Working medium filling system and working medium filling method

A technology of working medium and filling medium, which is applied in the direction of container filling method, container discharge method, pipeline system, etc., can solve the problems of working medium gas volume not meeting the design requirements, low saturated steam pressure, large error, etc., to achieve The effect of low non-condensable gas content, stable filling flow rate and reasonable structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

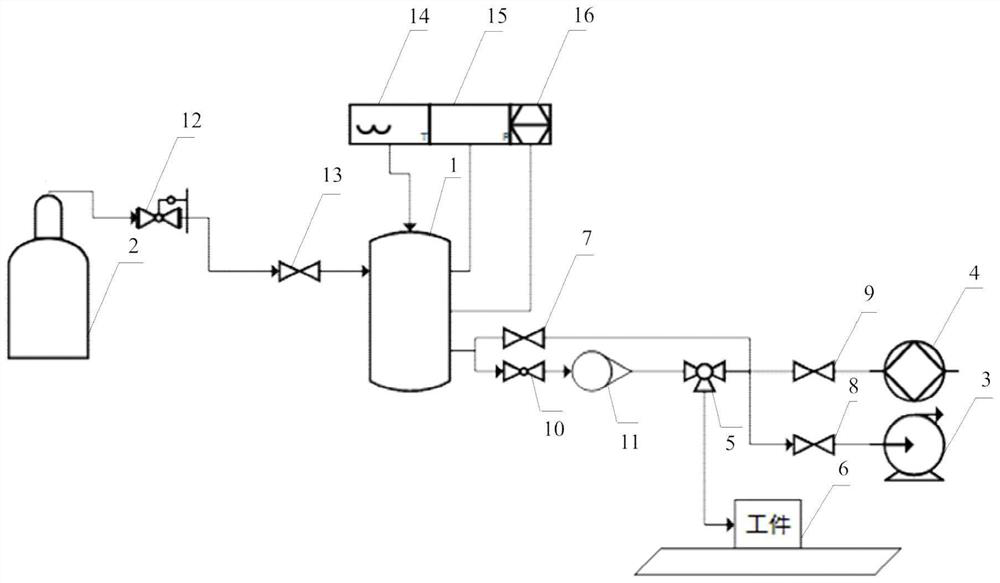

[0079] One working fluid filling system provided in the present embodiment is provided, such as Figure 1 Shown, comprising: a first working fluid storage device 1, a second working fluid storage device 2, a first vacuum device 3 and a second vacuum device 4;

[0080] Wherein, the first working fluid storage device 1 and the second working fluid storage device 2 are connected to each other; the first working fluid storage device 1 is connected to the first vacuum device 3 and the second vacuum device 4 are connected by the first and second lines, respectively; the second pipeline is further provided with a three-way commutation valve 5, the three-way commutation valve 5 for connecting the first working fluid storage device 1, the second vacuum device 4 and the workpiece to be charged working medium 6; the first line is connected to the second pipe, And communicate at the connection point;

[0081]On the first piping, the connection point and the first working fluid storage device 1...

Embodiment 2

[0085] The present embodiment provides a method of filling the working fluid, comprising the following steps:

[0086] 1, using the first vacuum device 3 to the first working fluid storage device 1 vacuum, the vacuum degree of the first working fluid storage device 1 ≤ 10Pa, close the first vacuum device 3, start the second vacuum device 4; the vacuum degree of the first working fluid storage device 1 ≤ 10 -2 Pa, close the second vacuum device 4; after closing the second vacuum device 4, to the first working fluid storage device 1 to fill the working medium; after filling the working fluid will be discharged from the first working fluid storage device 1;

[0087] 2, repeat step 1 5 times, control the temperature of the first working fluid storage device 1 is 259.9 ~ 260.1K;

[0088] 3, the second working fluid storage device 2 to the first working fluid storage device 1 after the first ventilation treatment is filled with working fluids;

[0089] 4, the use of the first vacuum dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com