Fixed pressure by-pass valve device for air quantity control system

An air volume control system and bypass valve technology, applied in the direction of ventilation valves, valve devices, safety valves, etc., can solve the problems of reducing the air volume and air pressure accuracy, time lag, and pressure oscillation of the ventilation and air conditioning system, so as to avoid the occurrence of And the effect of expanding, avoiding pressure oscillation, and stabilizing wind pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

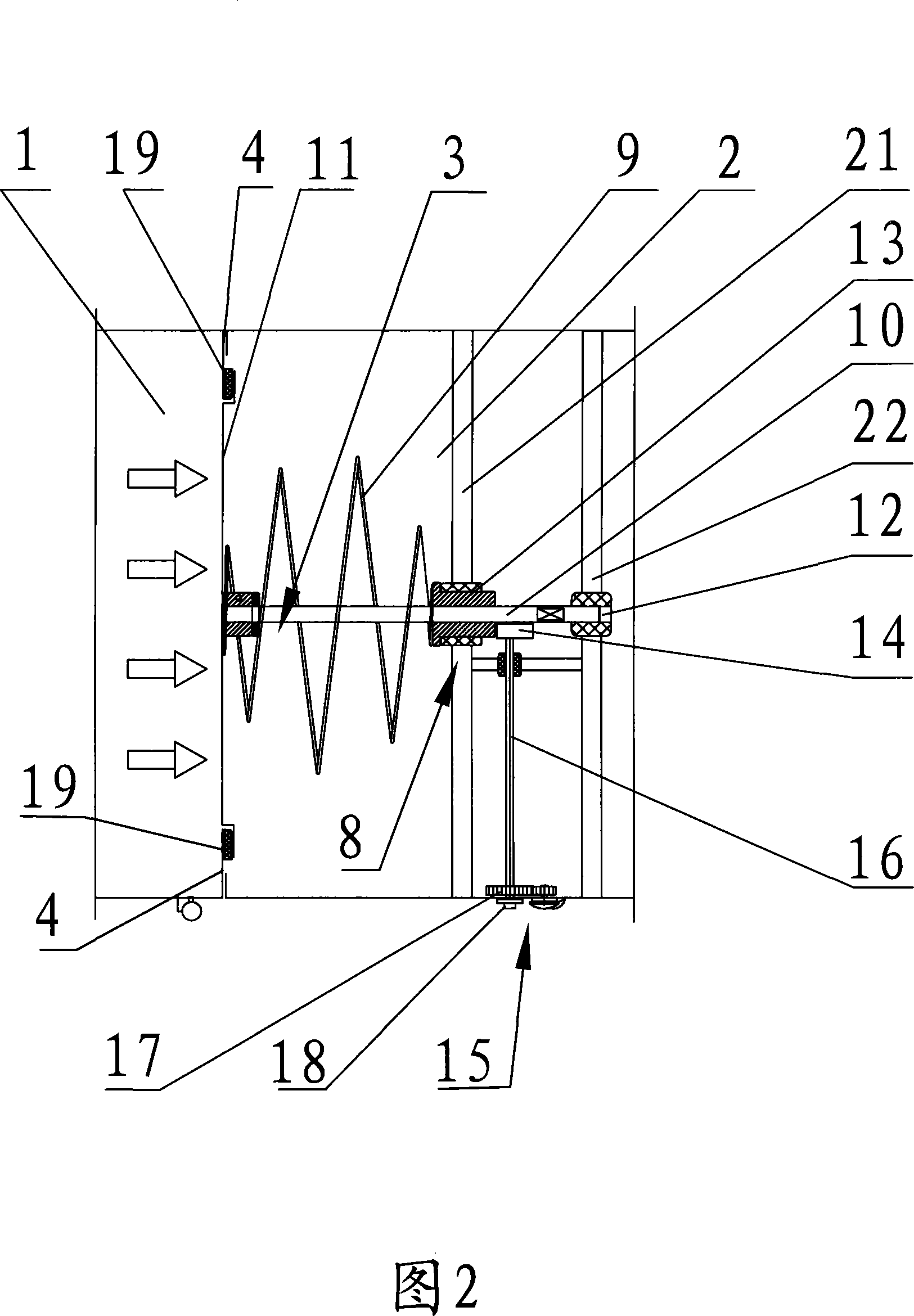

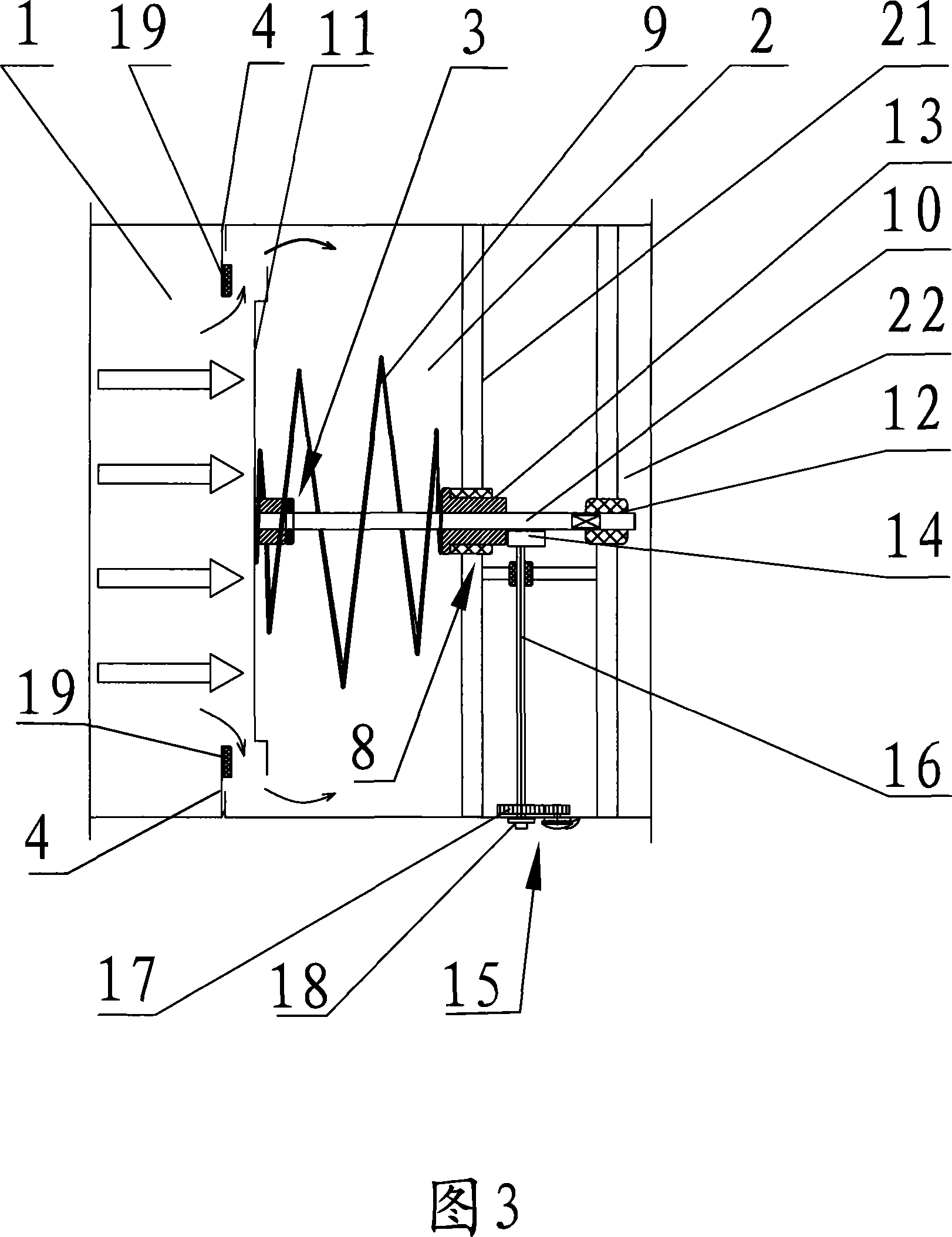

[0015] The structure and working principle of the present invention will be further elaborated below in conjunction with the accompanying drawings.

