Patents

Literature

46results about How to "Guaranteed to follow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for digging virtual digital coins in mining pool

InactiveCN104915249ATransaction realizationEffectively implement independent miningMultiprogramming arrangementsSocial webComputer science

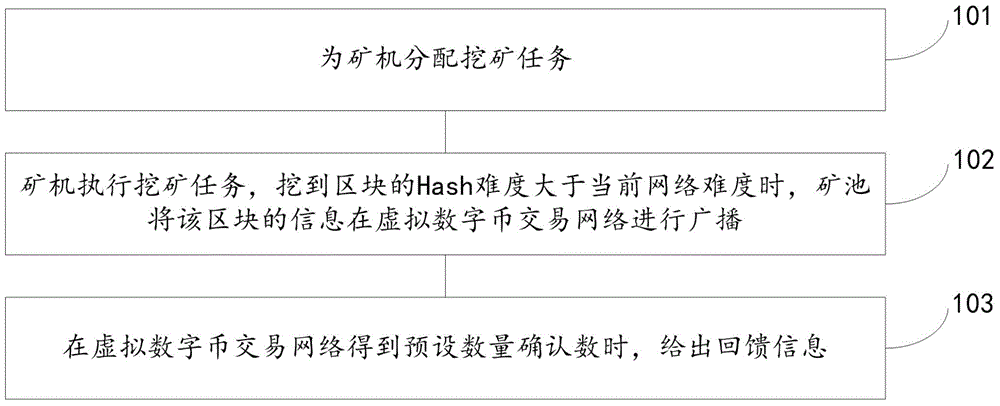

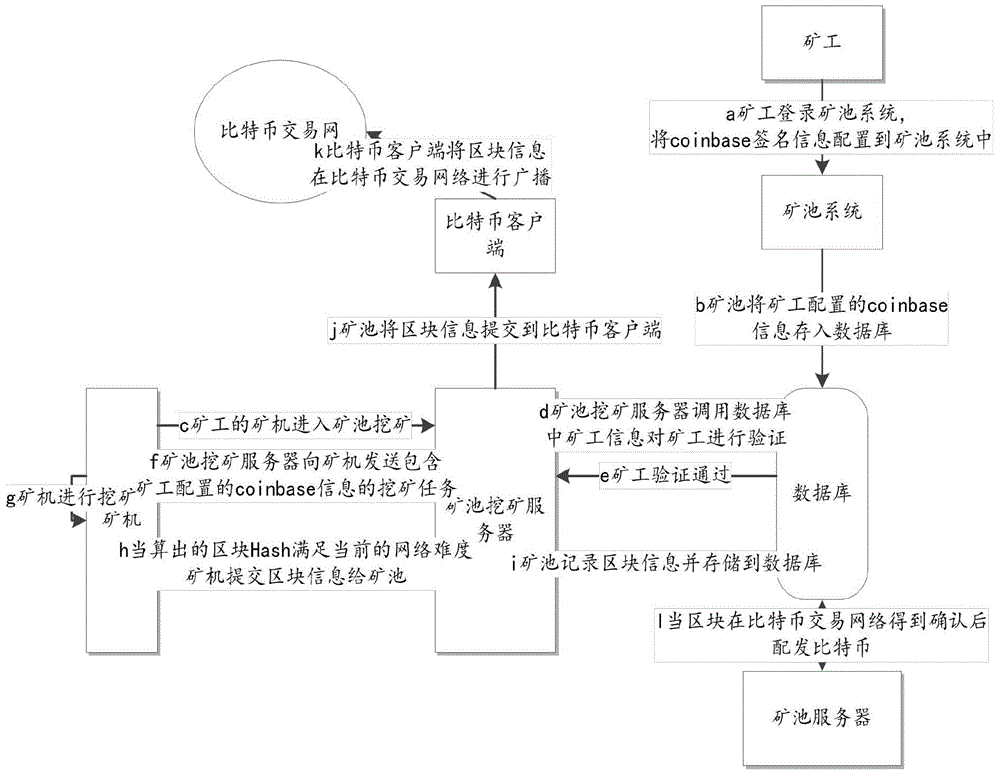

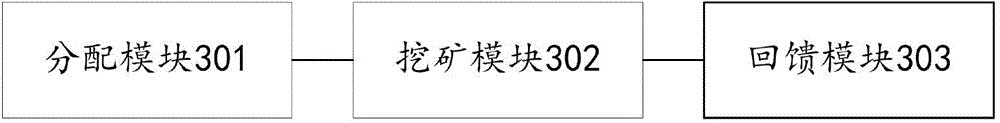

The invention discloses a method and device for digging virtual digital coins in a mining pool, and relates to the technical field of computer social networking services. The method for digging the virtual digital coins in the mining pool comprises the steps that a mining task is allocated to a mining machine; the mining task is executed through the mining machine, and when the Hash difficulty of a dug block is larger than the current network difficulty, the mining pool broadcasts the information in the virtual digital coin transaction network; when the preset number of confirmation numbers is obtained in the virtual digital coin transaction network, feedback information is given. According to the method for digging the virtual digital coins in the mining pool, the requirements of more users are met while the working efficiency is effectively improved.

Owner:BEIJING BITMAIN TECH LTD

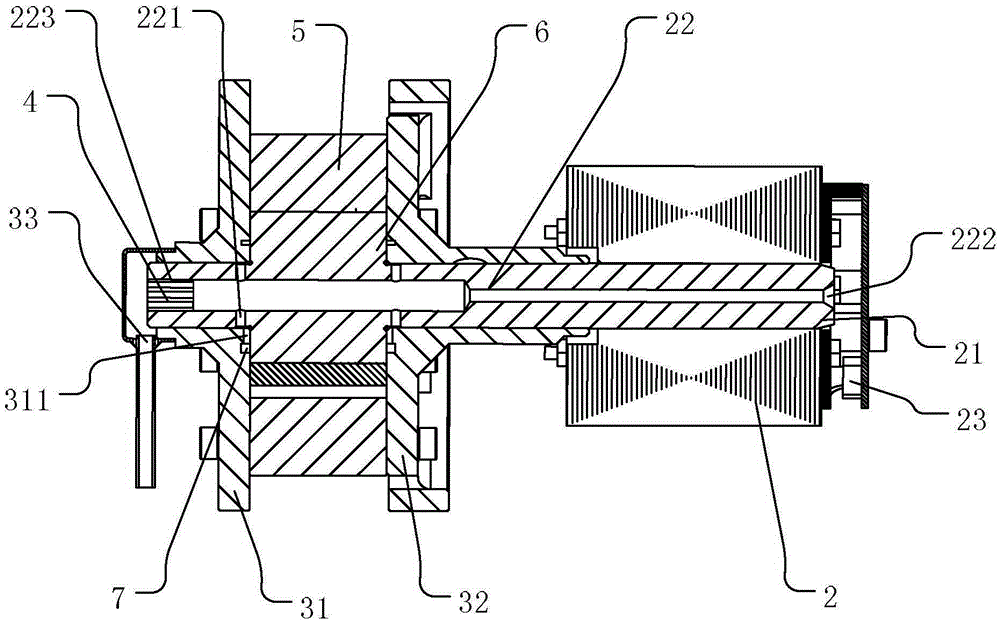

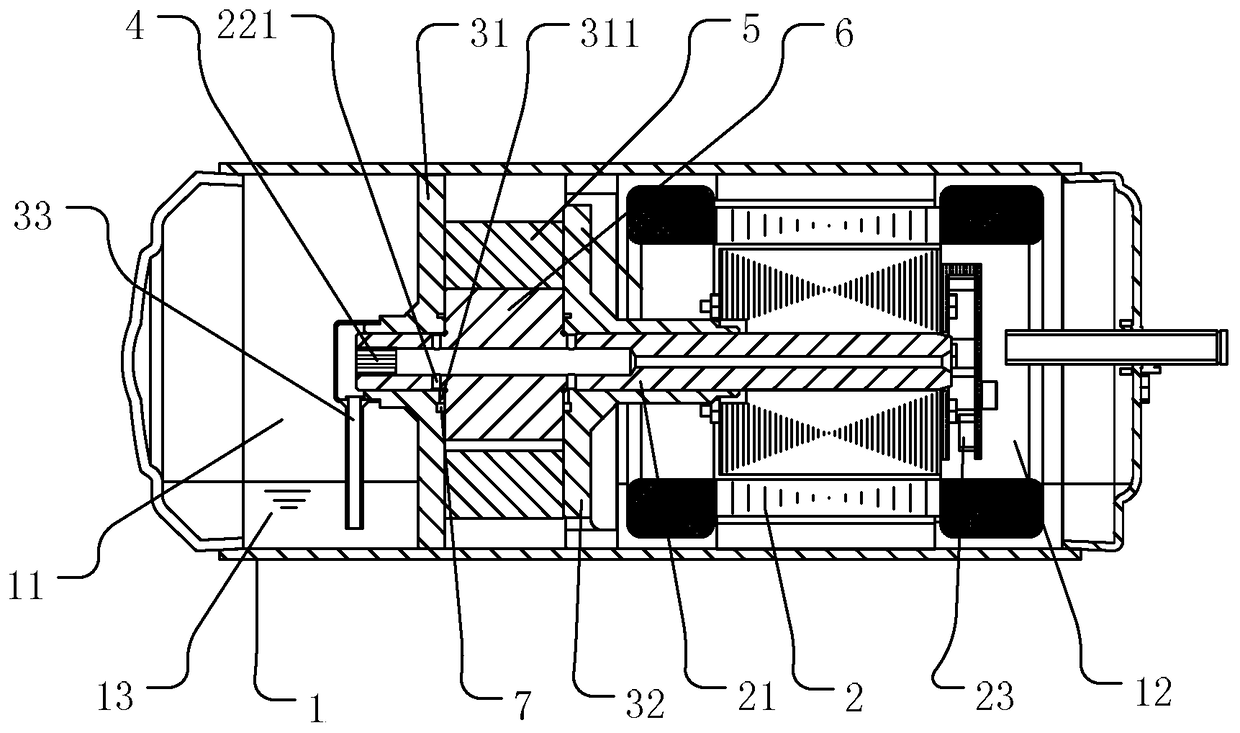

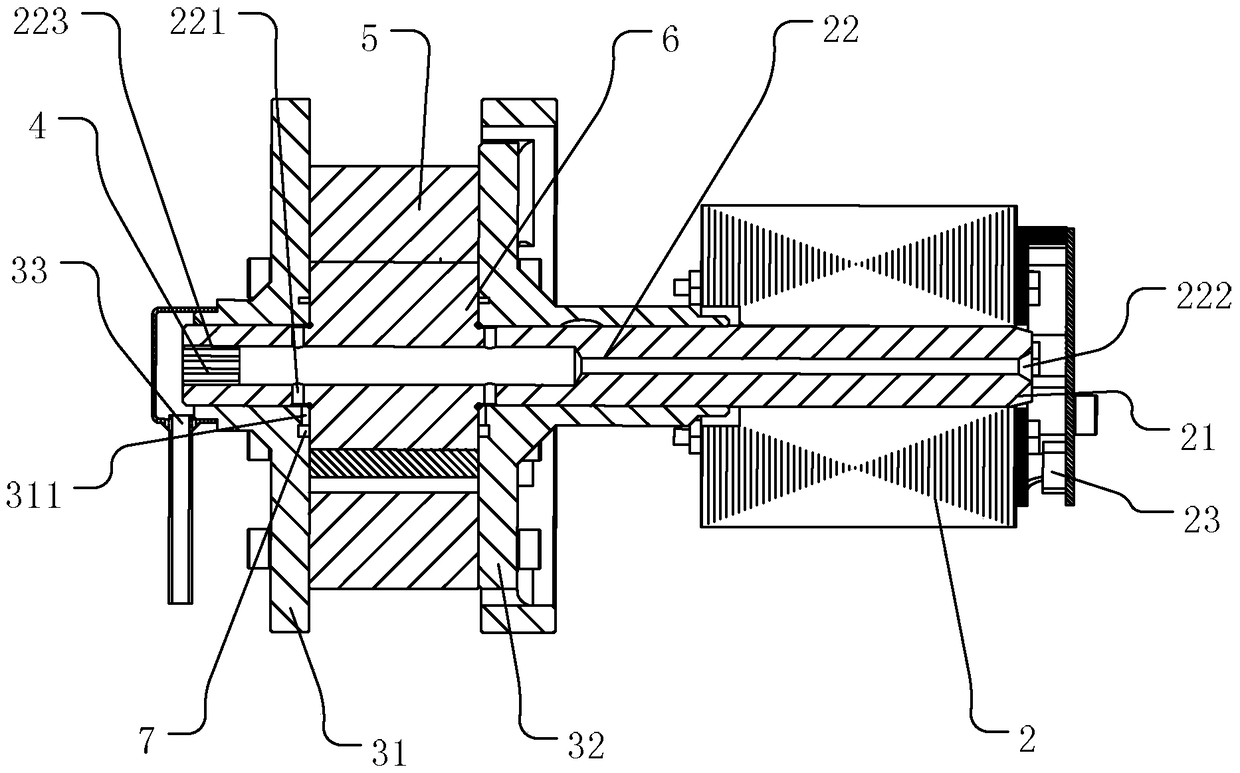

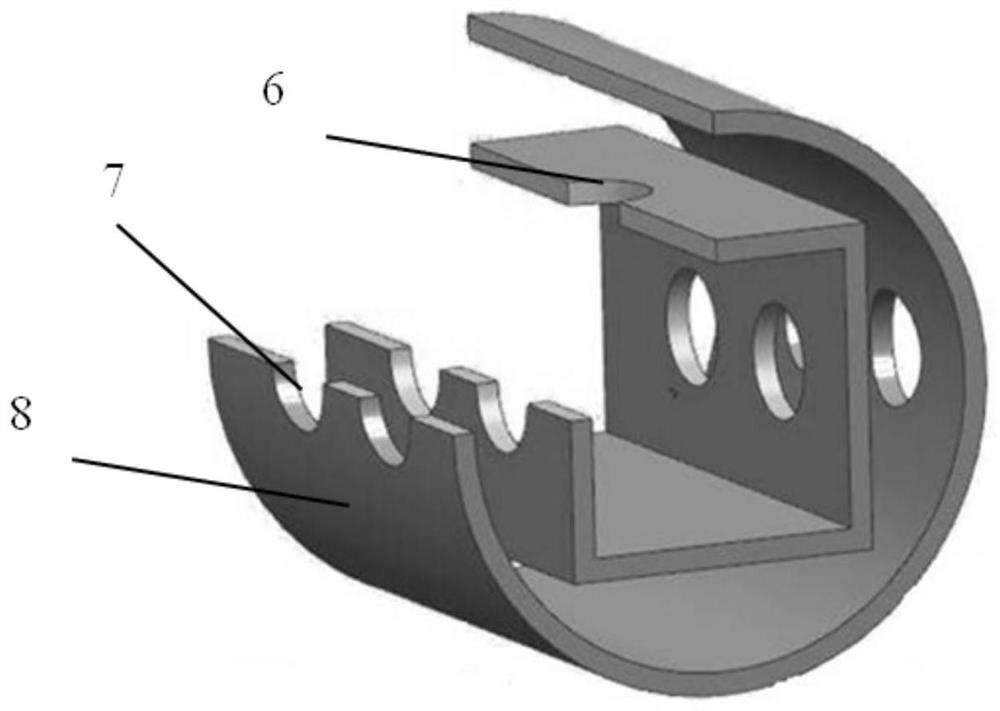

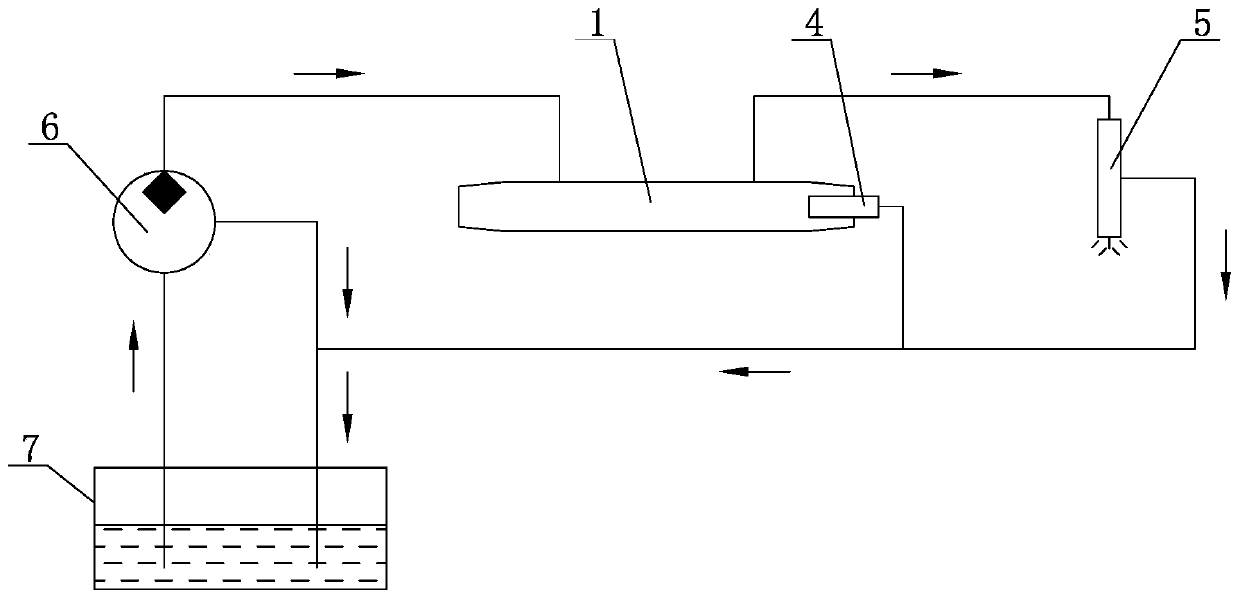

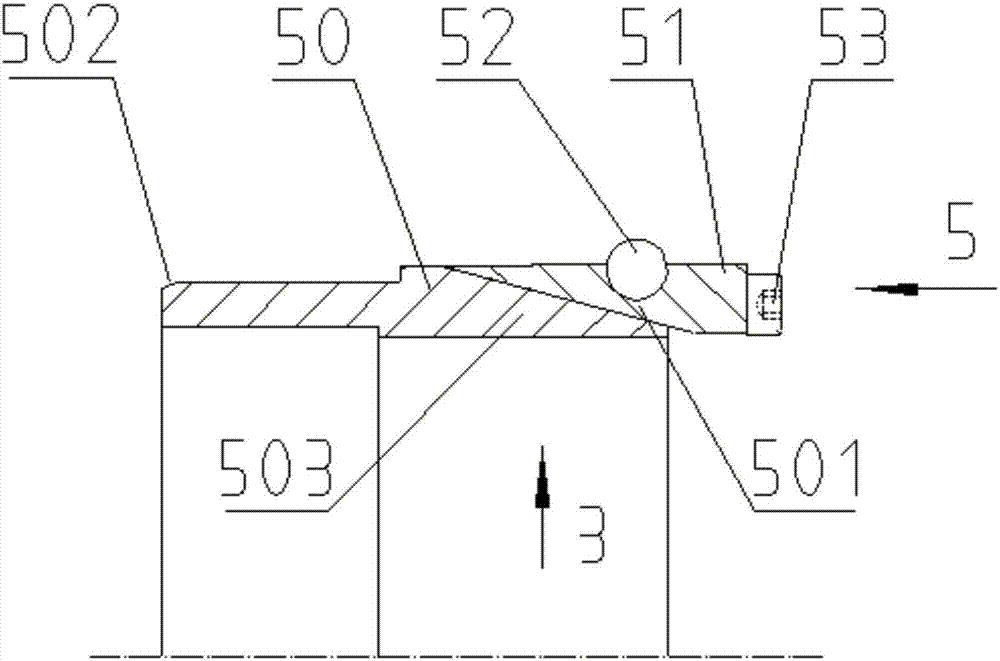

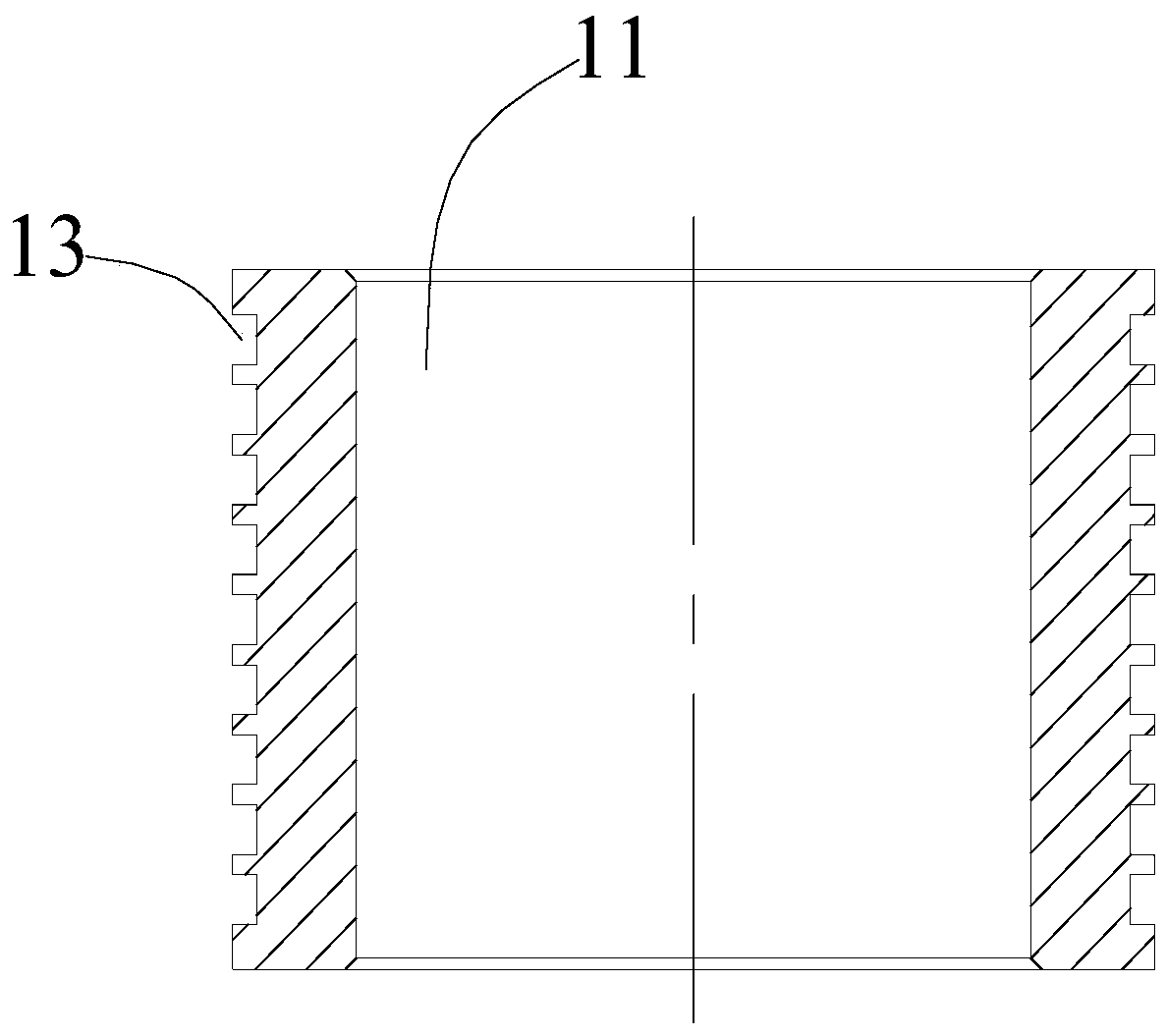

Slide vane compressor

ActiveCN105402125AStable back pressureReduce the cross-sectional areaRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsPetroleum engineering

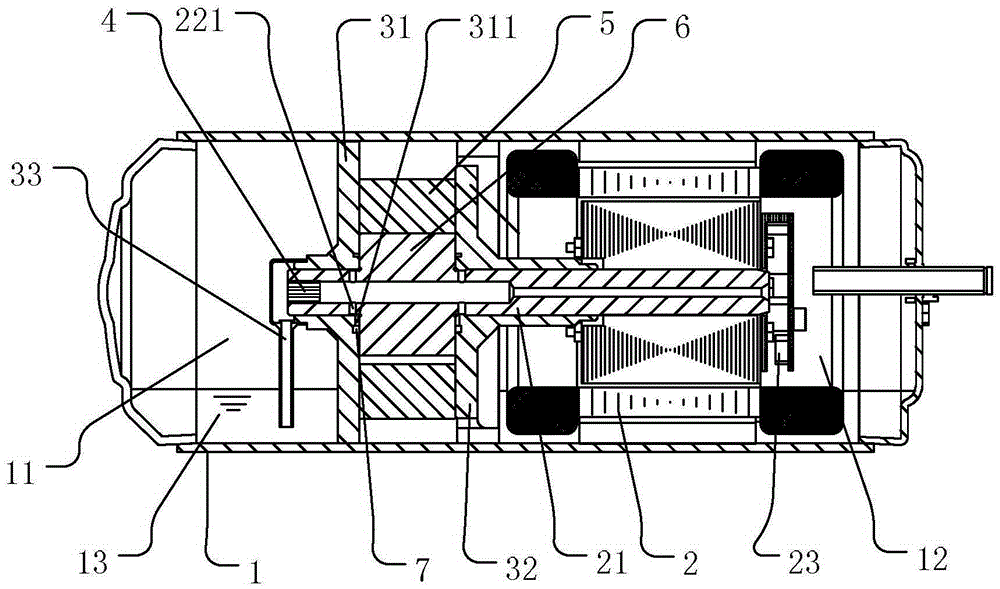

The invention aims at providing a slide vane compressor. The problem that backpressure oil supplying of an existing slide vane compressor is not stable is mainly solved. According to the technical scheme, negative pressure is generated in a main oil way in a spindle through a fan, and then an upper oil tube assembly is used for pumping oil from an oil pool; a backpressure oil tank is communicated with the main oil way, and the main oil way supplies pressure oil to the backpressure oil tank. Through the arrangement, oil supplying of the backpressure oil tank is more stable and reliable.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

