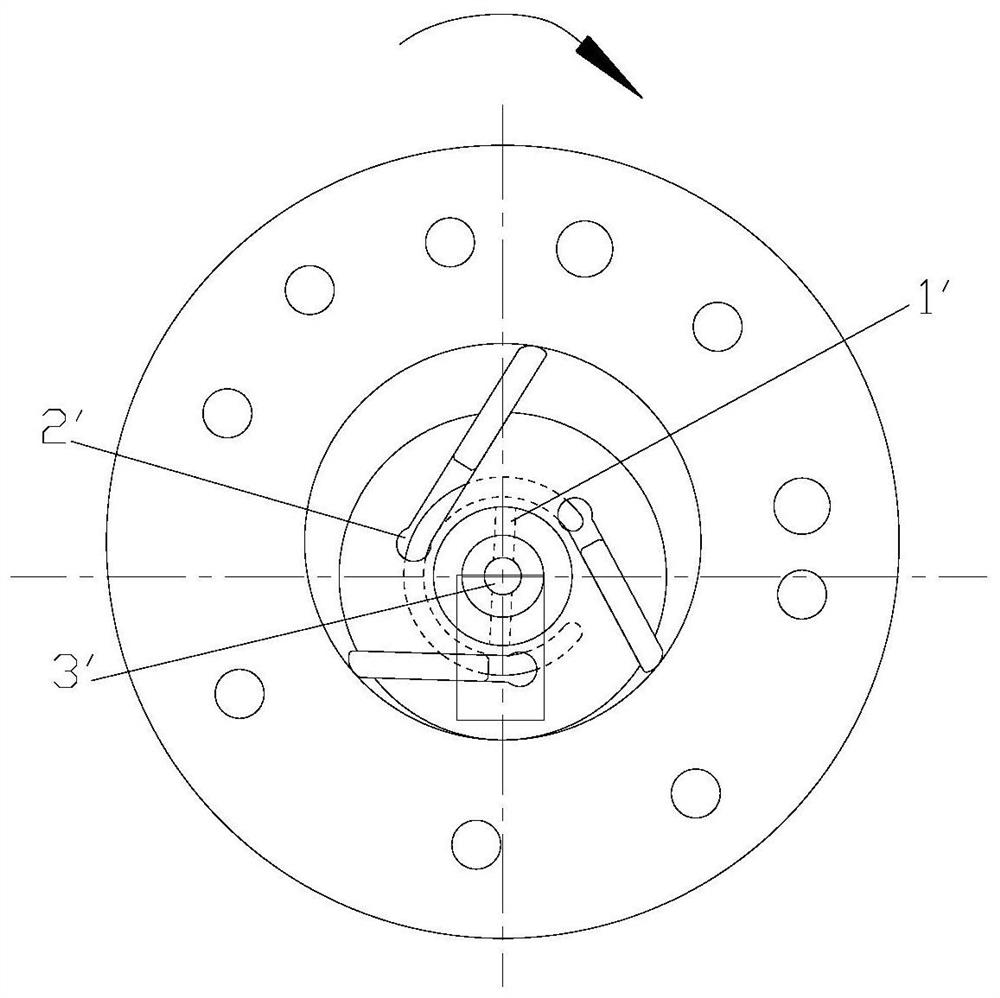

ActiveUS20200149531A1Improve reliabilityIncreased load-bearing capacityRotary piston pumpsRotary piston liquid enginesRotational axisEngineering

A vane rotary compressor has a cylinder. A main bearing and a sub bearing are coupled to the cylinder forming a compression space. The main and sub bearing each have a back pressure pocket on a surface facing the cylinder. The main bearing and the sub bearing radially support a rotation shaft. A roller coupled to the shaft is disposed within the compression space. The roller has circumferentially spaced vane slots, each vane slot extending from an open end on an outer circumferential surface of the roller to a back pressure chamber disposed within the roller at an opposite end of each vane slot. A plurality of vanes slide within the vane slots and divide the compression space into compression chambers. At least one of the back pressure chambers in the vane slots fluidly communicates with at least one of the back pressure pockets in the main and sub bearings.

Owner:LG ELECTRONICS INC

Bearing carrying component, compressor and refrigerant circulation system

PendingCN111365284APrevent stagnant fluidKeep back pressure stablePump componentsPumpsPhysicsEngineering

The invention provides a bearing carrying component, a compressor and a refrigerant circulation system. The bearing carrying component includes a bearing chamber for mounting radial bearings, mountingholes coaxially communicating with the bearing chamber, fluid entry channels communicating the bearing chamber to the outside of the bearing carrying component, and fluid outflow channels communicating the mounting holes to the outside of the bearing carrying component. The bearing carrying component is conducive to supplying fluid to radial bearings and keeping the back pressure stability of theradial bearings, so that the stable operation of the compressor is facilitated.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

