Multifunctional stringing auxiliary device for power distribution line

A technology of power distribution lines and auxiliary devices, which is applied in the direction of overhead lines/cable equipment, etc., and can solve the problems of lowering the quality of wiring construction, slow construction progress, and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

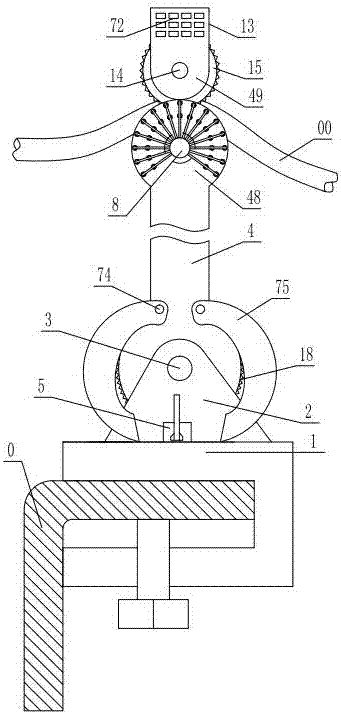

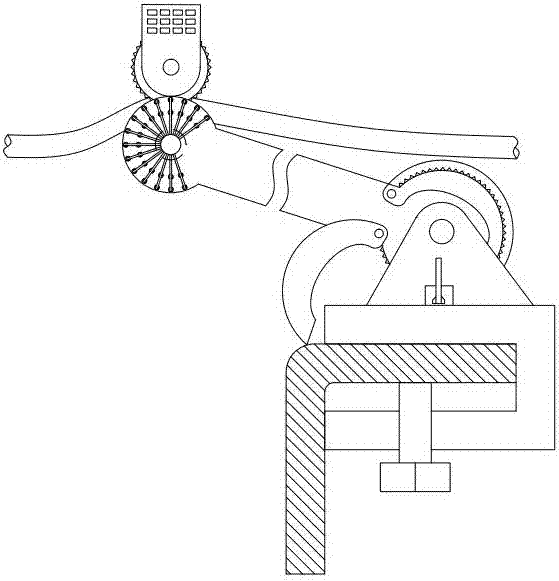

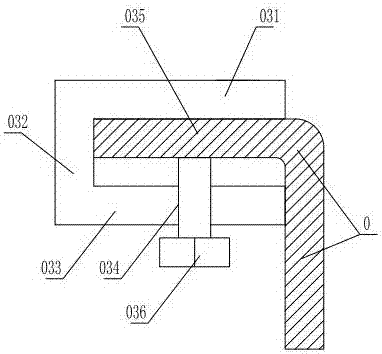

[0029]As shown in the figure, the multi-functional power distribution line stringing auxiliary device includes a base 1, and a lower locking device that is locked and matched with the cross arm 0 of the pole is provided at the bottom of the base. 1. The upper plate 031 extending horizontally at the bottom. The rear end of the upper plate 031 is vertically fixed with a vertical plate 032 extending downward. A screw hole 034 is provided, and the screw hole 034 is screwed with a positioning bolt 036 clamping the horizontal plate 035 of the cross arm 0 in the cavity between the upper plate 031 and the lower plate 032, and the base is fixed with a bracket 2, the bracket A support tube 4 is hinged through the support shaft 3, and the lower section of the support tube is fixed with a lower gear 18 coaxially arranged with the support shaft. There are two main struts 6 and auxiliary struts 7 that extend upwards and are arranged in parallel. A main wheel shaft 8 that is parallel to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com