Patents

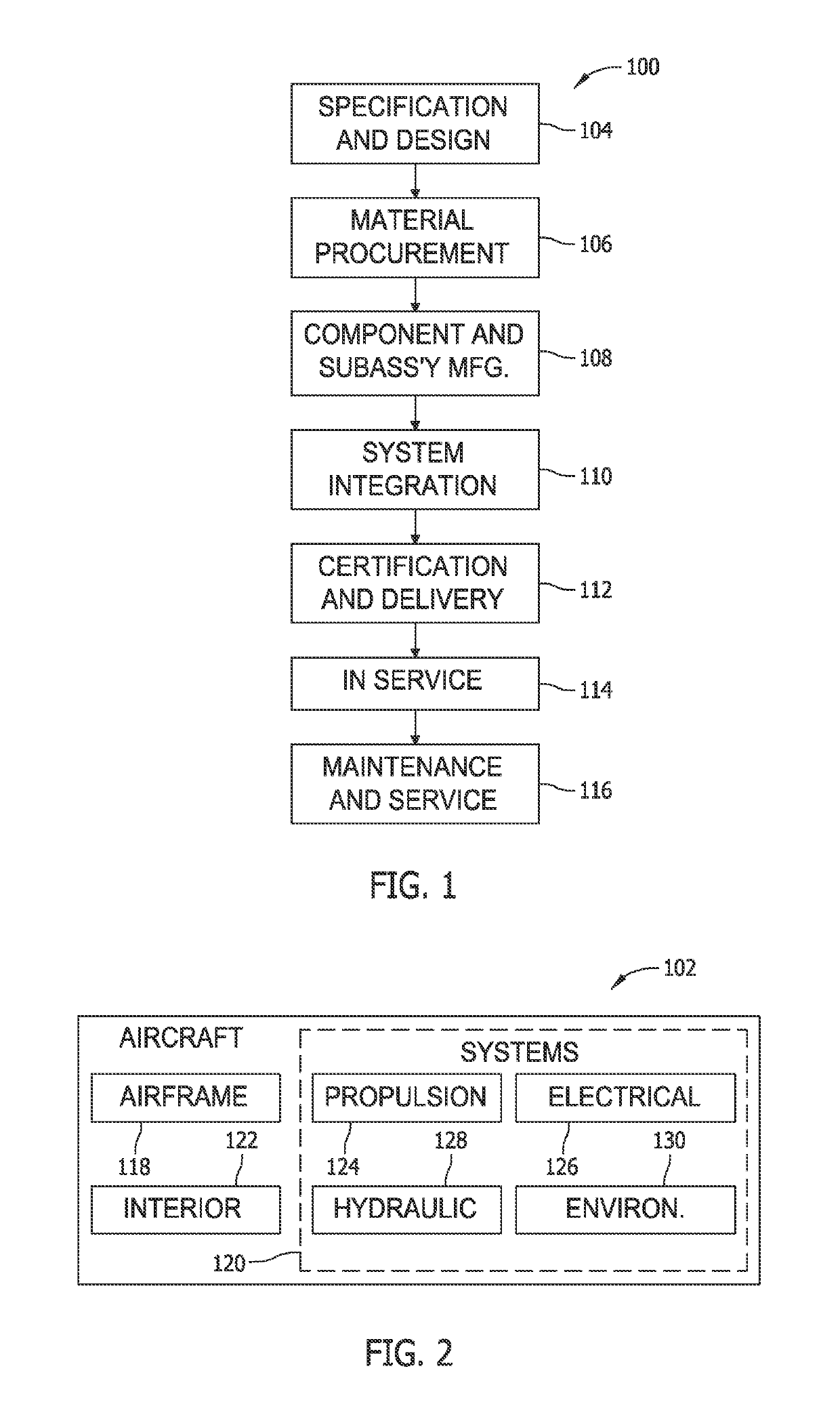

Literature

36results about How to "Improve airflow efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