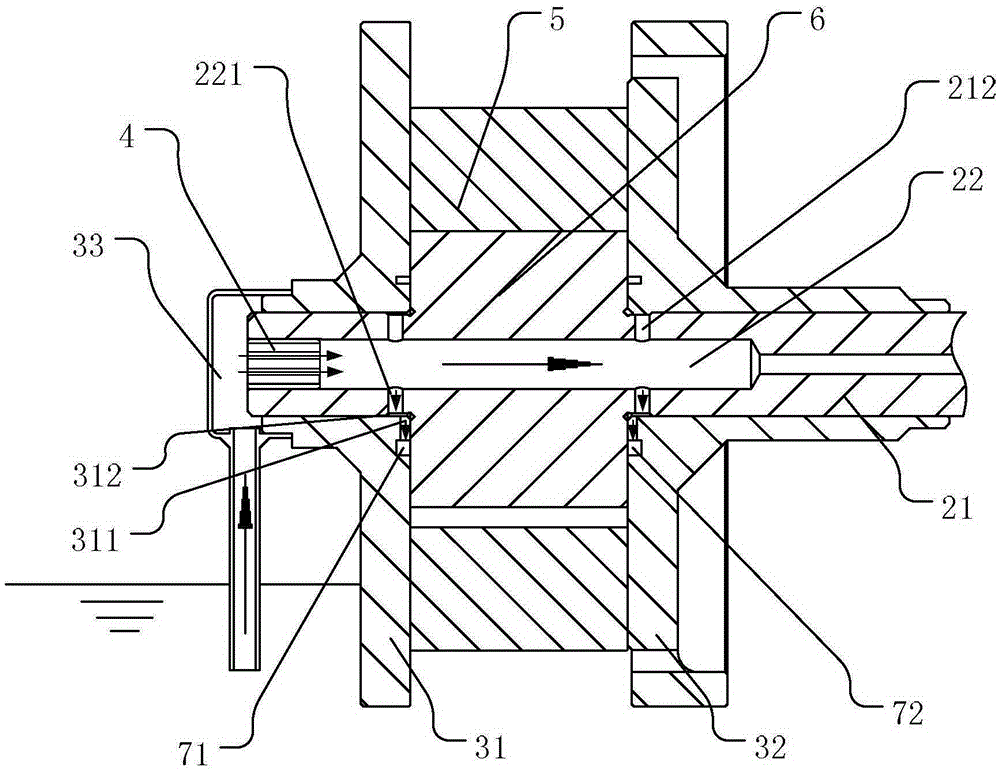

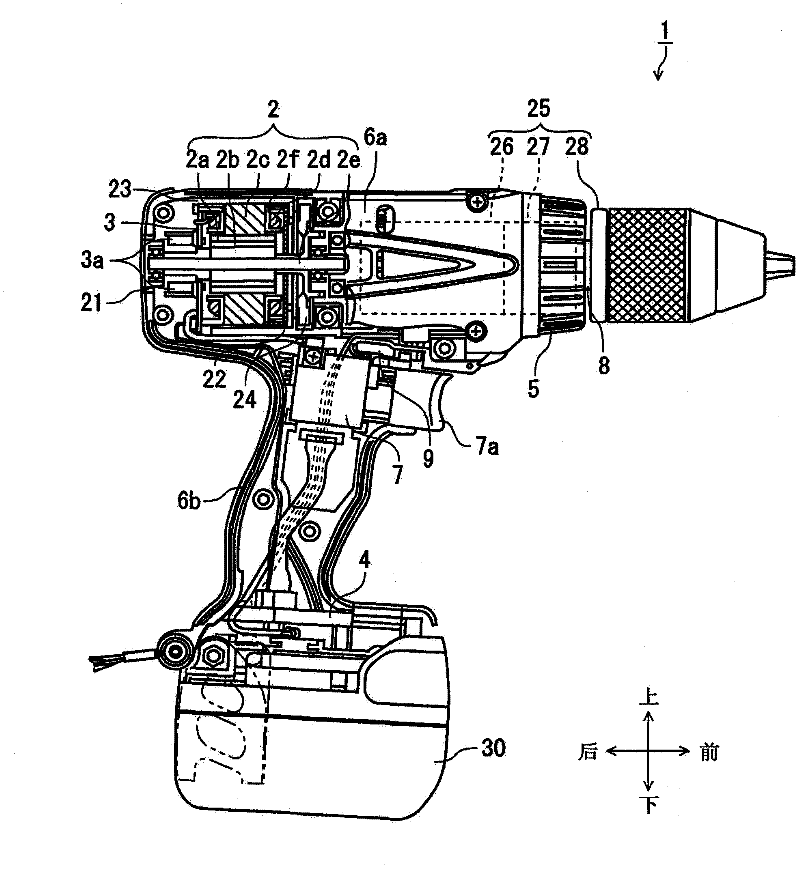

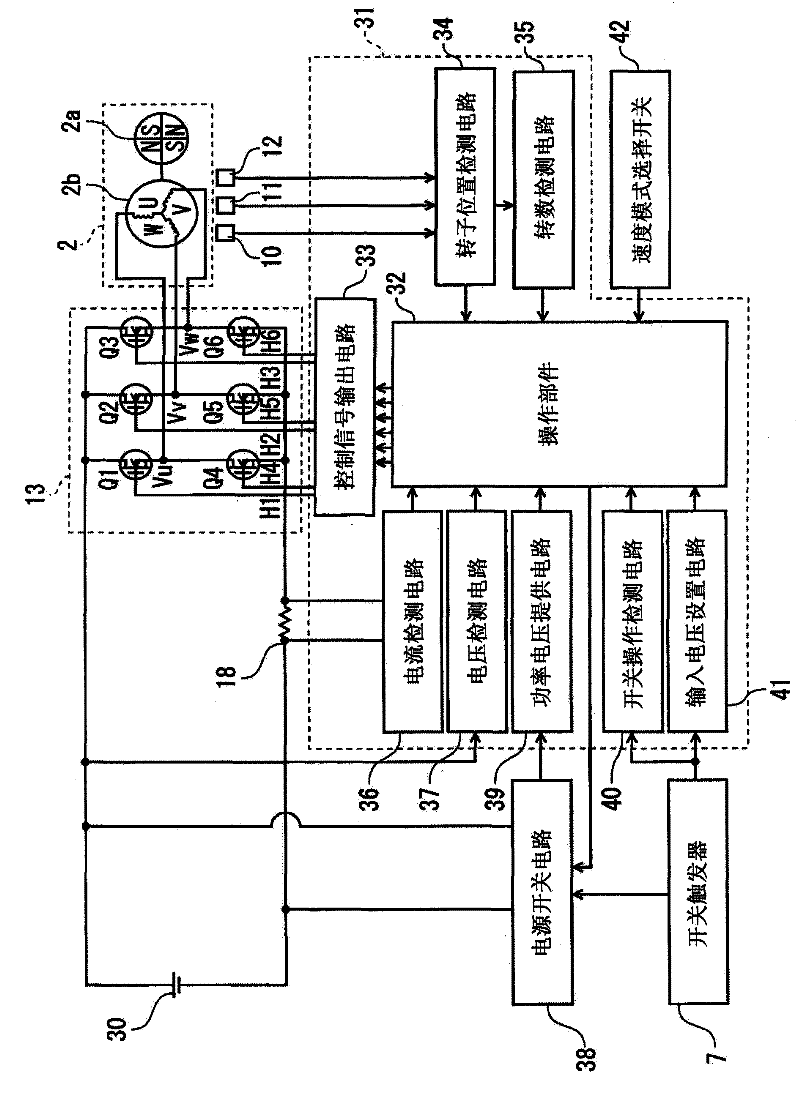

Power tool

InactiveCN102356540AChange target RPMGood target speedSingle motor speed/torque controlPortable power-driven toolsElectric power systemPower tool

According to an aspect of the present invention, there is provided a power tool including: a motor; a driving circuit that supplies an electric power from a power supply to the motor; a control part that sets a target rotation number for the motor in accordance with a mode selected from a plurality of modes, each mode having a corresponding target rotation number; and a voltage detecting circuit that detects a voltage of the power supply, wherein the target rotation number is varied based on the detected voltage.

Owner:KOKI HLDG CO LTD

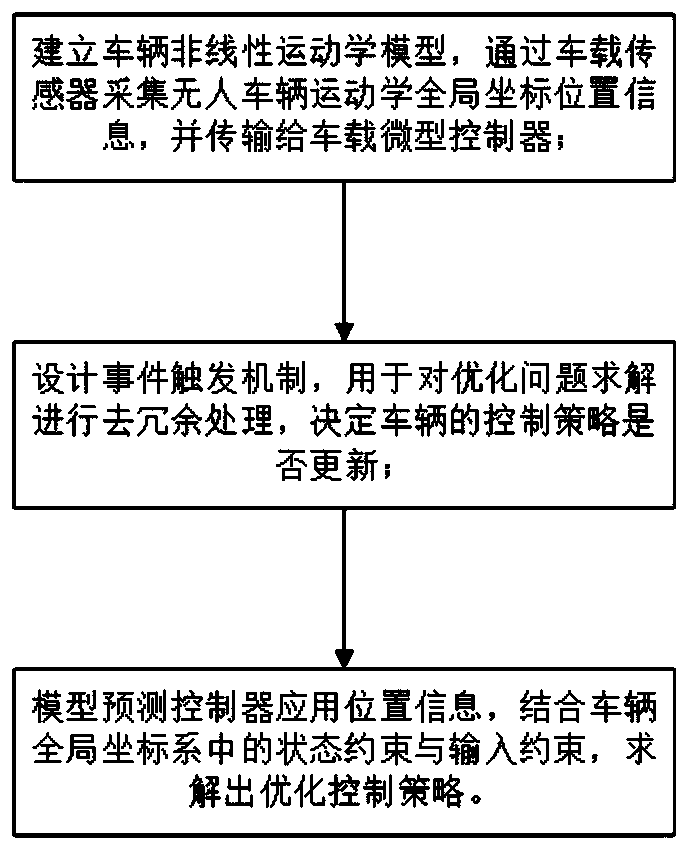

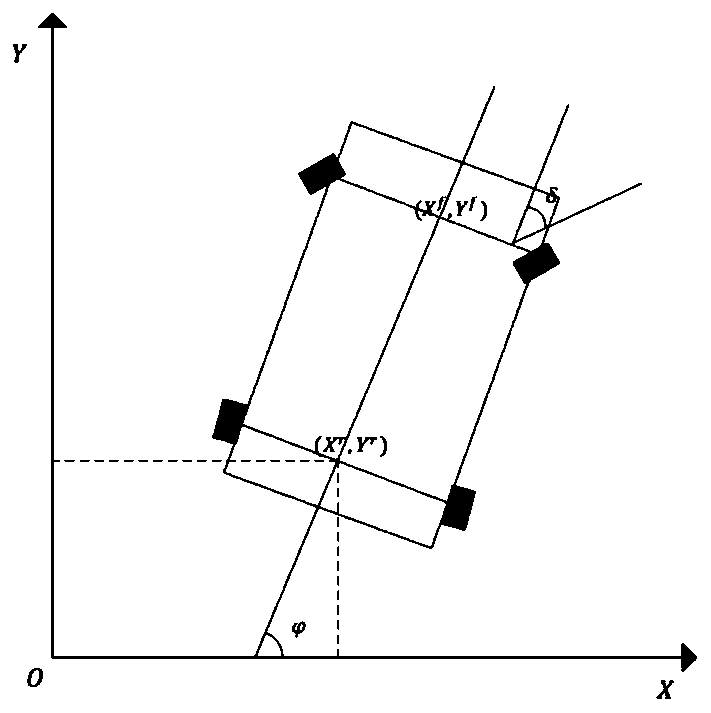

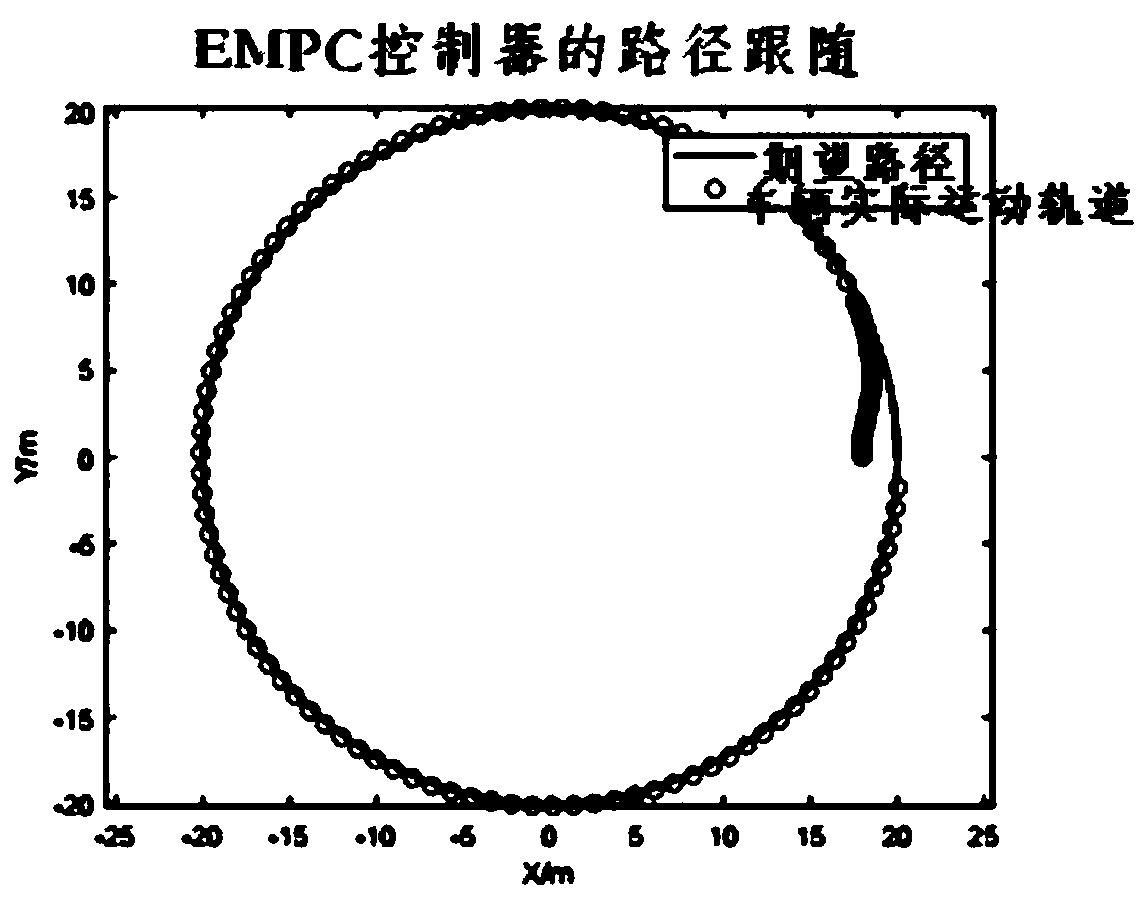

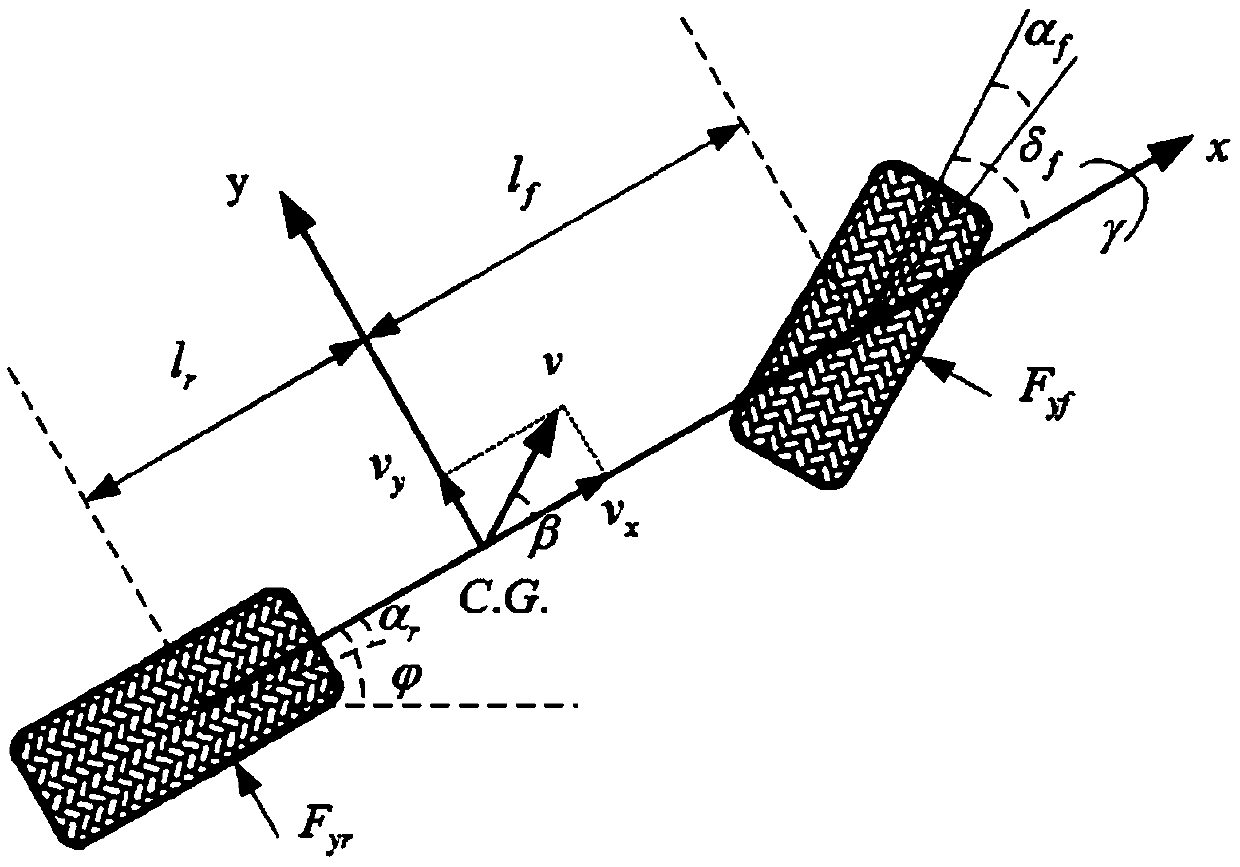

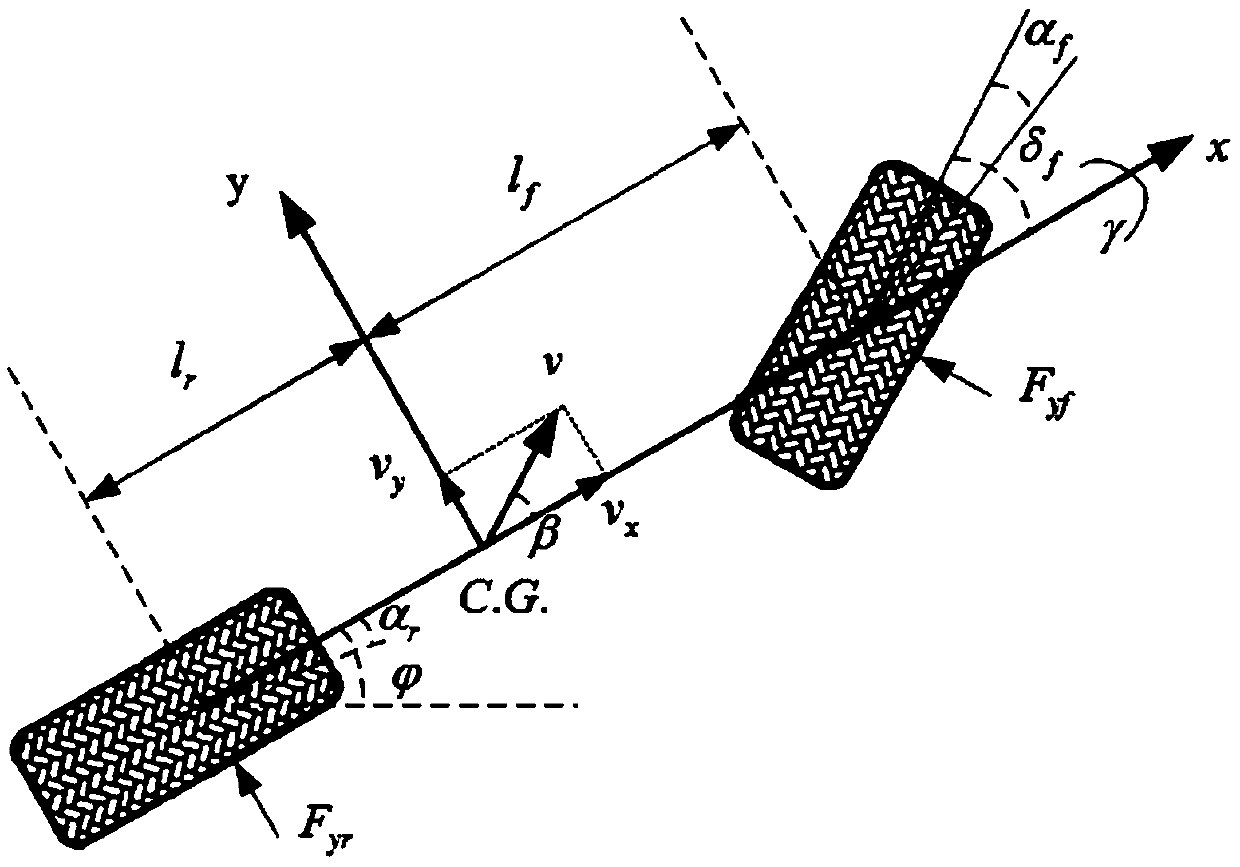

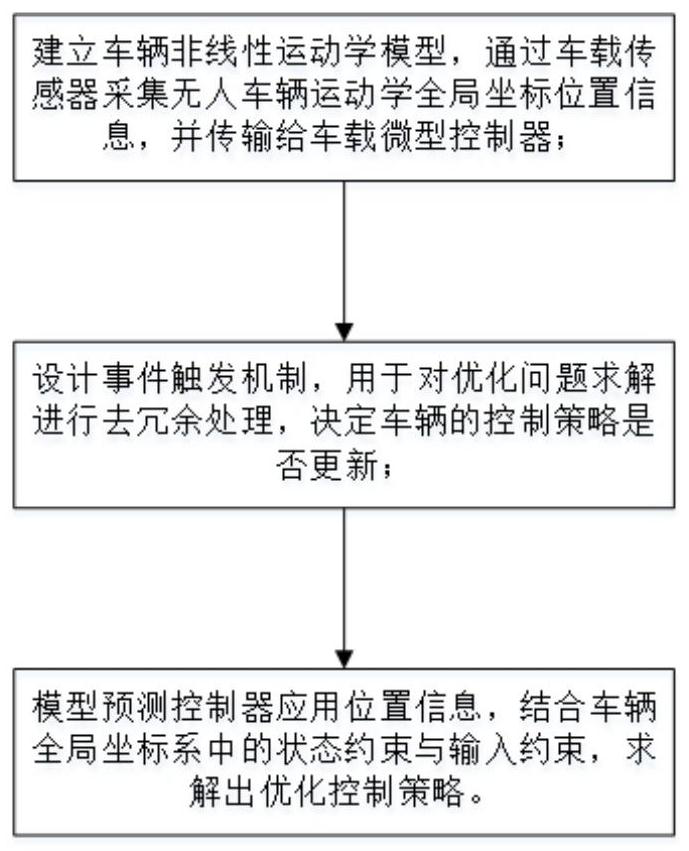

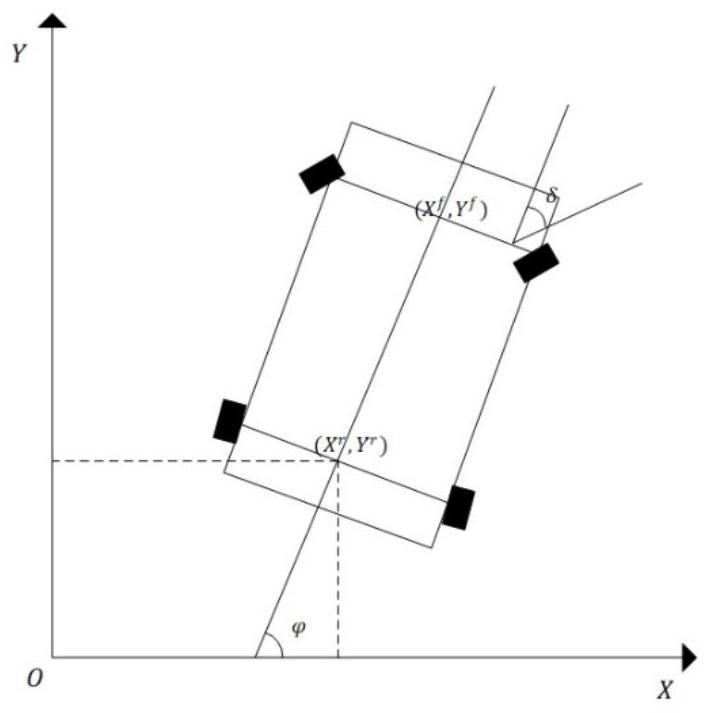

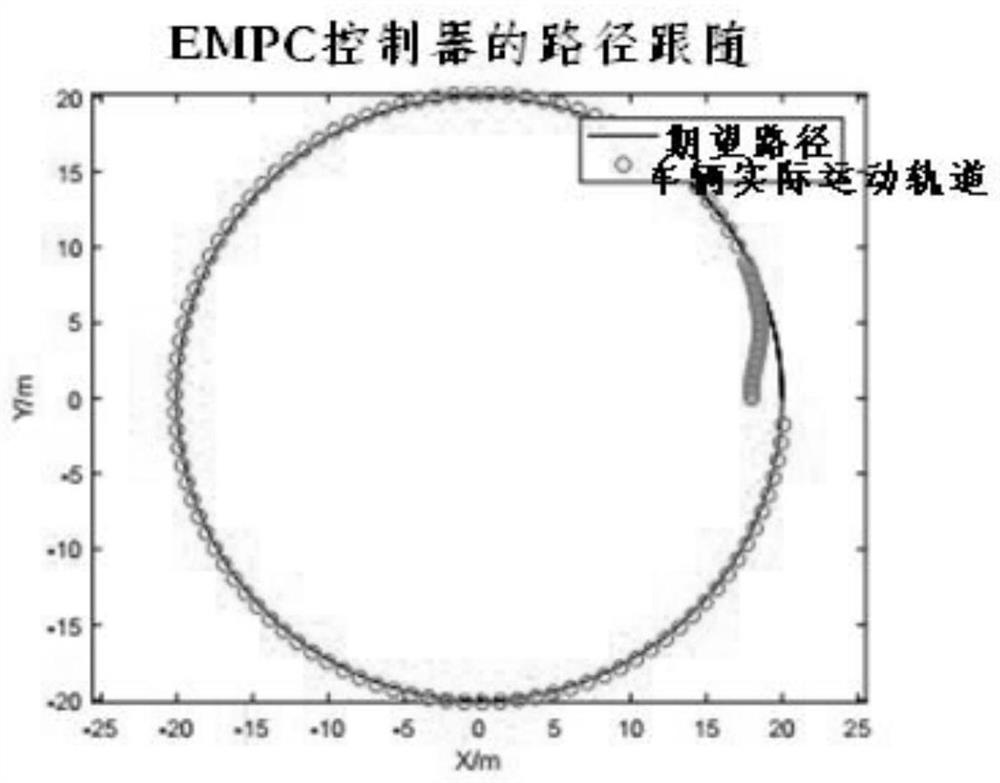

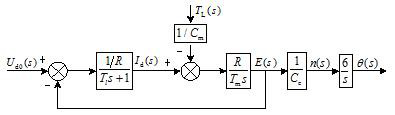

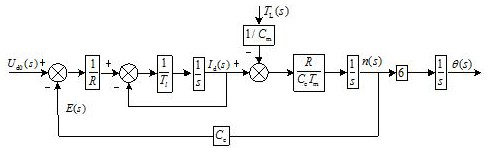

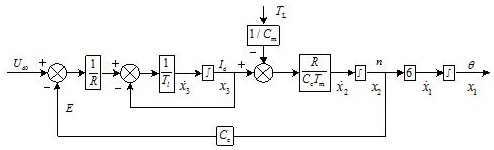

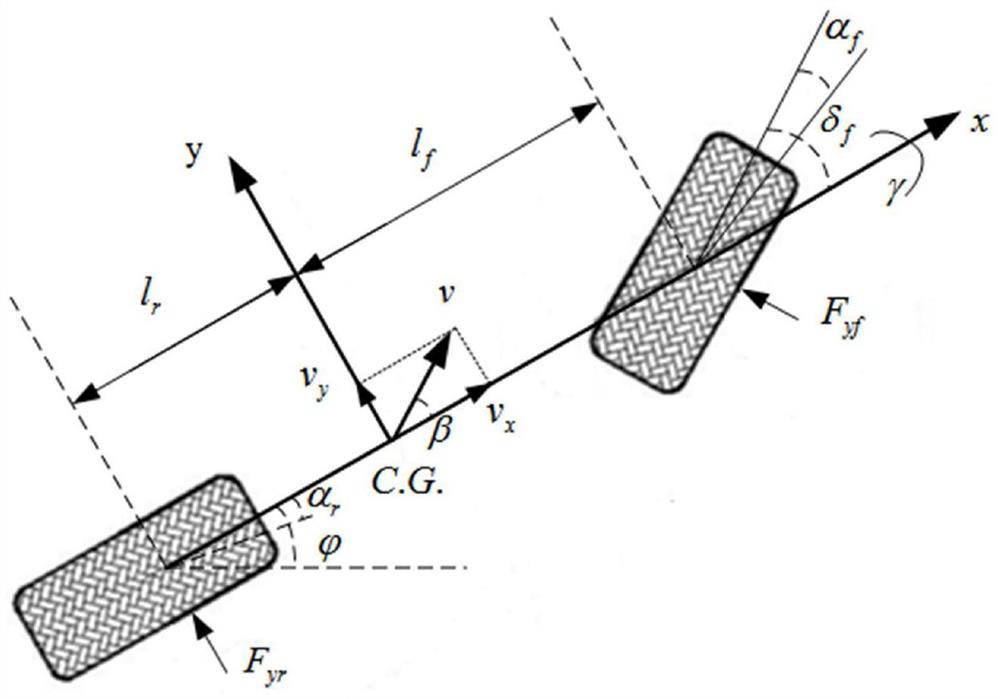

Unmanned vehicle path following method based on event-triggering model prediction control

