Pressure return device for water plugging profile control physical simulation experiment and use method of pressure return device

A technology of physical simulation, water plugging and profile control, applied in earthwork drilling, wellbore/well components, etc., can solve problems such as inability to conduct experiments, pressure fluctuations, severe shearing, etc., and achieve easy disassembly, cleaning and maintenance, and meet high The need for back pressure, the effect of not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

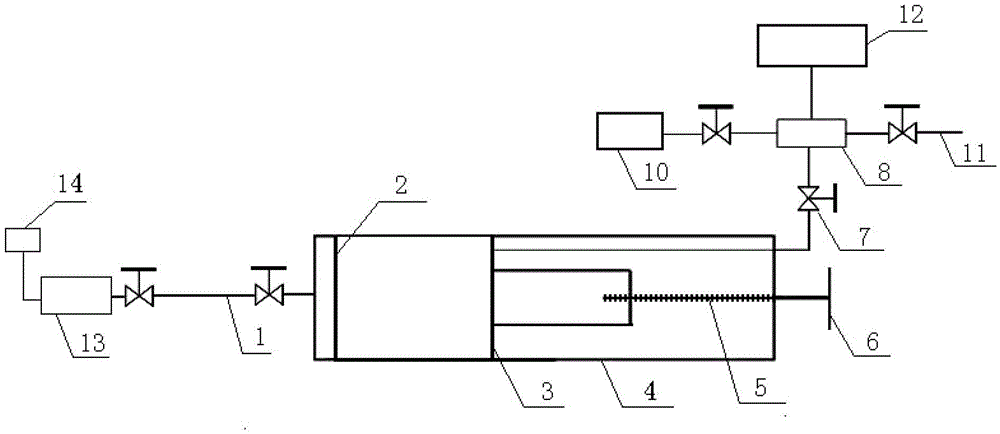

[0026] Such as figure 1 As shown, a back pressure device for physical simulation experiments of water plugging and profile control, including a pressure sensor and a stop valve, is characterized in that it also includes an intermediate container, a piston, a four-way valve and a high-pressure advection pump, and the intermediate container is provided with Two pistons, the space between the two pistons is used to fill the working fluid; the left side of the middle container is connected to the outlet pipeline of the core tube, and a space for filling plugging agent can be formed between the left piston and the middle container; the right piston is connected to the fine-tuning handwheel and Working fluid inlet pipe; the four-way valve is respectively connected to the working fluid inlet pipe, high-pressure advection pump, pressure sensor and pressure relief pipe.

[0027] A circular steel cylinder is fixed on the right side piston, and the rotating fine-tuning hand wheel is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com