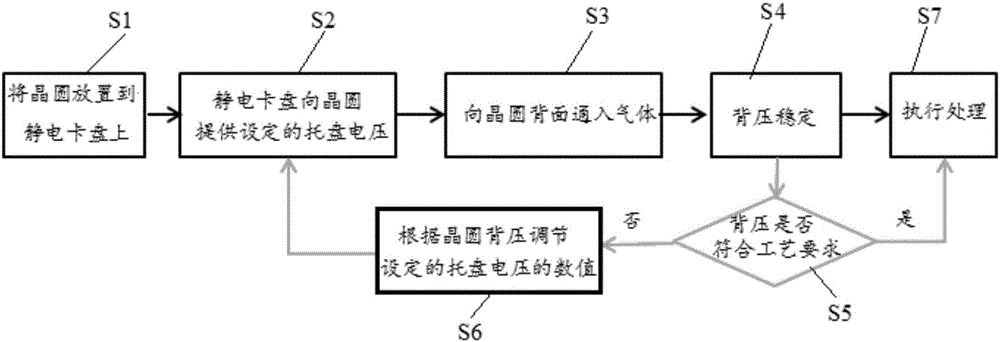

Method for keeping backpressure of wafer steady

InactiveCN106298453AStable back pressureSemiconductor/solid-state device manufacturingVoltageEngineering

The invention provides a method for keeping backpressure of a wafer steady. The method comprises the following steps of: putting the wafer on an electrostatic chuck; enabling the electrostatic chuck to provide one set tray voltage for the wafer; introducing gas into the wafer; enabling the backpressure of the wafer to be steady after introducing gas into the wafer; judging whether the backpressure of the wafer accords with process requirements or not after the backpressure of the wafer is steady; when the fact that the backpressure of the wafer does not accord with the process requirements is determined, adjusting the set numerical value of the tray voltage according to the backpressure of the waver, and then, returning to the second step again; and executing a treatment process when the fact that the backpressure of the wafer accords with the process requirements is determined.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