ActiveCN110162046AGuaranteed to followRealize following controlPosition/course control in two dimensionsVehiclesKinematicsNonlinear motion

The invention relates to an unmanned vehicle path following method based on event-triggering model prediction control. The method comprises the steps that a nonlinear kinematic model of a vehicle is established; unmanned vehicle kinematic global coordinate position information is collected and transmitted to a controller of the vehicle; an event triggering mechanism is designed, an optimization problem is solved to perform redundancy elimination processing, and whether a control strategy of the vehicle is updated or not is decided; and a model prediction controller solves an optimal control strategy by use of the position information in combination with state constraint and input constraint in a vehicle global coordinate system. According to the method, the event triggering mechanism is introduced, and it can be guaranteed that following to a reference path is guaranteed while the calculation amount is reduced; and compared with traditional periodical sampling control, an action is done only at the occurring moment of a determined event, for example, an error exceeds a threshold or a specific moment is reached, according to the event triggering mechanism, path following control isrealized, and meanwhile the calculation amount is greatly reduced.

Owner:TONGJI ARTIFICIAL INTELLIGENCE RES INST SUZHOU CO LTD

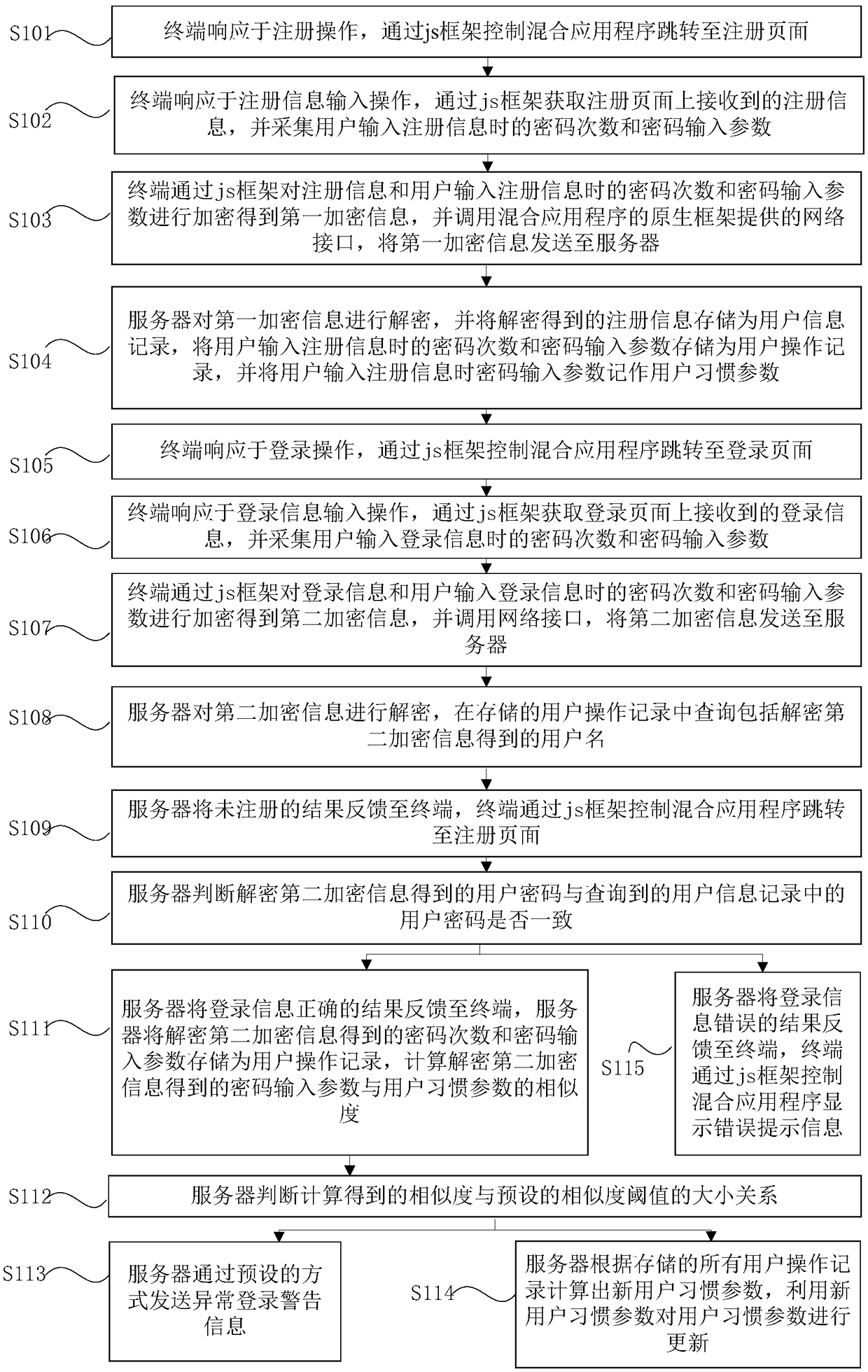

Registering and logging method and system of hybrid application, and computer equipment

The invention provides a registering and logging method and a registering and logging system of a hybrid application (app), and computer equipment. An original framework of the hybrid application program provides a basic interface method, the logging of a registration page and jumping logic are completely implemented and controlled by means of a js framework, a password input parameter of a user password input each time is encrypted to a server, the server calculates a user habit parameter, the server prompts if the similarity between the a password input parameter of the user password inputby a user once and the user habit parameter is low, thus the security of the hybrid app is improved, the user habit parameter is updated timely if the similarity between the a password input parameterof the user password input by the user once and the user habit parameter is high, thereby ensuring that the user habit parameter follows user habits dynamically.

Owner:PING AN TECH (SHENZHEN) CO LTD

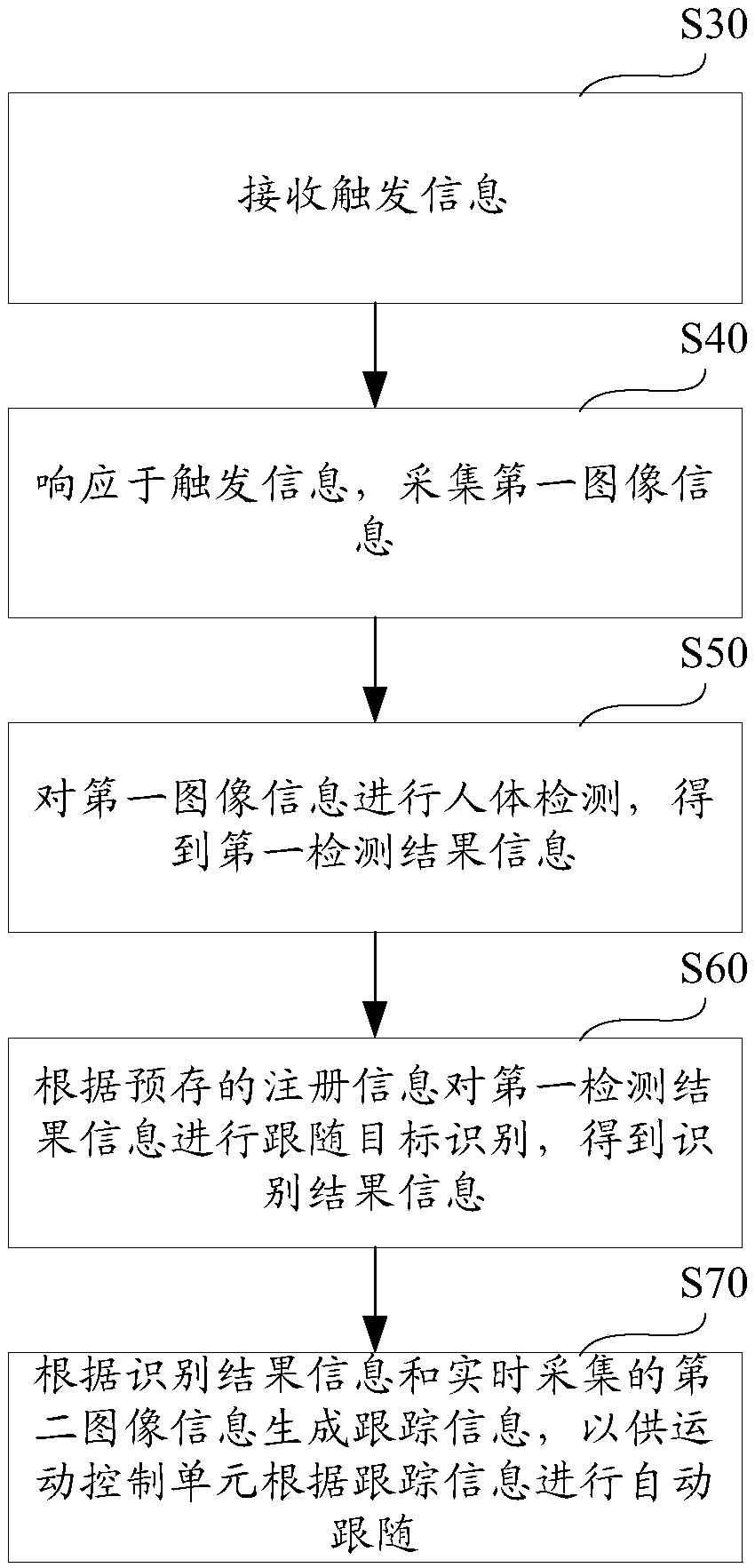

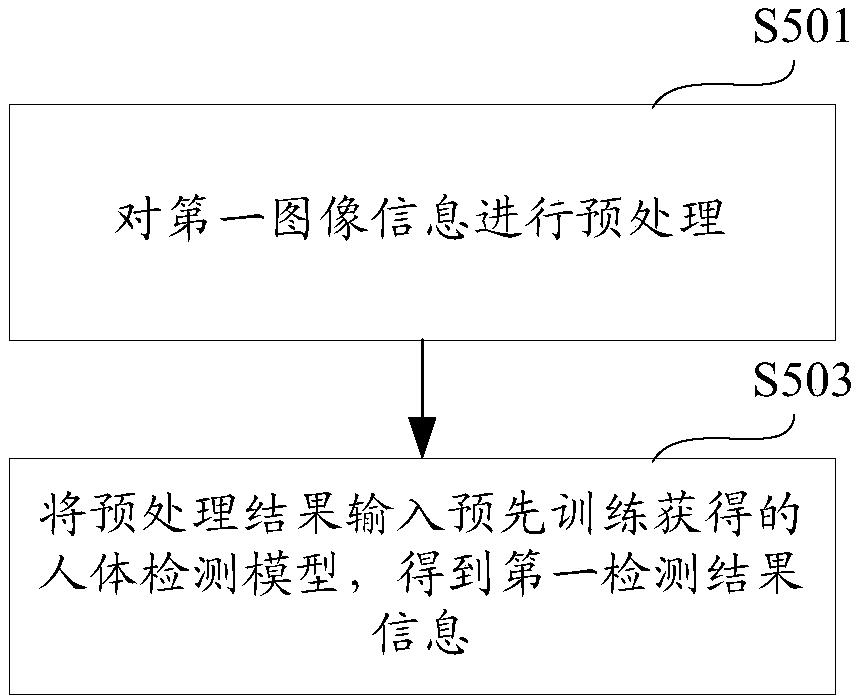

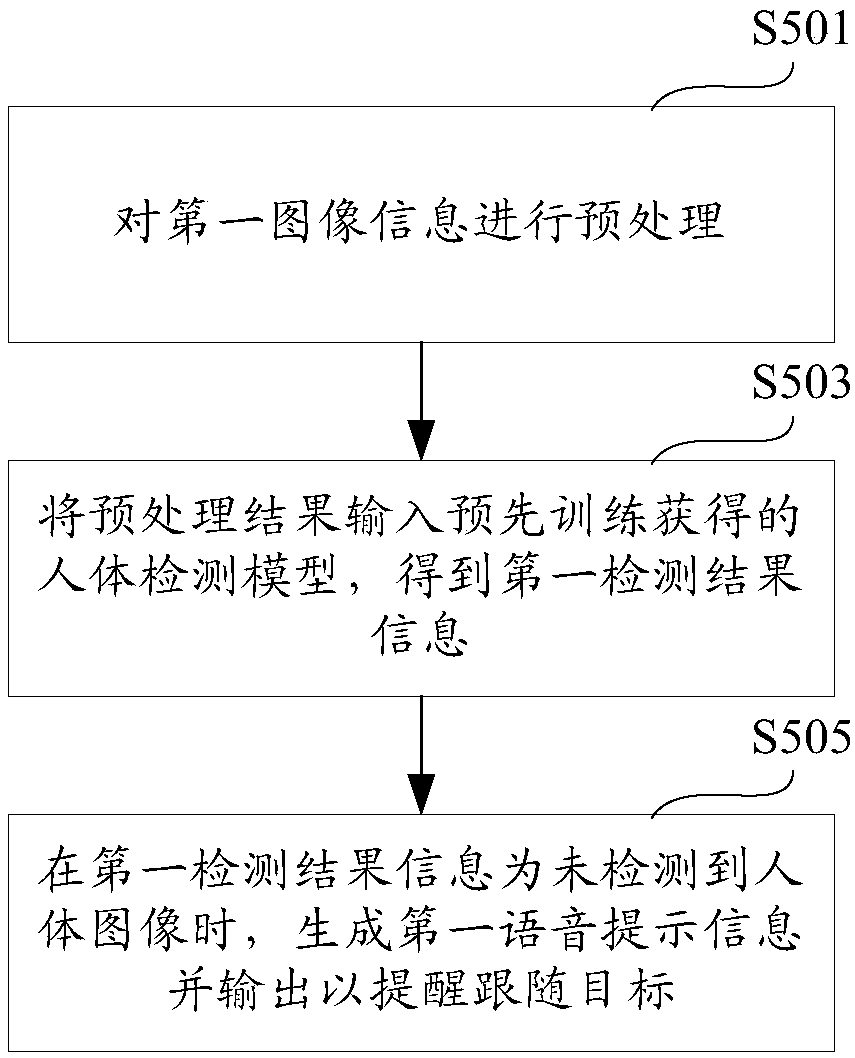

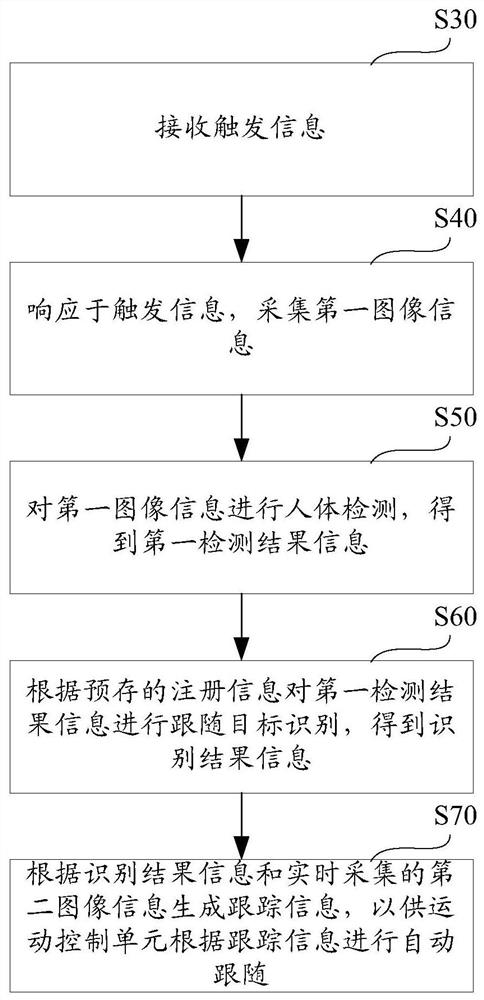

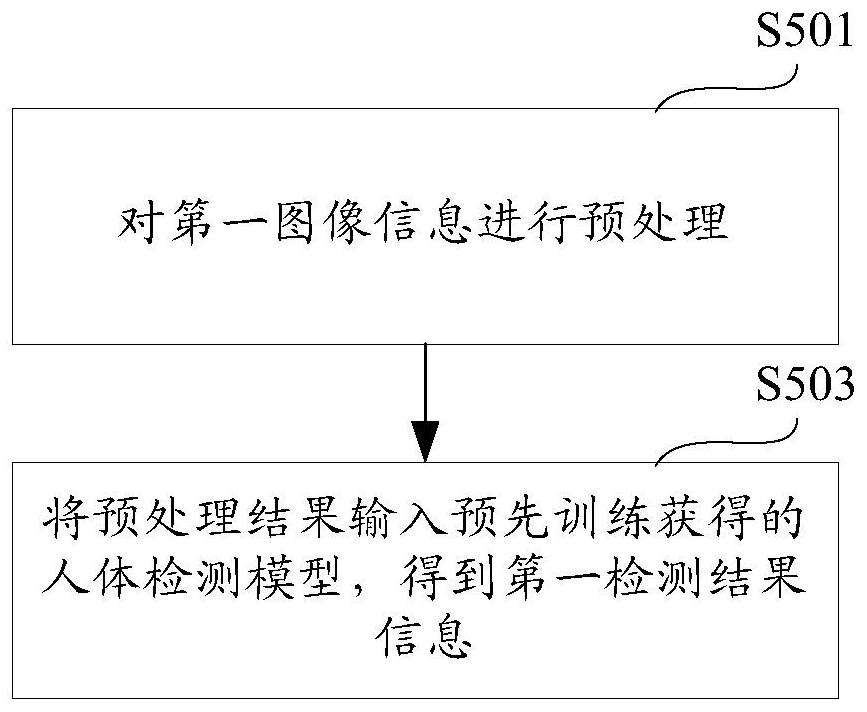

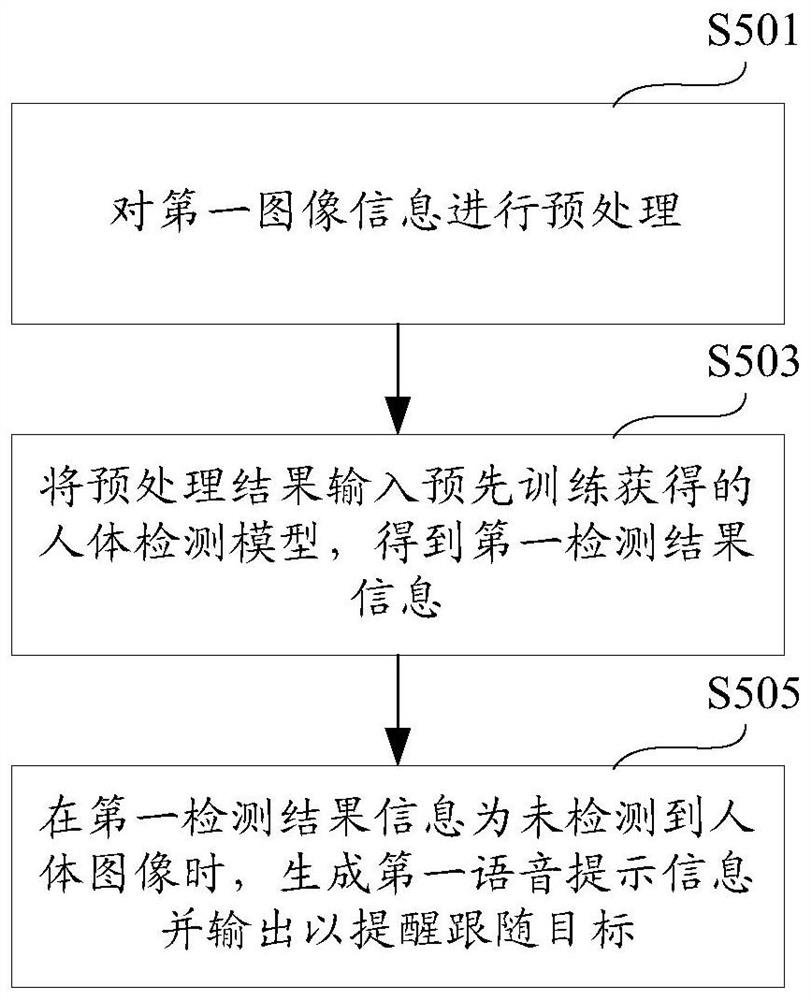

Autonomous following method and device of specific person, robot, equipment and storage medium

ActiveCN108724178ASelf-followingFollow the continuationProgramme-controlled manipulatorBiometric pattern recognitionPattern recognitionComputer vision

The invention provides an autonomous following method and a device of a specific person, a robot, equipment and a storage medium. The method comprises the steps of receiving triggering information; responding to the triggering information, and collecting first image information; performing human detection on the first image information so as to obtain first detection result information; performingfollowing target identification on the first detection result information according to prestored registration information so as to obtain identification result information; and generating tracking information according to the identification result information and second image information which is collected in real time, so that automatic following is performed by a motion control unit according to the tracking information. According to the autonomous following method, the human detection is performed on a collected image, the target identification is performed according to the registration information, then the tracking information is generated according to identification results and the real-time image information, and a specific target can be automatically followed without continuous human face collection in the whole following process, so that the specific target is automatically followed accurately and conveniently.