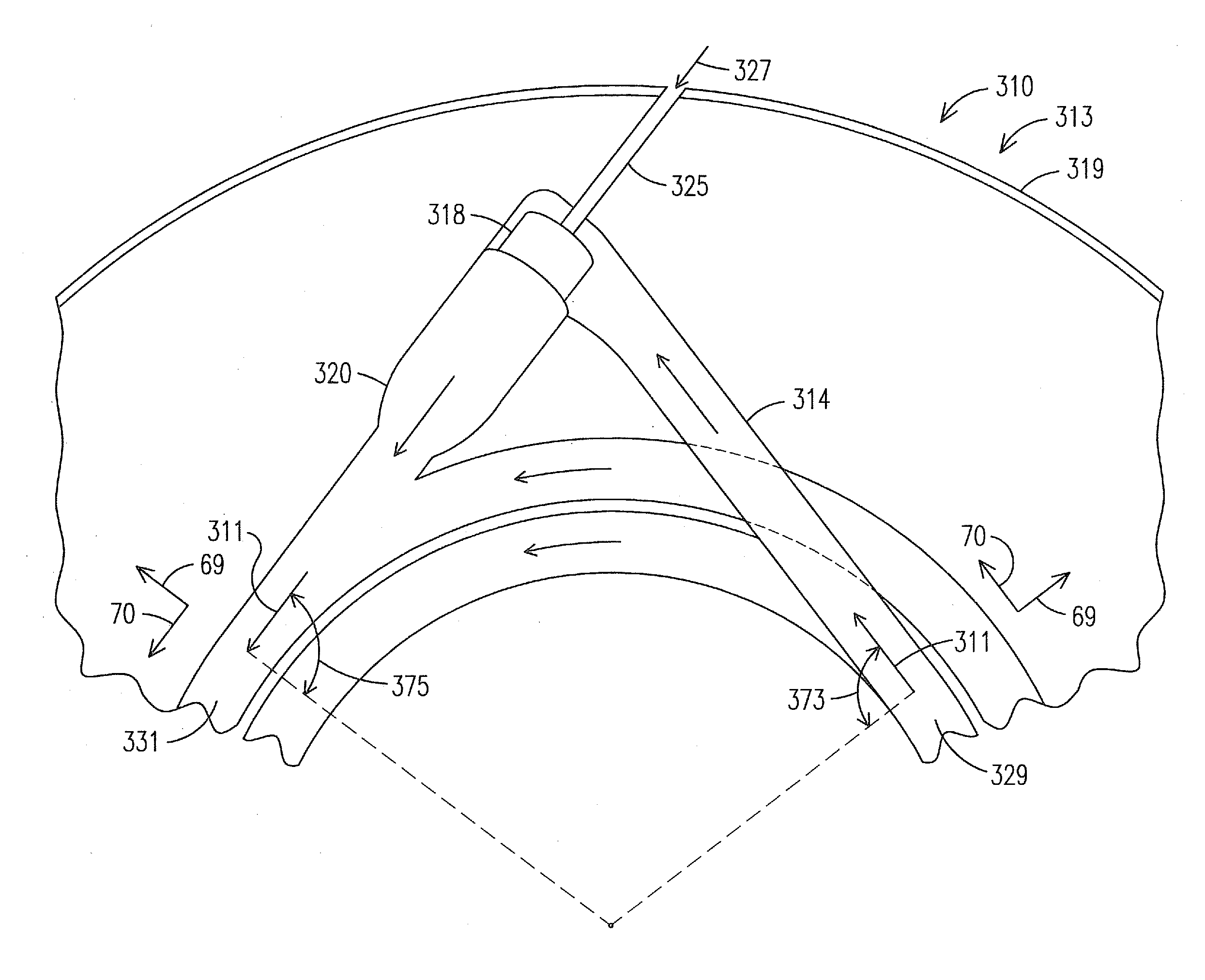

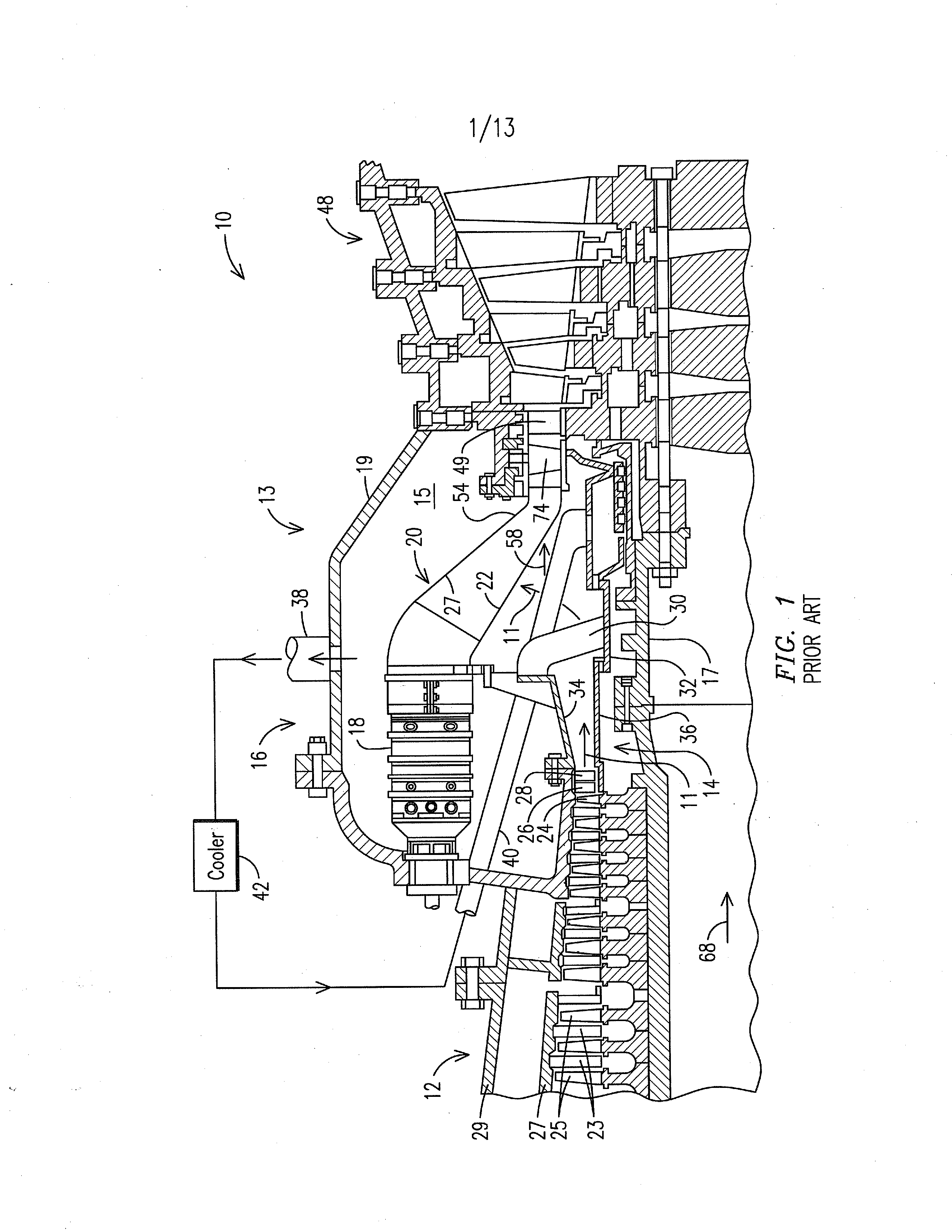

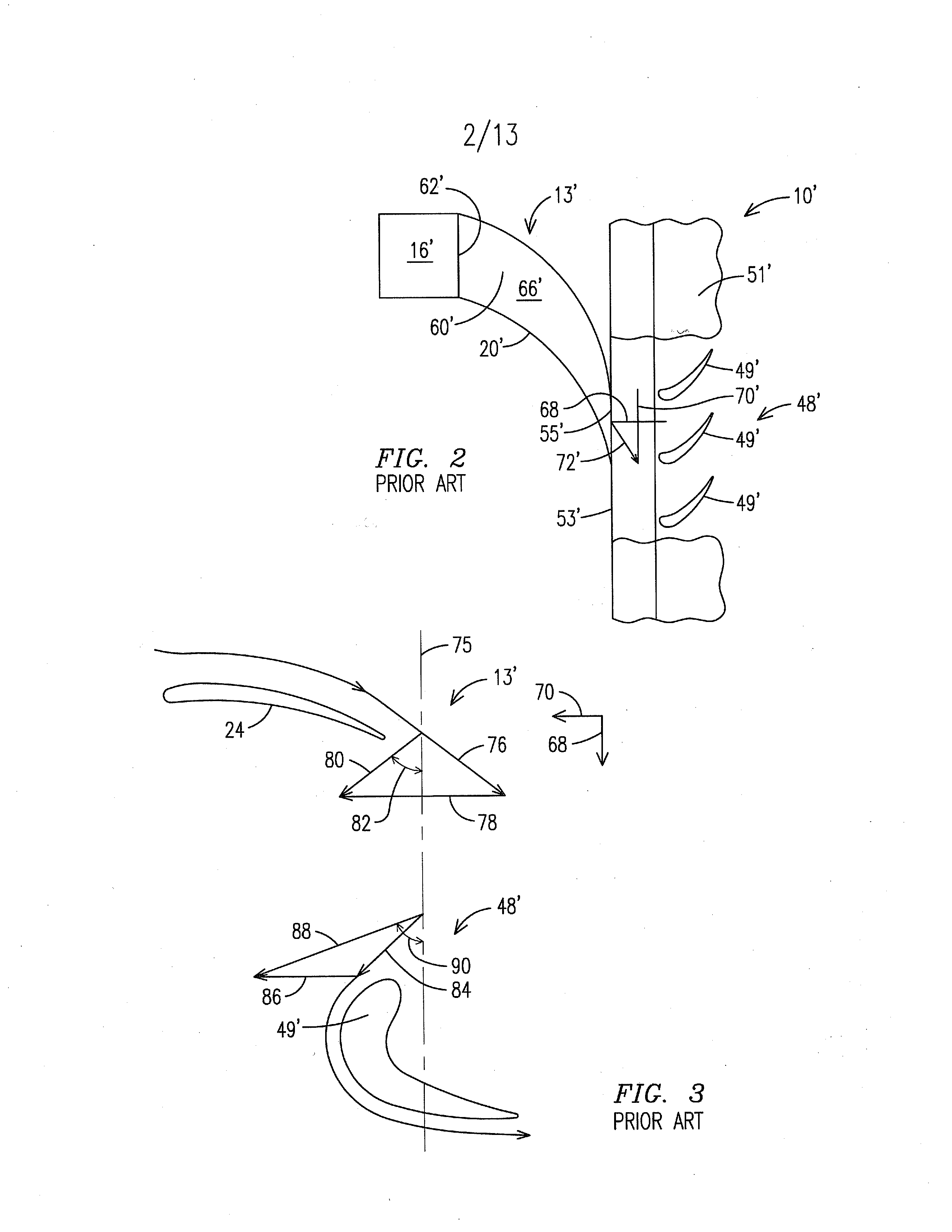

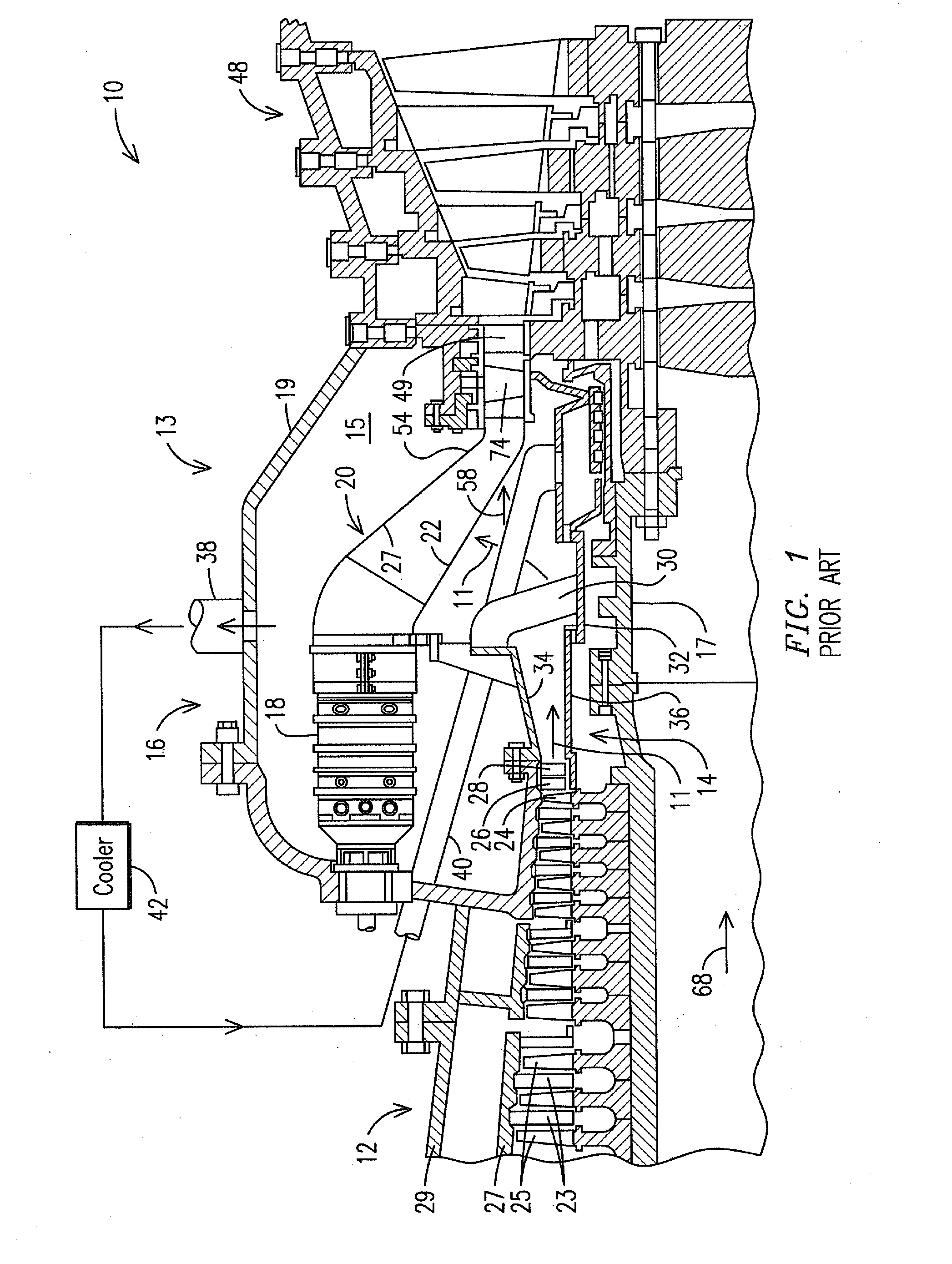

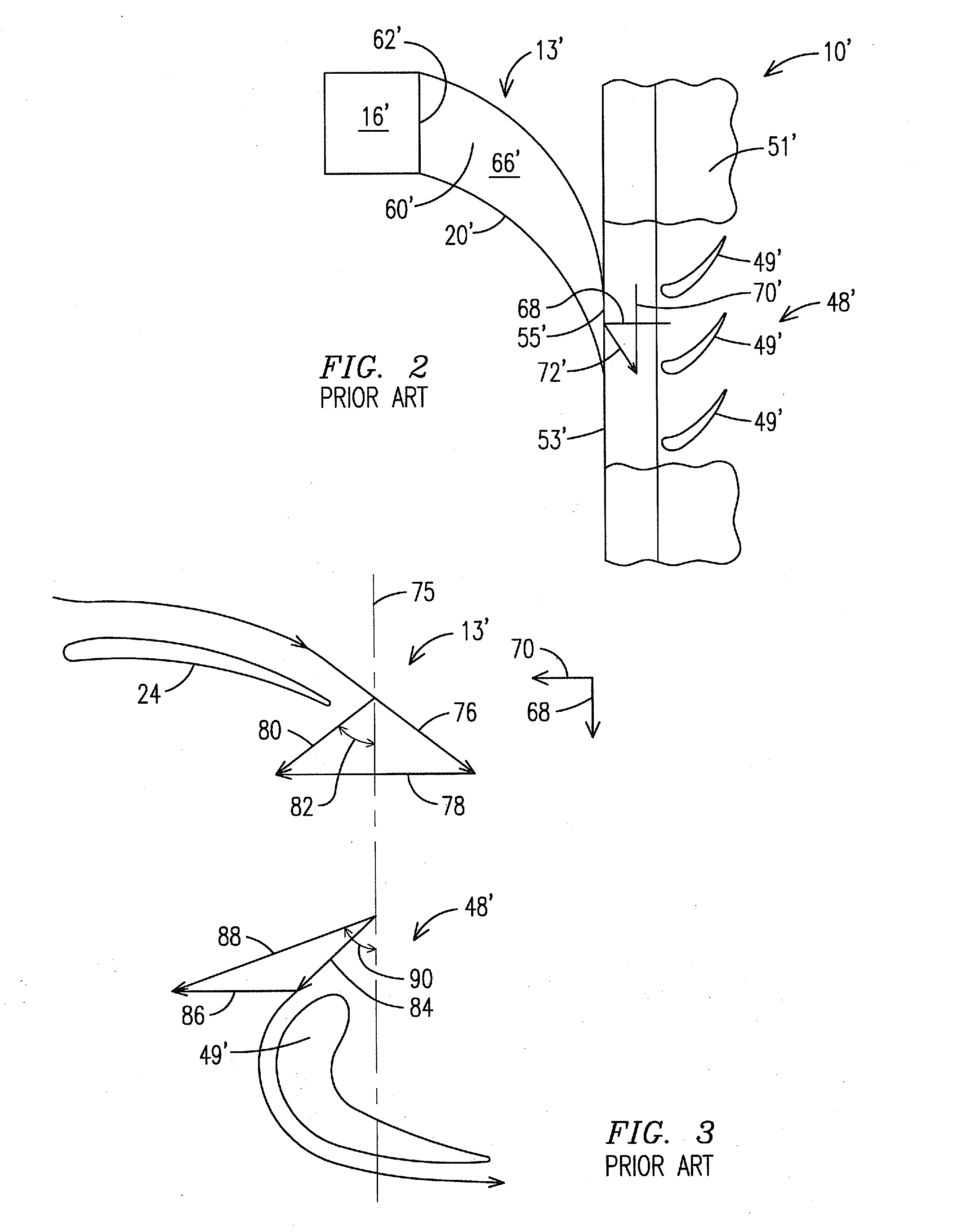

Mid-section of a can-annular gas turbine engine with an improved rotation of air flow from the compressor to the turbine

InactiveUS20130219853A1Easy to operateReduce lossesContinuous combustion chamberGas turbine plantsCombustorTurbine

A midframe portion (313) of a gas turbine engine (310) is presented and includes a compressor section with a last stage blade to orient an air flow (311) at a first angle (372). The midframe portion (313) further includes a turbine section with a first stage blade to receive the air flow (311) oriented at a second angle (374). The midframe portion (313) further includes a manifold (314) to directly couple the air flow (311) from the compressor section to a combustor head (318) upstream of the turbine section. The combustor head (318) introduces an offset angle in the air flow (311) from the first angle (372) to the second angle (374) to discharge the air flow (311) from the combustor head (318) at the second angle (374). While introducing the offset angle, the combustor head (318) at least maintains or augments the first angle (372).