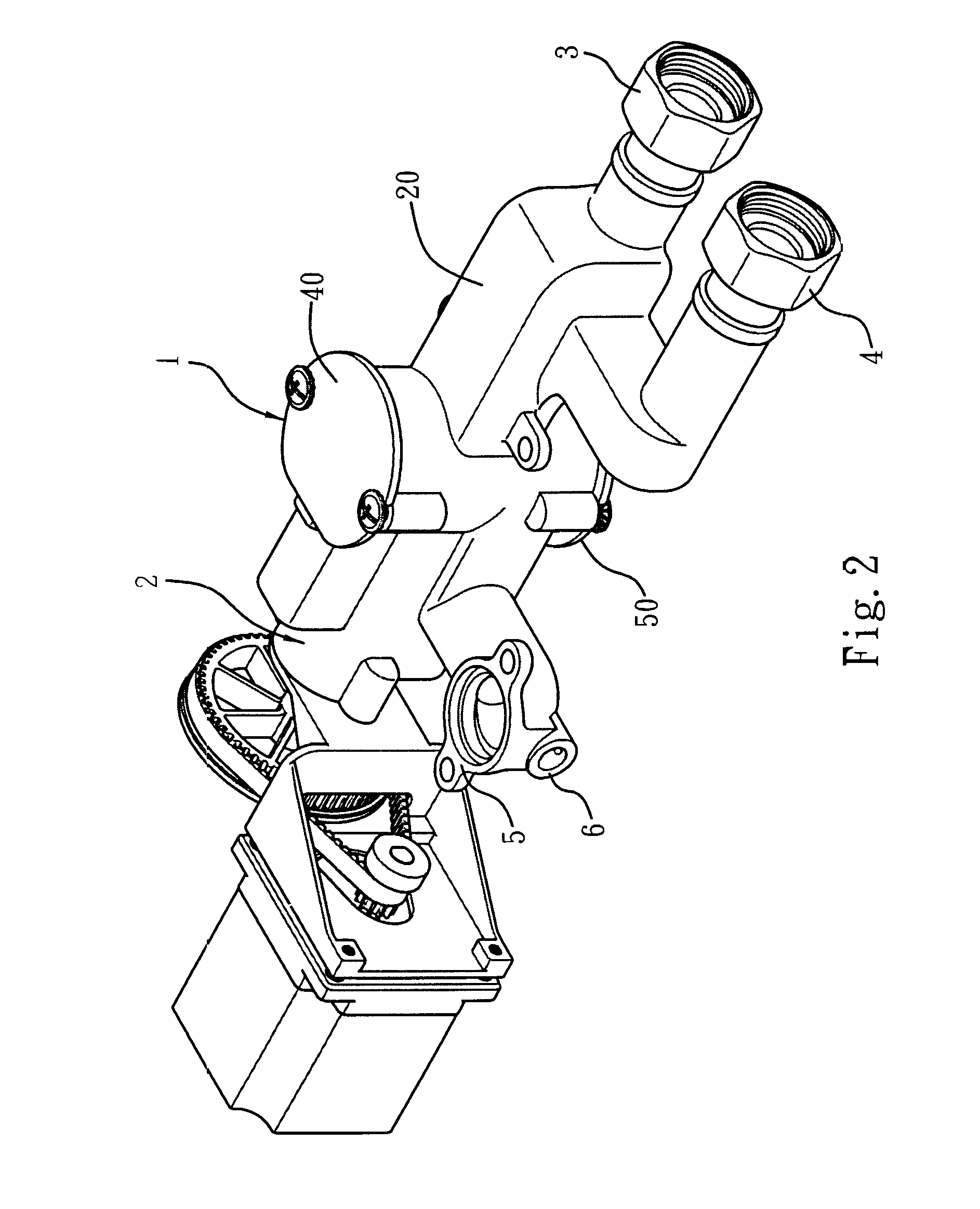

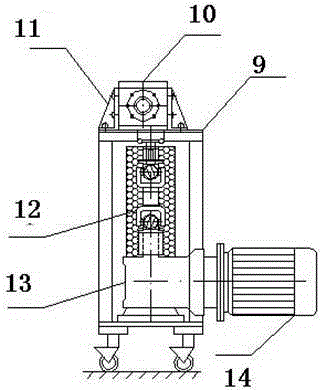

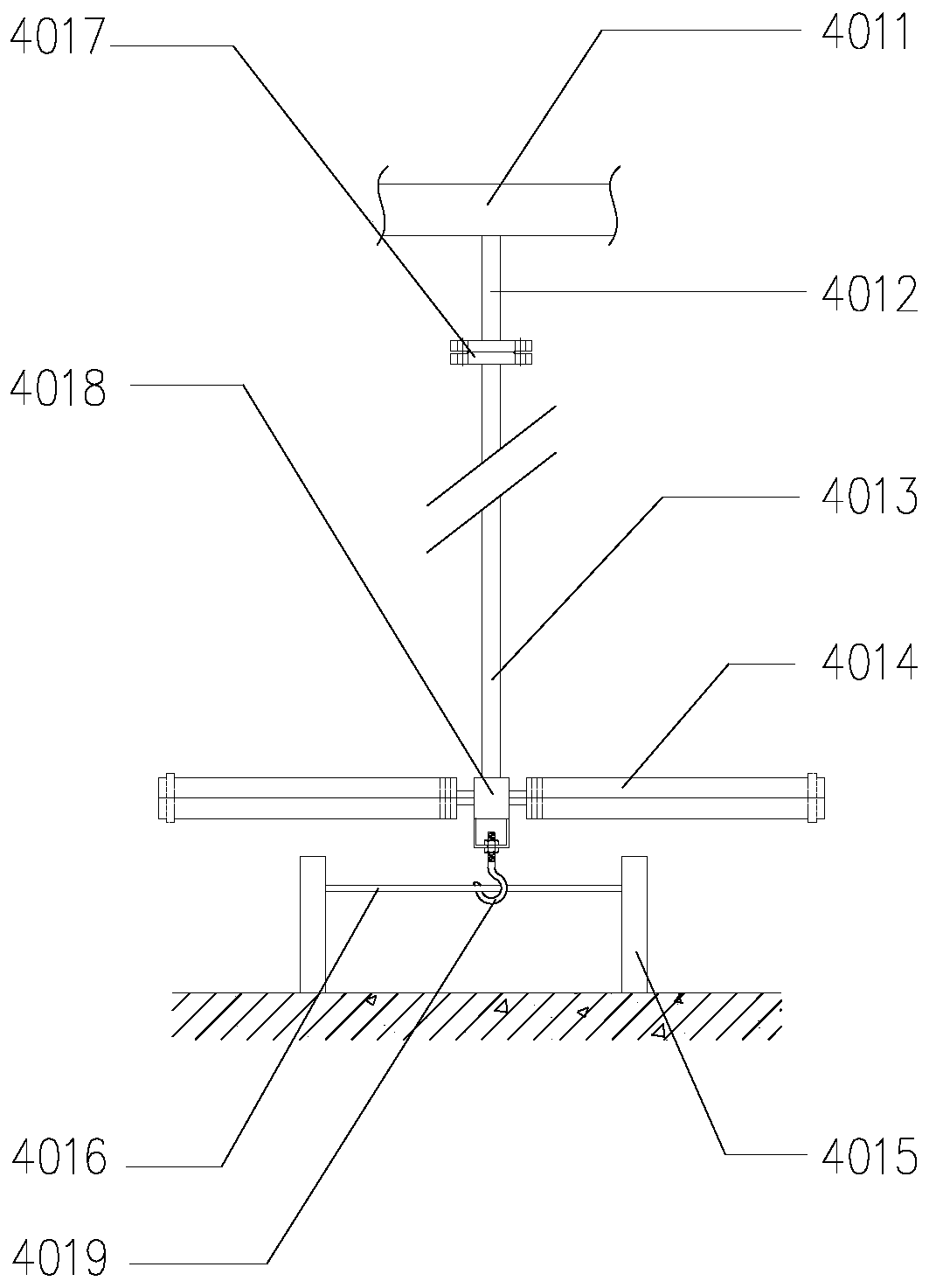

Pressure return device for water plugging profile control physical simulation experiment and use method of pressure return device

InactiveCN102828746BStable back pressureThere is no shear phenomenonBorehole/well accessoriesLine tubingRock core

