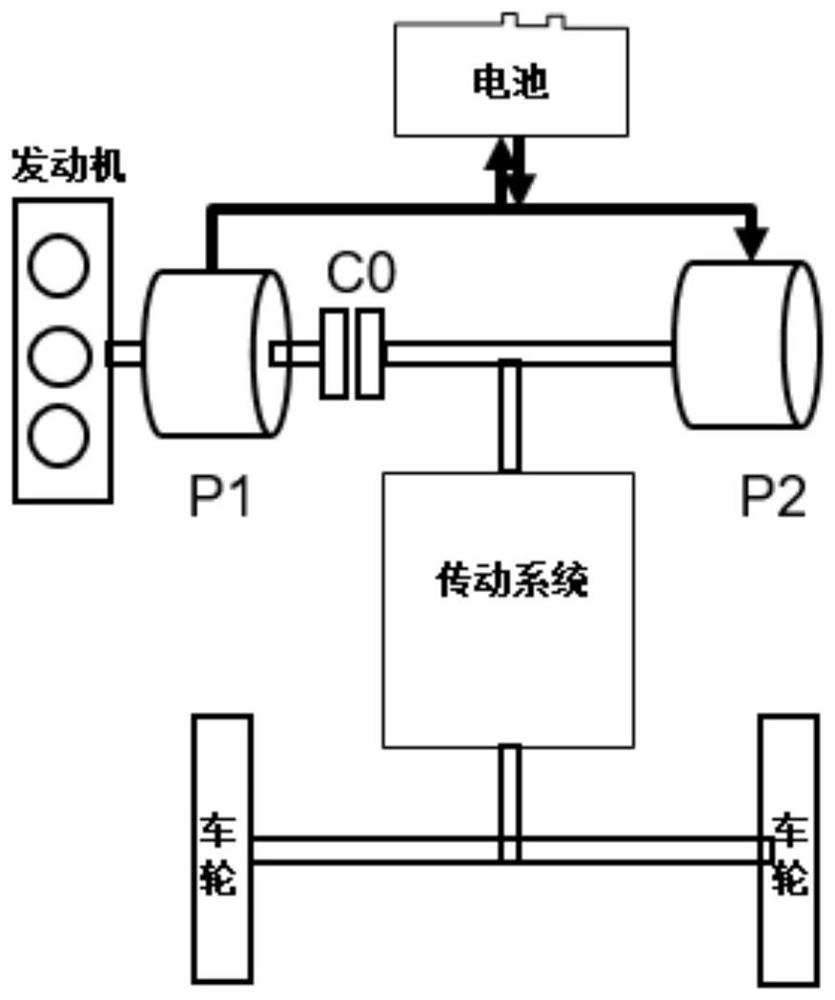

Motor torque filtering control method and system and hybrid vehicle

A filtering control and motor torque technology, applied in the field of torque filtering, can solve problems such as vehicle movement, poor driving experience, impact, etc., to achieve the effect of reducing fuel consumption and improving ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

