A sliding vane compressor

A compressor and sliding vane technology, applied in the field of compressors, can solve the problems of unfavorable sliding vane 99 protruding, increased power consumption, unstable pressure difference, etc., to reduce the power consumption of the sliding vane head and reduce power consumption , to ensure the effect of follow-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described below based on examples, but the present invention is not limited to these examples. In the following detailed description of the invention, some specific details are set forth in detail. The present invention can be fully understood by those skilled in the art without the description of these detailed parts. To avoid obscuring the essence of the present invention, well-known methods, procedures, procedures, and components have not been described in detail.

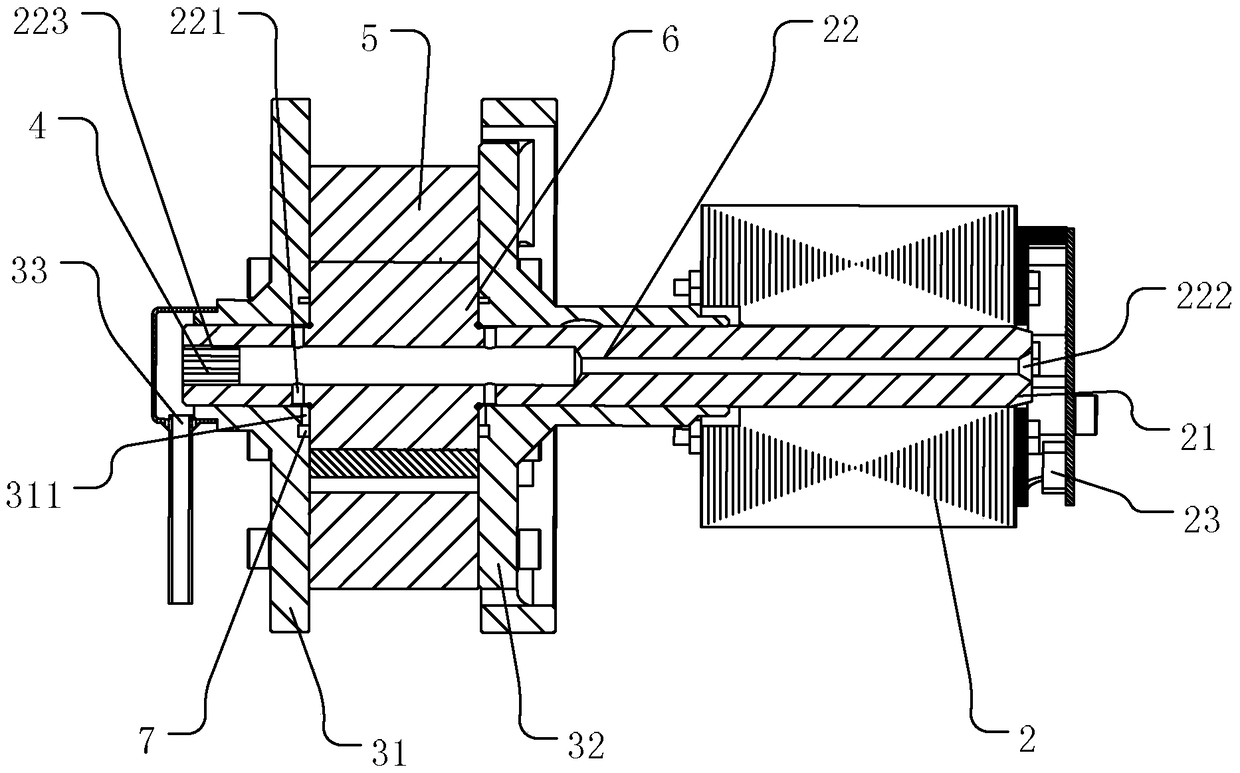

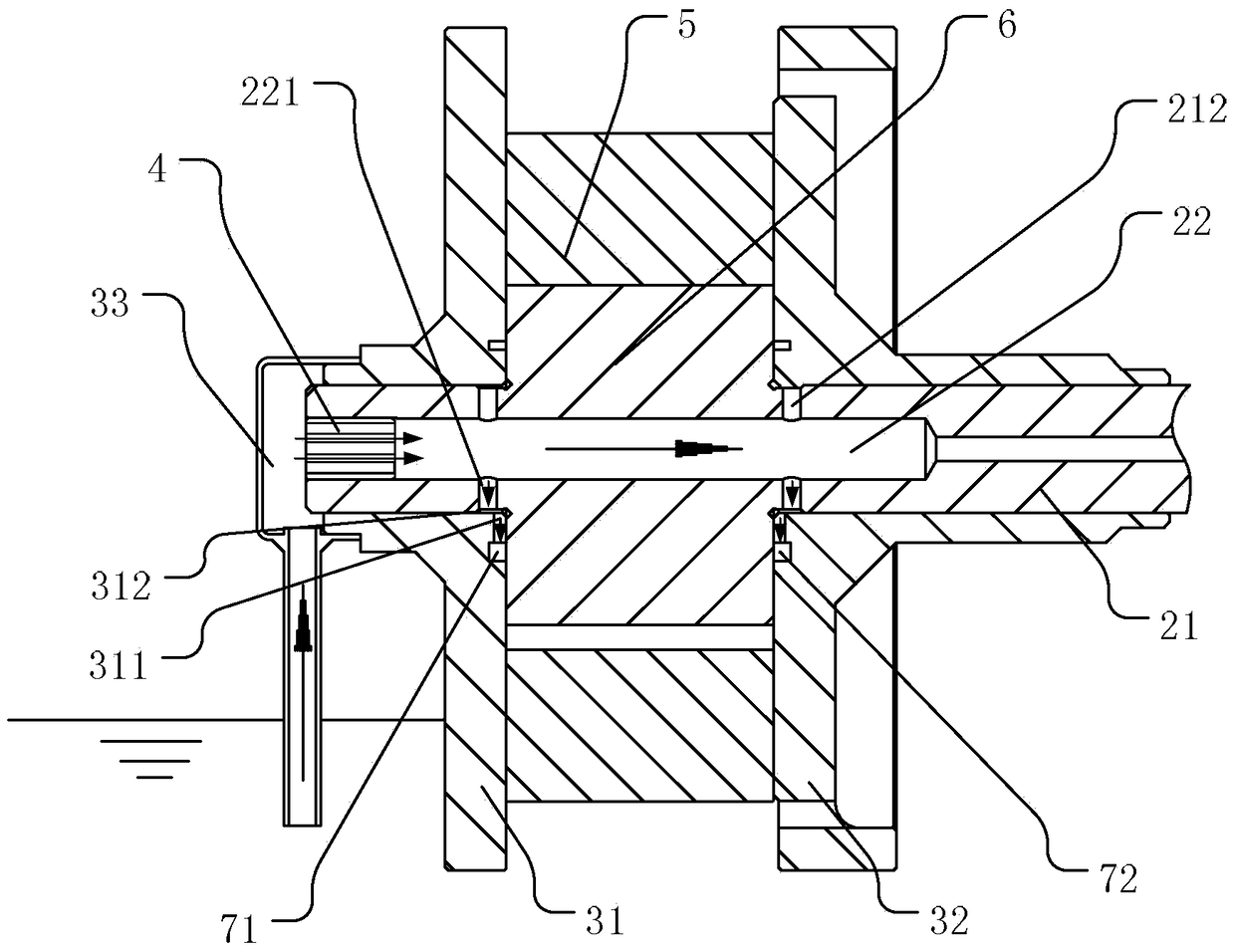

[0039]The directions in this application are defined as follows: the head end 81 of the slide plate 8 is the end away from the axis of the main shaft 21 , and the tail end 82 of the slide plate 8 is the end close to the axis of the main shaft 21 . The tail cavity 610 of the slide groove 61 is a part close to the axis of the main shaft 21 .

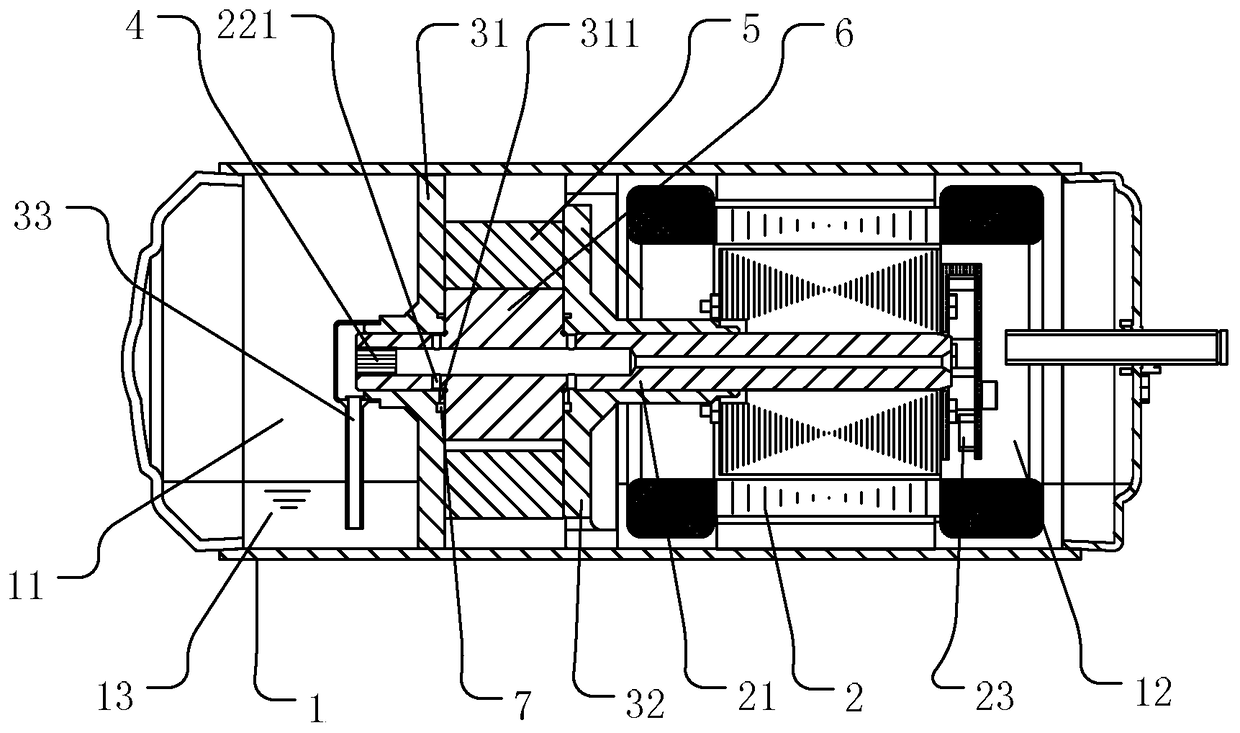

[0040] Such as Figure 1-9 As shown, the present invention relates to a vane compressor, the structure of which is mainly composed of a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com