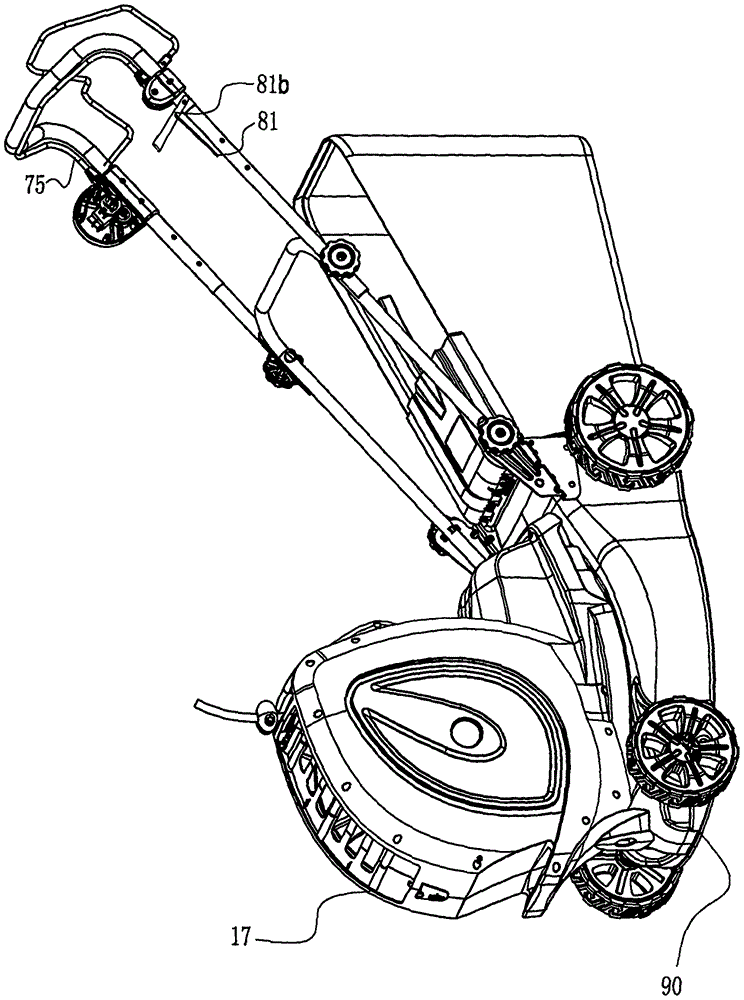

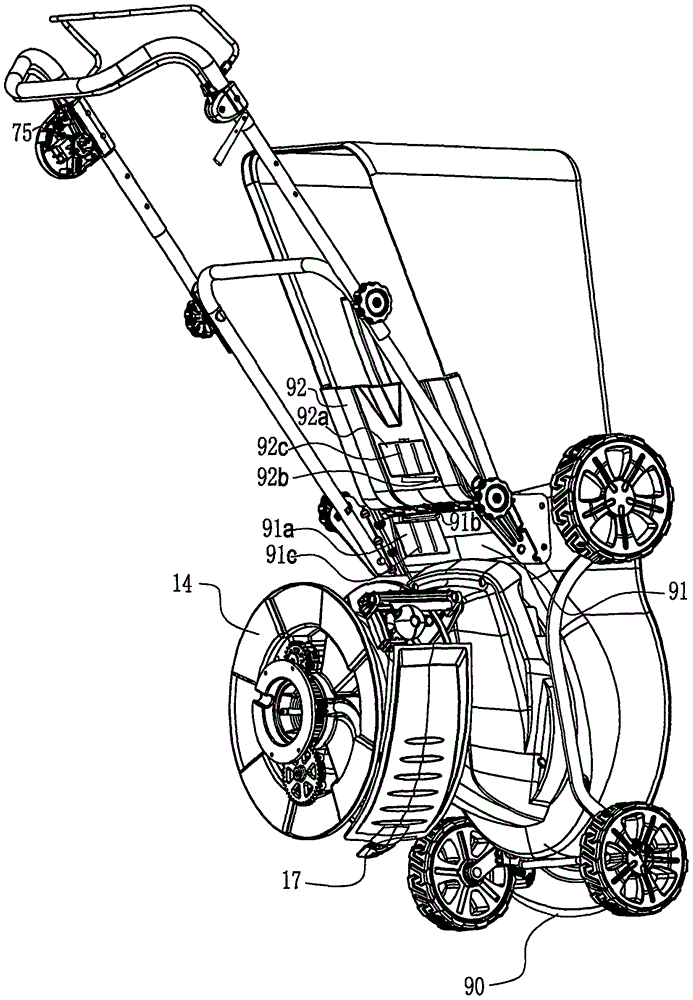

Automatic grass discharging passage cleaning mechanism of rear shaft of bottom of mower

A technology for automatic cleaning and lawn mowers, which is applied in the direction of lawn mowers, harvesters, agricultural machinery and implements, etc., and can solve the problems of affecting safety, falling off the ground, stepping on the ground, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

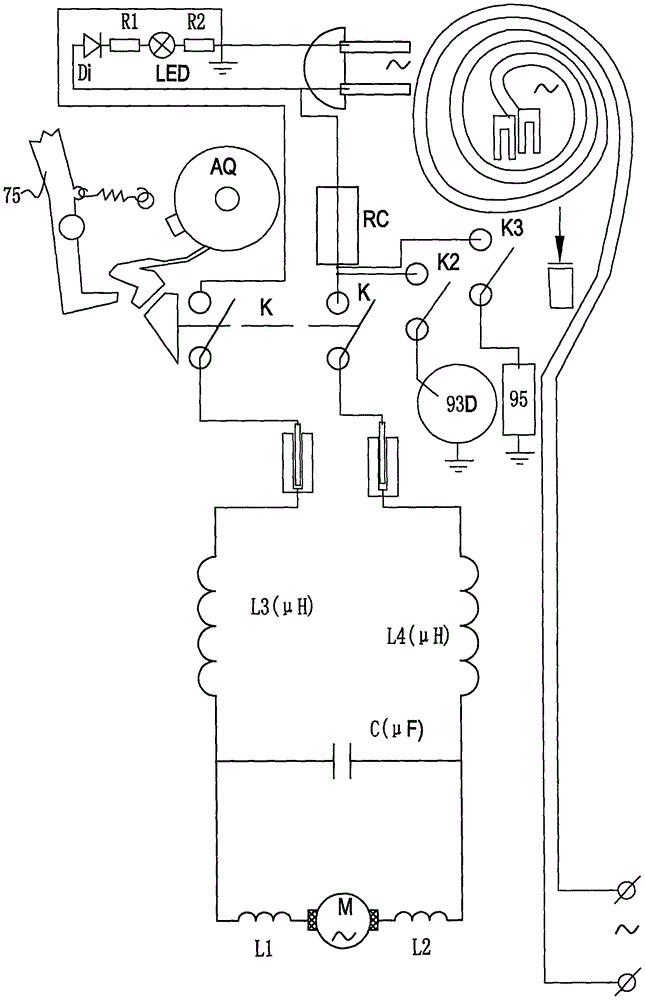

[0118] Build the computer 3D model first, then engrave the mold; then add anti-collision and brakes to the lawn mower. The technical equation and modeling method are: use PRO / ENGINEER WILDFIRE drawing software, create a new working directory, create new parts, and sketch 2 pieces concentric circles. Open the variable section sweep (Var Sect Sweep) command, select the above 2 circles as the sweep trajectory and the reference trajectory. Draw a straight line parallel to the plane of 2 circles, the length L=(D-d) / 2, and the projection line corresponding to the edge of the circle.

[0119] Establish parameter (PARAMETER) 1: C is a real number (real number), which can be assigned a value between 0.01-1 according to specific working conditions, such as 0.3; C is also called wave height. Establish parameter (PARAMETER) 2: N integer (integer), select a value between 2-100 according to specific working conditions, such as 13; N is also called wave number. Establish relation (RELATION...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com