Owner:SF TECH

A sliding vane compressor

ActiveCN105402125BStable back pressureReduce the cross-sectional areaRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsOil tank

The invention aims at providing a slide vane compressor. The problem that backpressure oil supplying of an existing slide vane compressor is not stable is mainly solved. According to the technical scheme, negative pressure is generated in a main oil way in a spindle through a fan, and then an upper oil tube assembly is used for pumping oil from an oil pool; a backpressure oil tank is communicated with the main oil way, and the main oil way supplies pressure oil to the backpressure oil tank. Through the arrangement, oil supplying of the backpressure oil tank is more stable and reliable.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

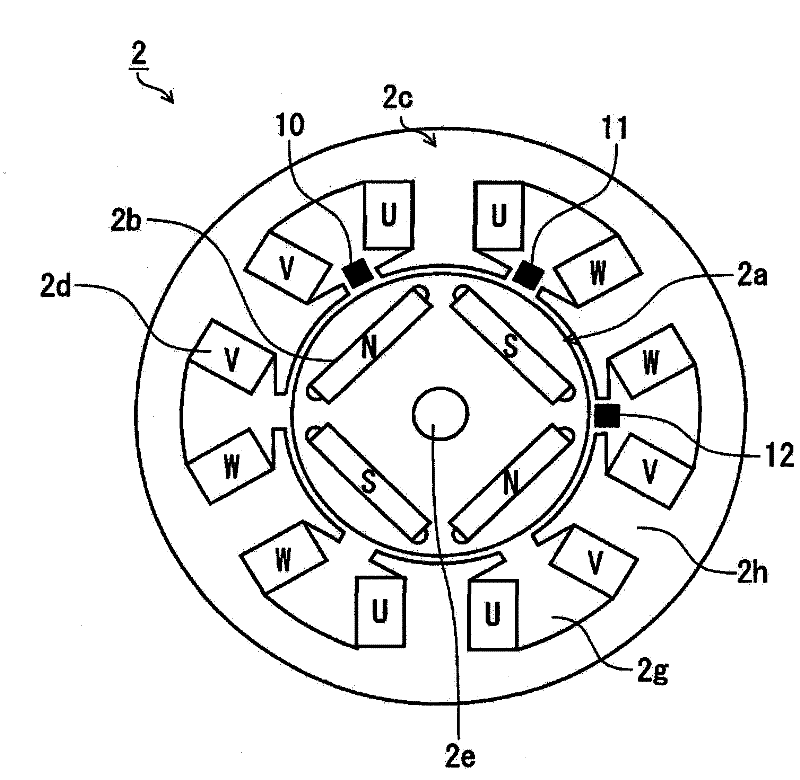

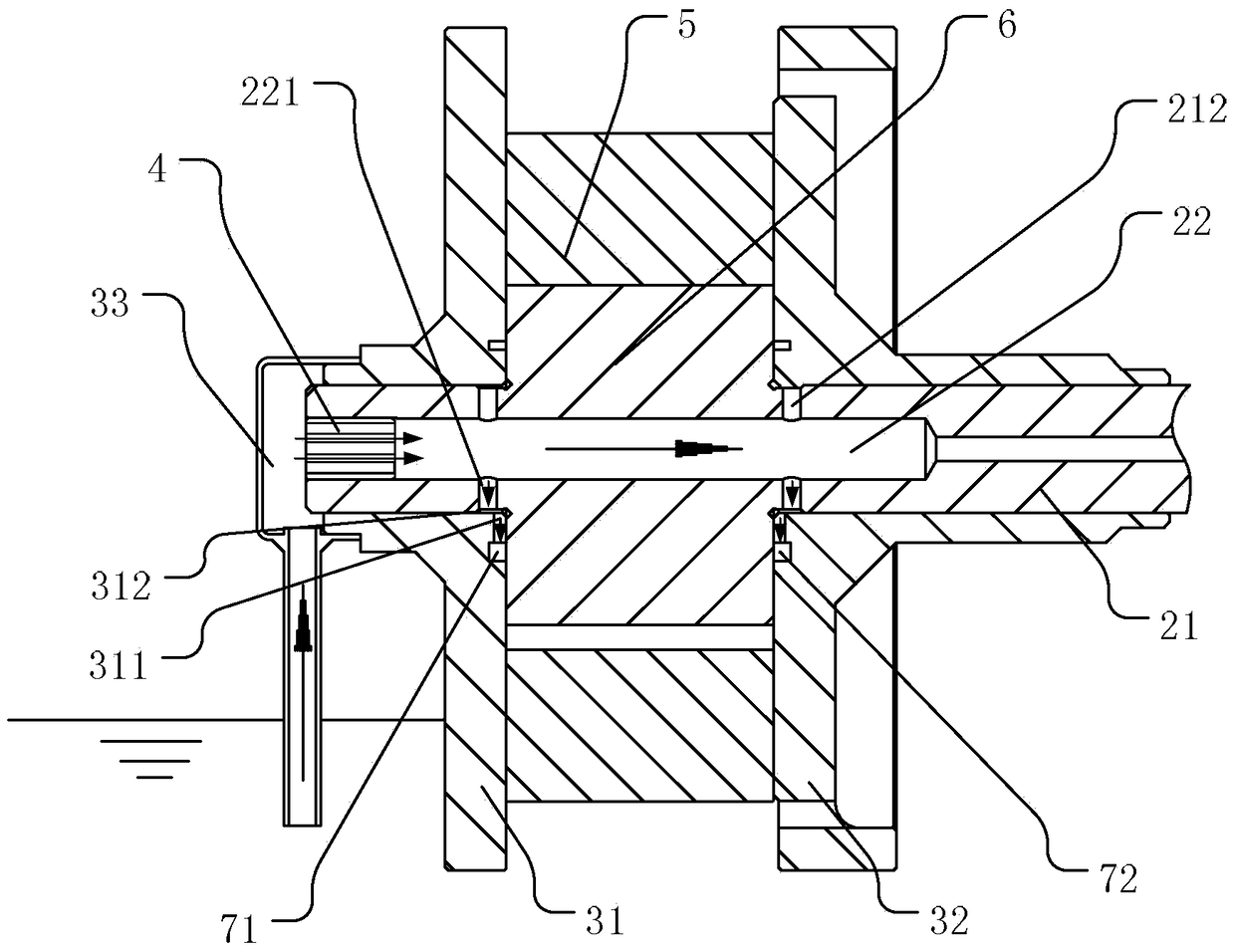

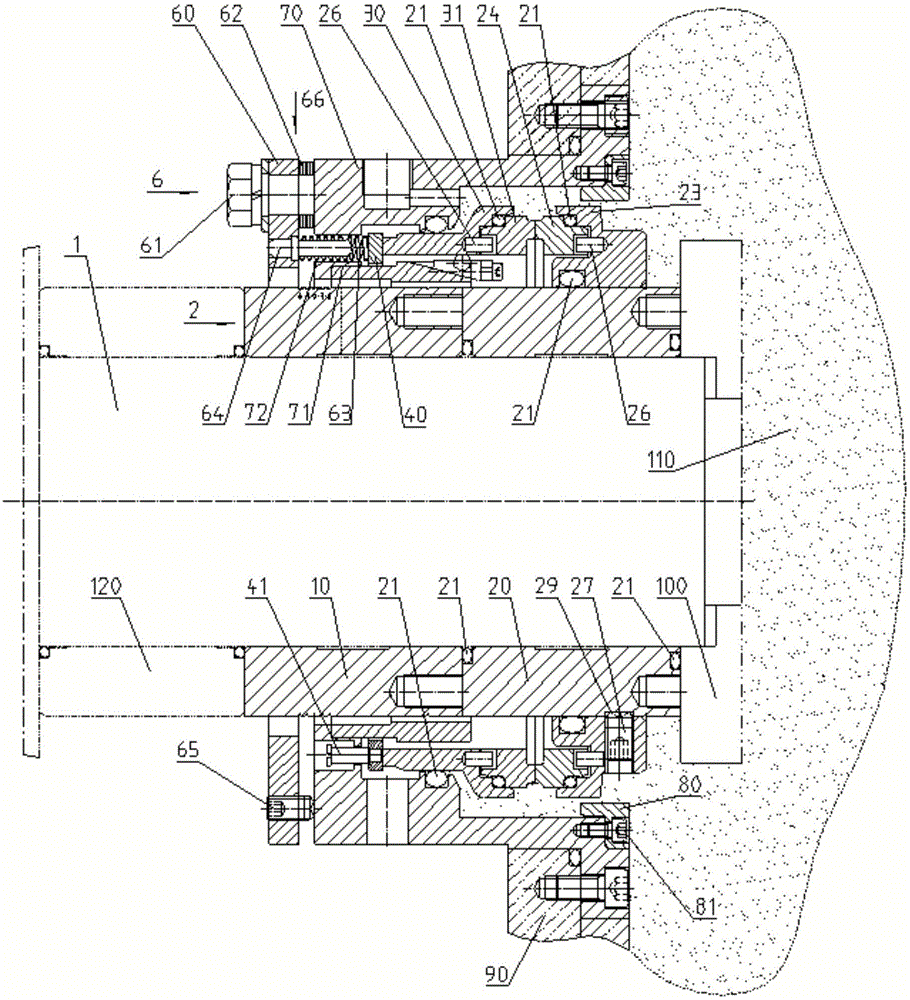

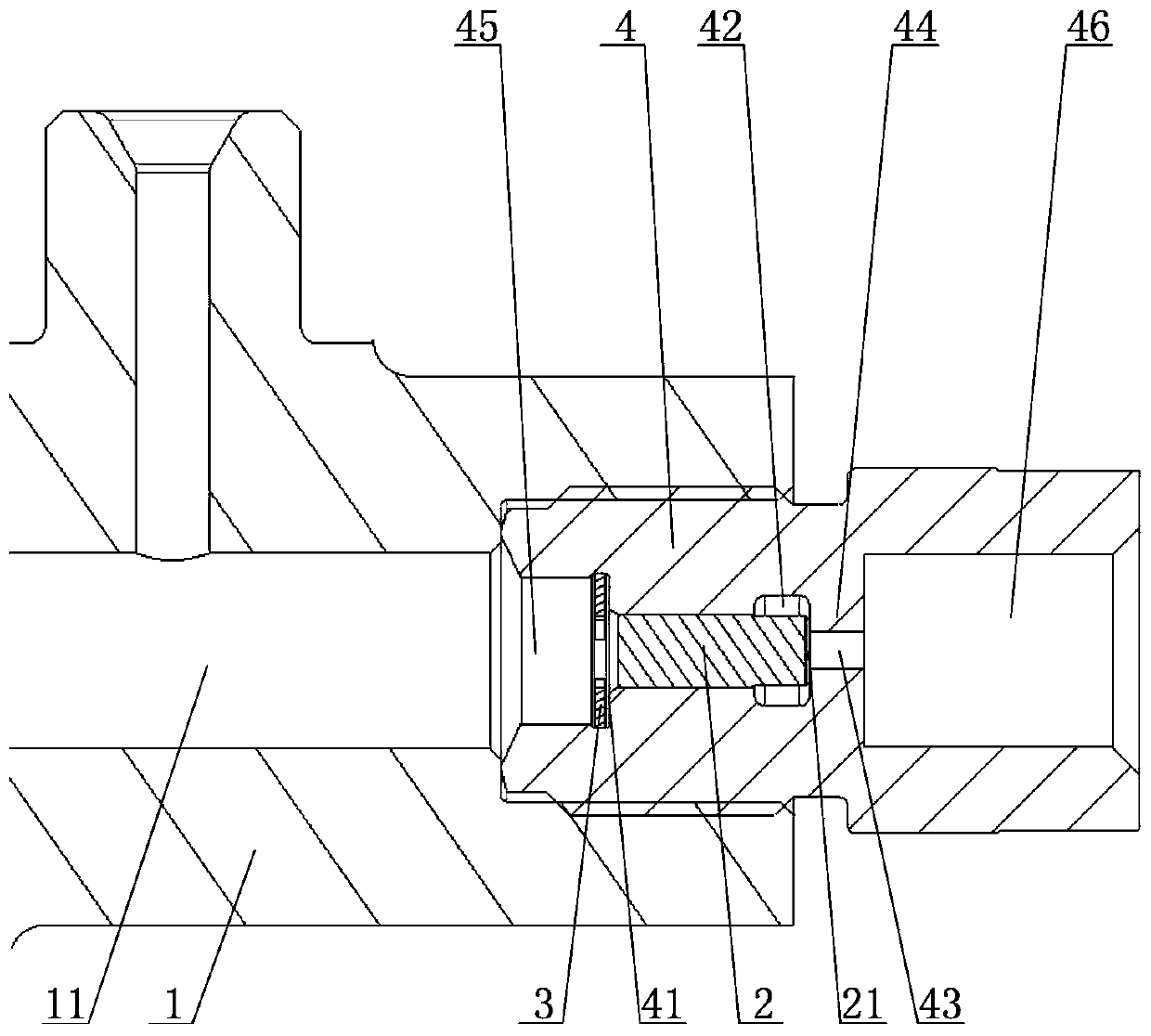

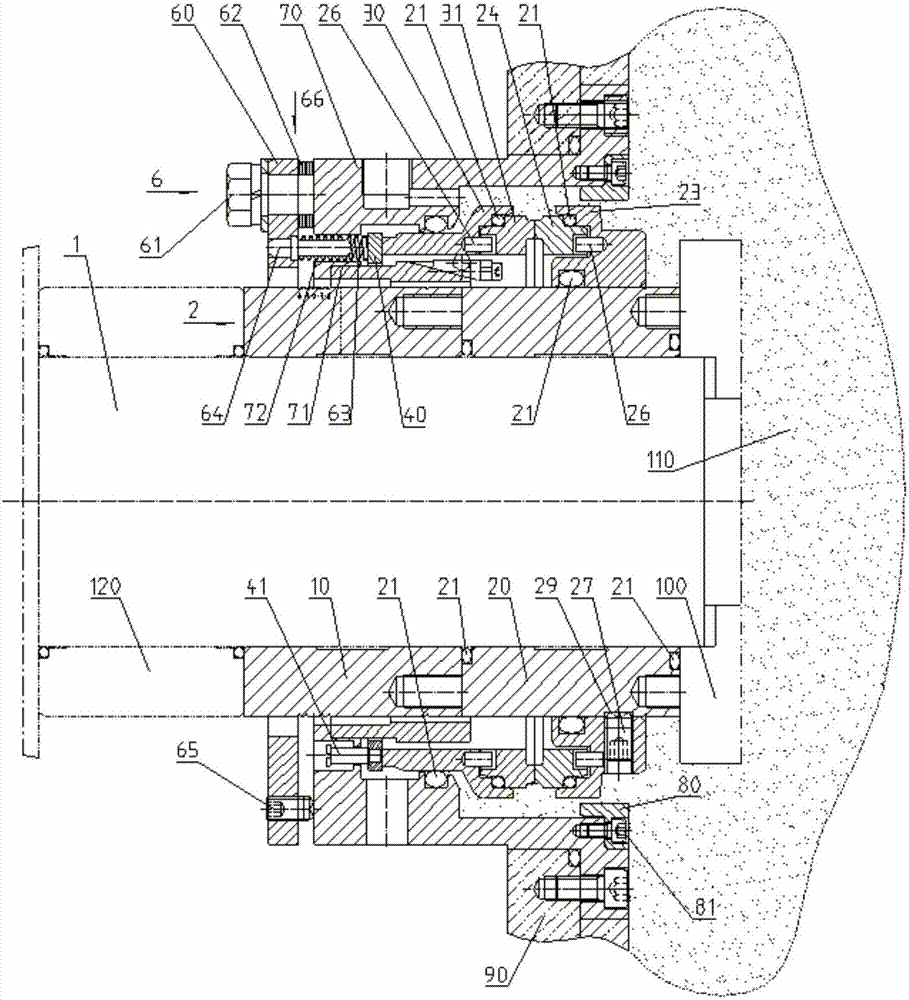

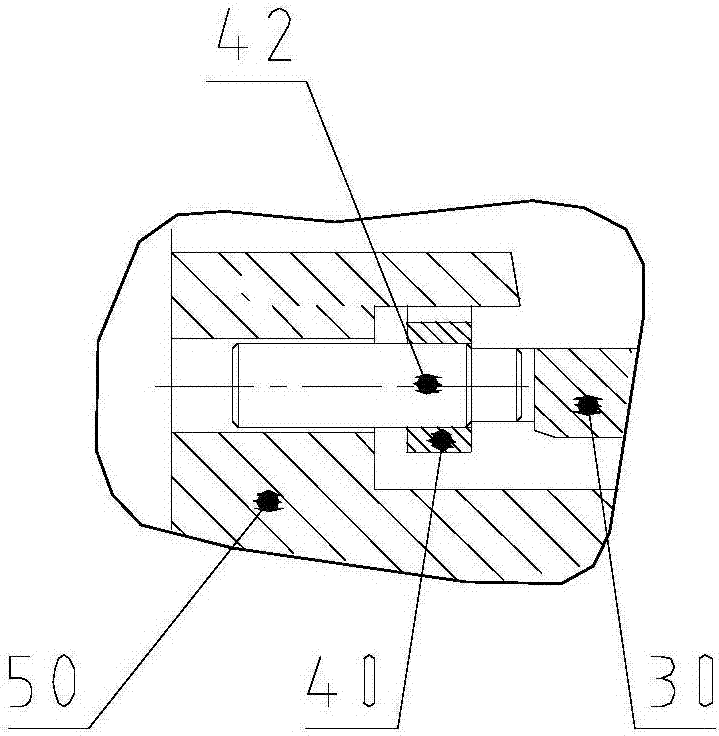

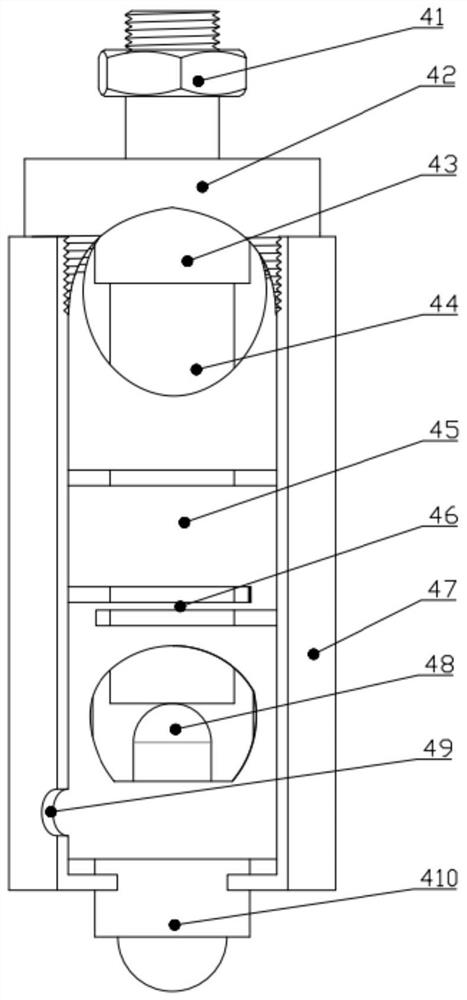

Mechanical sealing device with axial adjusting function for large-sized dredger sludge pump

ActiveCN106351847AFree to adjust the lengthFree replacementSpecific fluid pumpsPump componentsSludgeEngineering

The invention relates to a mechanical sealing device with an axial adjusting function for a large-sized dredger sludge pump. The mechanical sealing device comprises a seal tank connected with the sludge pump in a sealed mode, as well as a moving ring seat provided with a moving ring and a static ring seat provided with a static ring in the seal tank, wherein a push ring is arranged between the static ring seat and the seal tank; the moving ring seat is in fastened connection with a shaft sleeve via a fastening bolt, and rotates together with a pump shaft; an external adjustable static ring axial compensation mechanism is arranged on the outer end face of the seal tank; the external adjustable static ring axial compensation mechanism comprises a gland arranged at the outer end of the seal tank, and the gland is connected with the outer end face of the seal tank; an adjusting gasket is arranged between the gland and the outer end face of the seal tank; and static ring compensation assemblies are uniformly distributed in the circumferential direction of the outer end face of the seal tank. The mechanical sealing device is used for solving split and integrated mechanical sealing; and the working height of a spring is not changed with the adjustment of a pump body in installation and use processes, and the damaged spring element can be replaced timely without detaching equipment, so that the performance stability and reliability of user equipment are guaranteed, and the service life of the sealing device is prolonged.

Owner:天津市合润科技有限责任公司

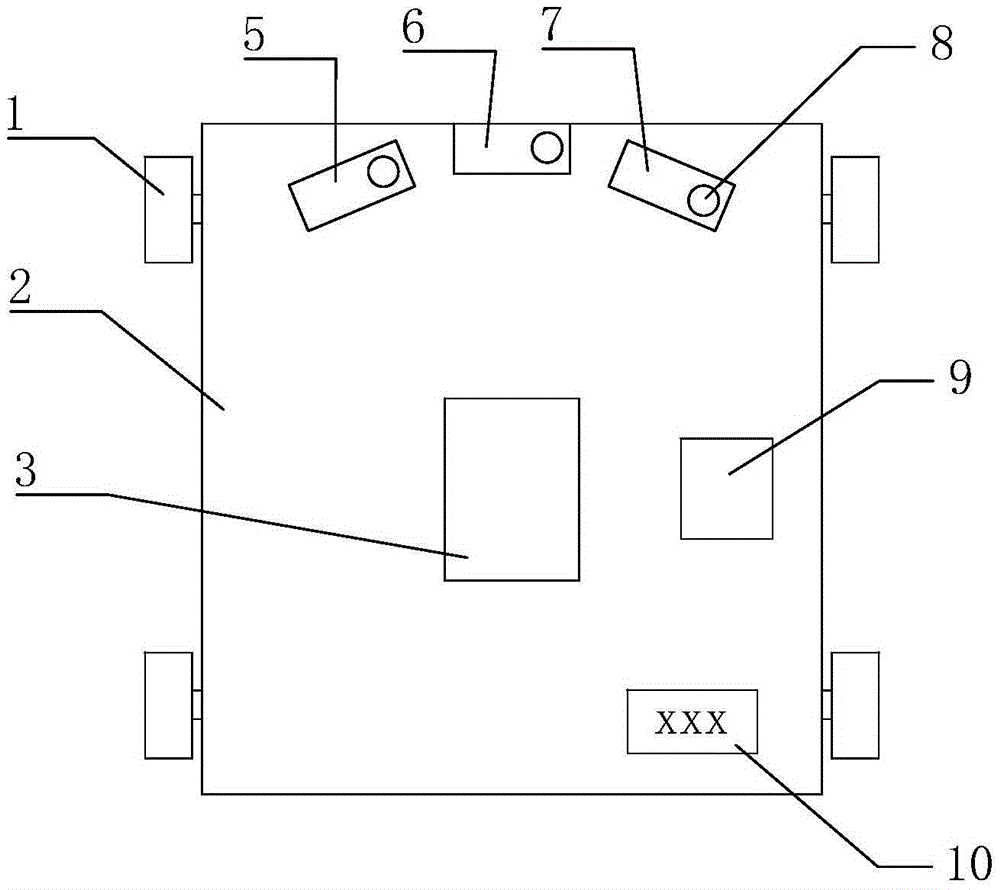

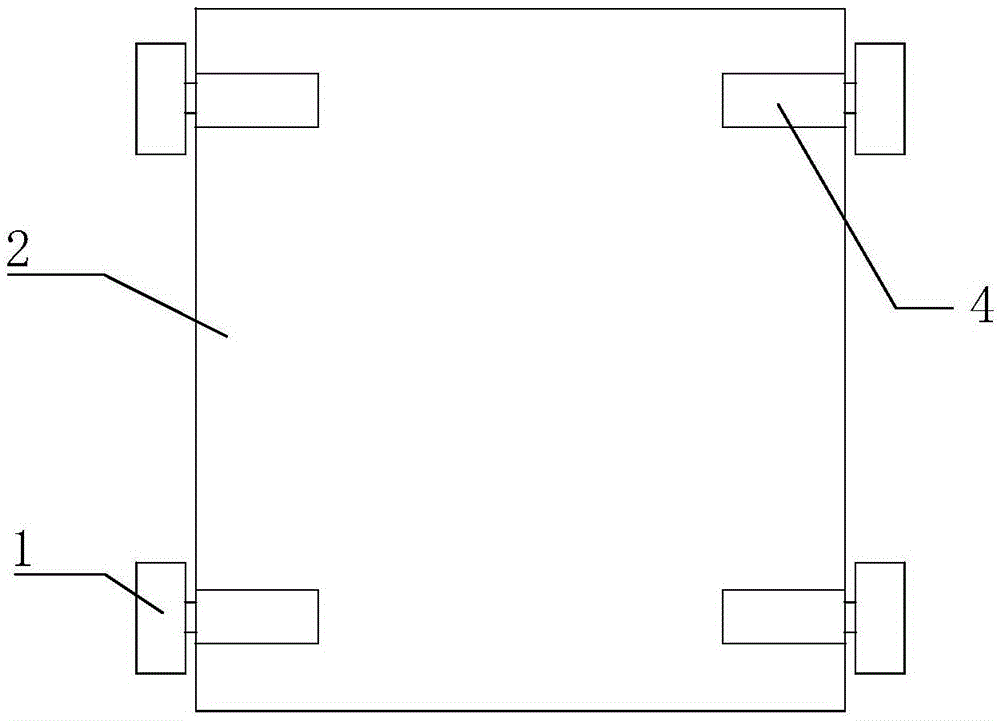

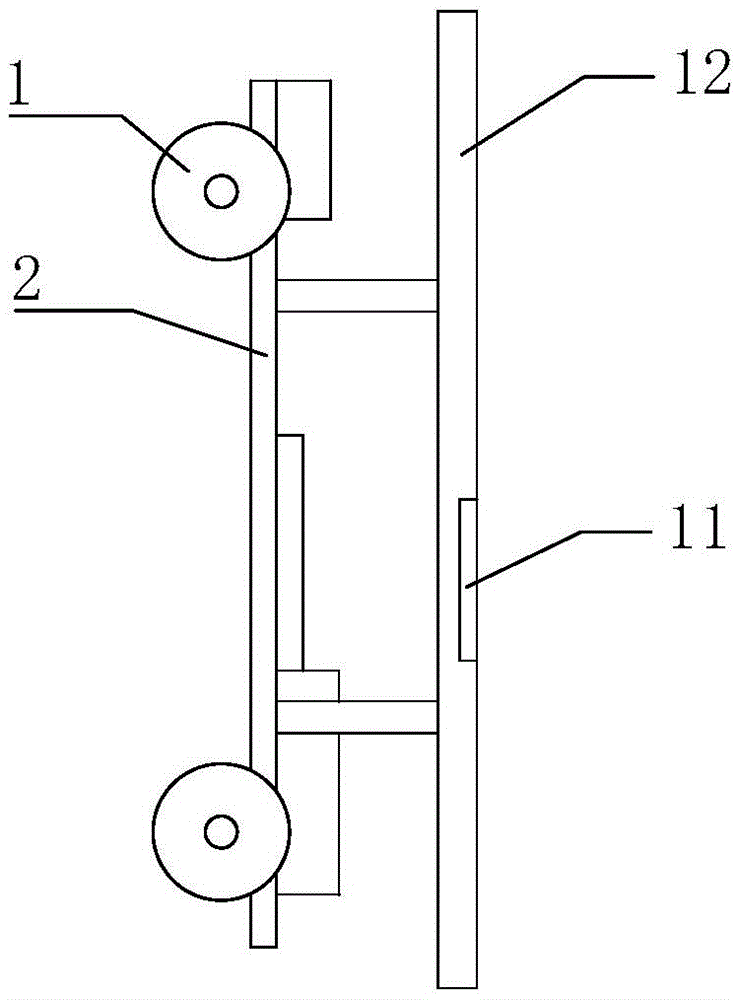

Loading following trolley

InactiveCN105629998AGuaranteed to followAvoid lossTransmission systemsTarget-seeking controlRemote controlDisplay device

The invention relates to an automatically-operating loading trolley, and particularly relates to a loading following trolley, which comprises a trolley body. The upper part of the trolley body is provided with a loading platform; the bottom part of the trolley body is provided with wheels; the trolley body is provided with a control module, sensor modules, a power module, a power supply module and a display; and the control module is respectively connected with the sensor modules, the power module, the power supply module and the display via lines. The loading following trolley has tracking, loading and remote control functions, warning is given when tracking fails, in combination with the functions, a heavy object can be placed on the trolley, the trolley can follow the person to move, and load of travelling is greatly lessened; and by using the remote control function, the heavy object can be remotely controlled to be transported to a designated place, and carrying by the user is not needed.

