A falling-weight hydraulic breaker and equipment

A hydraulic breaker and drop-weight technology, applied in the field of mining machinery, can solve the problems of low crushing efficiency of large ores and hard materials, complex structure of hydraulic breaker, difficulty in improving production efficiency, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

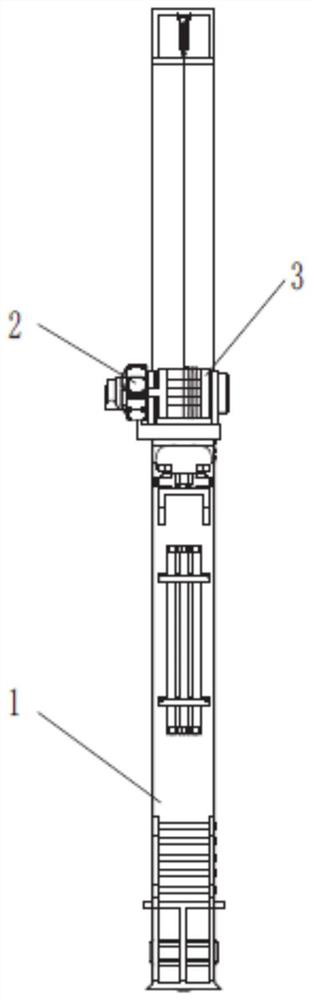

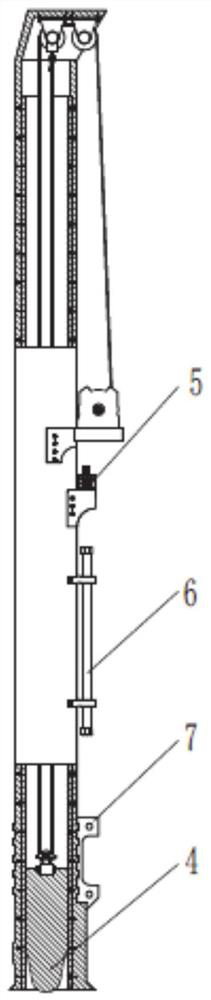

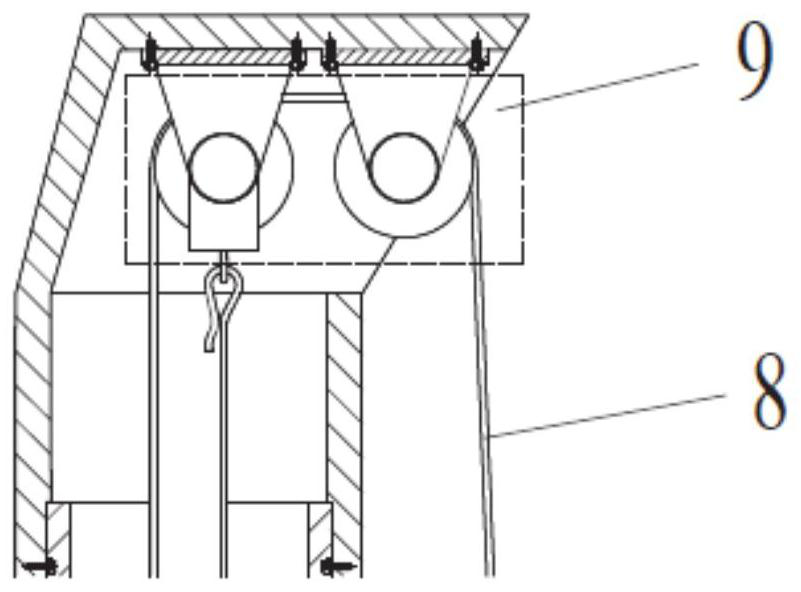

[0038] This embodiment provides a falling weight hydraulic breaker, which includes a hammering device and a hydraulic system, and the hammering device is connected to the hydraulic system. Among them, such as figure 1 and figure 2 As shown, the hammering device includes a guide cylinder 1, a lifting mechanism, and a weight 4. The weight 4 is set in the guide cylinder 1, and the weight 4 is connected to the lifting mechanism. The lifting mechanism drives the weight 4 to move axially along the guide cylinder 1. , to achieve the hammering action.

[0039] Specifically, the guide cylinder 1 is a hollow cylinder or a square cylinder formed by welding section steel. A linear guide rail extending from the bottom to the top is provided inside the guide cylinder 1 along the axial direction, and the weight 4 is slidably connected to the linear guide rail. A first connecting piece 7 is installed on the side of the guide cylinder 1, and the first connecting piece 7 is used for connect...

Embodiment 2

[0058] This embodiment provides a crushing device, including construction machinery and the hydraulic breaker described in Embodiment 1. The hydraulic breaker is installed in front of the construction machinery through the first connecting piece 7 .

[0059] The heavy hammer 4 extracts the hydraulic oil in the oil tank of the construction machinery through the hydraulic oil pump installed on the construction machinery. The oil enters the hydraulic motor 2 through the proportional valve 13, drives the hydraulic motor 2 to rotate, and then drives the reel 3 to rotate. The pulley assembly lifts the weight 4, and the weight 4 accelerates up along the linear guide rail inside the guide cylinder 1.

[0060] When the weight 4 is lifted close to the top, the position of the weight 4 is detected by the travel switch, and the controller 14 sends a signal to the brake device, the brake device starts, stops the rotation of the reel 3, and the weight 4 stops at the predetermined position. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com