Phased array ultrasonic detection self-adaptive balance probe bin for fillet welds of tube and tube plates

A technology for ultrasonic testing and fillet welds, applied in the direction of material analysis, measuring devices, and instruments using sound waves/ultrasonic waves/infrasonic waves, which can solve problems such as signal loss, signal drift, and poor coupling, and achieve good contact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

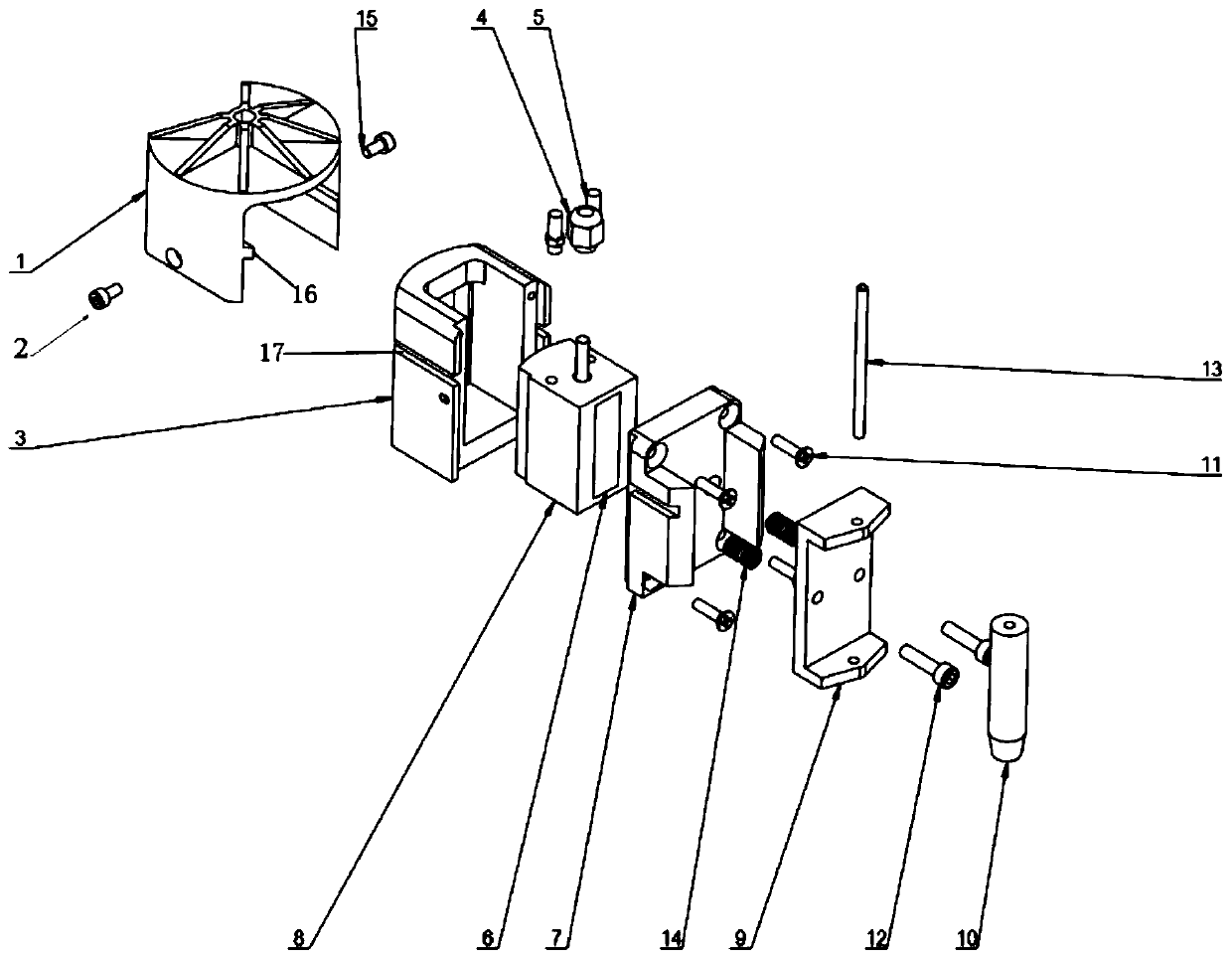

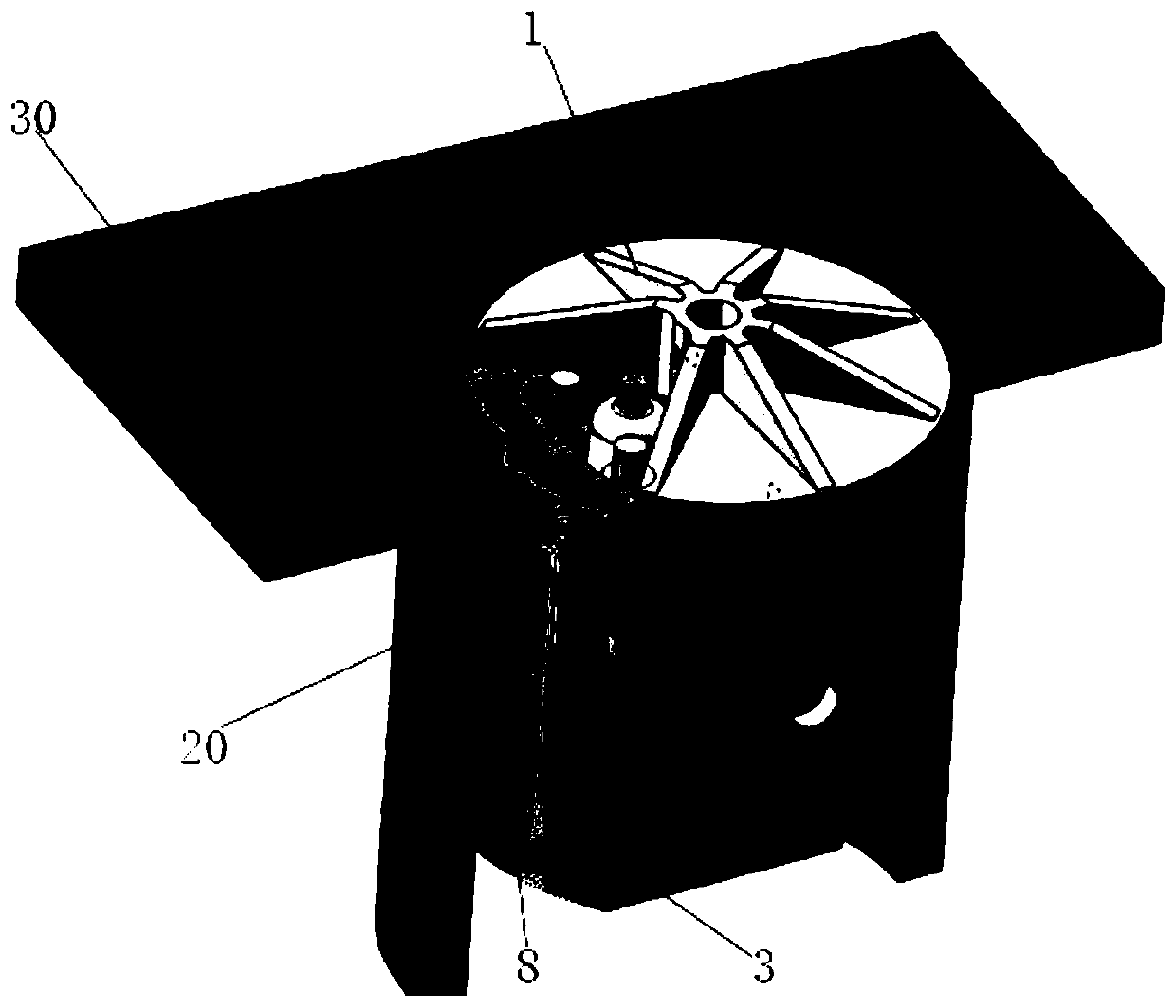