The invention discloses a pressure return device for a water plugging profile control physical simulation experiment and a use method of the pressure return device. The pressure return device comprises a pressure sensor and a stop valve, and is characterized by also comprising an intermediate container, pistons, a four-way valve and a high-pressure pulsation-free pump, wherein the intermediate container is internally provided with two pistons, a working liquid is filled in a space between the two pistons, the left side of the intermediate container is connected with an outlet pipe of a core barrel, a space for filling a plugging agent can be formed between the left piston and the intermediate container, and the right piston is connected with a fine tuning hand wheel and a working liquid inlet pipe. Through controlling the pressure of the working liquid between the two pistons, an actual stratum pressure born by a water shutoff profile control agent in a mine field is simulated. The pressure return device has the advantages of simple structure and convenience for use, is easy to dismantle for cleaning and maintaining, and difficult to plug, and has reliable performance to easily maintain the stability of return pressure on the outlet end of the core barrel; return pressure is high to meet the demand of experiments on high return pressure; and an obtained sample is not sheared by a return pressure device.

Owner:CHINA PETROLEUM & CHEM CORP +1

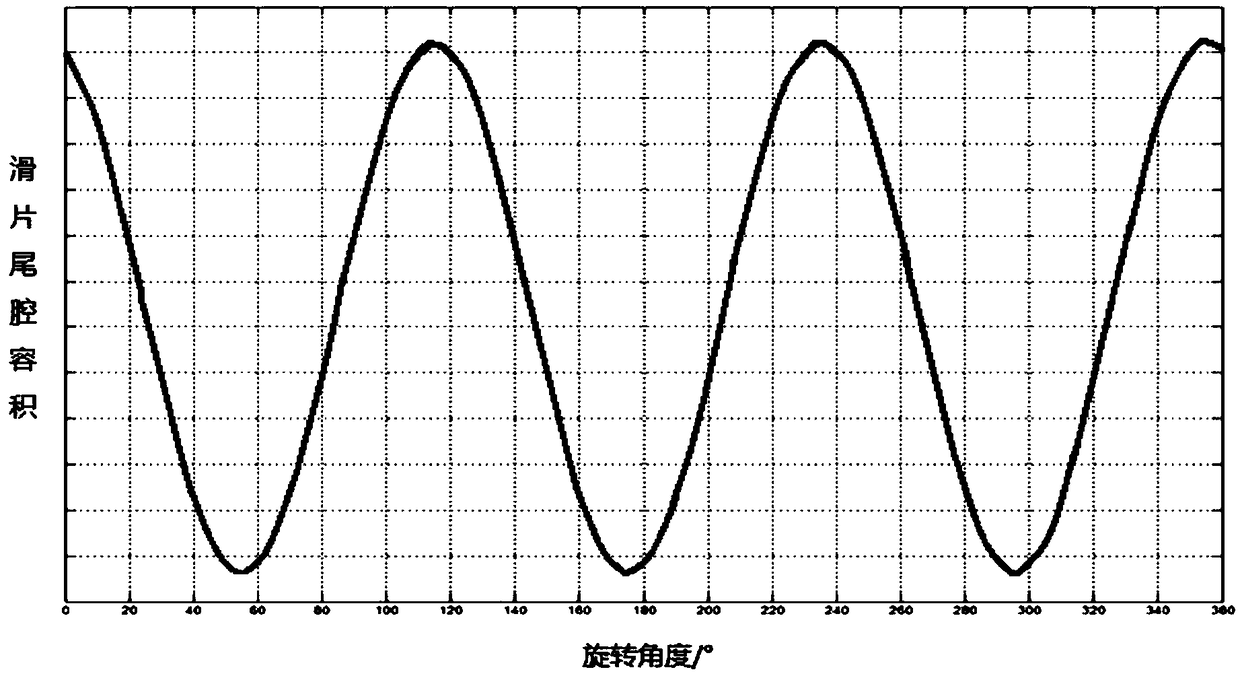

Pump body assembly, compressor and air conditioner

ActiveCN111794964ABack pressure in timeStable back pressureRotary piston pumpsRotary piston liquid enginesSlip sheetPhysics

The invention provides a pump body assembly, a compressor and an air conditioner. The pump body assembly comprises a spindle, an upper flange, a lower flange, an air cylinder and a roller. The rolleris fixed circumferentially relative to the spindle, a slip sheet chute is formed in the roller, a slip sheet is slidably arranged in the slip sheet chute, the head of the slip sheet is abutted to theinner wall of the air cylinder, the tail of the slip sheet and the tail of the slip sheet chute form a tail cavity, a first backpressure groove is formed in the upper flange and / or a second backpressure groove is formed in the lower flange, a center hole and a side hole are formed in the spindle, the tail cavity communicates to the side hole through the backpressure grooves, each tail cavity is provided with at least one side hole correspondingly in a section vertical to the central axis of the spindle, and the tail cavity is located on an extension line of a center line of the side hole corresponding to the tail cavity. The pump body assembly according to the invention can solve the problem that the head of the slip sheet is separated from the inner wall of the air cylinder to further lead to leakage to affect the energy efficiency and the reliability of the compressor as the backpressure of the slip sheet is insufficient due to belated oil supply when an existing compressor operatesat low and medium frequency.

