New-type finalized vulcanizer overflow control valve

A technology for shaping and vulcanizing and controlling valves, used in safety valves, balance valves, valve devices, etc., can solve problems such as easy leakage, poor sealing performance, port pulling, etc., to achieve good sealing reliability, improve reliability, and reduce leakage. point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

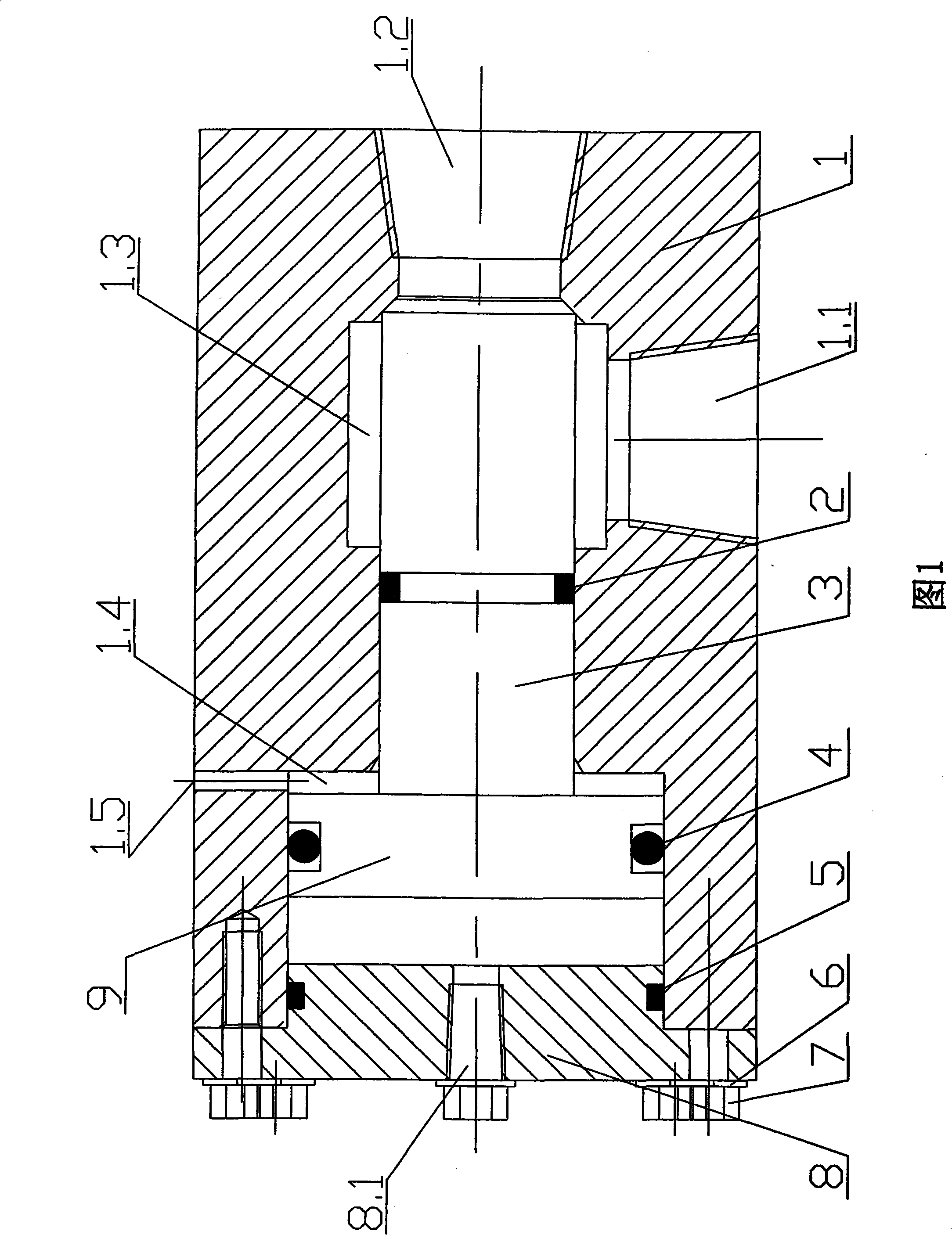

[0020] Referring to Fig. 1, the overflow control valve of the novel tire shaping vulcanizing machine that the present invention relates to is mainly made up of valve body 1, piston 9, piston rod 3 and valve cover 8. The valve body 1 is an integral structure, and the center of the valve body 1 is axially provided with a piston hole 1.4 and a piston rod hole 1.3, and the piston hole 1.4 is connected to the piston rod hole 1.3. The piston 9 is placed in the piston hole 1.4, the piston rod 3 is placed in the piston rod hole 1.3, and an O-ring 12 is embedded between the piston rod 3 and the wall of the piston rod hole 1.3 of the valve body 1 for sealing, and the piston 9 and the wall of the piston hole 1.4 of the valve body 1 is embedded with an O-ring II 4 for sealing. One side of the valve body 1 is provided with a water outlet 1.1, and one end of the valve body 1 is provided with a water inlet 1.2. Both the water inlet 1.1 and the water inlet 1.2 are connected with the piston ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com