Piezoelectric actuating type accompanying hammering strengthening device and method for electric arc additive manufacturing

A technology of additive manufacturing and piezoelectric actuation, applied in the field of additive manufacturing, can solve the problems of small hammering frequency and hammering force range, large hammering equipment, and failure to achieve hammering efficiency, etc., to achieve precise control, Improve the hammering frequency and avoid the effect of high temperature in the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

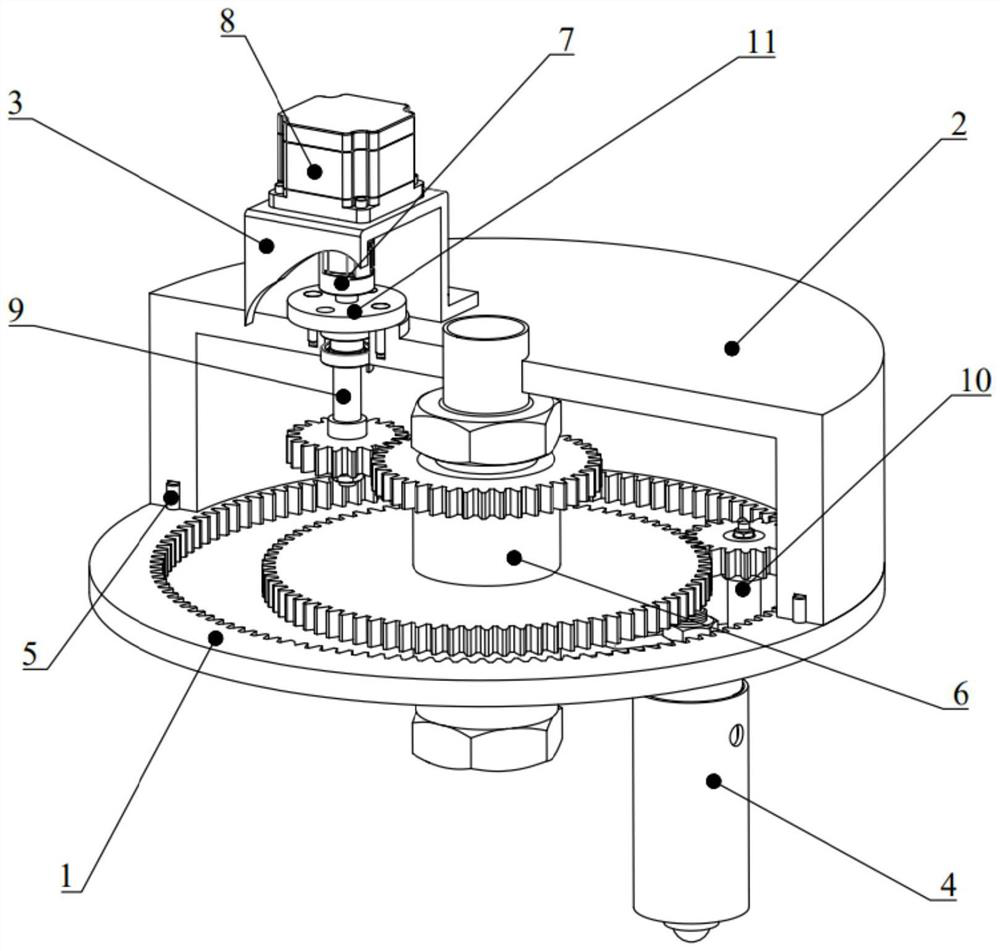

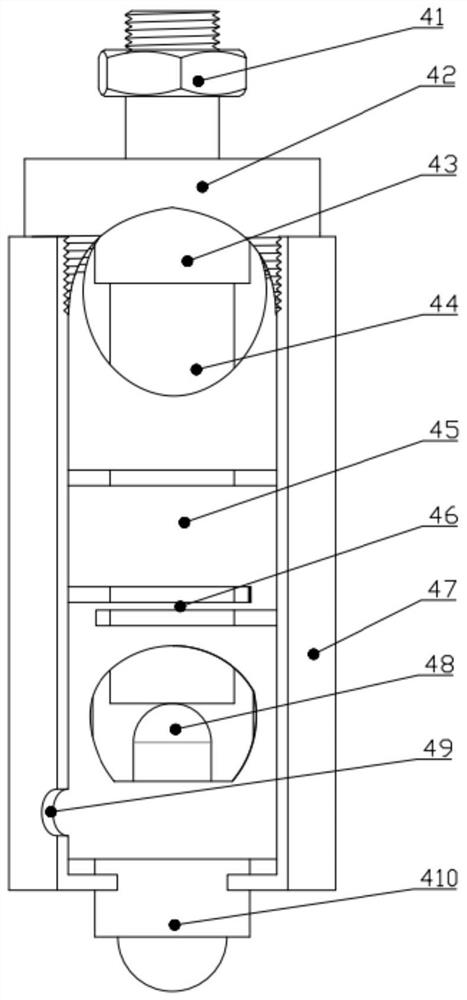

[0033] see Figure 1 to Figure 5 , a piezoelectric-actuated traveling hammer strengthening device for arc additive manufacturing, including a traveling gear transmission system and a piezoelectric hammering head system;

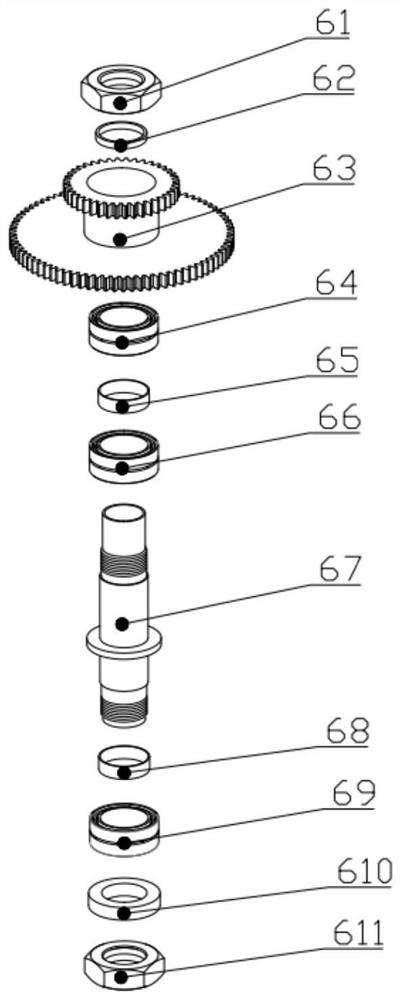

[0034] The traveling gear transmission system includes an internal gear 1, a frame 2, a hollow fixed shaft system 6, a motor 8, an input shaft system 9 and a planet carrier system 10; the frame 2 is used to support the motor 8; the motor 8 is connected to the input shaft system 9; the input shaft system 9 transmits motion to the hollow fixed shaft system 6 through gear meshing; the hollow fixed shaft system is connected to the planet carrier system 10 through gear meshing; the internal gear 1 is detachably connected to the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com