Owner:GREE ELECTRIC APPLIANCES INC

Unbounded ejector for conveying condensed oil and its conveying method

InactiveCN1174813CUniform pressureStable back pressureJet pumpsMachines/enginesEngineeringDirect heating

The present invention relates to the unbounded ejector for conveying condensed oil and its conveying method. The unbounded ejector includes one assembly comprising a nozzle seat, a heat insulating seat and a sleeve with steam inlet and steam outlet; one mixing section with two ends connected to sealing washer, flange and end cap with a union; one passage beside the flange central hole and with one end communicated with a heating layer, a steam inlet at one end and a steam outlet at the other end; nozzle installed in the inclined hole in the nozzle seat, ring partition board, washer, and positioning board. The ejector has no driving unit. The present invention adopts direct heating of medium for saving steam and fast heating of condensed oil and unbounded ejection with coagulation of condensed oil in the equipment.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Pump components, compressors and air conditioners

ActiveCN111794965BImprove energy efficiencyImprove reliabilityRotary piston pumpsRotary piston liquid enginesEngineeringFlange

The application provides a pump body assembly, a compressor and an air conditioner. The pump body assembly includes a main shaft, an upper flange, a lower flange, a cylinder and rollers. The rollers are fixed circumferentially relative to the main shaft. A slide groove is arranged on the roller, and a slide is provided for sliding in the slide groove. The head of the cylinder abuts against the inner wall of the cylinder, a tail cavity is formed between the tail of the slide vane and the tail of the slide vane groove, the upper flange is provided with a first back pressure groove and / or the lower flange is provided with a second back pressure The groove, the main shaft is provided with a central hole and a side hole connected to each other, the tail cavity and the side hole are arranged in a dislocation along the circumferential direction of the roller, and the side hole communicates with the tail cavity through the first back pressure groove and the second back pressure groove. According to the pump body assembly of the present application, when the compressor in the prior art operates at high frequency, the back pressure is unstable and fluctuates greatly, which affects the energy efficiency and reliability of the compressor.

Owner:GREE ELECTRIC APPLIANCES INC

Compressed air energy storage system and energy storage method

ActiveCN111412126BStable pressureStable back pressurePositive displacement pump componentsSteam engine plantsThermal energy storageHeat balance

The invention relates to the technical field of energy storage, and discloses a compressed air energy storage system and an energy storage method. The compressed air energy storage system comprises anair compressor, a heat exchanger, a gas storage, an air expansion, a heat regenerator and a heat accumulator. An air outlet of the air compressor communicates with a gas-phase space of the gas storage through a first heat exchanging pipeline of the heat exchanger, the gas-phase space is further connected with an inlet of the air expansion through a third heat exchanging pipeline of the heat regenerator, a heat storage medium space of the gas storage is connected with an inlet of the heat accumulator through a second heat exchanging pipeline of the heat exchanger, and an outlet of the heat accumulator is connected to the heat storage medium space through a fourth heat exchanging pipeline of the heat regenerator. According to the energy storage method of the energy storage system, energy-releasing storage is combined with a heat energy storage system, the gas storage, the heat exchanger, the heat accumulator and the heat regenerator are used for forming a heat regenerative cycle, internal heat balance and pressure balance of the compressed air energy storage system can be simultaneously realized, and the conditions of variable backpressure operation of the air compressor becoming and sliding pressure operation of the air expansion are avoided.