Owner:SIEMENS ENERGY INC

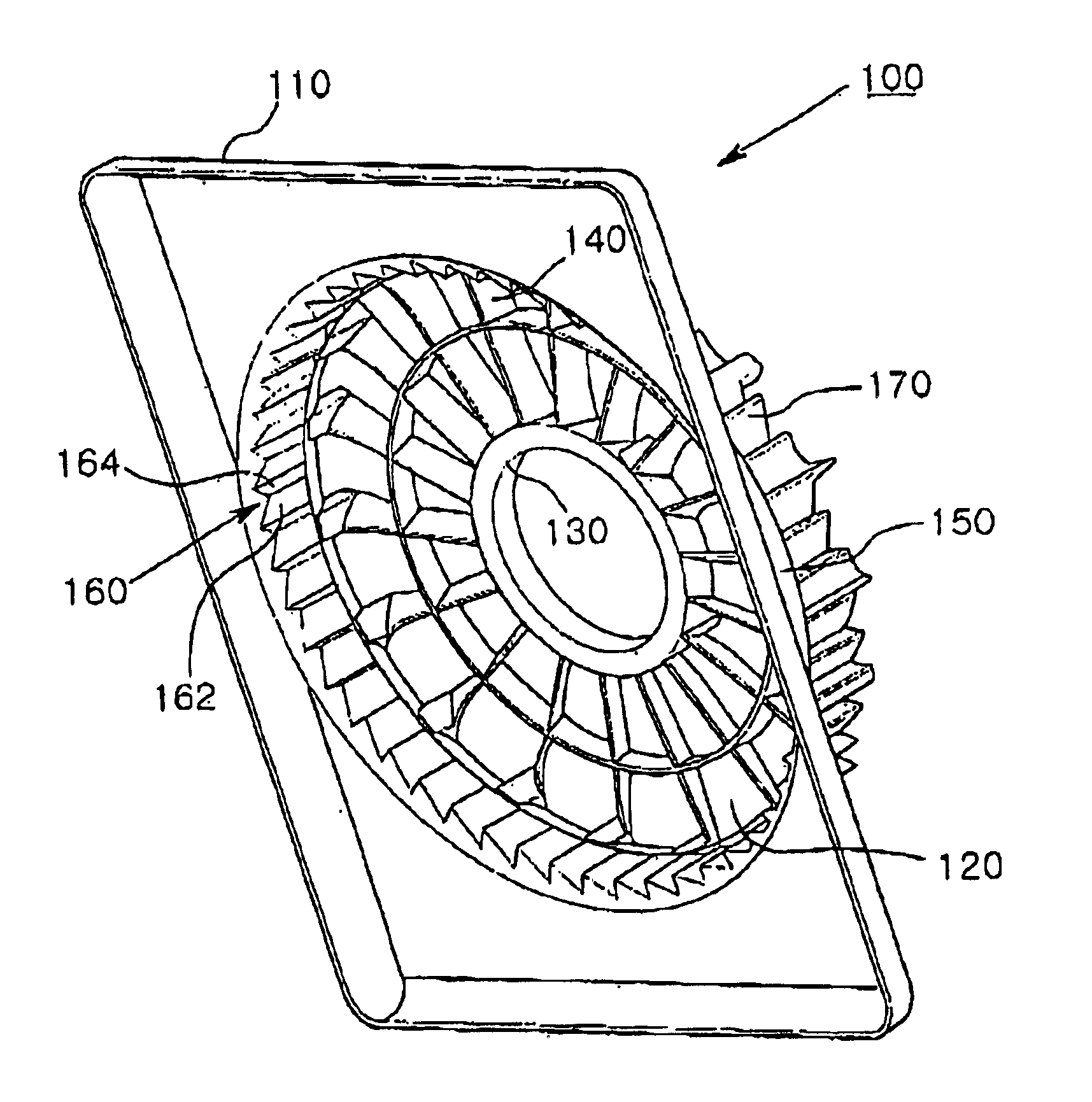

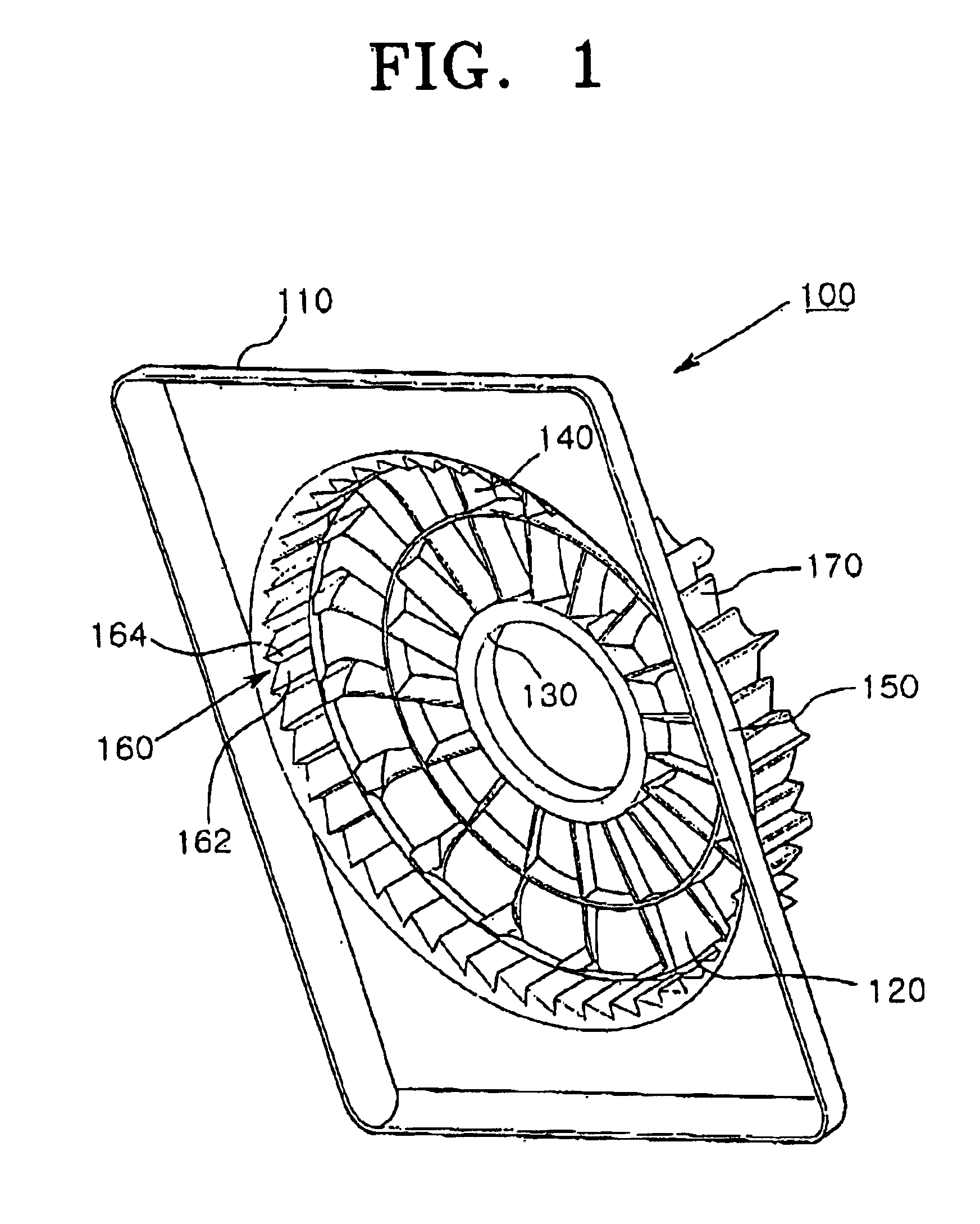

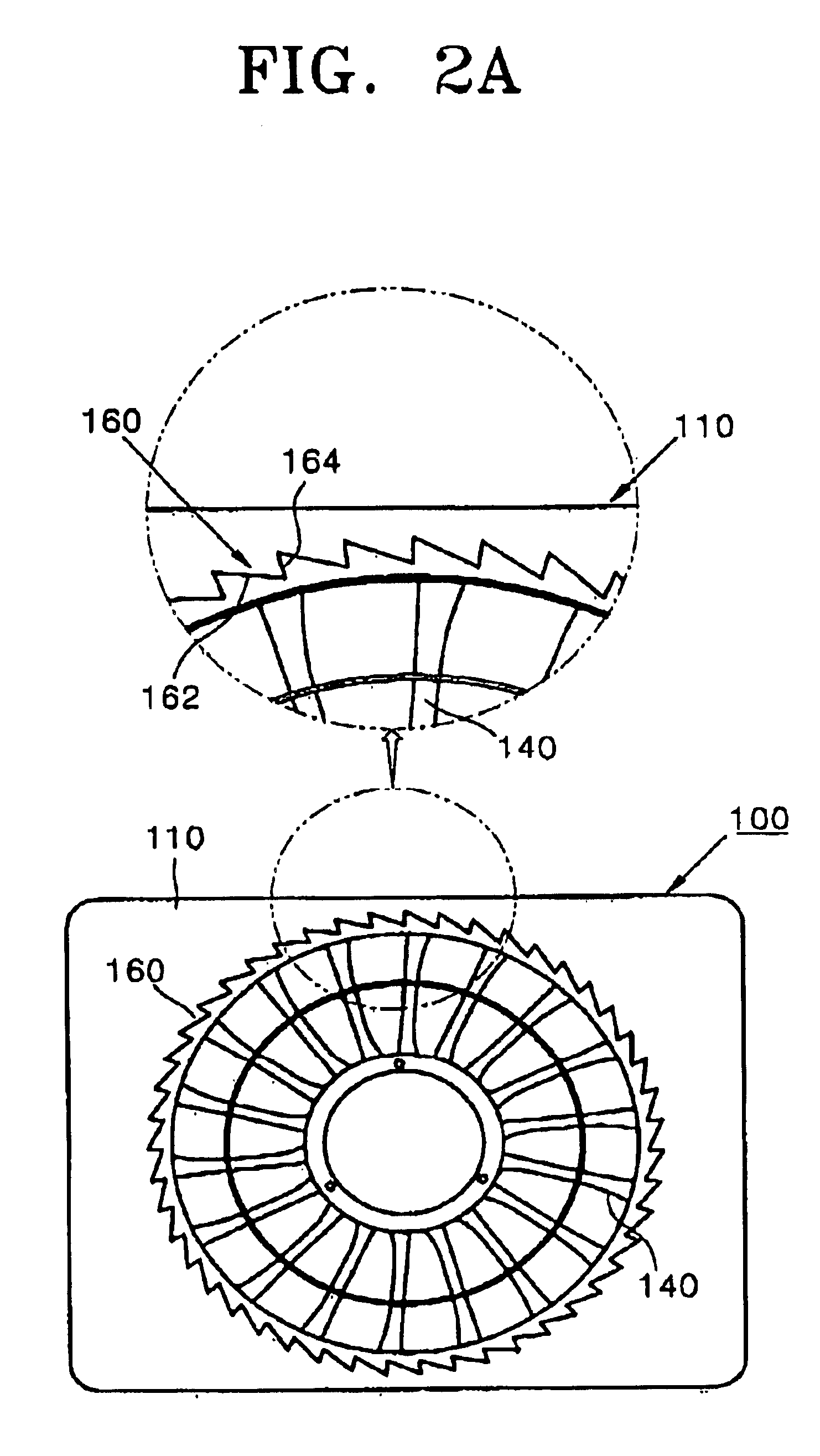

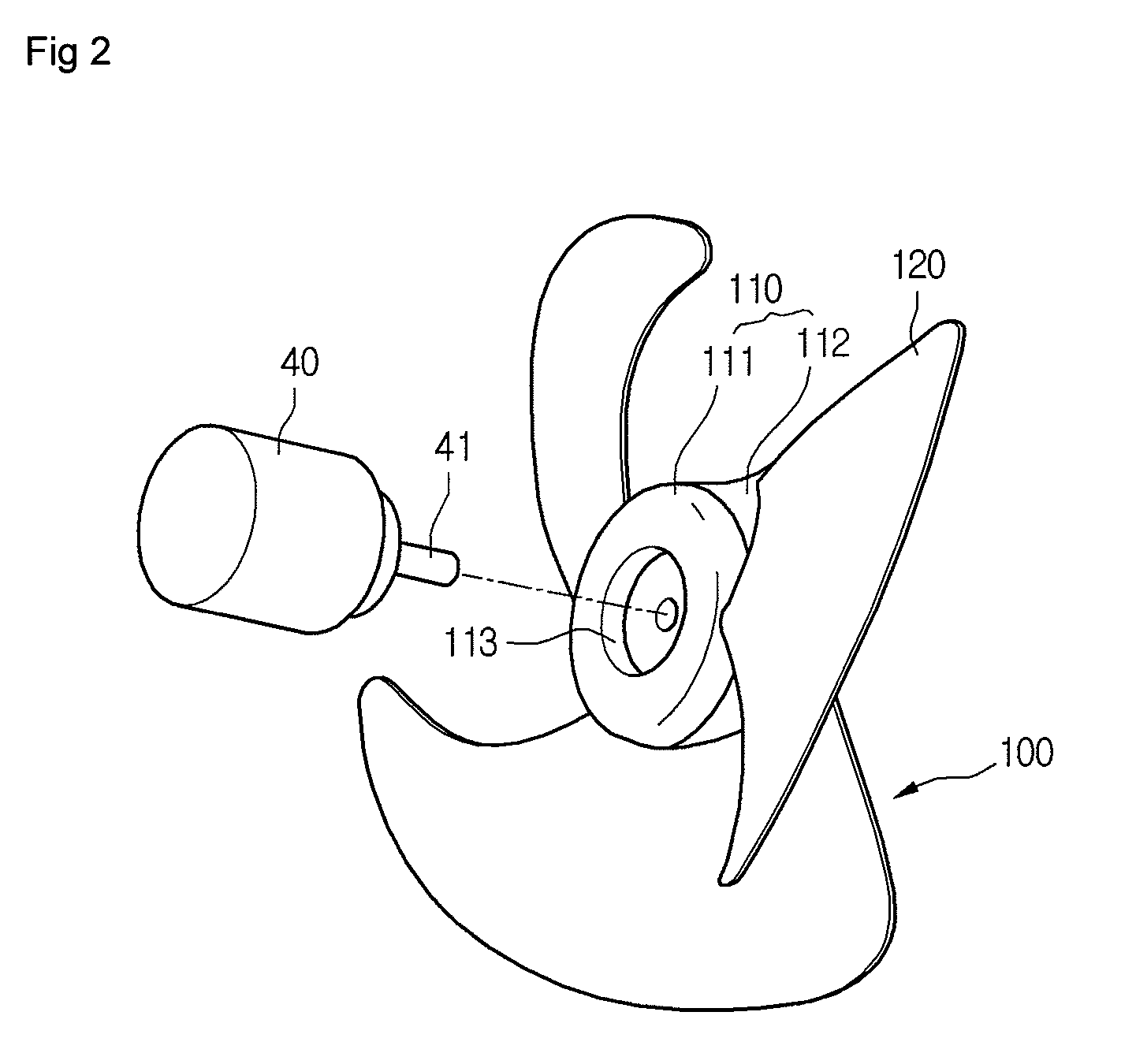

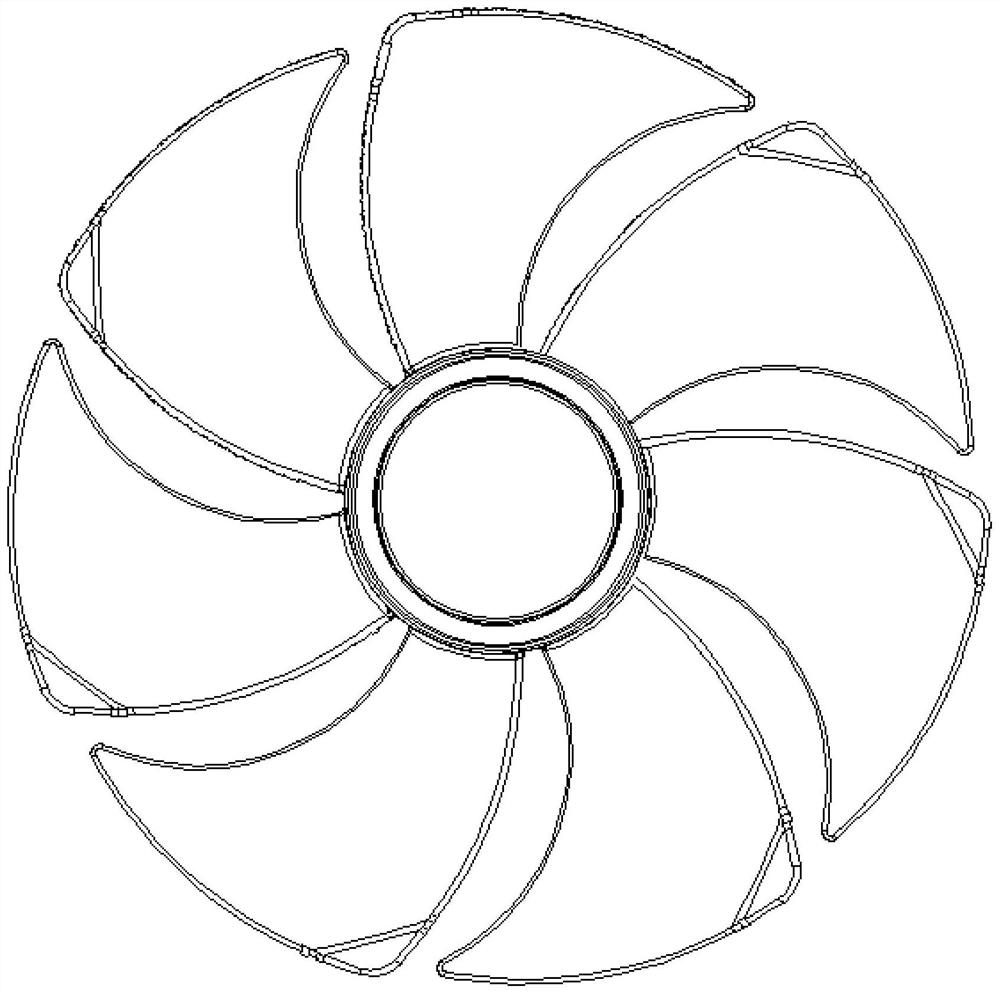

Fan and shroud assembly

