Cooperating structure of a compressor and its rollers and sliding vanes

A technology of matching structure and compressor, applied in the field of compressor, can solve the problems of small difference between discharge pressure and suction pressure, small suction pressure and discharge pressure of compressor, abnormal noise of compressor, etc., so as to increase friction force. , the effect of maintaining followability, increasing contact length and contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The purpose of this specific embodiment is to provide a cooperation structure between the roller and the sliding vane of the compressor, which can avoid the problem that the sliding vane and the roller are detached in the prior art. The purpose of this specific embodiment is also to provide a compressor including the cooperation structure of the above-mentioned rollers and sliding vanes.

[0021] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

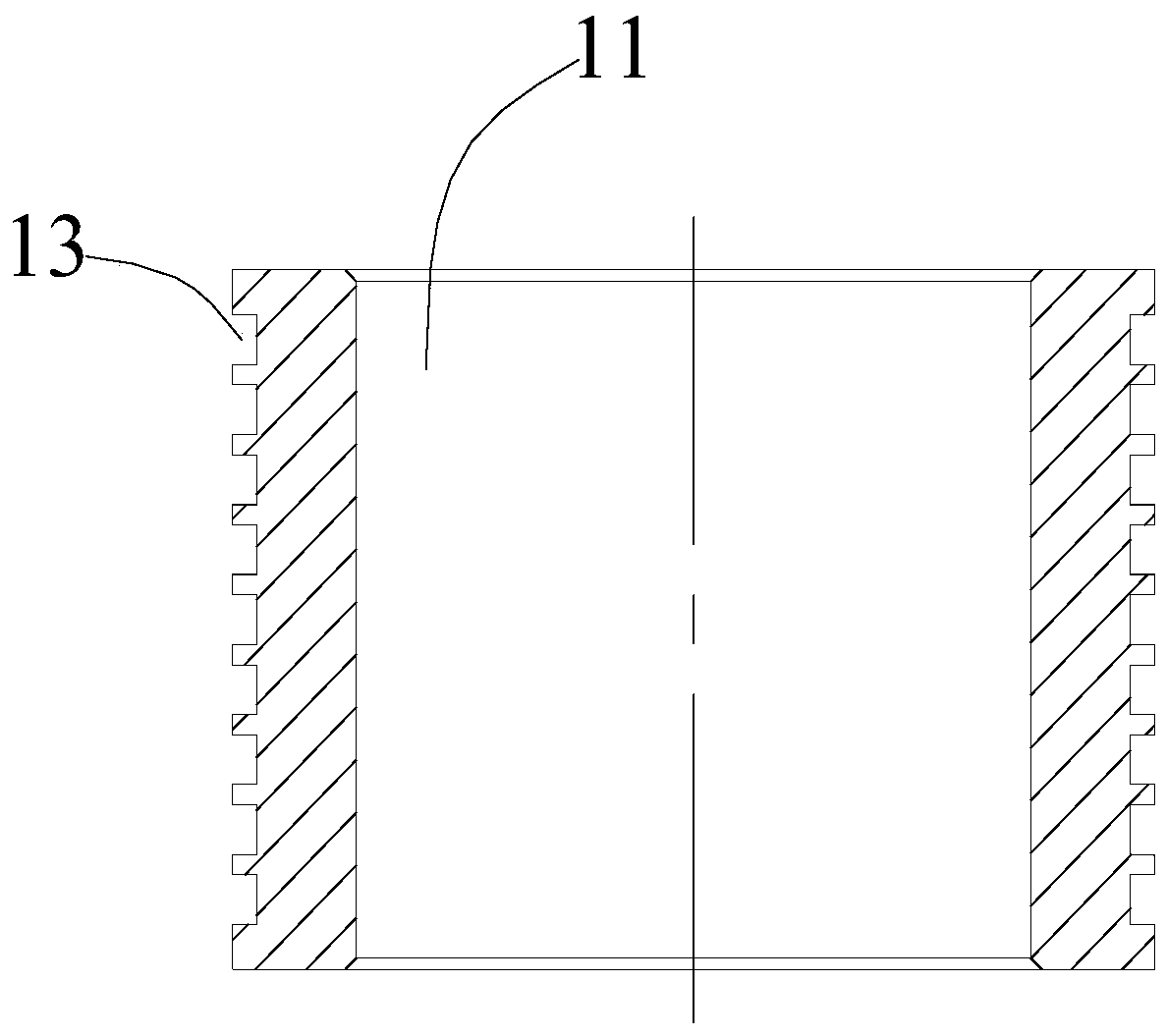

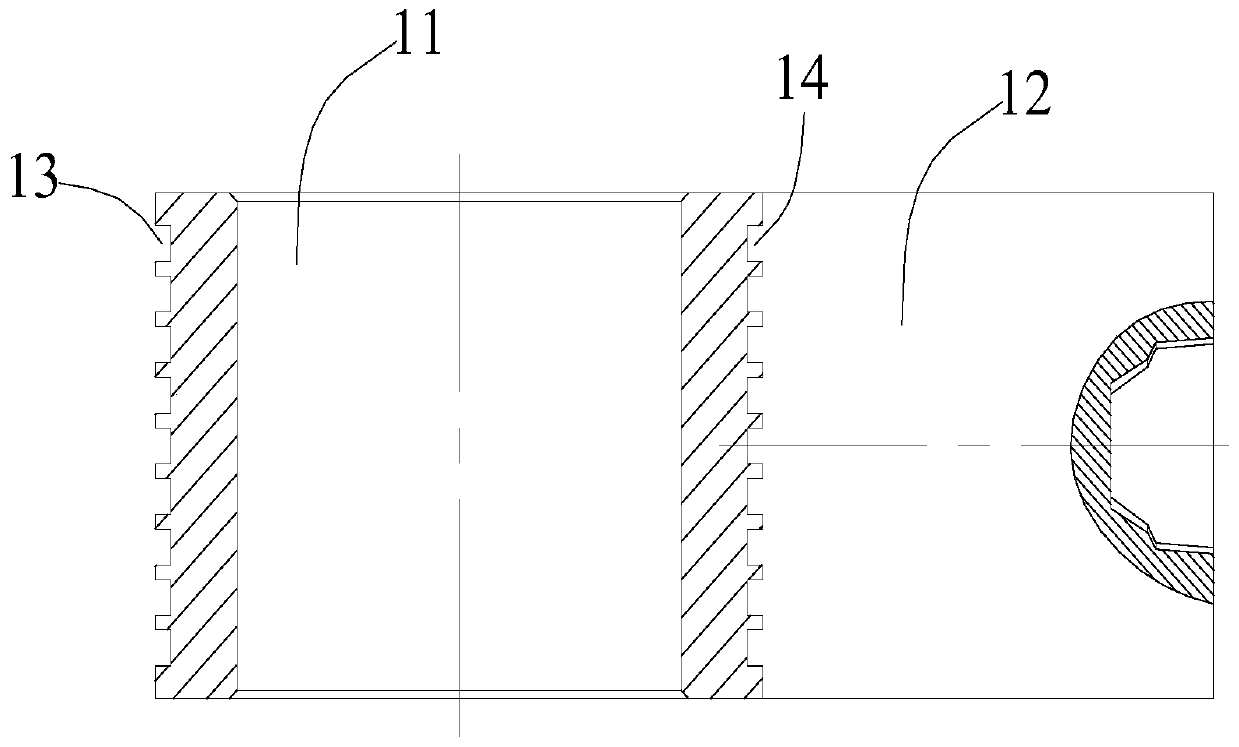

[0022] Please refer to Figure 1-Figure 2 , the cooperation structure between the roller 11 and the sliding plate 12 of the compressor provided in this specific embodiment, wherein an annular protrusion (not s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com