Owner:TSINGHUA UNIV

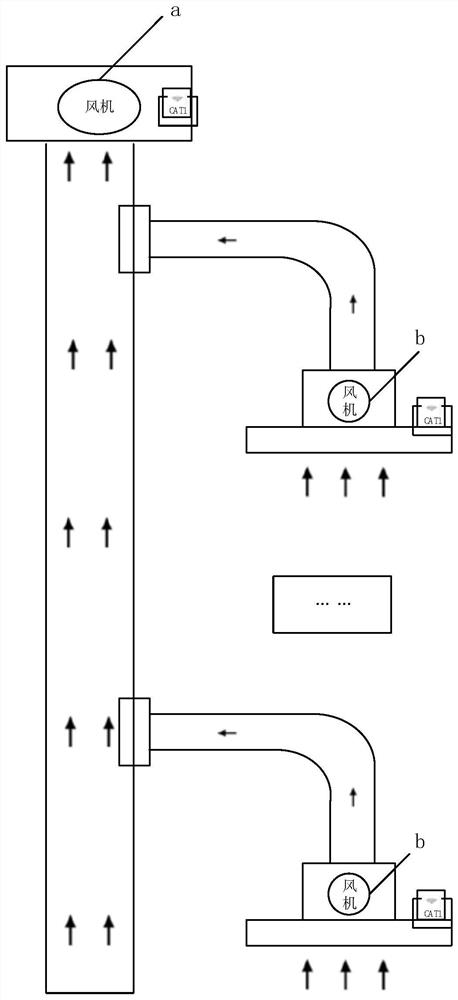

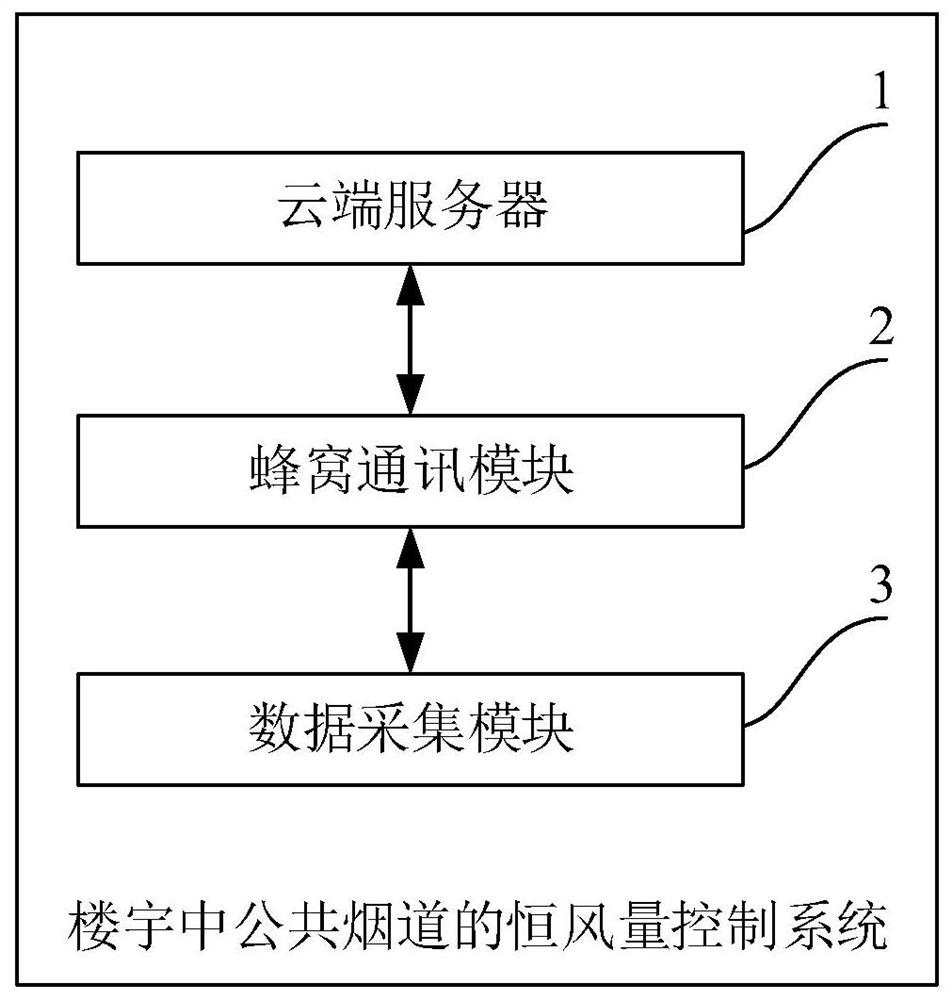

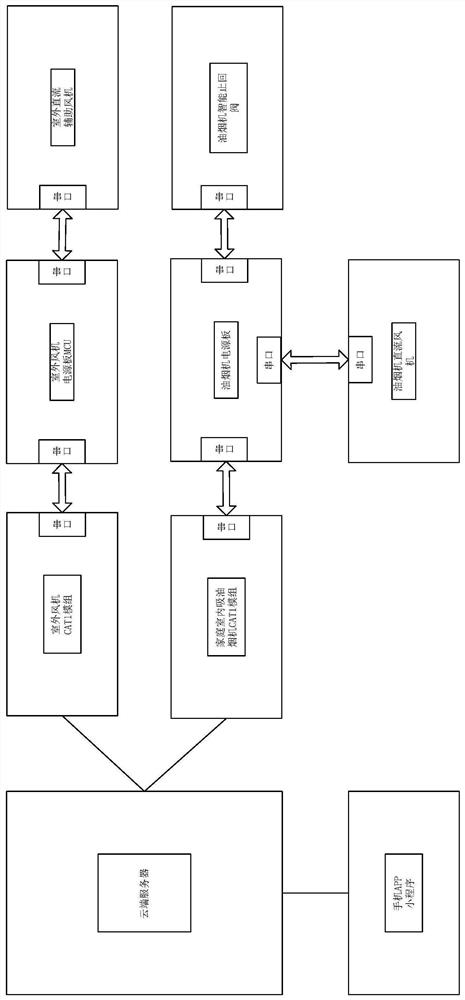

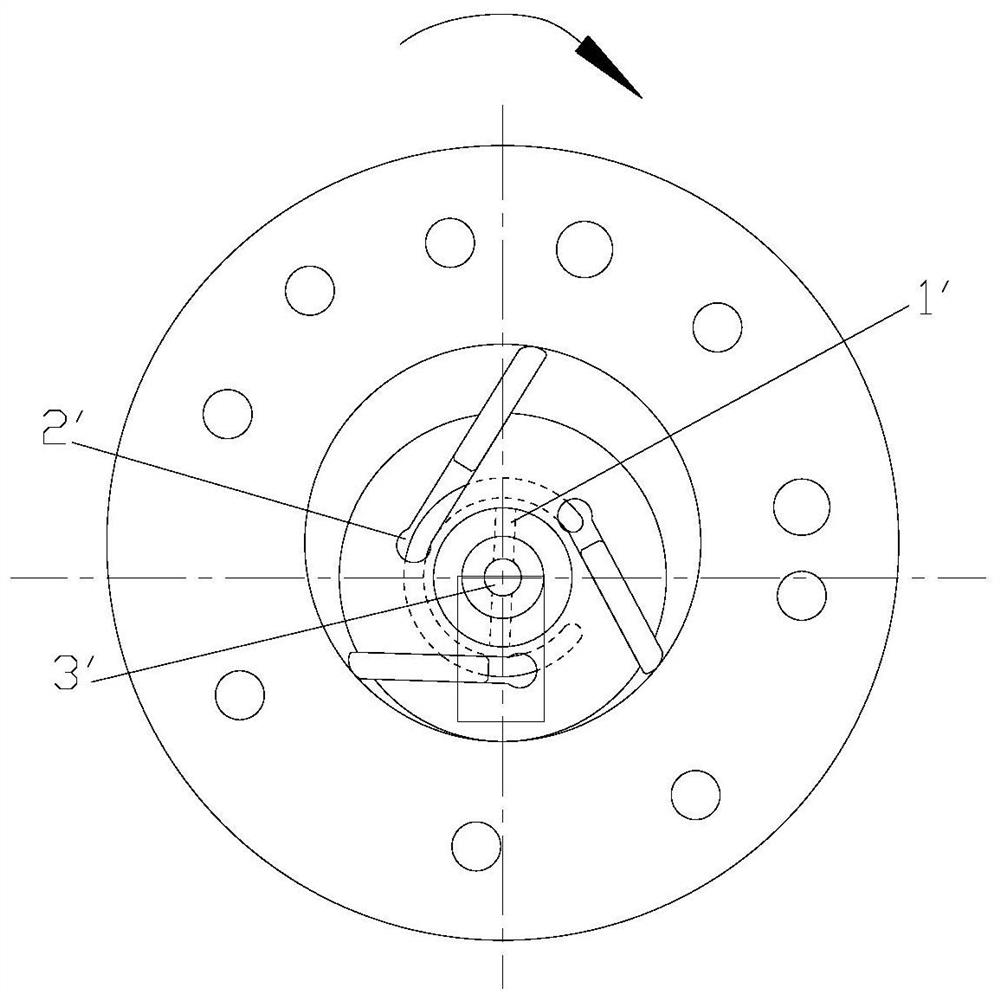

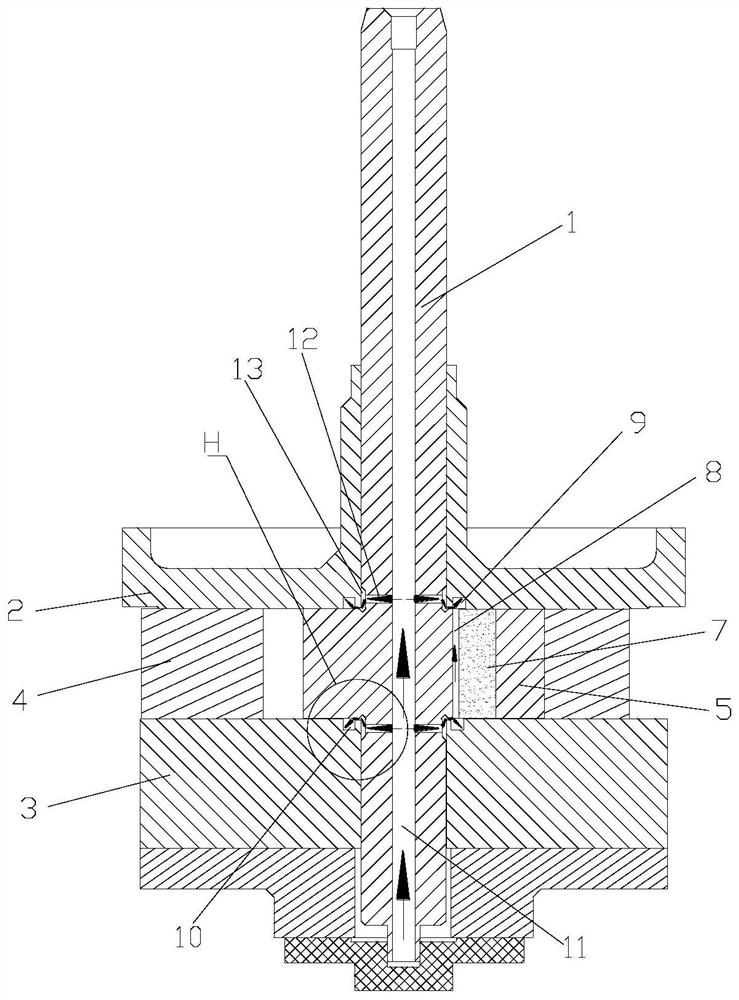

Constant air volume control method and system for public flue in building

ActiveCN113074395BGuaranteed uptimeRun smart controlDomestic stoves or rangesLighting and heating apparatusAir volumeData acquisition

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Pump assemblies, compressors and air conditioners

ActiveCN111794964BBack pressure in timeStable back pressureRotary piston pumpsRotary piston liquid enginesPhysicsBack pressure