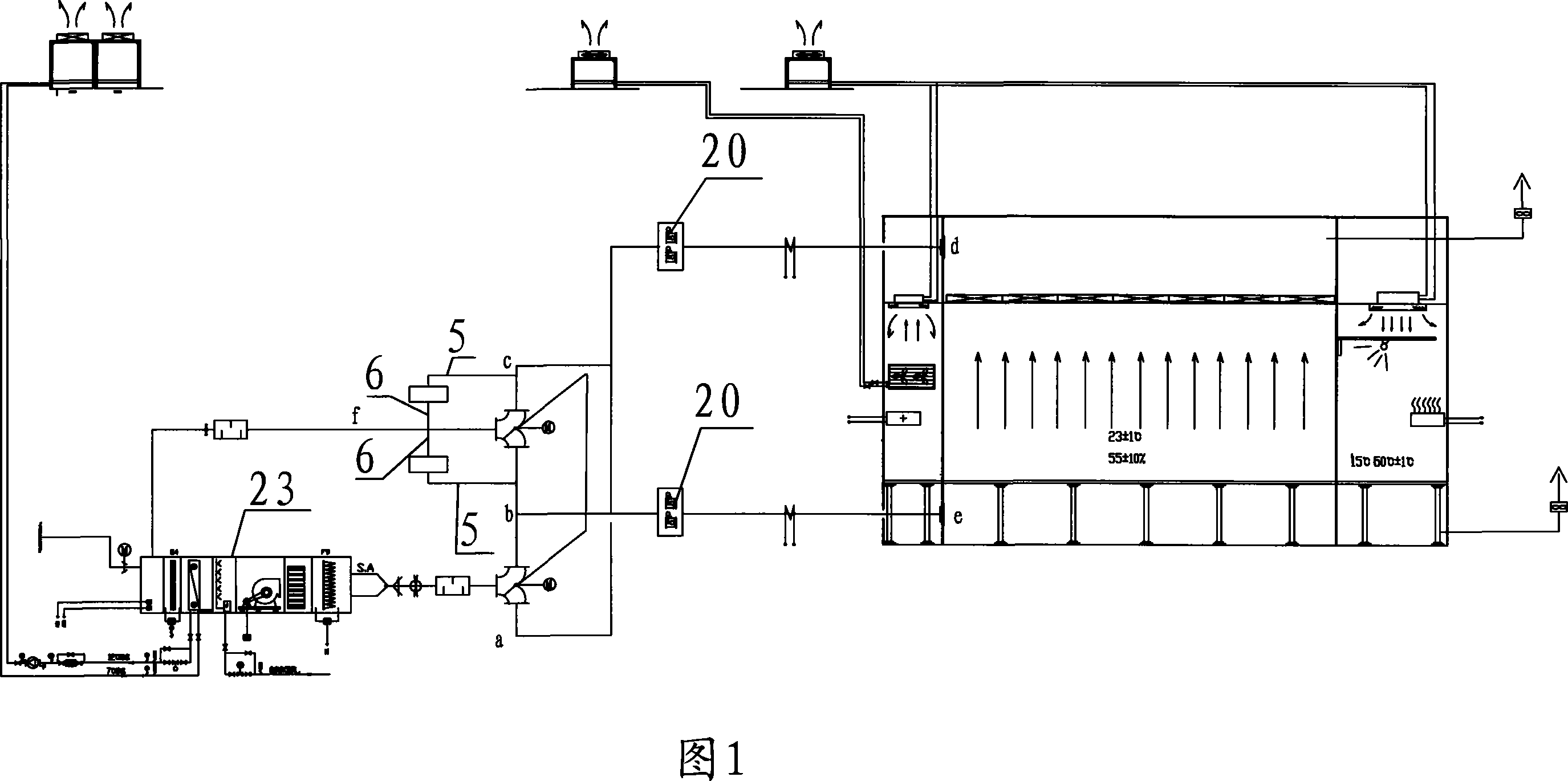

[0016] Referring to accompanying drawing 1, accompanying drawing 1 has shown the structural schematic diagram of the multifunctional air flow analysis and thermal parameter analysis laboratory under construction, in order to improve the air volume accuracy of the variable air volume valve, the present invention is placed in the return air section electric three-way valve two Side, bridged between the air supply and return air ducts, in Figure 1, considering that the direction of laboratory air flow can be switched up and down, so two sets of devices of the present invention are equipped. The working process of the ventilation system in this laboratory is as follows: the system air is mixed by outdoor fresh air and indoor return air through the 23 mixing section of the combined air conditioner, pressed out by the fan section, passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com