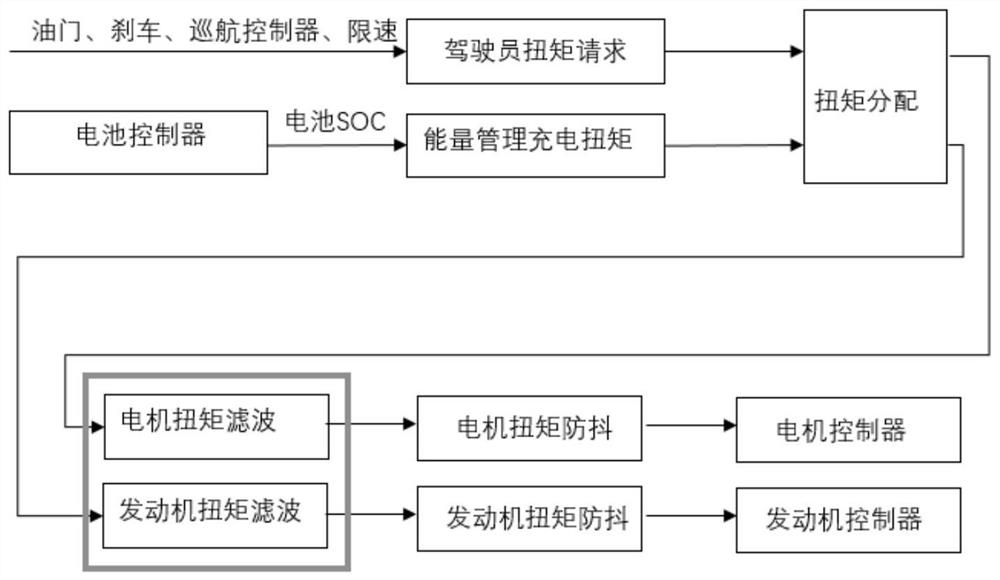

Method used

Image

Examples

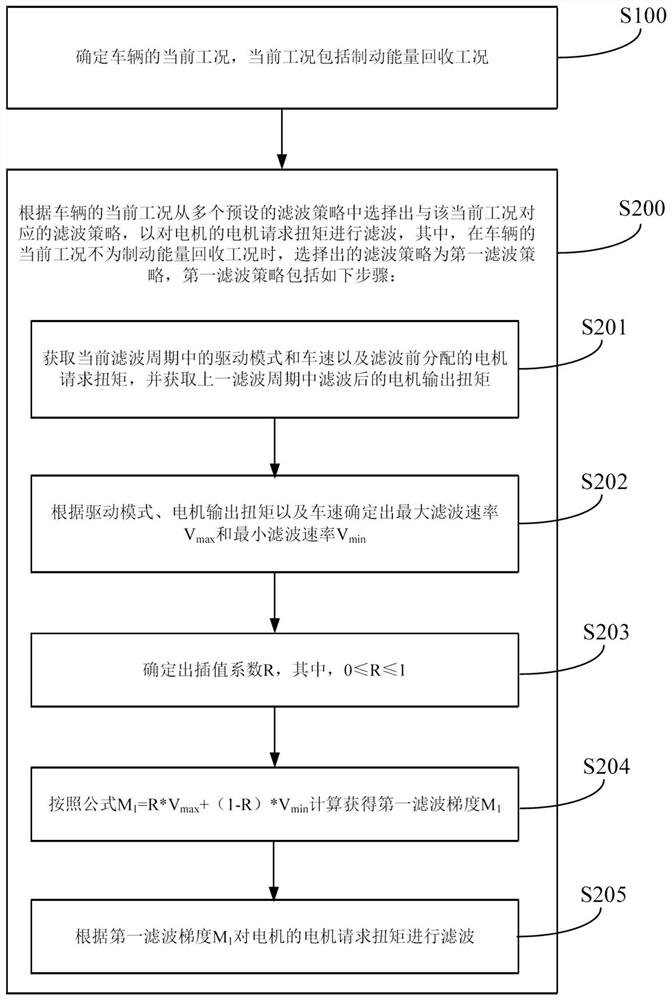

Embodiment 1

[0124] Under the pedaling condition and the pedal release condition, the vehicle has normal working conditions and special working conditions. Among them, the special working conditions include the braking energy recovery working condition, the torque zero-crossing working condition, the full throttle acceleration working condition and the current driving condition. The mode is parallel drive mode. The values of the filter gradients are different for the normal working conditions and special working conditions corresponding to the pedaling working condition, and for the normal working conditions and special working conditions corresponding to the pedal loosening working condition.

[0125] In this embodiment, a new motor torque filter control method is proposed only for the normal working conditions corresponding to the pedaling condition and the special working conditions except the braking energy recovery working condition. The normal working conditions and the special wor...

Embodiment 2

[0237] The difference between the second embodiment of the present invention and the first embodiment is that the second embodiment improves the motor torque filtering under the braking energy recovery working condition.

[0238] In this embodiment, the method from step S210 to step S230 is adopted when the vehicle is in the braking energy recovery condition. Such as Figure 13 As shown, the fourth mapping relationship table in the above step S210 is calibrated in the following way:

[0239] Step S2101, generating motor output torque, vehicle speed and second preset filter gradient M under braking energy recovery conditions 2 'The third initial mapping relationship table;

[0240] Step S2102, according to the third initial mapping relationship table, control the vehicle to run under the braking energy recovery working condition and different motor output torques and vehicle speeds, and use the motor output in the third initial mapping relationship table when the vehicle is r...

Embodiment 3

[0266] The difference between Embodiment 3 of the present invention and Embodiment 1 or Embodiment 3 of the present invention and Embodiment 2 is that Embodiment 3 improves the motor filter generator for each normal working condition and special working condition corresponding to the loose pedal working condition. . In the third embodiment, the motor filtering method of each normal working condition and special working condition corresponding to the pedal loosening condition is consistent with the motor filtering method of each normal working condition and special working condition corresponding to the pedaling working condition, but The various parameters involved in V max , V min And the value of R is different.

[0267] Since the motor filtering method under each working condition under the pedal loosening condition is consistent with the motor filtering method under each working condition under the pedaling working condition (except for the torque zero-crossing working c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com