Loading following trolley

A car and load technology, applied in the direction of vehicle position/route/height control, signal transmission system, instruments, etc., can solve the problem of heavy load of students, and achieve the effect of ensuring the follow-up effect and preventing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

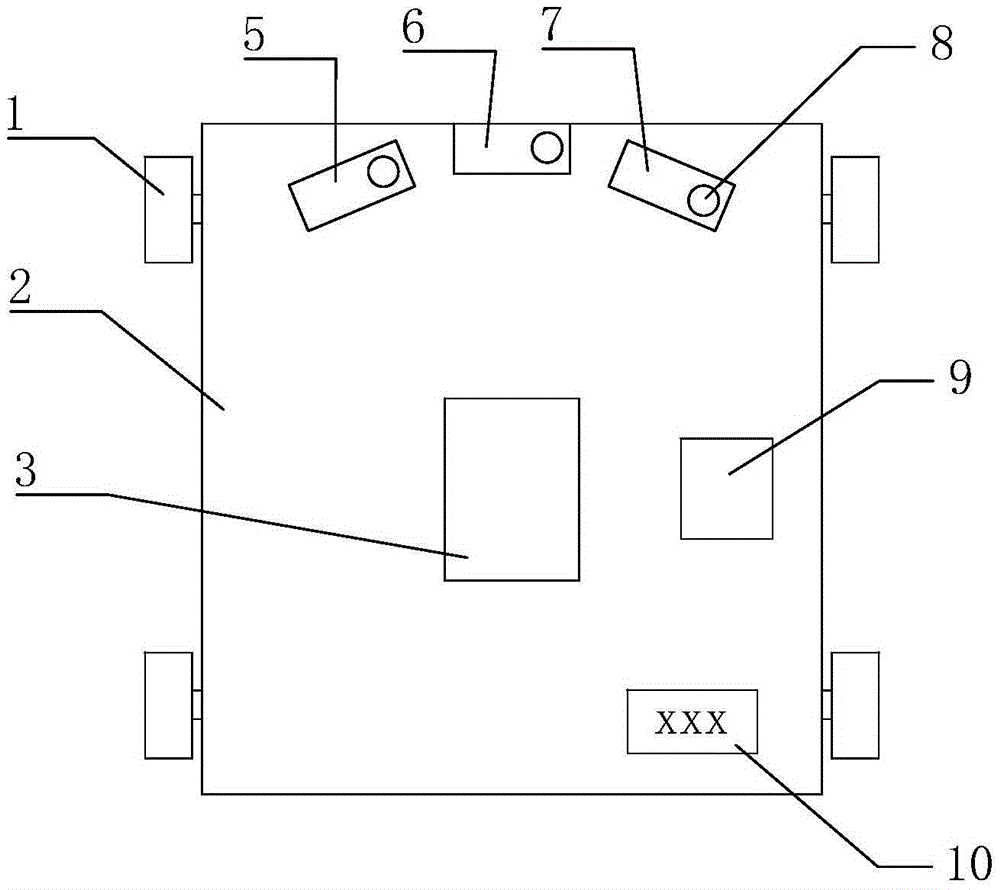

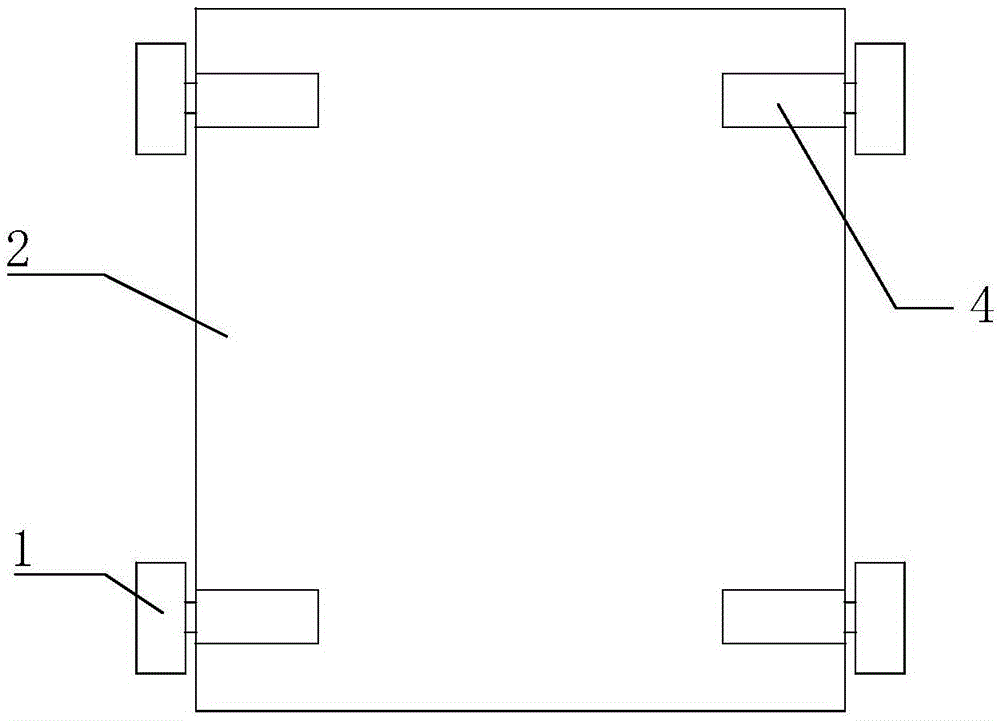

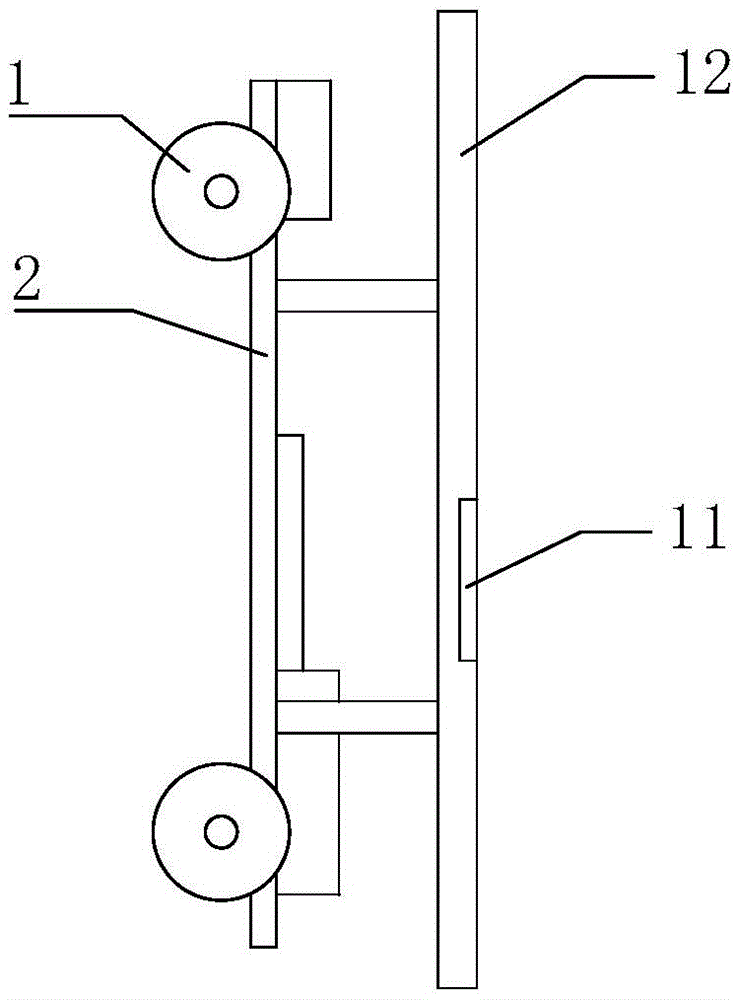

[0035] Such as Figure 1 to Figure 3 As shown, a kind of load following trolley comprises a car body 2, and the upper part of the car body 2 is supported by a support column to be provided with a loading platform 12, and an electronic weighing device 11 is arranged on the loading platform 12, and the electronic weighing device 11 Connect the control module 3.

[0036] The car body is provided with a control module 3, a sensor module, a power module, a power module 9, a display 10 and a remote control device:

[0037] The control module 3 is the control core, adopts an arduino single-chip microcomputer, and is respectively connected with the sensor module, the power module, the power supply module 9 and the display 10 through lines, and the control module can also be manually set through buttons;

[0038] The power module includes a motor 4. In order to realize the load function, a high-power geared motor is used. The power module 9 uses a 12v voltage to ensure sufficient powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com