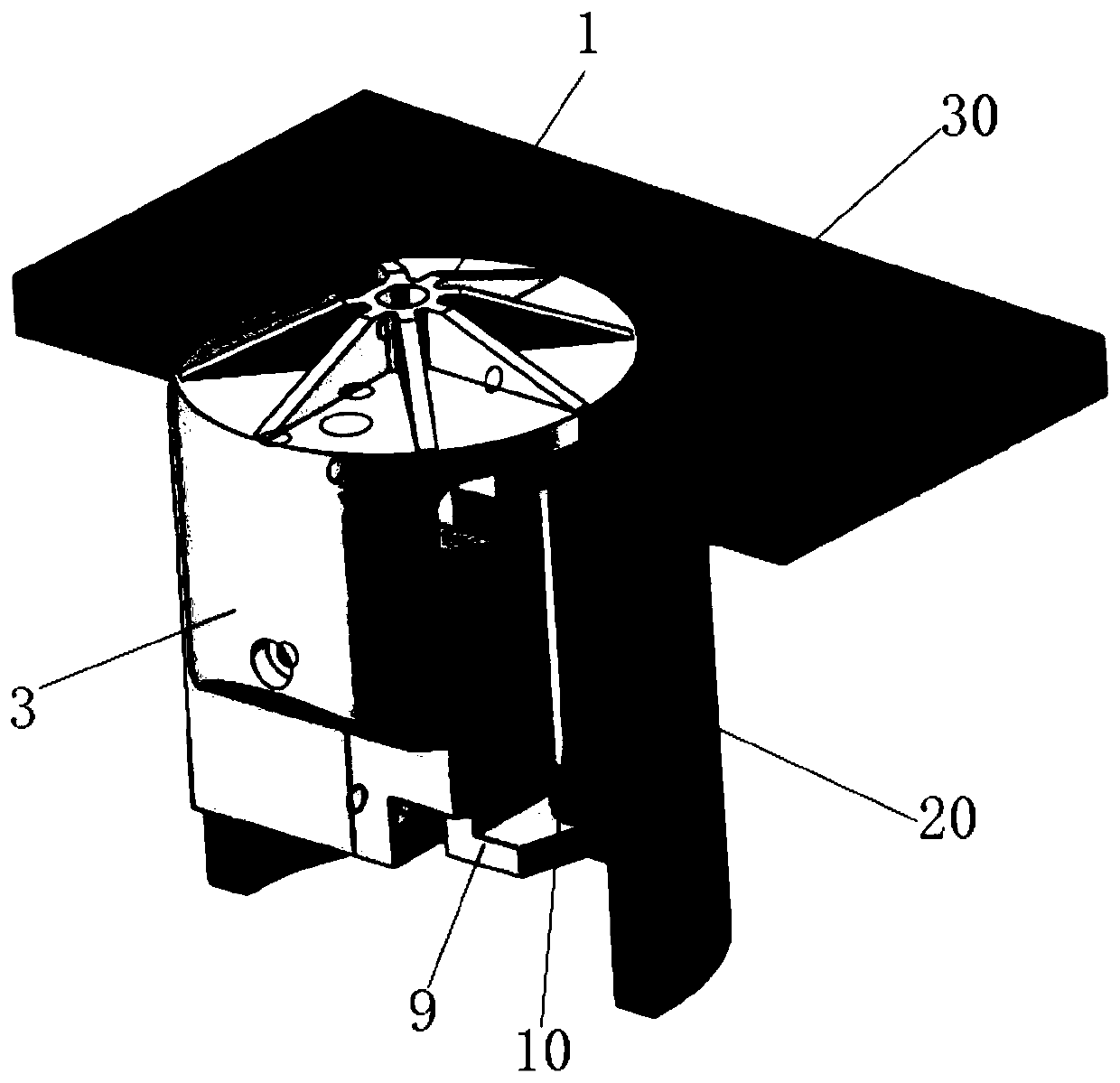

[0022] The present invention will be further explained below in conjunction with the accompanying drawings.

[0023] At first some technical terms involved in the present invention are explained:

[0024] Phased array ultrasonic testing of tube-tube-sheet fillet welds: tube-tube-sheet fillet welds are the main welding structure of tube-and-tube heat exchangers and reactors. This structure is a weak link in the equipment and is prone to leakage. Therefore, non-destructive testing is required. Phased-array ultrasonic testing of tube-tube-sheet fillet welds is an advanced non-destructive testing technology newly invented in recent years.

[0025] Probe chamber: During the phased array inspection of the tube plate fillet weld, the probe is put into the probe chamber, the probe chamber is put into the pipe, the chamber is filled with water as the coupling agent, and rotates under the drive of the motor, the ultrasonic waves emitted by the probe Scan the whole fillet weld and recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com