Owner:田君泽

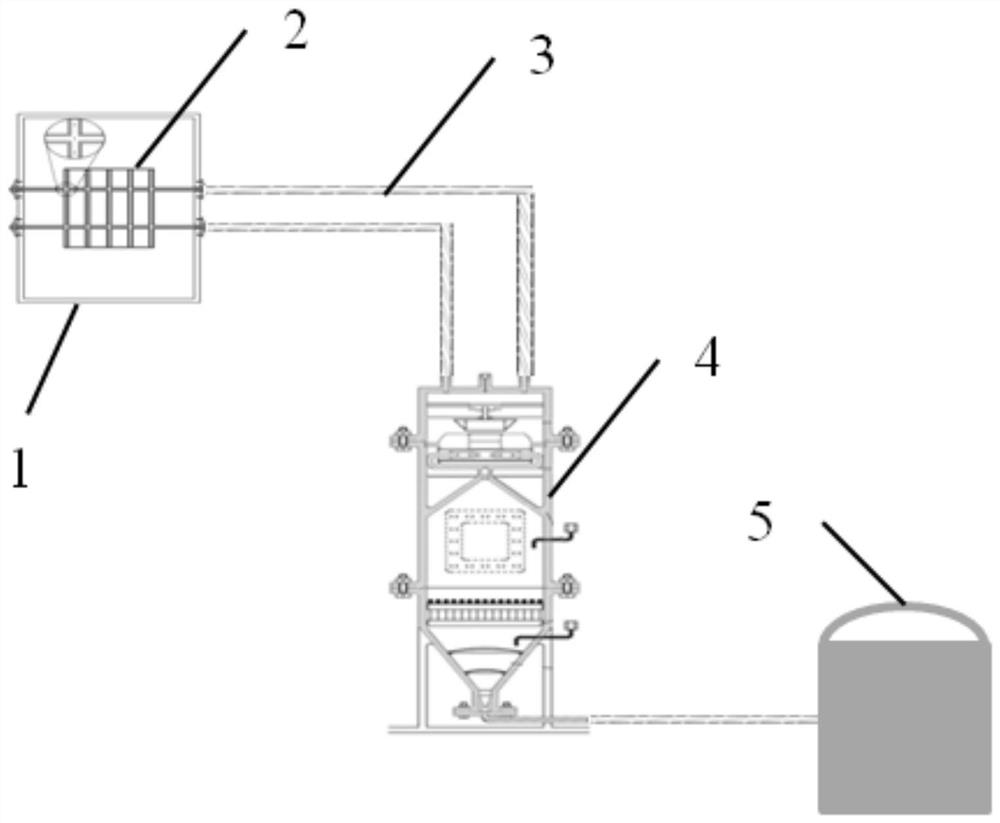

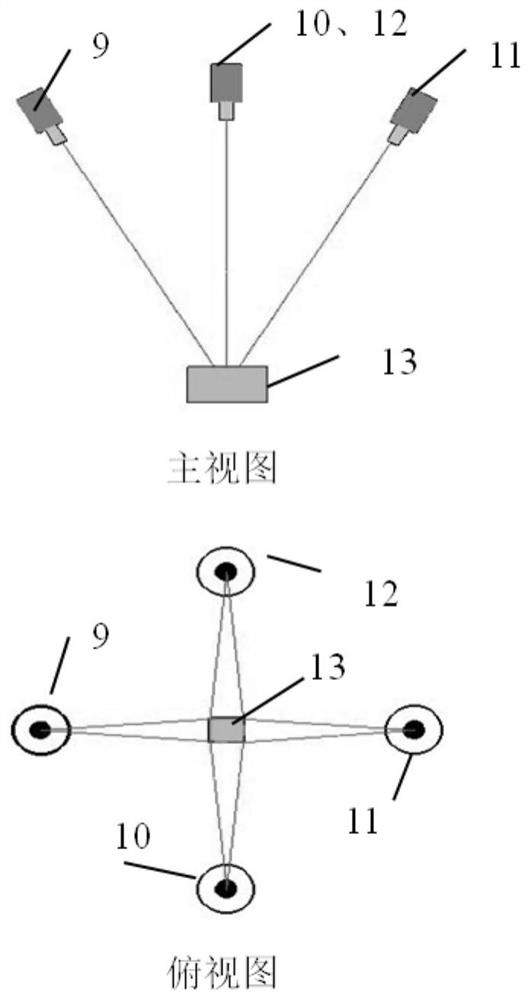

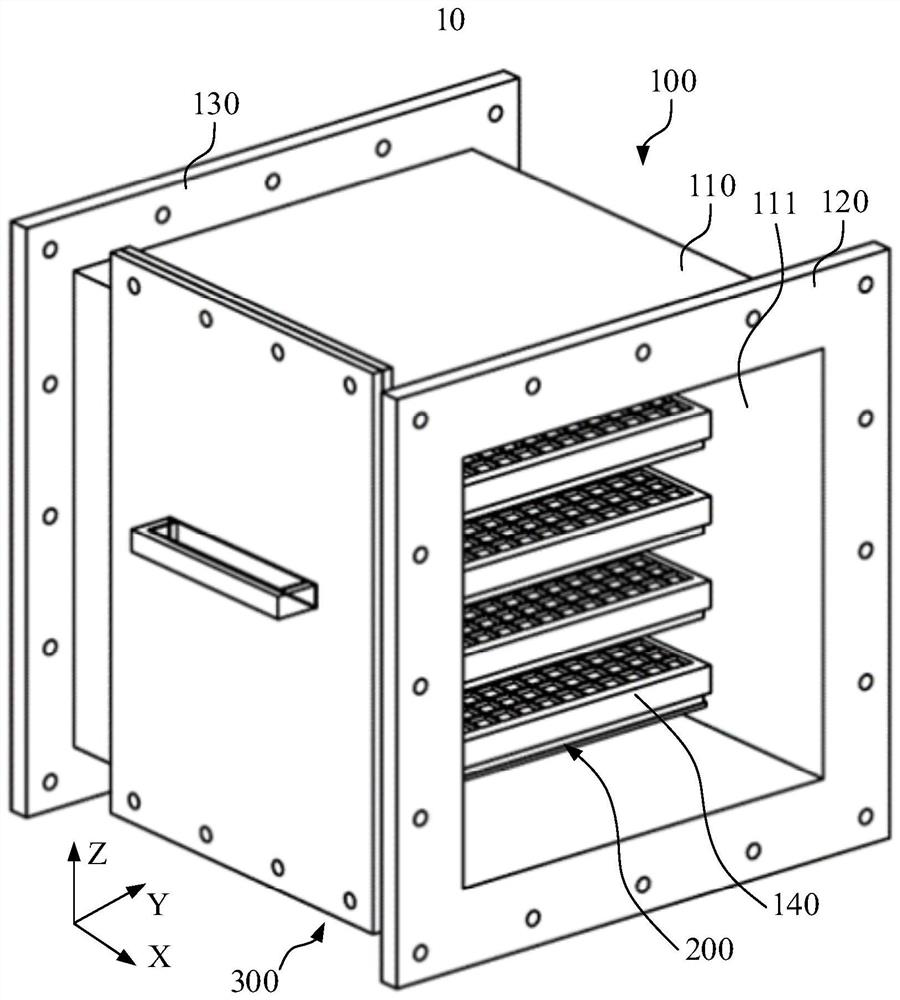

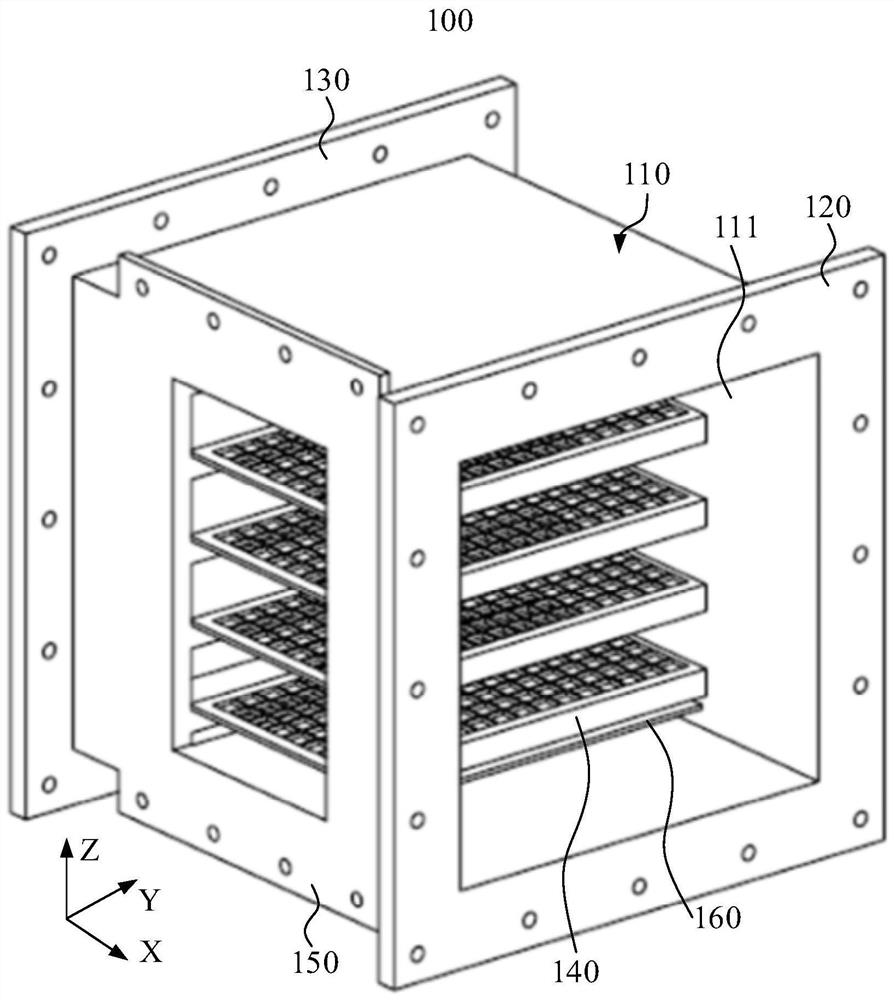

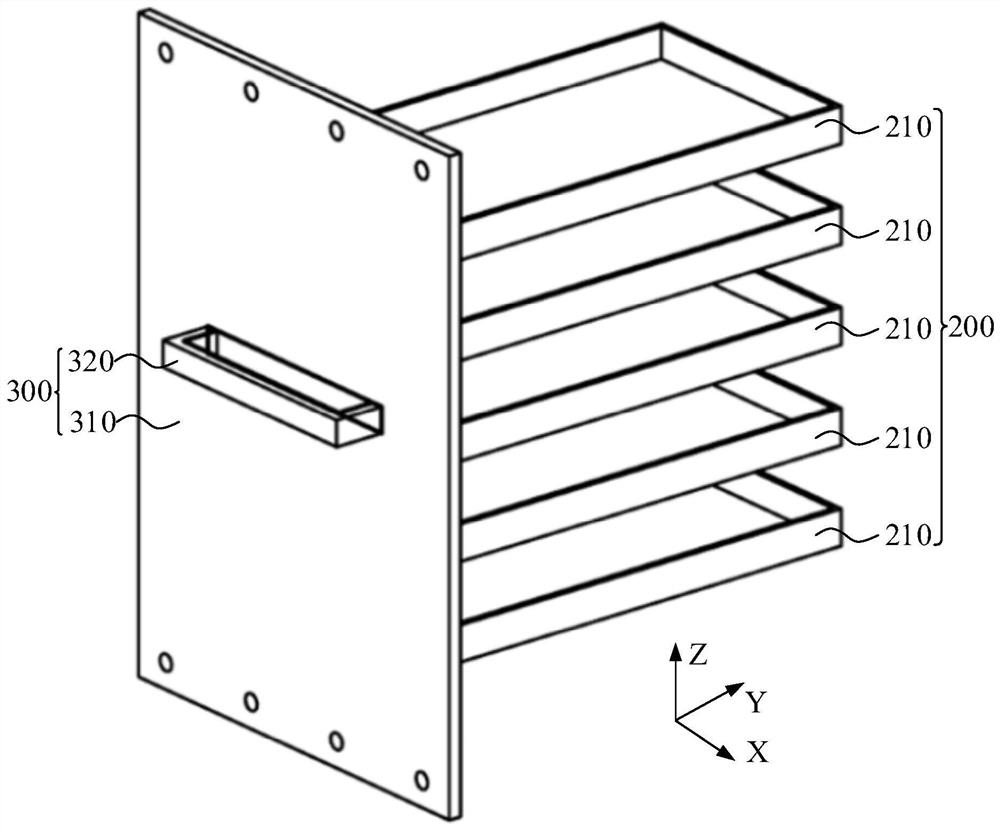

Device and method for measuring three-dimensional space flow field in sub-span wind tunnel

The invention discloses a device and method for measuring a three-dimensional space flow field in a sub-span wind tunnel. Firstly, a tracer particle spreader for spreading tracer particles are connected with a high-pressure air source, the tracer particles are placed in the spreader, and since the tracer particle spreader is connected with the high-pressure air source through a pipeline, the spreading density of the tracer particles is adjusted by adjusting the pressure of the high-pressure air source; four cross-frame CCD cameras are equipped with anti-focal-length perspective control lensesto shoot the flow field, so that clear imaging of a three-dimensional space is ensured; by utilizing lasers, three-dimensional space illumination of the flow field is carried out through the assembledbody light source; a synchronous controller sends out a trigger signal to control synchronous work of the cameras and the laser, and the pressure of the high-pressure air source is adjusted; and after tracer particles in a test area meet the requirements, flow field images are collected through all the cameras, the flow field images shot by the four cameras are reconstructed, and a three-dimensional space flow field of the test area is obtained.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

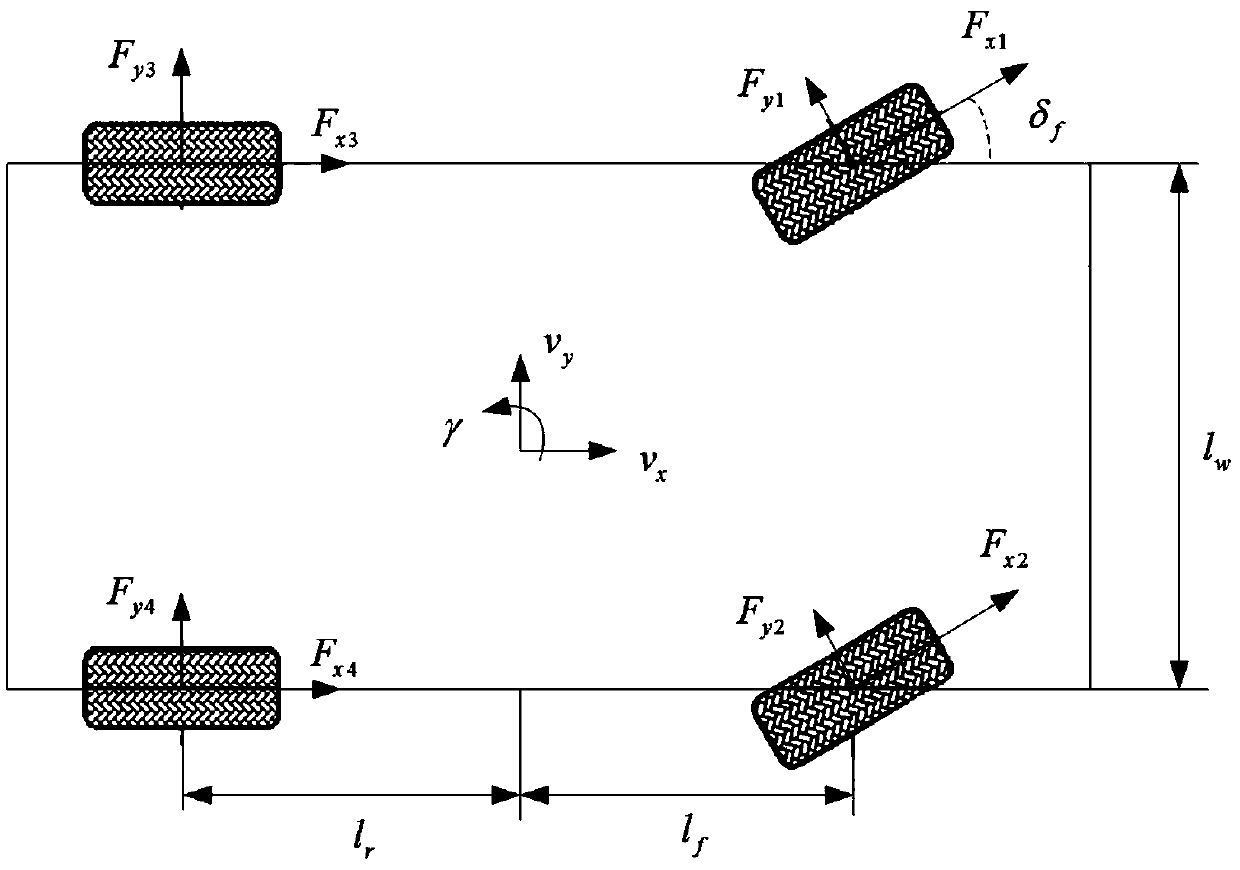

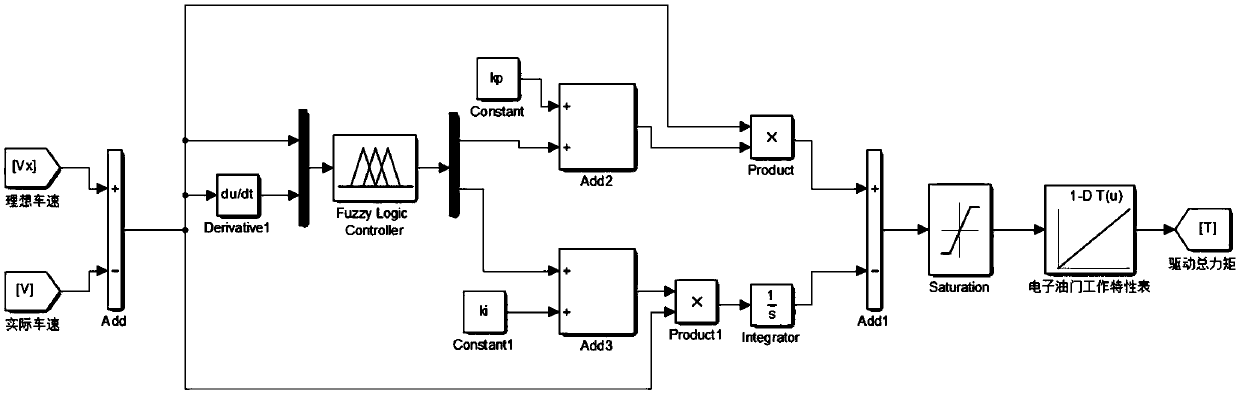

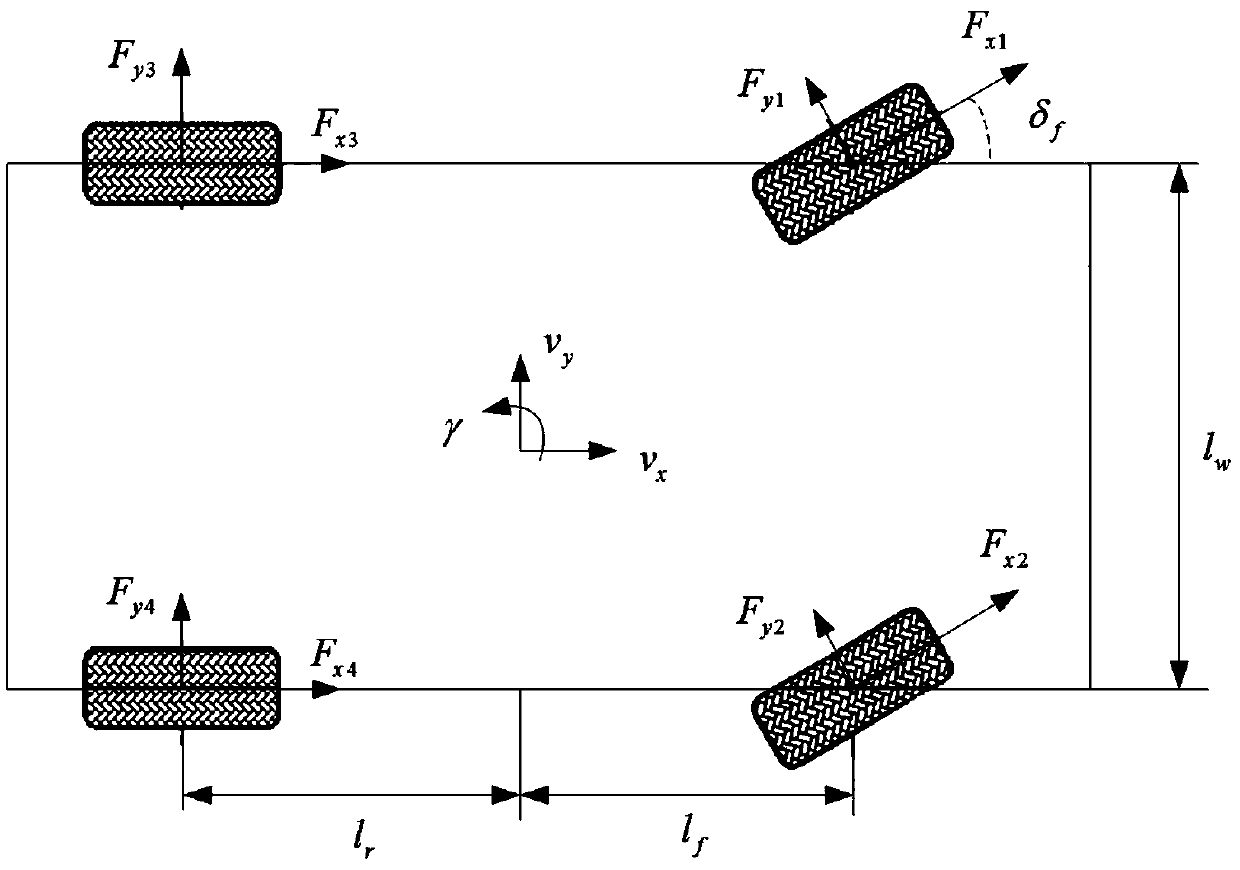

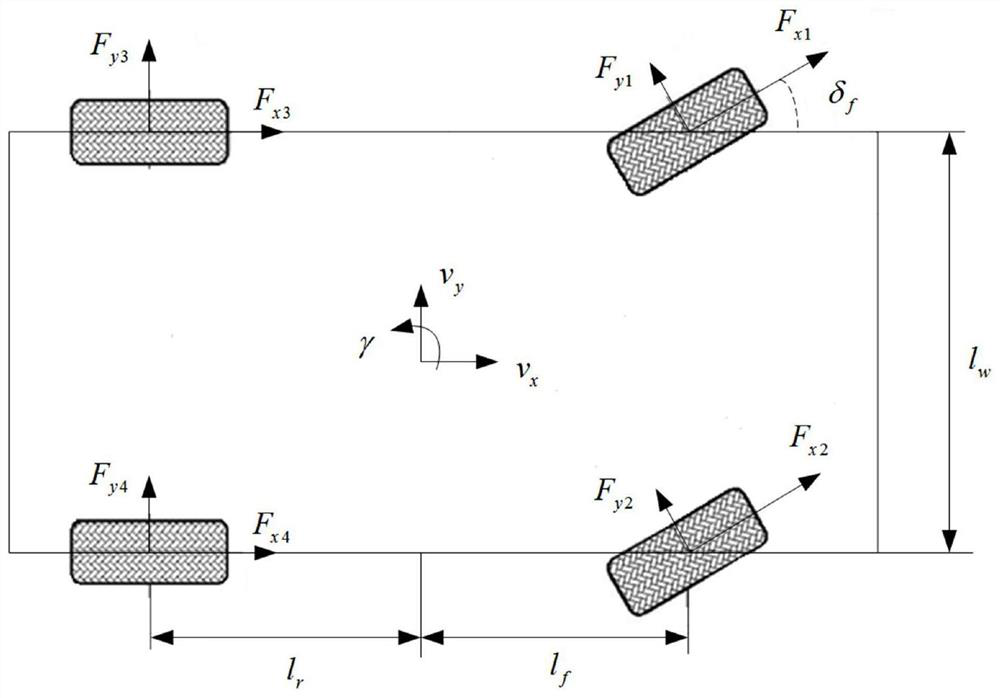

A longitudinal speed trac control method and a device for an expected path vehicle

ActiveCN109017446AAccurate trackingGuaranteed to followSpeed controllerElectric energy managementDistribution controlEngineering

A longitudinal speed trac control method and a device for an expected path vehicle, belongs to the field of driverless vehicle control, In order to solve the problem of longitudinal speed tracking control of vehicles on expected path, the total drive torque is calculated and distributed to the drive torque of each hub motor by a torque distribution controller, the output torque of the hub motor acts on the wheels, The longitudinal speed control is used to track the desired trajectory, in which the tire utilization rate is used as the optimization function, and the moment distribution algorithmis designed according to the pseudo-inverse method to distribute the total moment. The effect is to ensure that the tire is in the stable range without exceeding the adhesion limit, and the requiredprecision of the distribution is higher, so that the longitudinal speed tracking is more accurate.

