Watering port

A body and shell technology, applied in the field of the upper nozzle, can solve the problems of impurity deposition, increased argon blowing volume, unstable back pressure, etc., and achieve the effects of stabilizing back pressure, preventing clogging, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

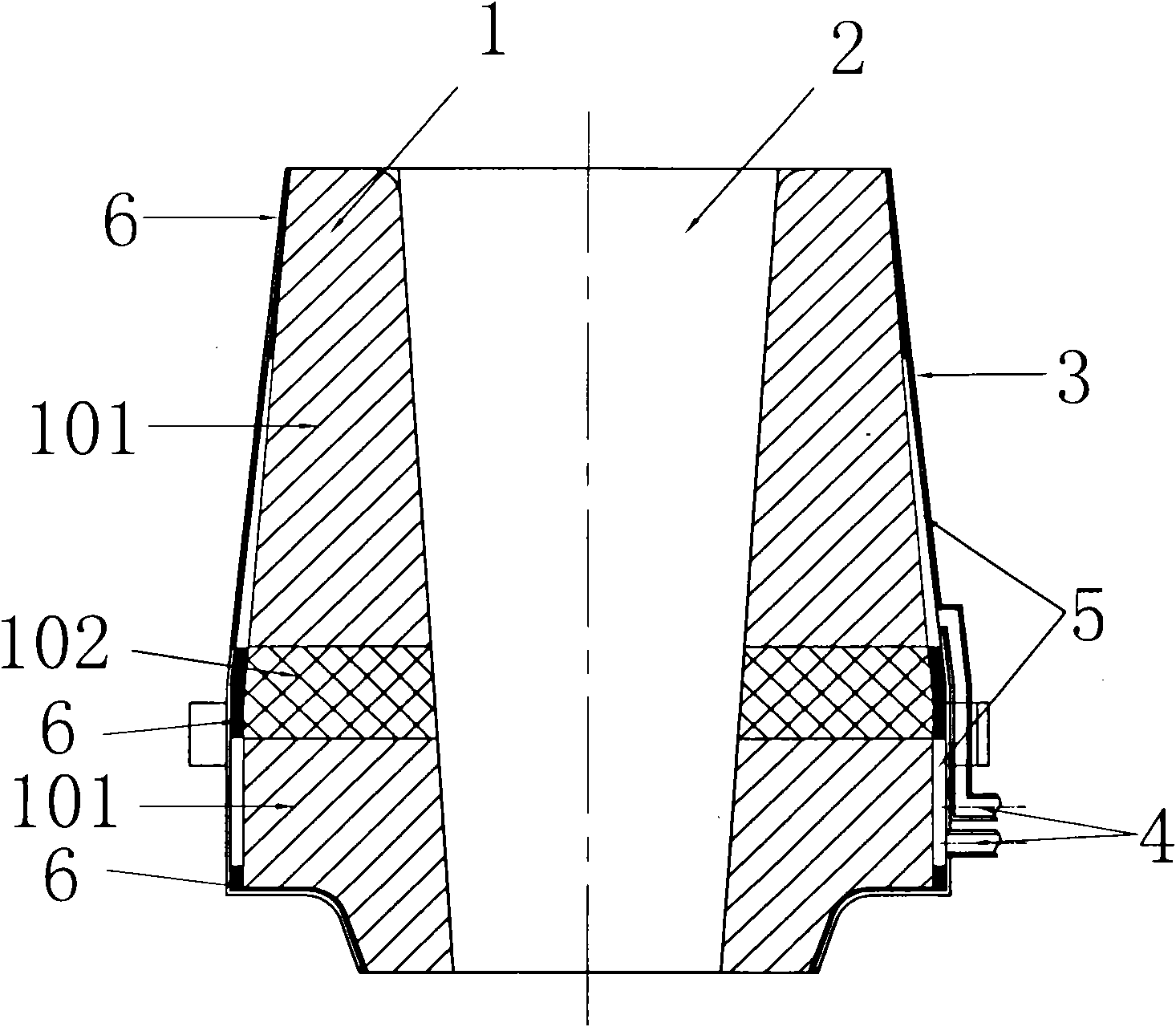

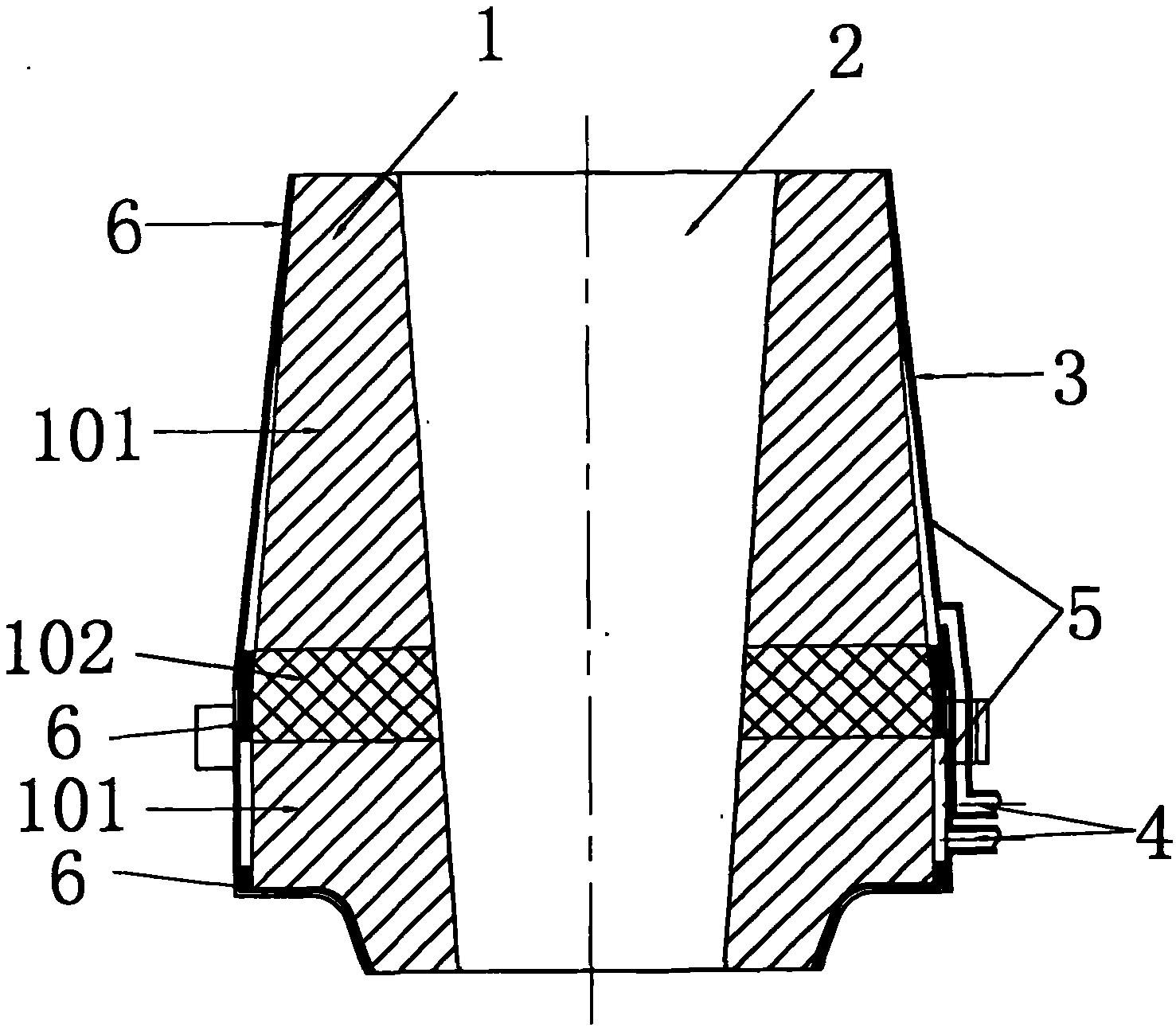

[0010] The present invention is an upper nozzle, comprising a refractory body 1, a pouring channel 2 located in the center of the body, a shell 3 surrounding the body and the top, an argon blowing nozzle 4 arranged on the shell 3, and an arrangement between the shell 3 and the body 1 There is an air channel 5 communicating with the argon blowing nozzle 4, wherein the refractory body 1 is divided into three layers, from top to bottom are gas permeable layer 101, gas impermeable layer 102 and gas permeable layer 101 respectively.

[0011] In the specific implementation process, the upper, middle and lower parts between the outer shell 3 and the main body 1 can be provided with sealing mortar 6, thereby forming two air passages 5, and the outer shell 3 is provided with two air passages 5 respectively. Connected argon blowing nozzle 4.

[0012] The refractory body 1 in the present invention adopts zirconium-mullite refractory material. Described casing 3 adopts iron sheet.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com