Mechanical sealing device with axial adjusting function for large-sized dredger sludge pump

A mechanical seal device and axial adjustment technology, which is applied to parts of pumping devices for elastic fluids, mechanical equipment, pumps for special fluids, etc., can solve the problem of reducing the utilization rate of mud pump equipment, aggravating the wear of sealing rings, and sealing Unstable use effect and other problems, to achieve the effect of ensuring reliability and maintenance convenience, ensuring concentricity and followability, convenient transportation and on-site installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

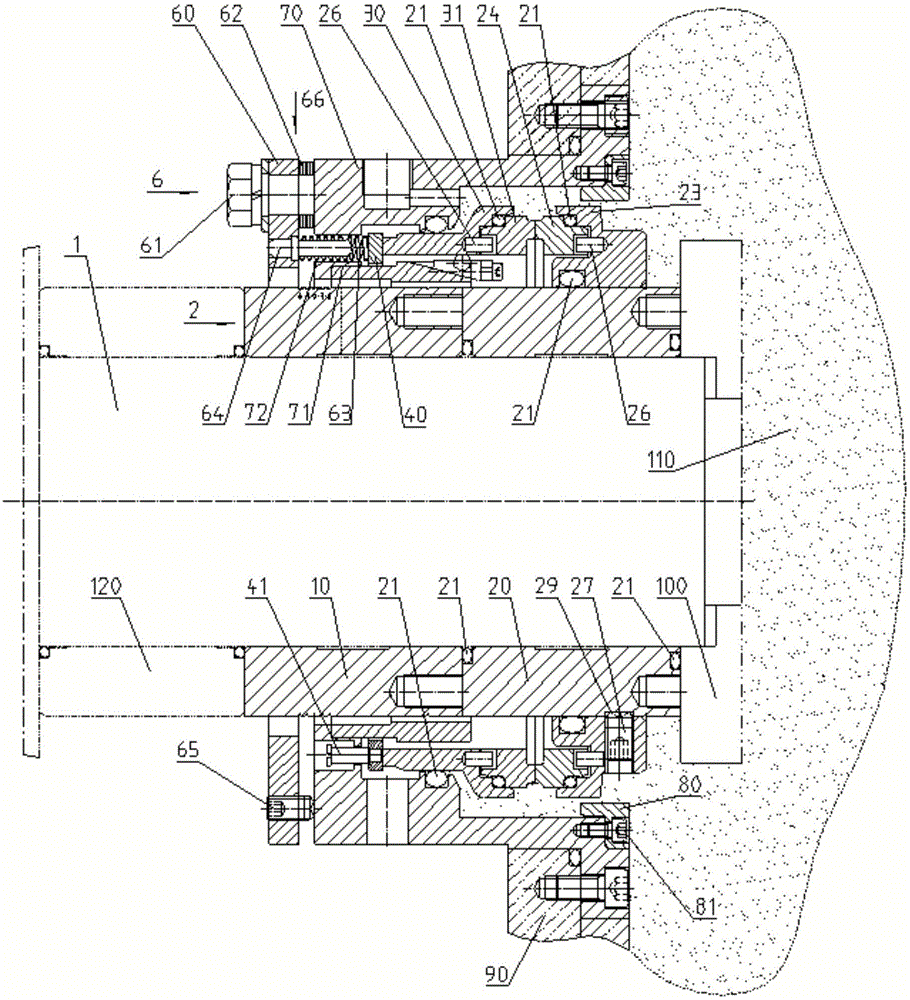

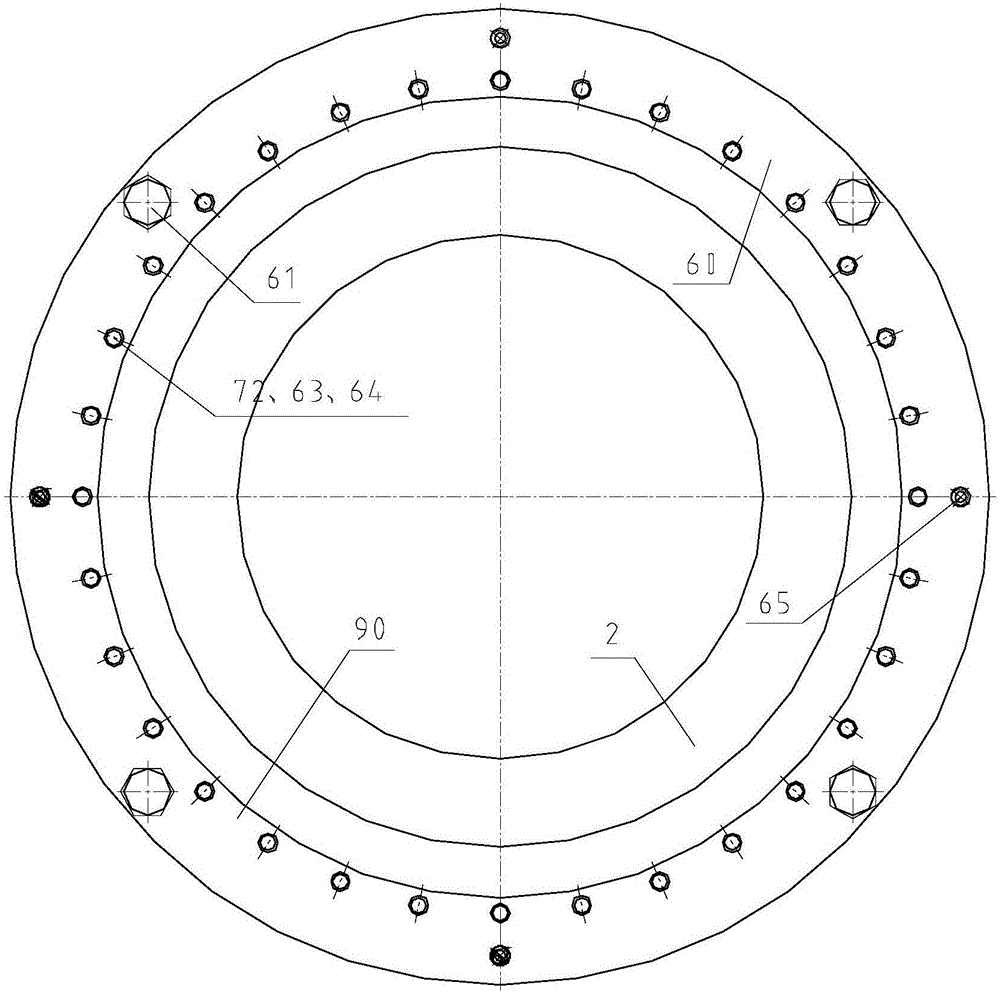

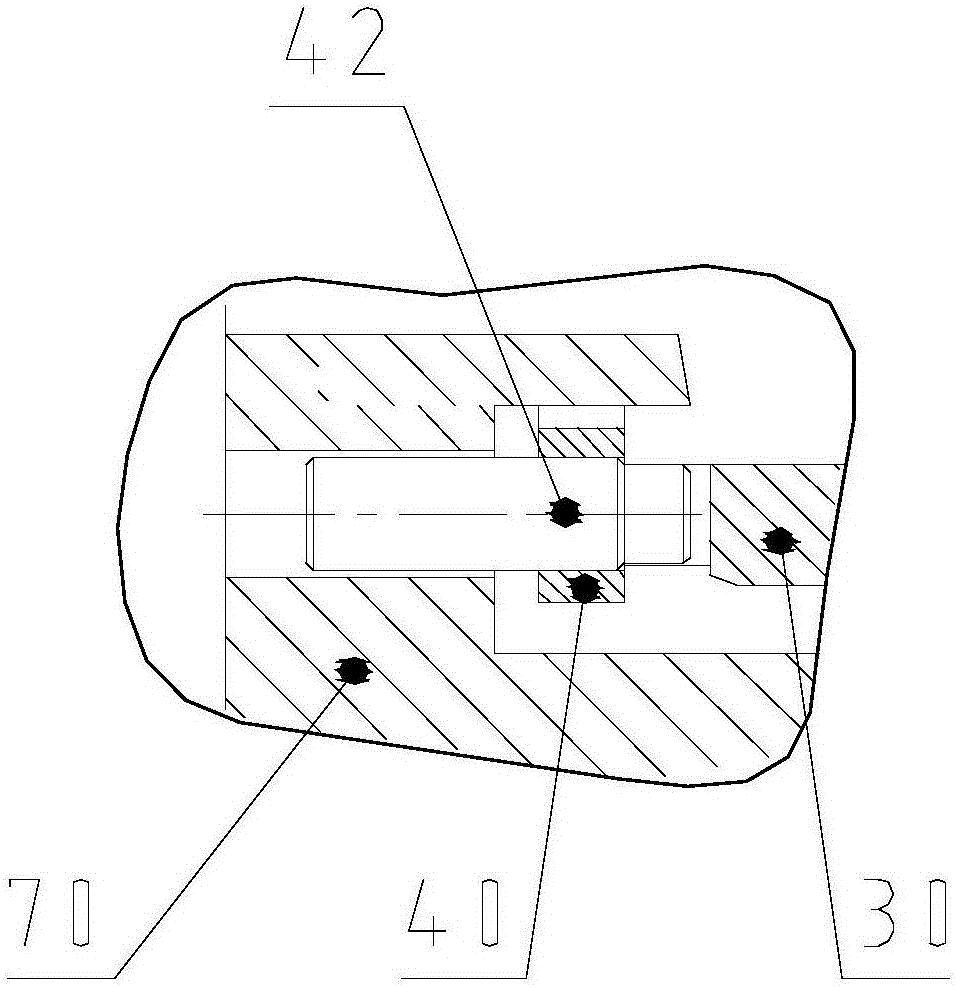

[0029] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0030] see Figure 1 to Figure 5 , a mechanical seal device of a large dredger dredger pump with an axial adjustment function, the mechanical seal device is installed on the pump shaft 1 of the dredger inner dredger pump, and includes a seal box 70 sealingly connected with the dredger pump 90, Its main function is to fix the static part of the whole set of mechanical seal with the mud pump 90, so that the static ring 31 will not rotate without the rotation of the moving ring 24; The pump shaft is free from wear and corrosion of external factors, and is used to support and connect other parts of the mechanical seal; the moving ring seat 23 with the moving ring 24 installed in the seal box 70 and the static ring seat 30 with the static ring 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com