Owner:DALIAN NATIONALITIES UNIVERSITY

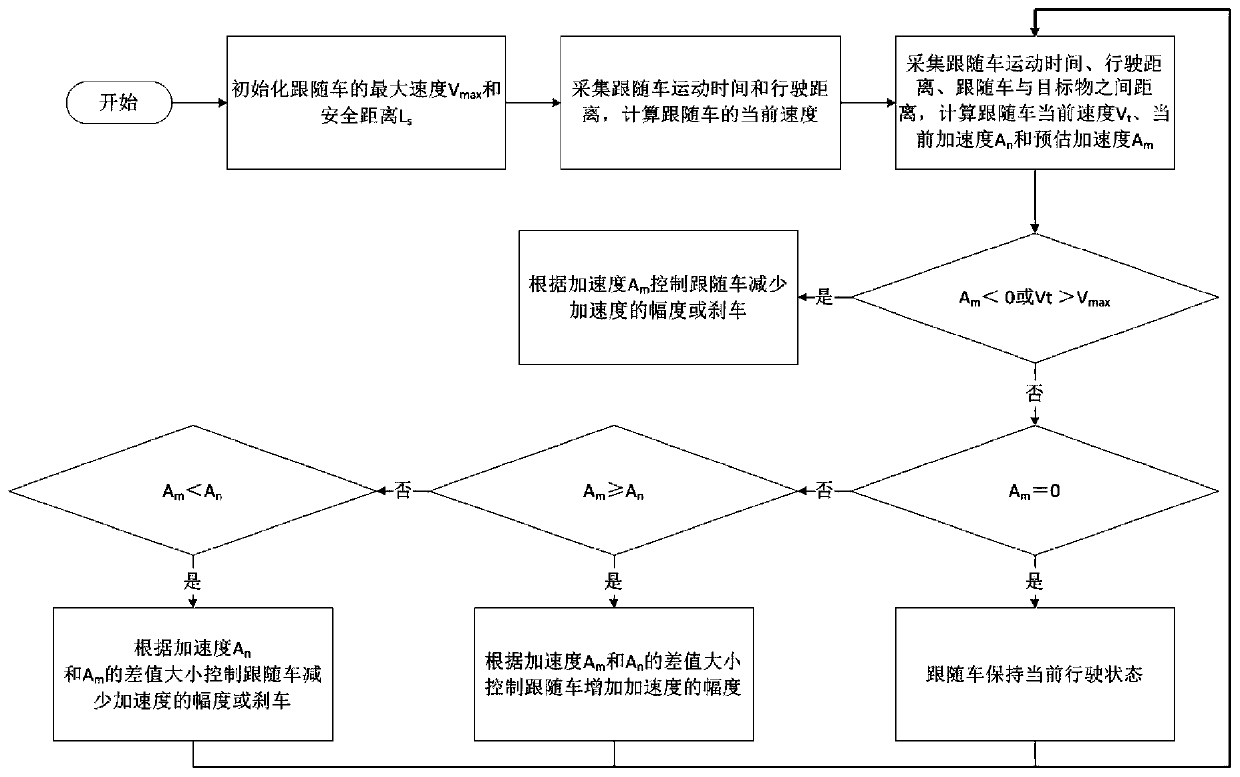

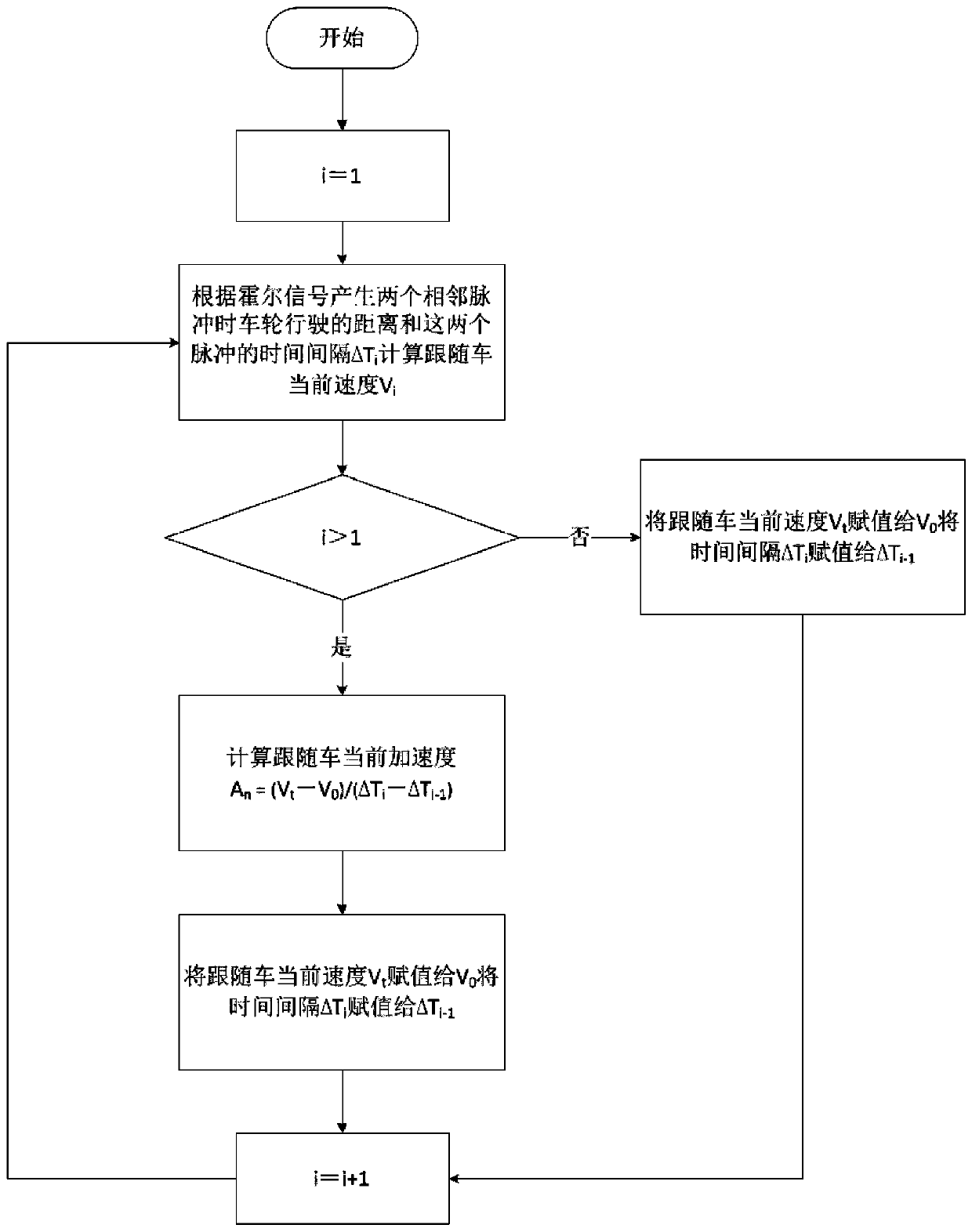

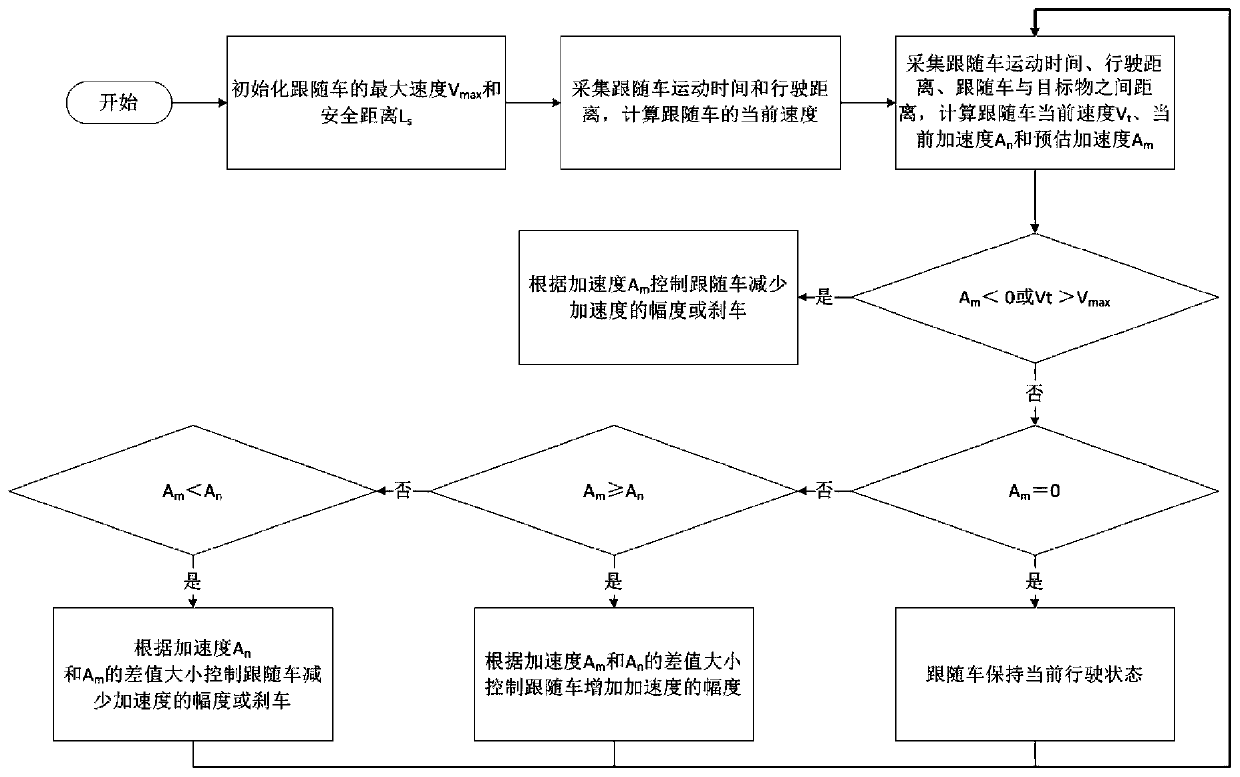

Acceleration-based follow-up vehicle control method

InactiveCN109976385ASmooth movementGuaranteed to followTarget-seeking controlPosition/course control in two dimensionsAerospace engineeringIntelligent control

The invention discloses an acceleration-based follow-up vehicle control method, which relates to the technical field of intelligent control, and comprises the steps of: 1, setting a safety distance Lsof a base station of a follow-up vehicle and a target tag, a maximum speed Vmax of the follow-up vehicle, and a time shortening amount Tv of shortening the distance between the base station of the follow-up vehicle and the target tag to the safety distance Ls, and initializing an acquisition number i=0; 2, setting i=1, and acquiring a current speed of the follow-up vehicle after a time interval Delta Ti; 3, setting i=i+1, acquiring a current speed Vt of the follow-up vehicle after the time interval Delta Ti and acquiring a distance Li between a current base station of the follow-up vehicle and the target tag; 4, calculating current acceleration An of the follow-up vehicle according to the current speed Vt of the follow-up vehicle after the time interval Delta Ti and a speed of the follow-up vehicle after the time interval Delta Ti-1; 5, calculating estimated acceleration Am of the follow-up vehicle according to the distance Li, the safety distance Ls, the current speed Vt and the timeTv; 6, controlling a motion state of the follow-up vehicle according to the Am, An, Vt, and Vmax; 7, and repeating the steps from 3 to 6.

Owner:成都永奉科技有限公司

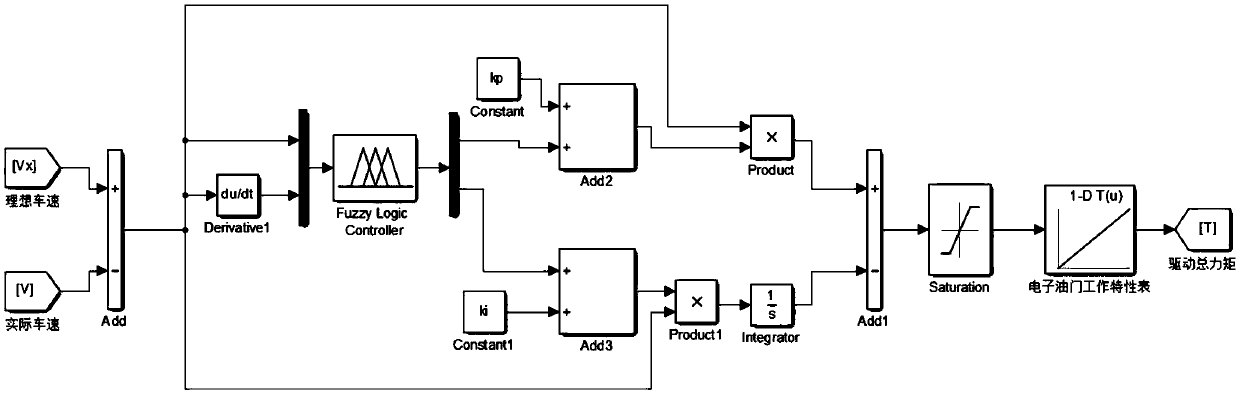

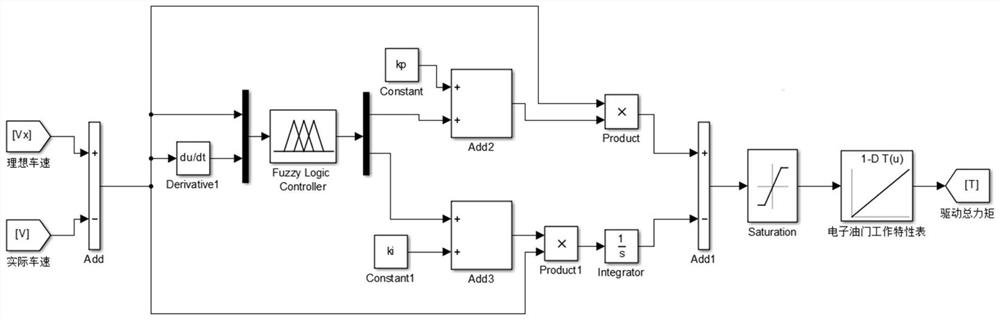

Total drive torque output method for unmanned vehicle

ActiveCN109017447AGuaranteed to followAccurate torqueSpeed controllerElectric energy managementElectronic throttleControl theory

A method for total drive torque output of an unmanned vehicle, belongs to the field of driverless vehicle control, In order to solve the problem of the accuracy of the total drive torque output of theunmanned vehicle, the main point is to take the error between the ideal longitudinal speed and the actual longitudinal speed and the error rate of change as the input of the controller, The controller outputs the electronic throttle opening and searches for the hub motor torque map corresponding to the electronic throttle opening prepared in advance to output the total driving torque of the vehicle. The effect is to ensure the following performance of the longitudinal speed of the vehicle and provide the accurate total torque for each wheel to distribute torque.

Owner:DALIAN NATIONALITIES UNIVERSITY

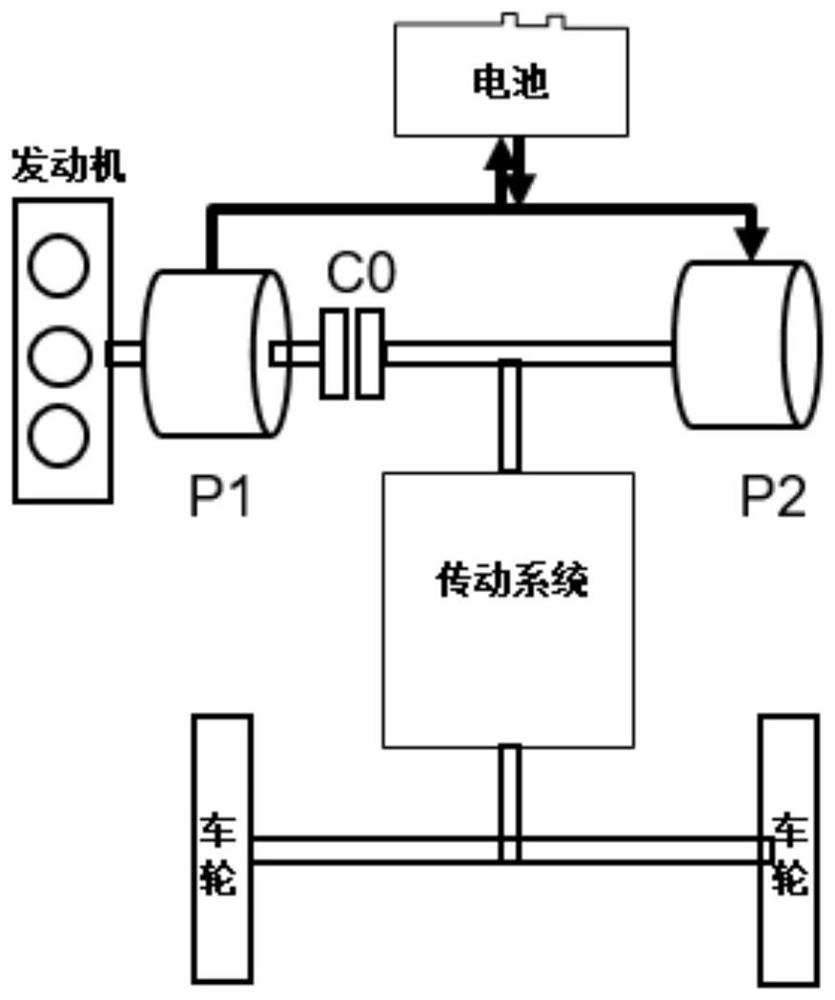

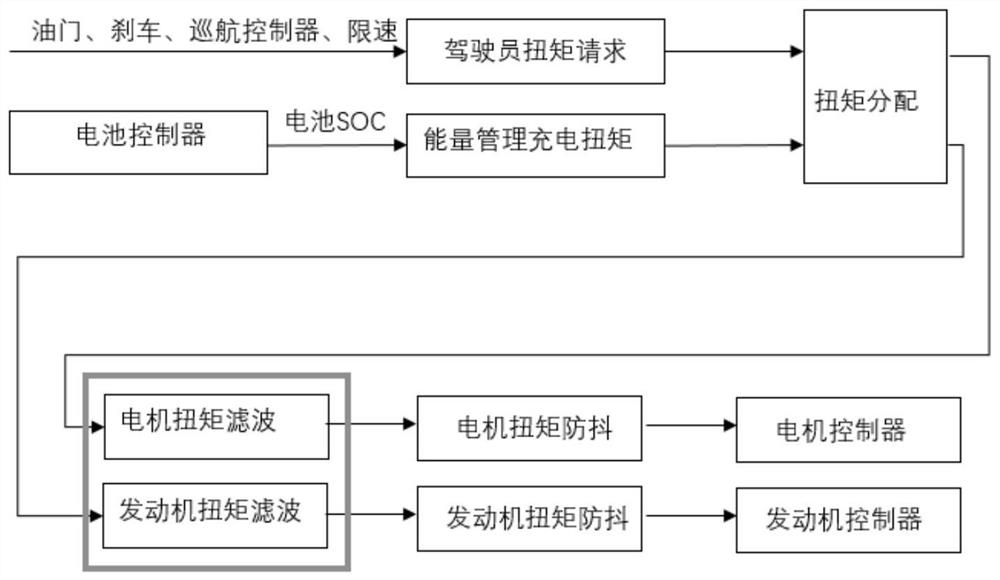

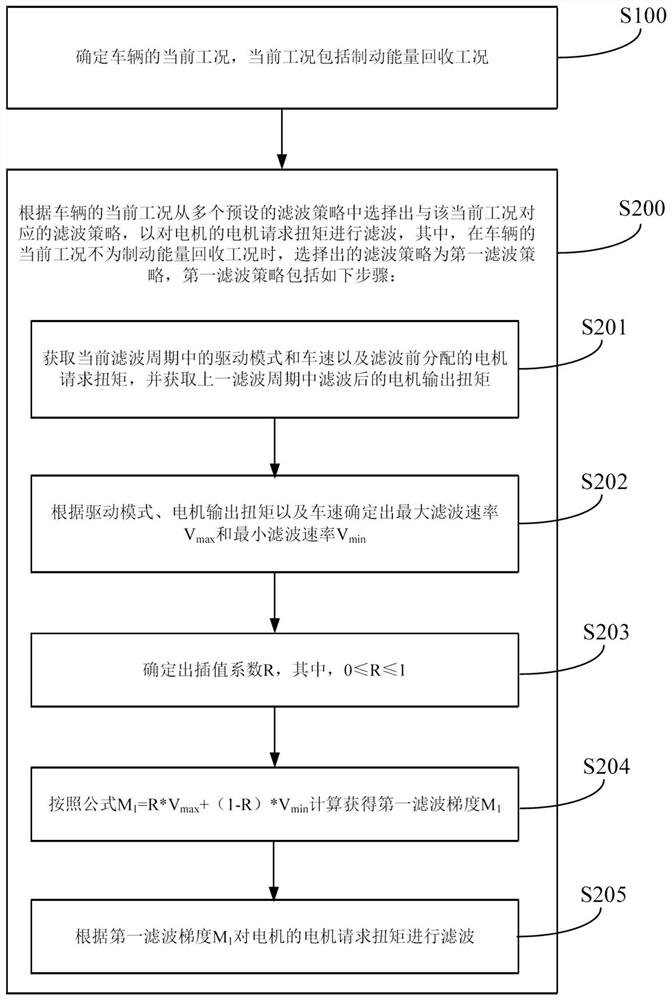

Motor torque filtering control method and system and hybrid vehicle

PendingCN114144329ASmooth rideImprove ride comfort performanceHybrid vehiclesSpeed controllerElectric machineryControl theory

The invention provides a motor torque filtering control method and system and a hybrid vehicle. The motor torque filtering control method comprises the steps of obtaining a vehicle speed in a current filtering period and a motor request torque distributed before filtering, and obtaining a motor output torque after filtering in a previous filtering period; determining a maximum filtering rate Vmax and a minimum filtering rate Vmin according to the motor output torque and the vehicle speed; an interpolation coefficient R is determined according to the motor request torque and the vehicle speed or according to the motor request torque, the vehicle speed, the maximum filtering rate and the minimum filtering rate, and R is larger than or equal to 0 and smaller than or equal to 1; calculating a first filtering gradient M1 according to a formula M1 = R * Vmax + (1-R) * Vmin; and filtering the motor request torque of the motor according to the first filtering gradient M1. According to the scheme, it can be guaranteed that the vehicle runs smoothly without impact, and the riding comfort of a passenger is improved.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +2

Microleakage device and common rail tube

PendingCN110848061AThe actual rail is pressed wellGood followability of setting rail pressureFuel injection apparatusMachines/enginesRail pressureSprayer

The invention discloses a microleakage device and a common rail tube. The microleakage device comprises a valve seat, wherein a valve seat oil channel is formed in the valve seat, the valve seat is provided with an oil inlet and an oil return opening which communicate with the valve seat oil channel, a valve core and a first limiting structure are arranged in the valve seat, the valve core and thevalve seat are in clearance fit with each other, the clearance between the valve core and the valve seat respectively communicate with the air inlet and the air return opening, two ends of the valvecore are respectively a first end of the valve core and a second end of the valve core, and in the flowing direction of fuel oil, the first end of the valve core is located on the upper stream of thesecond end of the valve core, and the second end of the valve core is abutted against the first limiting structure. The microleakage device is added on the common rail tube, and when rail pressure isexcessively high, releasing of the rail pressure is performed through the microleakage device, the excessively high part of the rail pressure is released, following performance of actual rail pressureand set rail pressure of an engine is enabled to be good, and the problem that a microleakage oil sprayer is poor in rail pressure following performance is solved.

Owner:WEICHAI POWER CO LTD

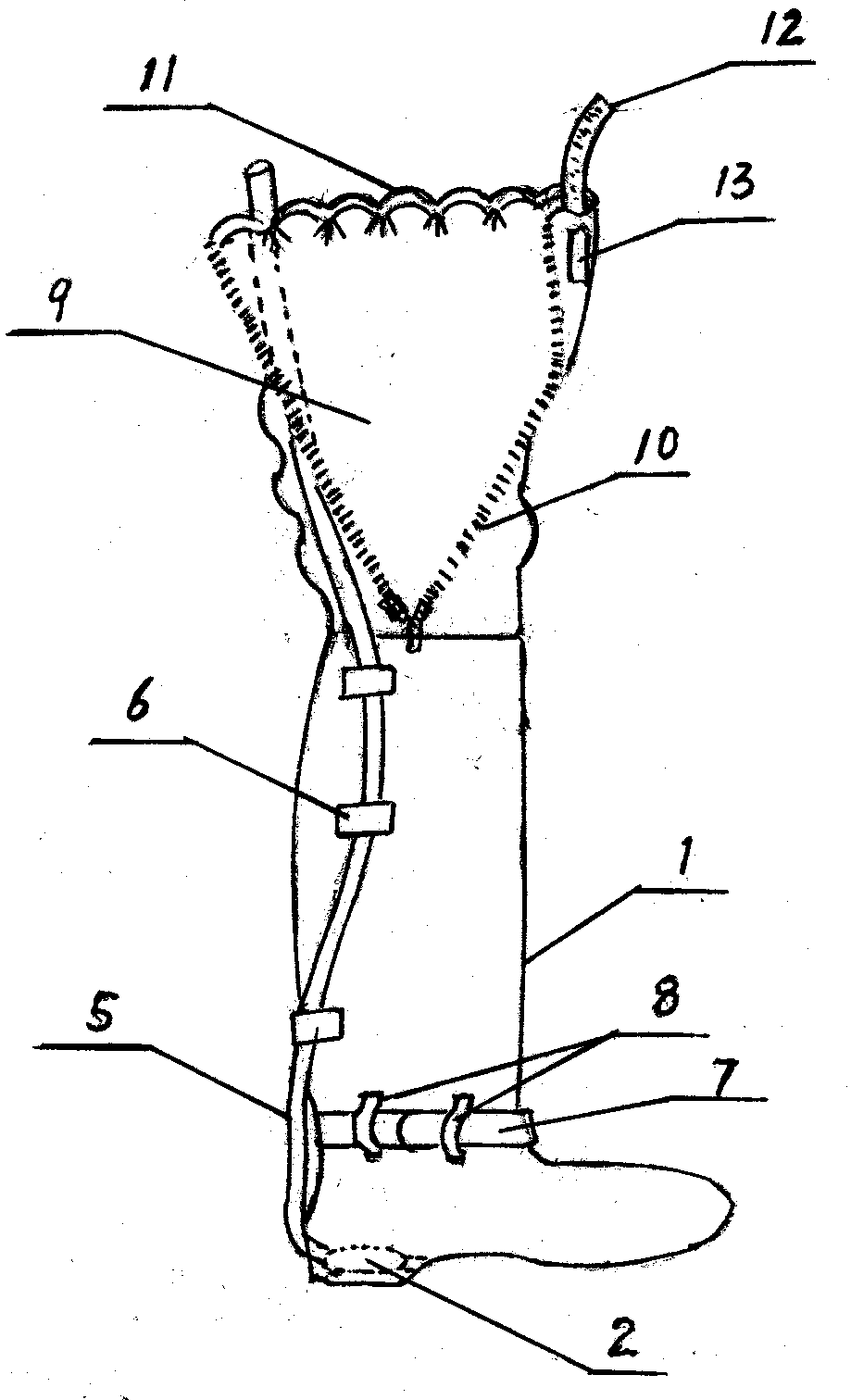

Wading boot special for flood-fighting and emergency rescue

The invention relates to a wading boot special for flood-fighting and emergency rescue. The wading boot special for flood-fighting and emergency rescue is characterized in that a treading type ventilation air bag is arranged in a rubber high-waist wading boot body and is located at the position of the heel, an air outlet and an air inlet are formed in the ventilation air bag, an exhaust ball valve with a spring is arranged at the position of the air outlet, an air inlet valve block is arranged at the position of the air inlet of the ventilation air bag, one end of an exhaust pipe stretches into the ventilation air bag from the rear heel of the high-waist wading boot body and is connected with the air outlet of the ventilation air bag, the other end of the exhaust pipe extends upwards to the uppermost end of the boot waist from the rear outer side of the surface of the boot waist after passing through the waterproof boot waist, and the exhaust pipe is fixed to the surface of the waterproof boot waist through a pipe fastener. According to the wading boot special for flood-fighting and emergency rescue, moisture in the boot can be discharged automatically, the situation that the boot is separated from the foot can be avoided, it is guaranteed that the boot is in close fit with the foot, the waterproof height of the wading boot is greatly increased, and water can be effectively prevented from entering the boot. The wading boot is quite suitable for flood-fighting and emergency rescue and can also be widely applied to mole drainage, underground coal mining, work of fisherman and work in paddy fields.

