Intelligent stage system based on multi-azimuth force measurement

A multi-directional, stage-based technology, applied to parts of lighting devices, devices used in theaters and circuses, lighting devices, etc., can solve the problem of not being able to track the position of performers in time, and achieve the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

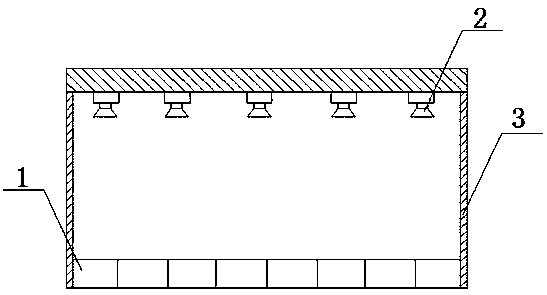

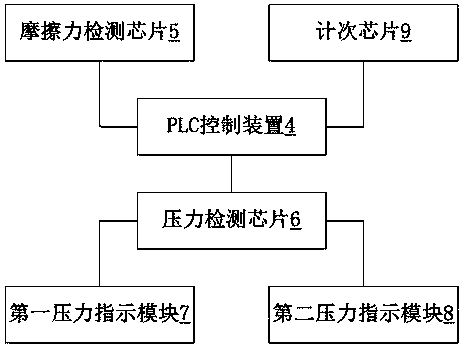

[0024] The reference picture is Figure 1-3 . An intelligent stage system based on the measurement of multi-directional force, including: several stage modules 1, stage follow spot lights 2, brackets 3 and PLC control devices 4, the stage modules 1 form the whole stage, and the brackets 3 are arranged on the stage On both sides, the stage follow spot light 2 is arranged on the bracket 3, and the stage module 1 includes several friction detection chips 5 and several pressure detection chips 6, and the friction detection chips 5 are arranged on the stage module 1 The surface layer of the surface layer, the pressure detection chip 6 is arranged on the lower layer of the friction detection chip 5, the PLC control device 4 is connected to the friction detection chip 5, the pressure detection chip 6 and the stage follow spot light 2, the pressure detection The chips 6 are related to each other. The pressure detection chip 6 is provided with a first pressure indication module 7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com