Pump assemblies, compressors and air conditioners

A component and pump body technology, which is applied in the direction of pump components, machines/engines, liquid fuel engines, etc., can solve the problems of insufficient back pressure of the slide vane, separation and leakage between the head of the slide vane and the inner wall of the cylinder, etc., and achieve timely oil supply Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

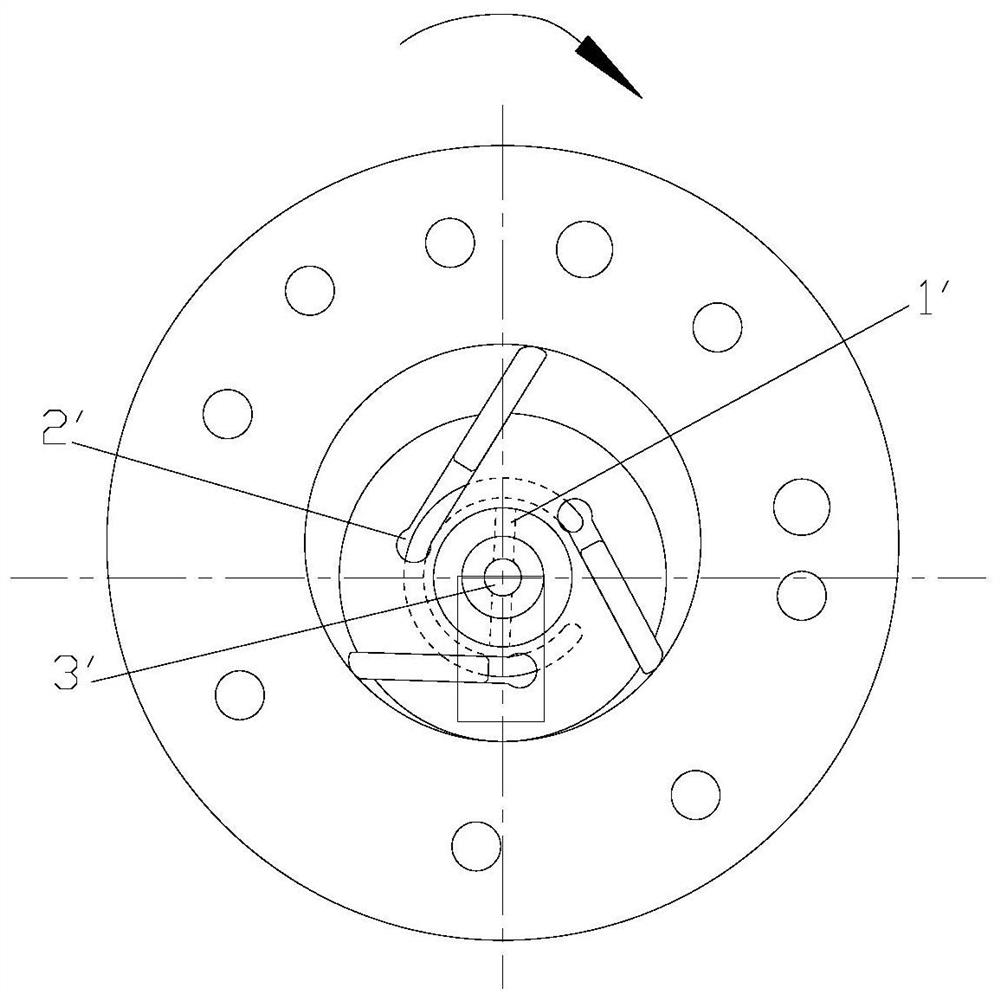

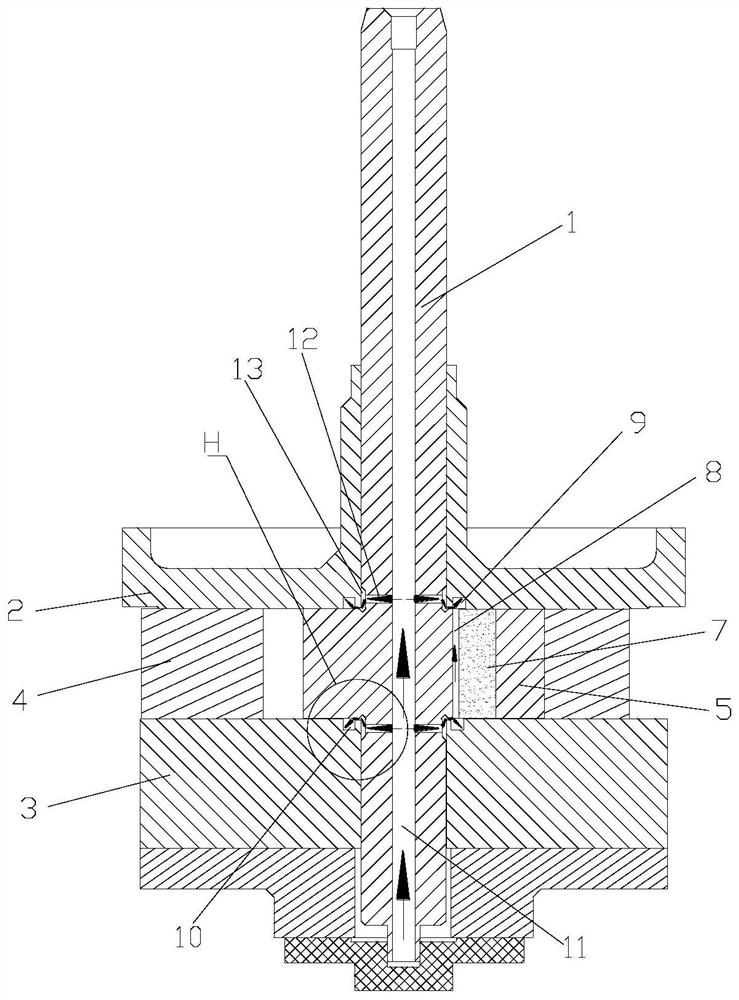

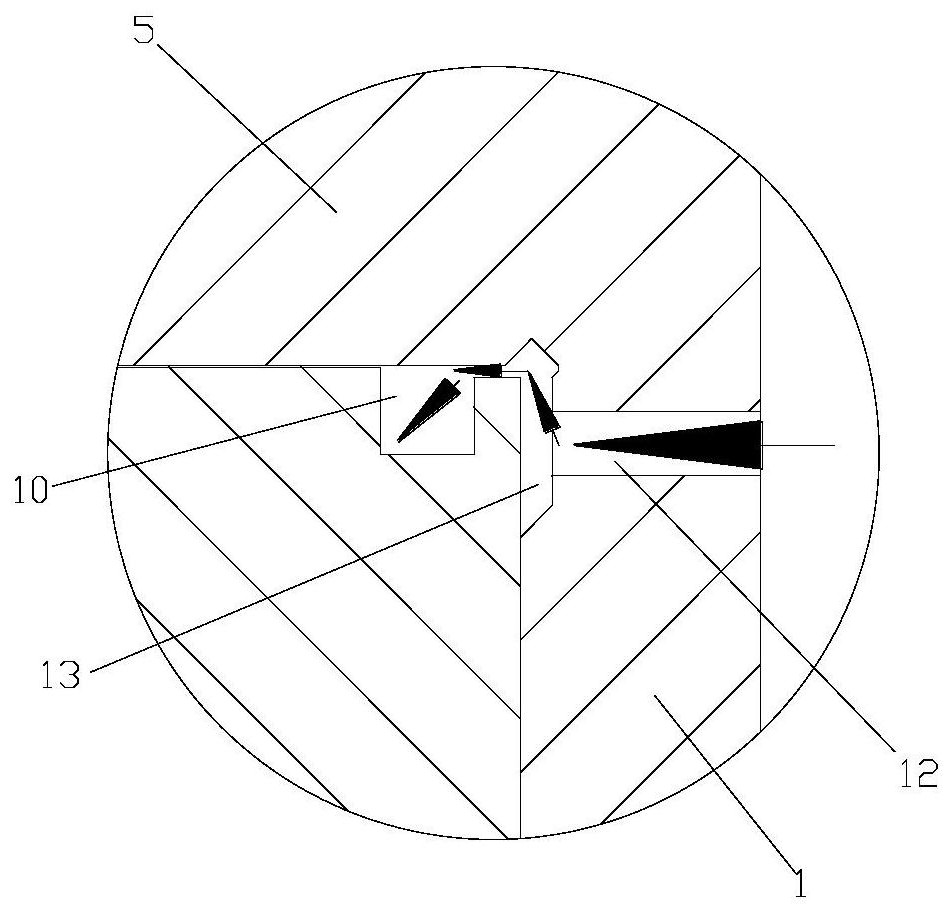

[0028] see in conjunction Figure 2 to Figure 8 As shown, according to the embodiment of the present application, the pump body assembly includes a main shaft 1, an upper flange 2, a lower flange 3, a cylinder 4 and a roller 5, the roller 5 is fixed circumferentially with respect to the main shaft 1, and the roller 5 is provided with There is a sliding piece groove 6, and a sliding piece 7 is slidably arranged in the sliding piece groove 6, the head of the sliding piece 7 abuts against the inner wall of the cylinder 4, and a tail cavity 8 is formed between the tail of the sliding piece 7 and the tail of the sliding piece groove 6 , the upper flange 2 is provided with a first back pressure groove 9 and / or the lower flange 3 is provided with a second back pressure groove 10, the main shaft 1 is provided with a connected central hole 11 and a side hole 12, and the tail chamber 8 The back pressure groove communicates with the side hole 12. In the section perpendicular to the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com