Owner:初东

Charging transaction management method

InactiveCN109767297ACharging transaction promotionEffectively completedBuying/selling/leasing transactionsApparatus for hiring articlesTransaction managementTransaction data

The invention provides a charging transaction management method. The method comprises the following steps of completing a charging transaction via a plurality of charging piles, wherein the transaction of the charging piles generates transaction data including the user information and accounts, and selecting a plurality of supervising roles from the user according to the transaction data, whereinthe supervising roles record the transaction data, and the rewards or penalties are made according to the work of the supervising roles. The data in the transaction process is digitally managed, the charging transaction of the electric vehicle is promoted, and each party can conveniently and effectively complete the electric quantity transaction.

Owner:上海悦充网络科技有限公司

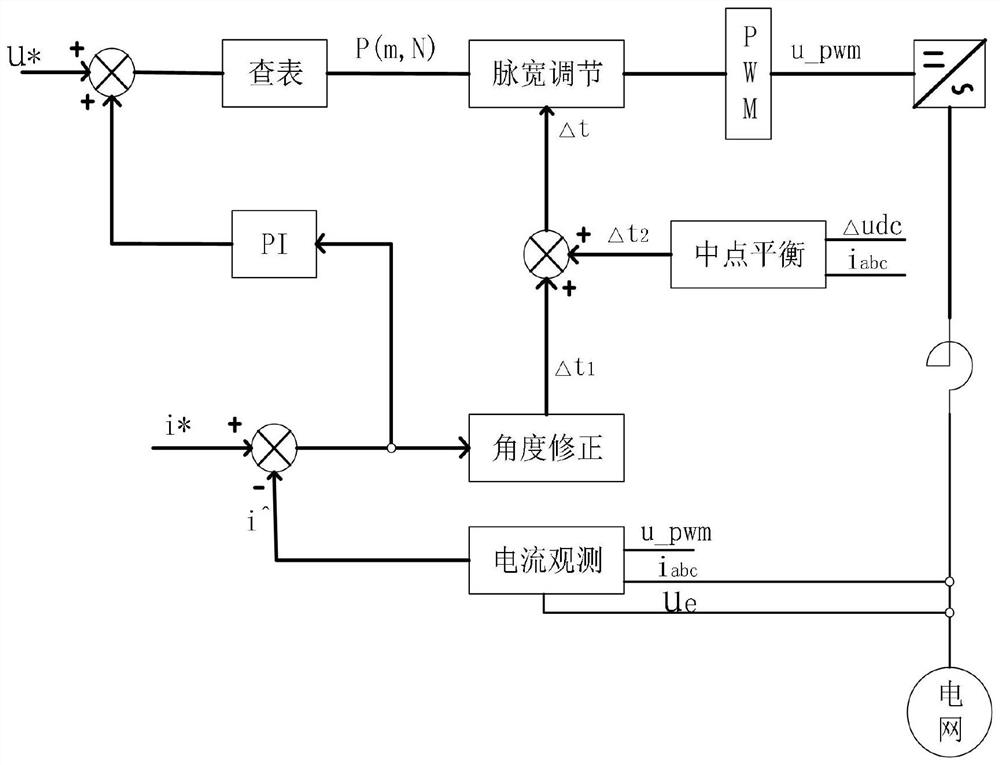

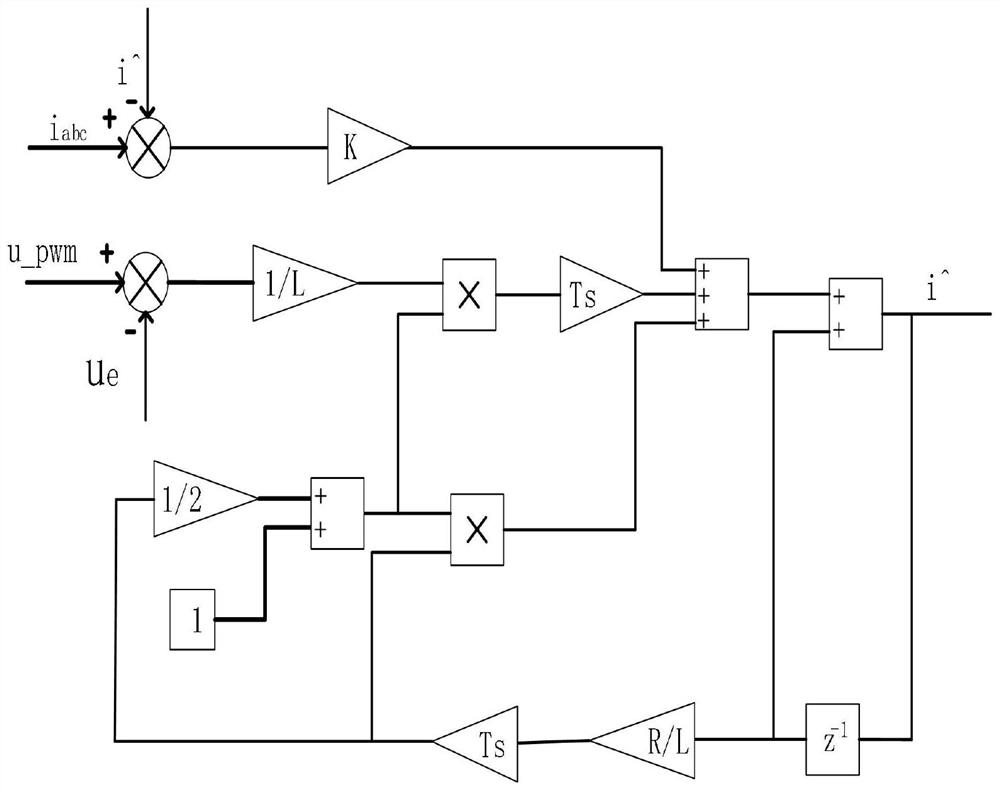

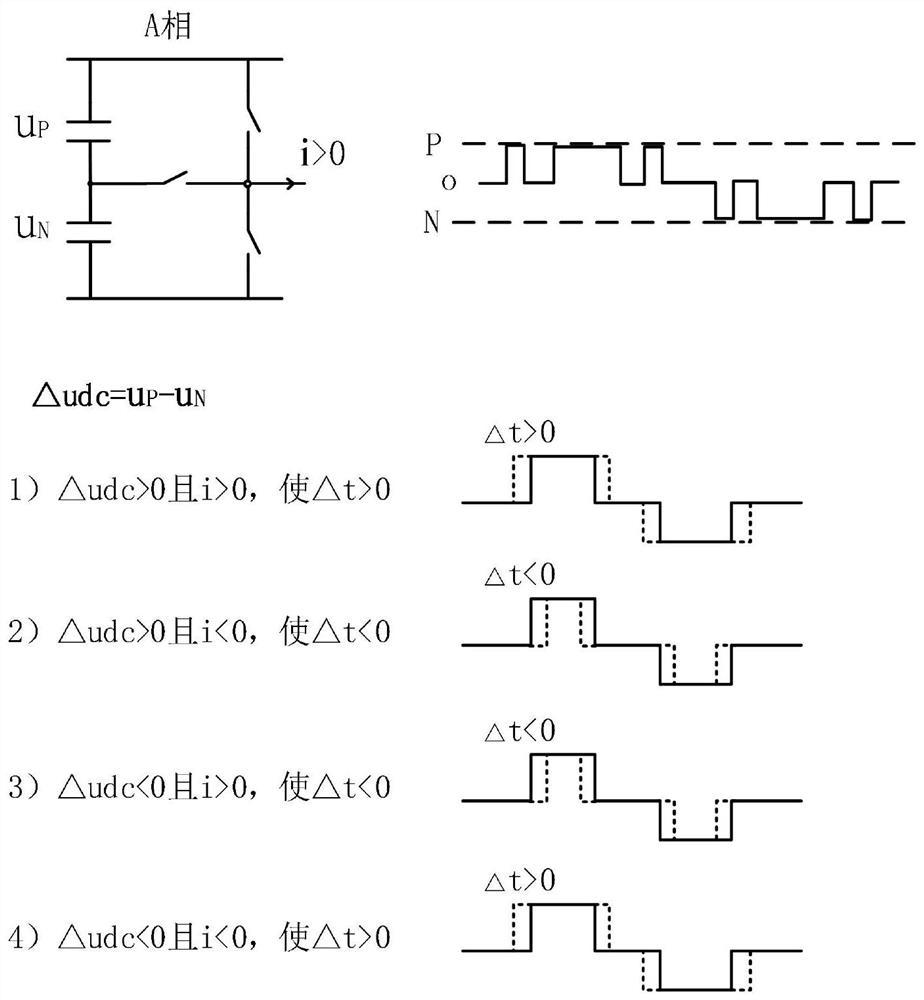

PWM (Pulse Width Modulation) pulse width dynamic adjustment and neutral-point balance method based on current observer

ActiveCN113395000APreserves the advantage of low current harmonicsAvoid defectsAc-dc conversionSingle network parallel feeding arrangementsClassical mechanicsHarmonics

The invention relates to a PWM pulse width dynamic adjustment and neutral point balance method based on a current observer, and the method is technically characterized in that a current fundamental component is extracted through current observation, the dynamic adjustment time and the steady-state adjustment voltage are calculated, the adjustment output level time is calculated through neutral point balance, and the adjustment output level time and the dynamic adjustment time are input to the pulse width adjustment to complete the adjustment of the PWM pulse width. The problems that PWM response lags behind in existing conventional table look-up control, current coupling and disorder exist in the adjusting process, harmonic waves are increased and the like are solved, the advantage that the current harmonic waves of an optimized PWM table look-up method are low is reserved, meanwhile, the defect of an existing neutral-point balance technology is overcome, the limitation that common-mode component adjustment must be used is broken through, and the problems of insufficient adjustment capability and poor real-time performance caused by limitation of zero-sequence voltage adjustment in an existing method are solved.

Owner:TIANJIN RES INST OF ELECTRIC SCI

Path-following method for unmanned vehicles based on event-triggered model predictive control

ActiveCN110162046BGuaranteed to followRealize following controlPosition/course control in two dimensionsVehiclesPredictive controllerControl engineering

Owner:TONGJI ARTIFICIAL INTELLIGENCE RES INST SUZHOU CO LTD

A device and control method for suppressing vibration of a shipboard stabilized platform

A shipboard stabilized platform control system under sliding-mode control has high precision and robustness, and the existence of a sign function will causes jittering of input control in the sliding-mode control. In order to eliminate the jittering, the present invention provides a device for inhibiting jittering shipboard stabilized platform and a control method thereof. Based on a double-shaftshipboard platform, a thin boundary layer is arranged at a sliding mode surface, a two-point form method is employed to change control output to a continuous function between two boundary layers, thesystem is converted from a switching state to a continuous state, the system slowly approaches, passes through and keeps away from a jittering switching platform in the whole control process, a motiondirection is only changed when the system reaches the boundary layers, and therefore the jittering frequency of the system is greatly reduced. The method is simple, good in jittering elimination effect and good in universality.

Owner:HARBIN INST OF TECH AT WEIHAI

Longitudinal speed tracking control method and device for vehicles on expected path

ActiveCN109017446BAccurate trackingGuaranteed to followSpeed controllerElectric energy managementElectric machineryControl theory

A longitudinal speed trac control method and a device for an expected path vehicle, belongs to the field of driverless vehicle control, In order to solve the problem of longitudinal speed tracking control of vehicles on expected path, the total drive torque is calculated and distributed to the drive torque of each hub motor by a torque distribution controller, the output torque of the hub motor acts on the wheels, The longitudinal speed control is used to track the desired trajectory, in which the tire utilization rate is used as the optimization function, and the moment distribution algorithmis designed according to the pseudo-inverse method to distribute the total moment. The effect is to ensure that the tire is in the stable range without exceeding the adhesion limit, and the requiredprecision of the distribution is higher, so that the longitudinal speed tracking is more accurate.

Owner:DALIAN NATIONALITIES UNIVERSITY

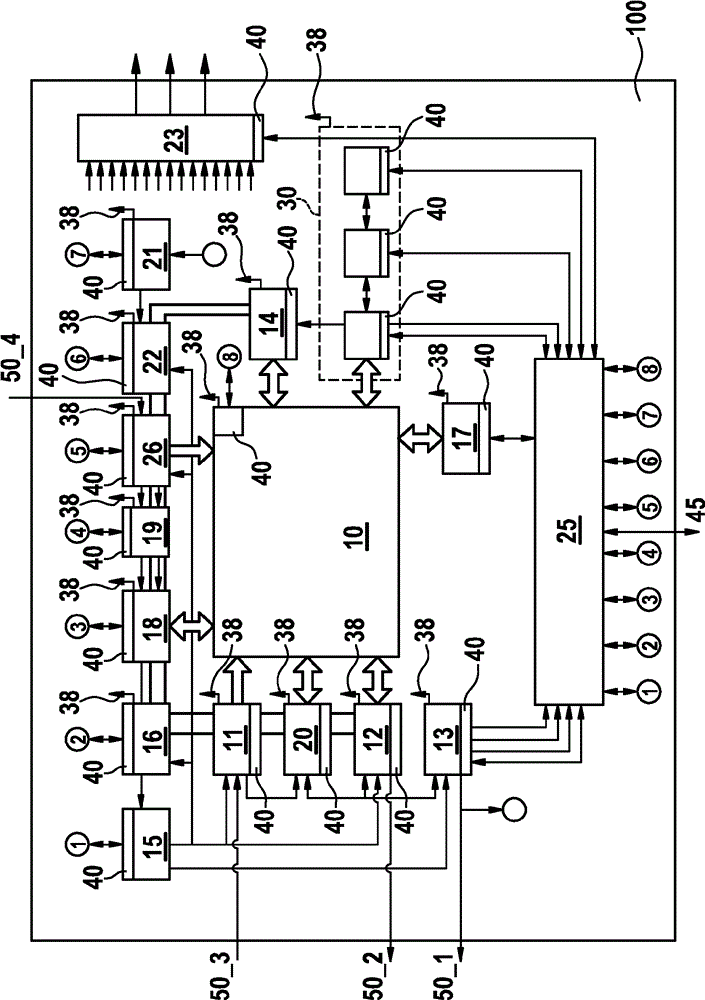

Modular structure for working with data

ActiveCN102822764BAvoid jitterGuaranteed to followGenerating/distributing signalsData processing systemModular structure

A circuit arrangement for a data processing system is configured to process data in a plurality of modules. The circuit arrangement is configured such that each module is provided with at least one clock pulse, a time base and a base of at least one additional physical variable. The circuit arrangement also comprises a central routing unit to which the plurality of modules are coupled and via which the plurality of modules can periodically exchange data amongst themselves, based on the time base and / or the base of other physical variables. Each module is configured independently and parallel to other modules of the plurality of modules in order to process data. The circuit arrangement is employed in a corresponding method.

Owner:ROBERT BOSCH GMBH

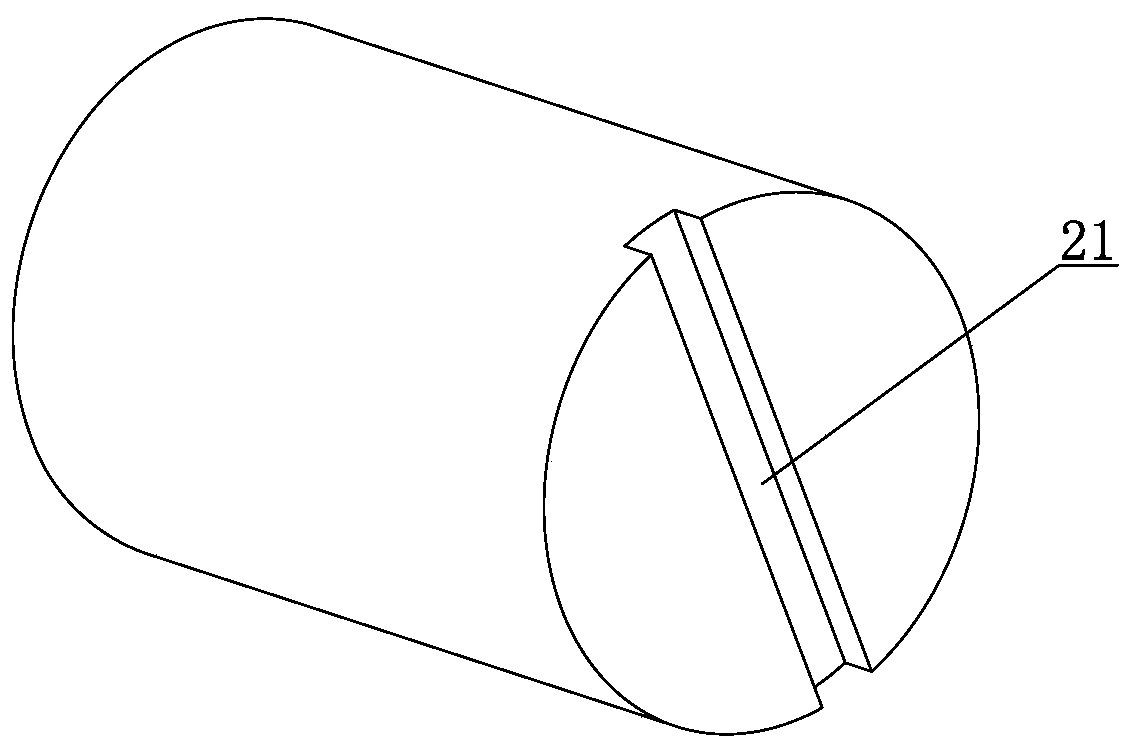

A mechanical seal

ActiveCN106523707BEnsure pairing stabilityStable and reliable working parametersEngine sealsFriction forceGravitation

The invention relates to a mechanical sealing device. The mechanical sealing device comprises a sealing box, a dynamic ring base with a dynamic ring and a static ring base with a static ring, wherein a pushing ring is arranged between the static ring base and the sealing box; the dynamic ring base is in fastening connection with a shaft sleeve through a fastening bolt, and the dynamic ring base and the shaft sleeve rotate together; a supporting space is reserved between the inner wall of the static ring base and the outer wall of the shaft sleeve; a static ring radial regulating mechanism which overcomes the problem that the static ring and the static ring base sink as a result of gravity is mounted in the supporting space; and an external adjustable type static ring axial compensating mechanism is arranged on the outer end surface of the sealing box. The mechanical sealing device solves the problem that the dynamic ring and the static ring are not concentric as a result of gravity of a large-shaft-diameter mechanical seal compensating static ring, and the problem that friction force in the circumferential axial direction is not uniformly distributed due to the fact that circumferential clearances of a seal ring between the static ring and the static ring base are not uniform, and the like; and meanwhile, the mechanical sealing device has the advantages that: for a split type mechanical seal and an integrated type mechanical seal, working strength, in a mounting using process, of a spring does not change due to regulation of a pump body, and in use, a damaged spring element can be timely replaced without dismounting equipment.

Owner:天津市合润科技有限责任公司

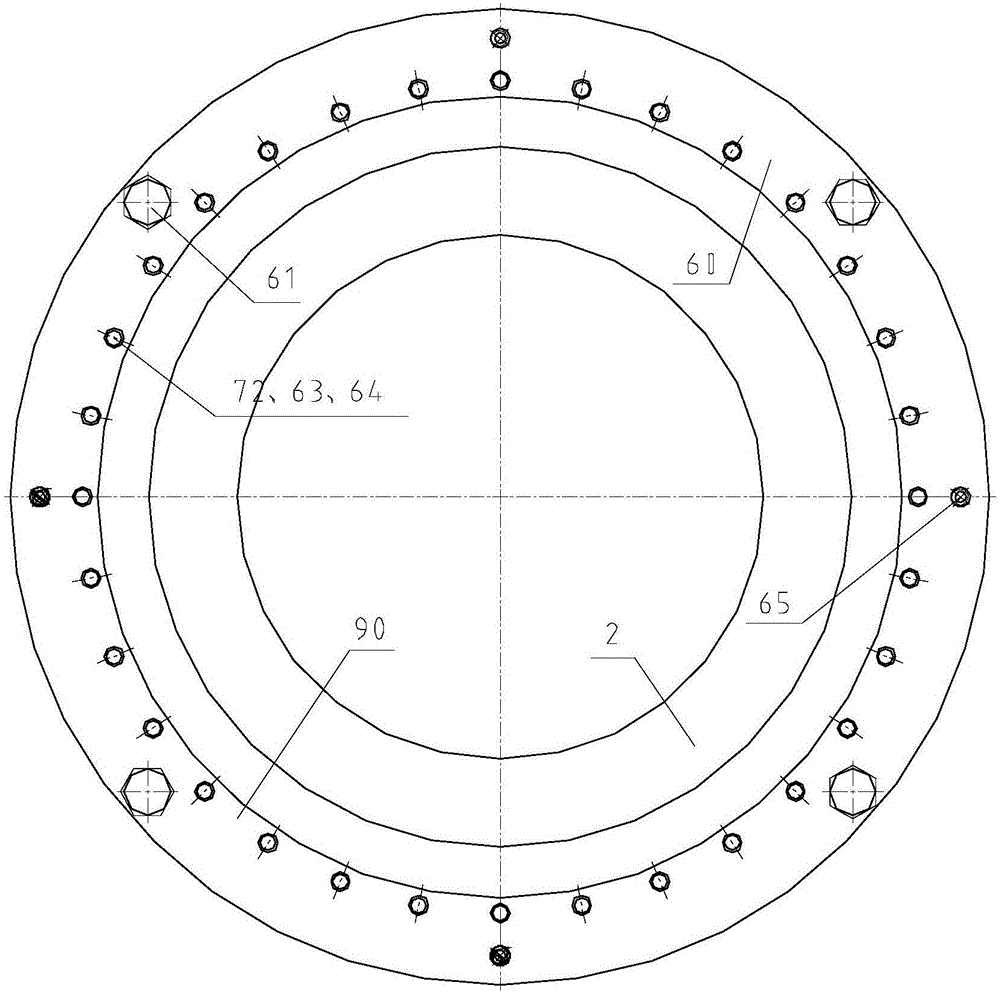

An external static ring axial compensation mechanism for mechanical seals

The invention relates to an external stationary ring axle compensation mechanism for a mechanical sealing device. The external stationary ring axle compensation mechanism comprises a movable ring base which is installed in a sealing box and provided with a movable ring, a seal washer achieving floatation sealing and a first anti-rotating pin preventing rotation are arranged between the movable ring and the movable ring base. An external adjustable stationary ring axle compensation mechanism body is arranged on the outer end face of the sealing box. The external adjustable stationary ring axle compensation mechanism body comprises a gland arranged at the outer end of the sealing box, and the gland is connected with the outer end face of the sealing box through a bolt. An adjusting shim is arranged between the gland and the outer end face of the sealing box. Stationary ring compensation assemblies are evenly distributed in the circumferential direction of the outer end face of the sealing box. According to the structure, elastic components can be adjusted and replaced at will under the situation that the whole device is not dismounted, and the specific pressure of the sealing end face reaches a designed ideal value; and moreover, the concentricity and the following performance of the movable ring and the stationary ring are effectively guaranteed, the sealing effect is improved, and the service life is prolonged.