Owner:GREE ELECTRIC APPLIANCES INC

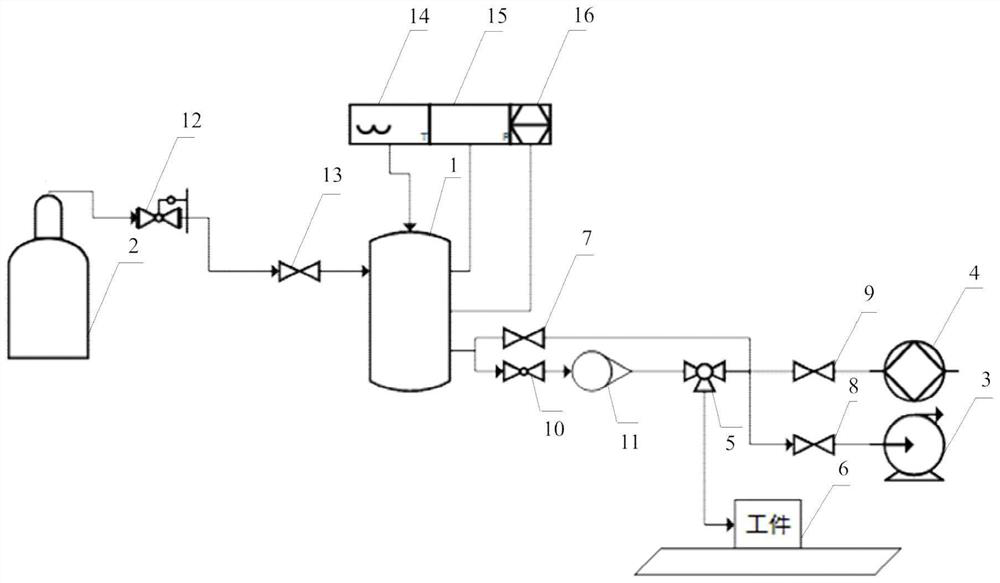

Working medium filling system and working medium filling method

PendingCN114542954AAccurate fillingReduce contentPipeline systemsFluid transferredEngineeringMechanical engineering

The invention relates to the field of working medium filling, in particular to a working medium filling system and a working medium filling method. The working medium filling system comprises a first working medium storage device, a second working medium storage device, a first vacuum device and a second vacuum device, wherein the first working medium storage device is connected with the second working medium storage device; the first working medium storage device is connected with the first vacuum device and the second vacuum device through a first pipeline and a second pipeline respectively; a three-way reversing valve is further arranged on the second pipeline and used for being connected with the first working medium storage device, the second vacuum device and a workpiece to be filled with the working medium; the first pipeline is connected with the second pipeline, and the first pipeline and the second pipeline are communicated with each other at a connecting point. The working medium filling system is reasonable in arrangement, high in safety and capable of achieving accurate filling of the working medium.

Owner:北京微焓科技有限公司

Watering port

InactiveCN101856720AAvoid cloggingStable back pressureMelt-holding vesselsMaterials scienceRefractory

The invention discloses a watering port belonging to the field of continuous steel casting. The watering port comprises a refractory material body, a pouring path, a housing and an argon blowing port, wherein the pouring path is arranged in the center of the body, the housing surrounds the body and the top, and the argon blowing port is arranged on the housing; an air path communicated with the argon blowing port is arranged between the housing and the body; and the refractory material body is divided into three layers which are respectively a venting layer, an airtight layer and a venting layer.

Owner:SHANGHAI BAOMING REFRACTORIES CO LTD

Scroll compressor

ActiveCN102016319BAvoid back pressureStable back pressureRotary piston pumpsRotary piston liquid enginesEngineeringHigh pressure

Owner:PANASONIC CORP

fuel supply holding valve

ActiveCN108317031BEasy to operateAchieve linear adjustmentFuel injection apparatusMachines/enginesEngineeringFuel supply

Owner:CHINA FIRST AUTOMOBILE

Performance test device and test method of seawater hydraulic motor in deep sea high back pressure environment

ActiveCN105443503BStable back pressureAvoid mixingFluid-pressure actuator testingPilot systemHigh pressure

The invention discloses a performance test device and a performance test method for a seawater hydraulic motor under a deep-sea high-back-pressure environment. The performance test device mainly comprises a seawater hydraulic motor test system, a monitoring control system, a deep-sea simulation cabin, a pressure loading system and a circulating water cooling system, wherein the deep-sea simulation cabin provides back pressure required to bear while working under different water-depth environments for performance test of the tested seawater hydraulic motor by virtue of the pressure loading system; test load of the tested seawater hydraulic motor is freely regulated by virtue of a high-pressure flow control valve mounted in the circulating water cooling pipeline; and the circulating water cooling pipeline can effectively avoid rising the water temperature in the cabin due to heat generated by the seawater hydraulic motor operated under load, the motor and the like. The method can simulate the back pressure environment at a set ocean depth and can realize performance test for the seawater hydraulic motor, is simple to operate, easy to realize, not only overcomes the technical difficulty of lowering the seawater hydraulic motor into great-depth deep sea, but also can accurately obtain performance parameters of the seawater hydraulic motor.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com