Owner:天津市合润科技有限责任公司

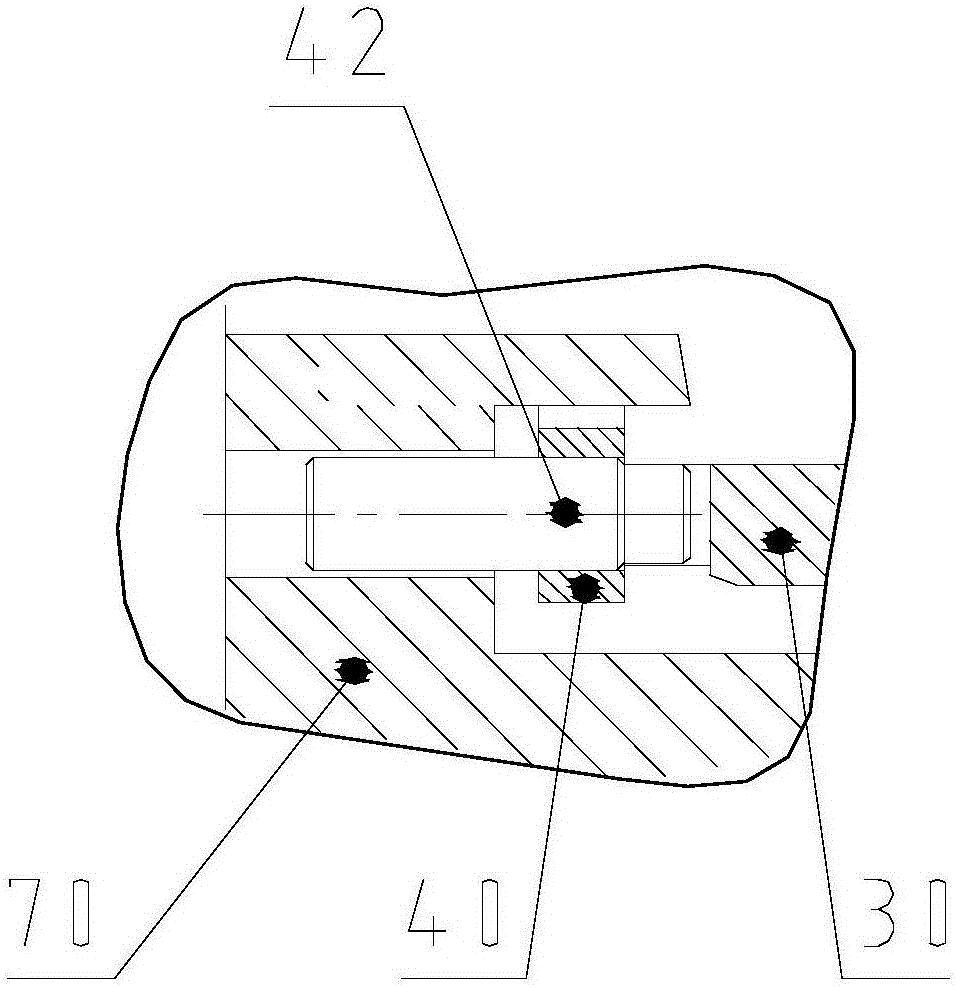

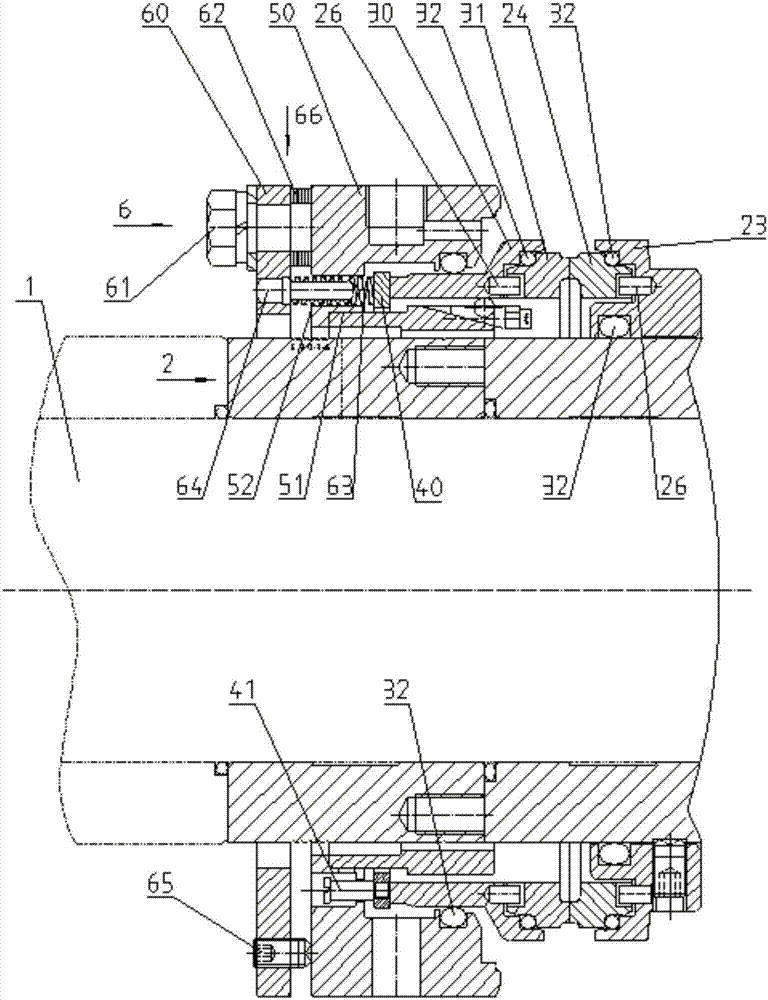

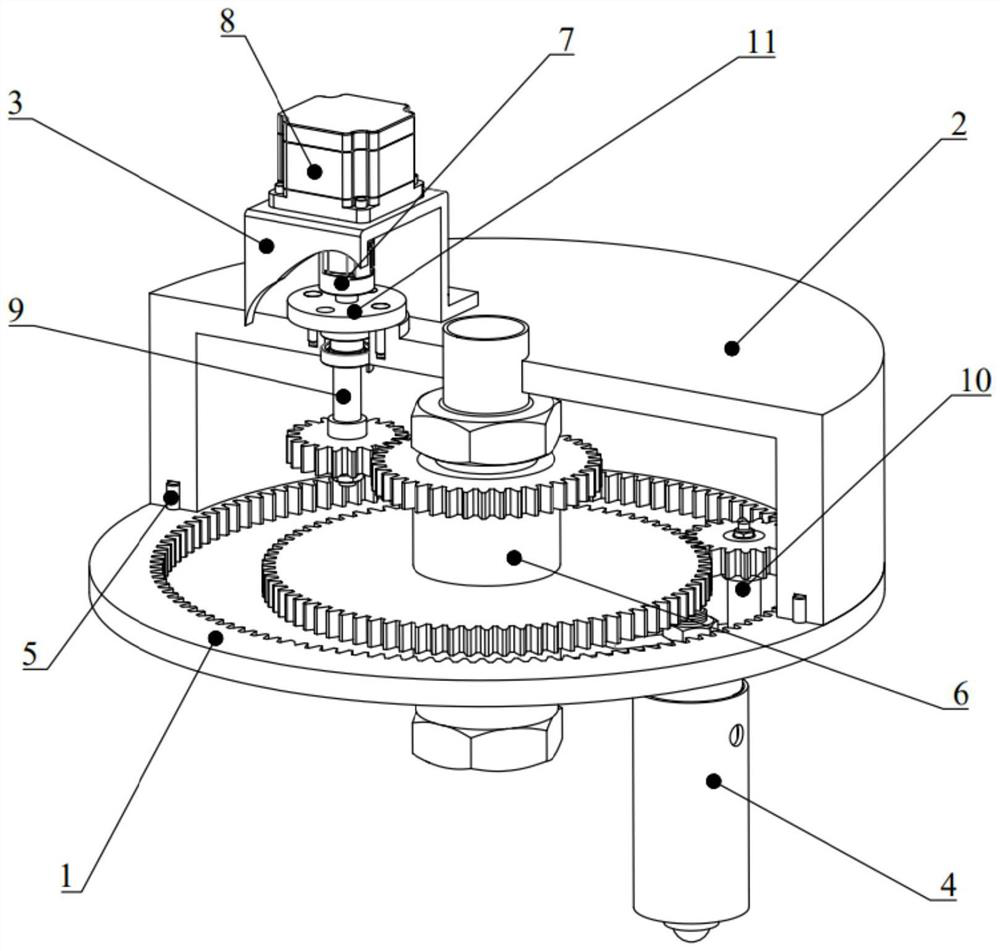

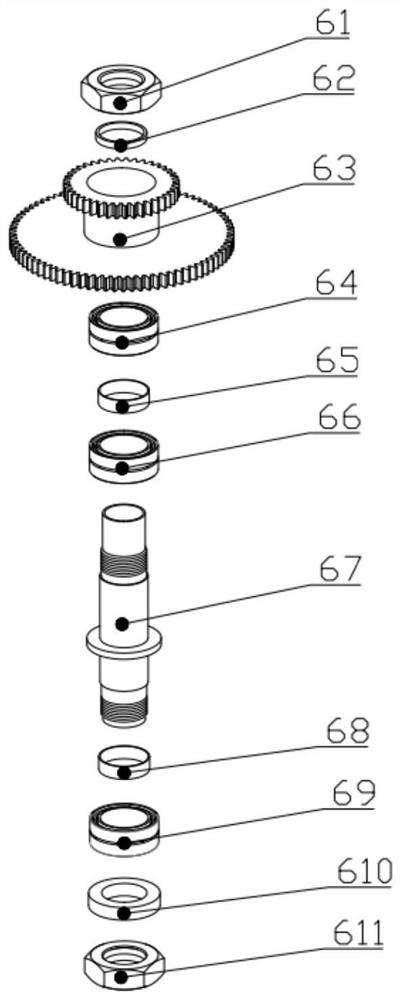

Piezoelectric actuating type accompanying hammering strengthening device and method for electric arc additive manufacturing

PendingCN114535572AIncrease hammering frequencyFor precise controlAdditive manufacturing apparatusIncreasing energy efficiencyPhysicsElectric arc

The invention relates to the technical field of additive manufacturing, in particular to a piezoelectric actuating type accompanying hammering strengthening device and method for electric arc additive manufacturing, and the device comprises an accompanying gear transmission system and a piezoelectric hammering head; the following gear transmission system comprises an inner gear, a machine base, a hollow fixed shaft system, a motor, an input shaft system and a planet carrier system. The base is used for supporting the motor; the motor is connected with the input shaft system; the input shaft system transmits the motion to the hollow fixed shaft system; the hollow fixed shaft system is connected with the planet carrier system; the planet carrier system is in meshed connection with the inner gear through a gear; the piezoelectric hammering head system is vertically connected to the lower portion of the planet carrier system and right faces the weld joint, and the piezoelectric hammering head system rotates around the welding gun in a whole circle when rotating along with the planet carrier system. According to the invention, the whole-circle position control of the piezoelectric hammering head around the fixed hollow shaft can be realized, and the device has the advantages of accurate hammering force control, high hammering frequency and small structural size.

Owner:CIVIL AVIATION UNIV OF CHINA

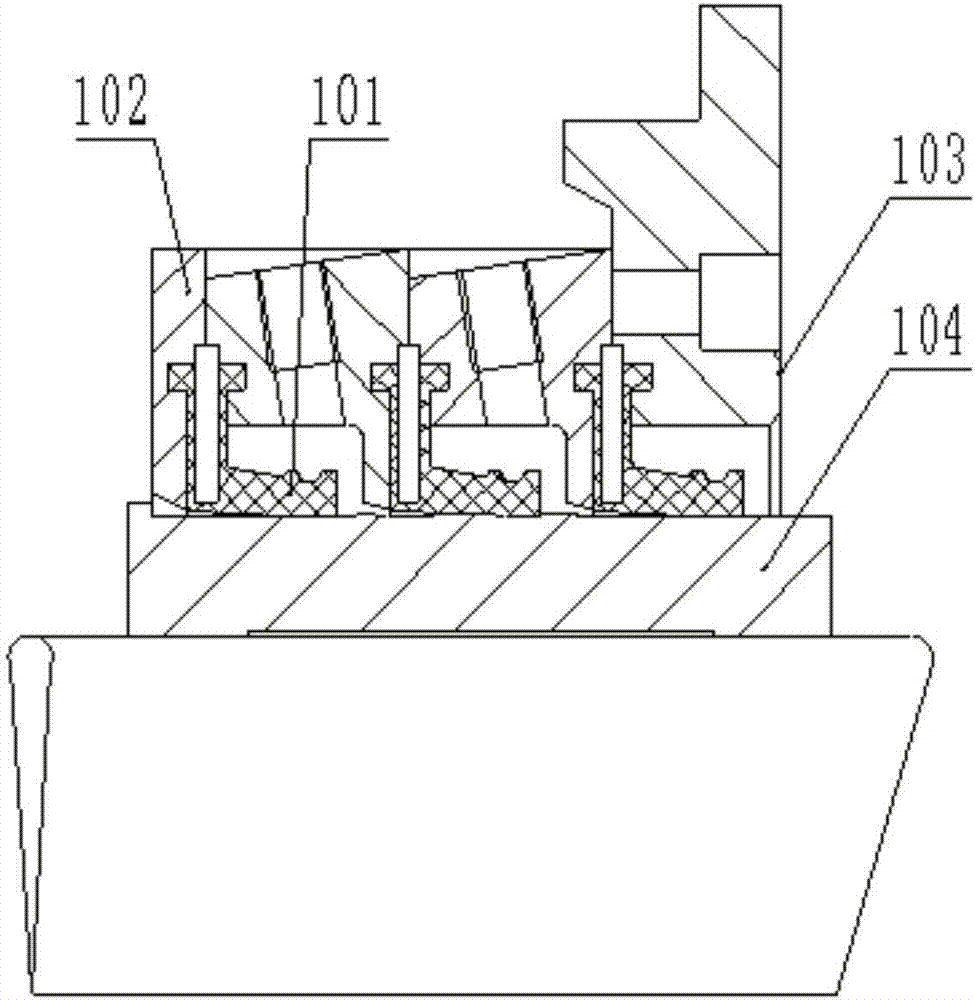

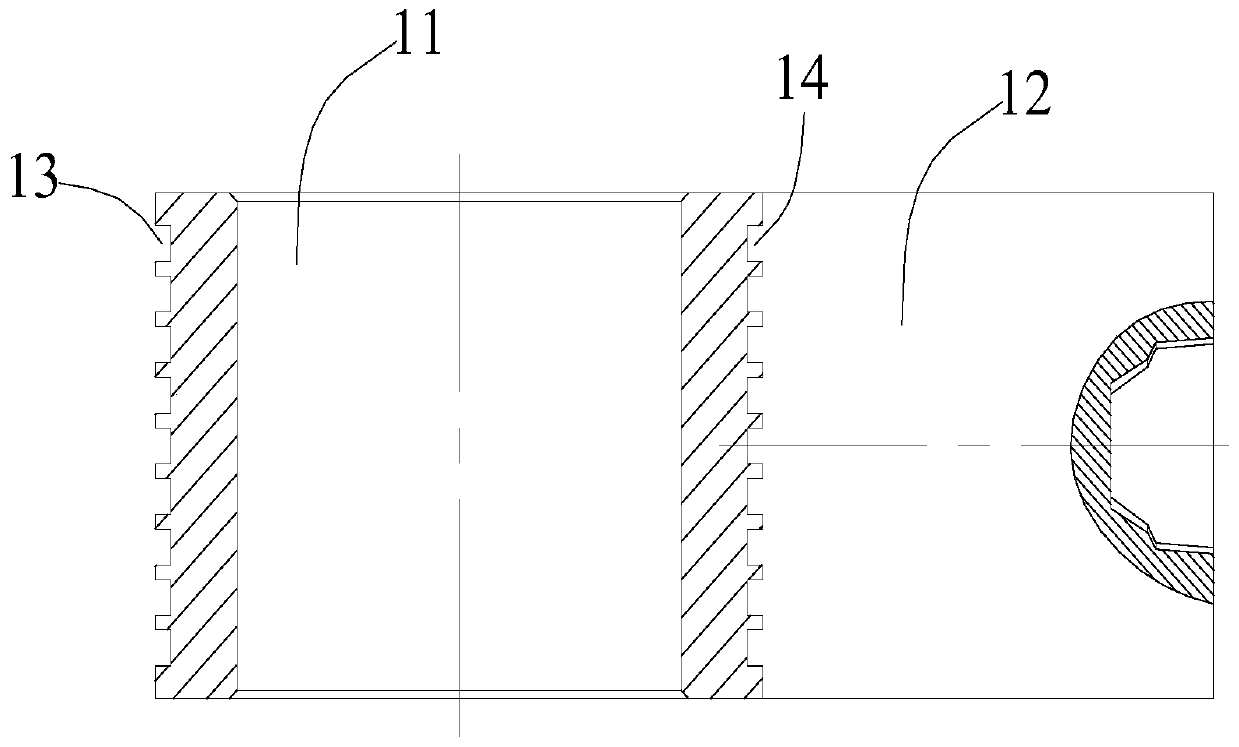

Cooperating structure of a compressor and its rollers and sliding vanes

ActiveCN106246543BPromise not to leaveIncrease contact lengthRotary piston pumpsRotary piston liquid enginesEngineeringSlide plate

Owner:GREE ELECTRIC APPLIANCES INC +1

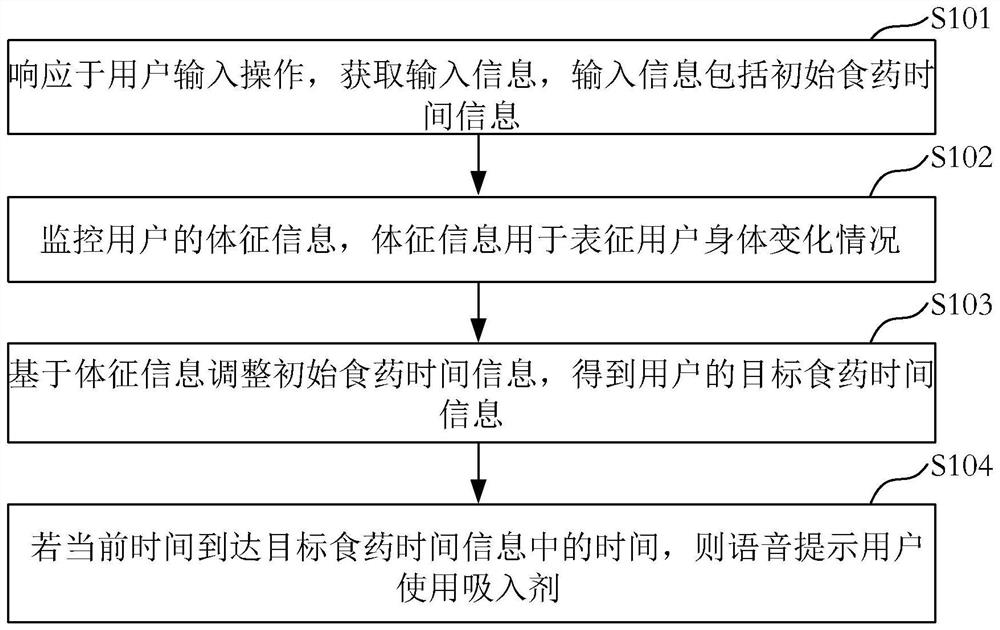

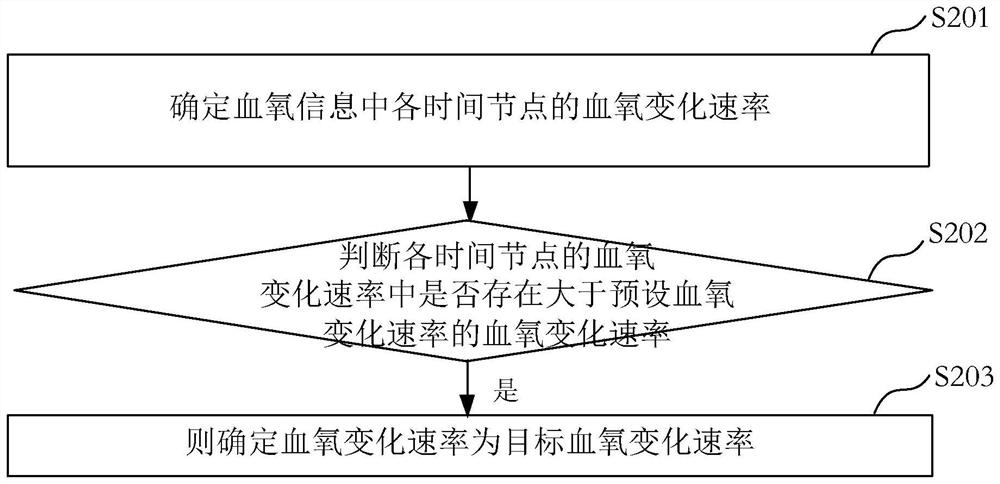

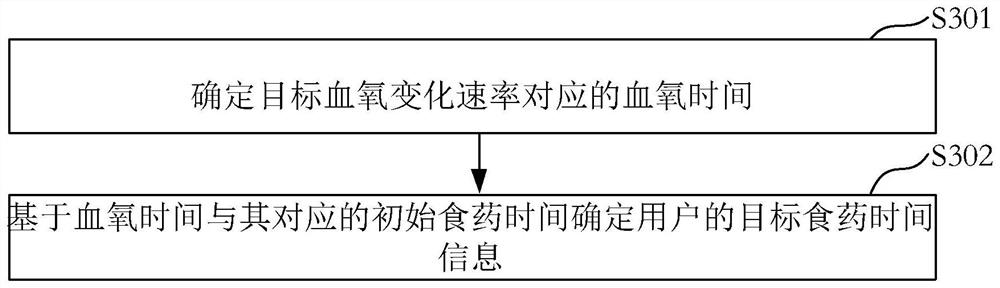

Voice reminding device and method for intelligently and interactively reminding patient to use inhalant

PendingCN114642800AGuaranteed to followGuaranteed to follow doctor's ordersDrug and medicationsEvaluation of blood vesselsTime informationInhalant Solution

The invention discloses a voice reminding device and method for intelligently and interactively reminding a patient to use inhalant. The voice reminding device for intelligently and interactively reminding a patient to use an inhalant comprises an acquisition module which is configured to respond to input operation of a user and acquire input information, and the input information comprises initial medicine taking time information; the monitoring module is configured to monitor physical sign information of the user, and the physical sign information is used for representing the body change condition of the user; the adjusting module is configured to adjust the initial medicine taking time information based on the physical sign information to obtain target medicine taking time information of the user; and the voice prompt module is configured to prompt the user to use the inhalant by voice if the current time reaches the time in the target medicine taking time information. The voice reminding device for intelligently and interactively reminding the patient to use the inhalant can remind the patient to use the inhalant at the target medicine taking time, so that the patient is prevented from forgetting to use the inhalant, and the patient is ensured to follow the doctor's advice.

Owner:THE SECOND AFFILIATED HOSPITAL OF CHONGQING MEDICAL UNIV

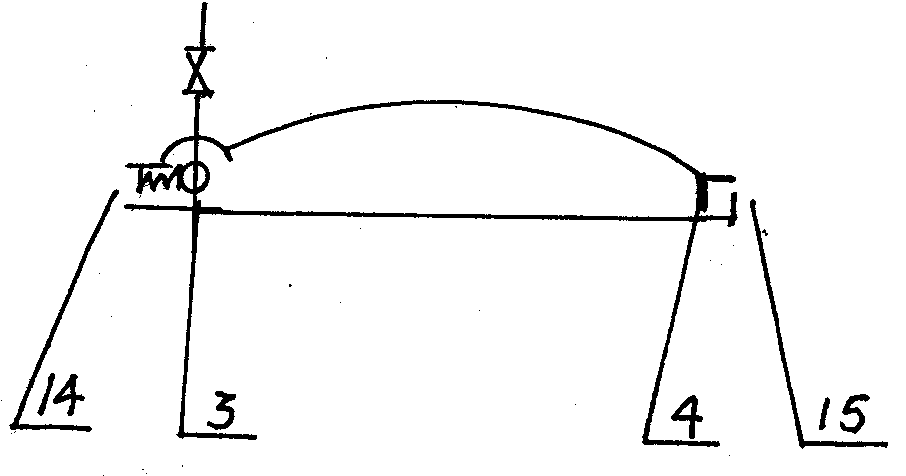

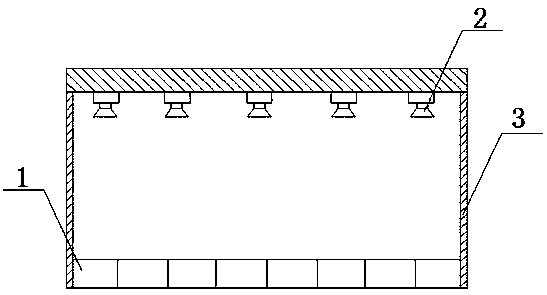

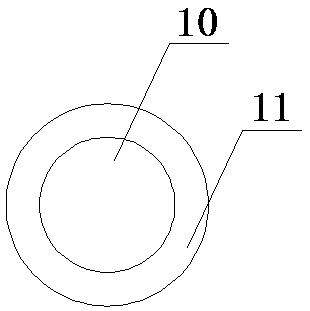

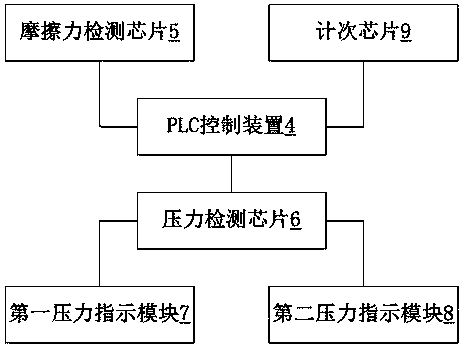

Intelligent stage system based on multi-azimuth force measurement

ActiveCN111076133AReduce errorsGuaranteed to followLighting applicationsMechanical apparatusPhysicsElectrical and Electronics engineering

The invention relates to an intelligent stage system based on multidirectional force measurement. The system comprises a plurality of stage modules, a stage follow spotlight, a support and a PLC device. The stage modules form a whole stage, the stage module comprises a plurality of friction force detection chips and a plurality of pressure detection chips, the friction force detection chips are arranged on the surface layers of the stage modules, the pressure detection chips are arranged on the lower layers of the friction force detection chips, the PLC device is connected with the friction force detection chips, the the pressure detection chips and the stage follow spotlight, the pressure detection chips are correlatied, the pressure detection chip is provided with a first pressure indication module and a second pressure indication module, the first pressure indication module and the second pressure indication module alternately flicker, the pressure detection chip is used for detecting the pressure position, the friction force detection chip is used for detecting the stage surface friction force, the friction force detection chip is used for detecting the moving direction of a stage performance personnel, and the PLC device controls the stage follow spotlight according to the moving direction of the performance personnel detected by the friction force detection chip.

Owner:陕西精诚展览装饰有限公司

Specific person autonomously following method and device, robot, equipment and storage medium

ActiveCN108724178BSelf-followingFollow the continuationProgramme-controlled manipulatorBiometric pattern recognitionHuman bodyMedicine

The present invention provides a specific person autonomously following method and device, a robot, equipment and a storage medium. The method includes: receiving trigger information; responding to the trigger information, collecting first image information; performing human body detection on the first image information to obtain the first detection Result information; according to the pre-stored registration information, the first detection result information is followed by target recognition to obtain the recognition result information; the tracking information is generated according to the recognition result information and the second image information collected in real time, for the motion control unit to automatically carry out according to the tracking information follow. The present invention performs human body detection on the collected images, and performs target recognition according to the registration information, and then generates tracking information according to the recognition results and real-time image information. It is convenient to automatically follow a specific target.

Owner:SF TECH

Solid tracer particle generator and flow field measuring device

PendingCN111650396AHigh measurement accuracyEasy to controlAerodynamic testingSpeed/acceleration/shock instrument detailsCombustionEngineering

The invention relates to a solid tracer particle generator. The solid tracer particle generator comprises a connecting flow channel and a combustion frame. A hollow combustion cavity is formed in theconnecting flow channel and can be connected to the experiment flow channel in series, and then experiment fluid in the experiment flow channel is allowed to flow through the combustion cavity. The combustion frame is arranged in the combustion cavity and can bear fuel, and tracer particles generated after the fuel is ignited can be mixed with experimental fluid in the experimental flow channel and move along with the experimental fluid. The invention further relates to a flow field measuring device comprising the solid tracer particle generator. According to the solid tracer particle generator and a flow field measuring device, the whole generation process of the solid tracer particles is completed in the experiment flow channel, fuel can be combusted with air in the experiment flow channel to generate the solid tracer particles in the experiment process, additional gas flow does not need to be added, control over the experiment fluid flow is facilitated, and the fluid following performance of the solid tracer particles is guaranteed.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com