A fan and shroud assembly includes a fan having a hub rotating around one shaft and a plurality of blades extending outwardly from the hub, a shroud encompassing the fan to adjust airflow by rotation of the fan, a guide ring portion located at a position where a predetermined gap exists between the shroud and a circumference connecting end tips of the blades so that the fan is supported by the shroud and rotates, and a plurality of swirl prevention units integrally formed with the guide ring portion to prevent a vortex from proceeding along the circumference in the predetermined gap, each swirl prevention unit having a shape in which the length of a circular arc passing through each of the swirl prevention units with respect to the center of the shroud decreases as the arc is closer to the center of the shroud.

Owner:HANON SYST

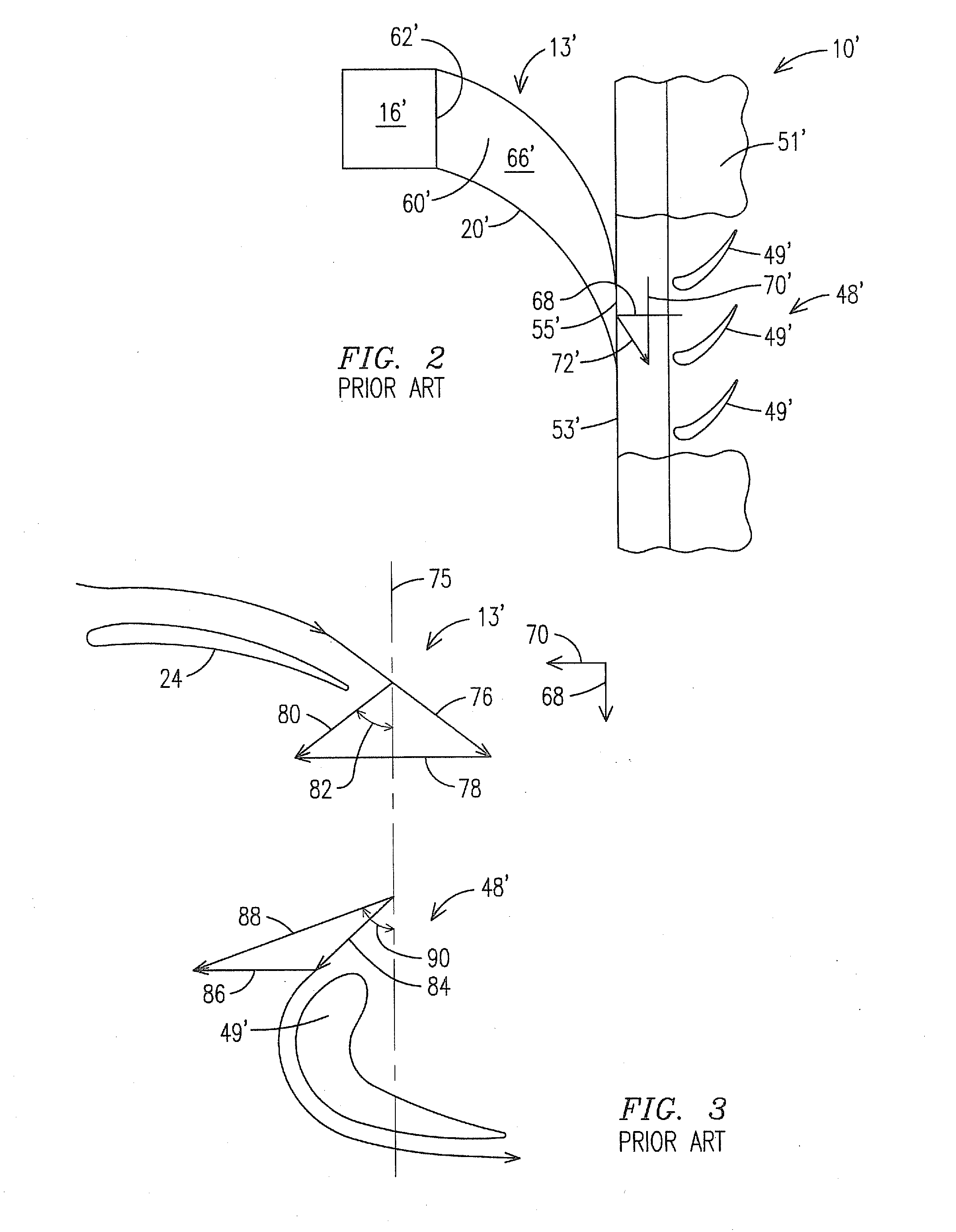

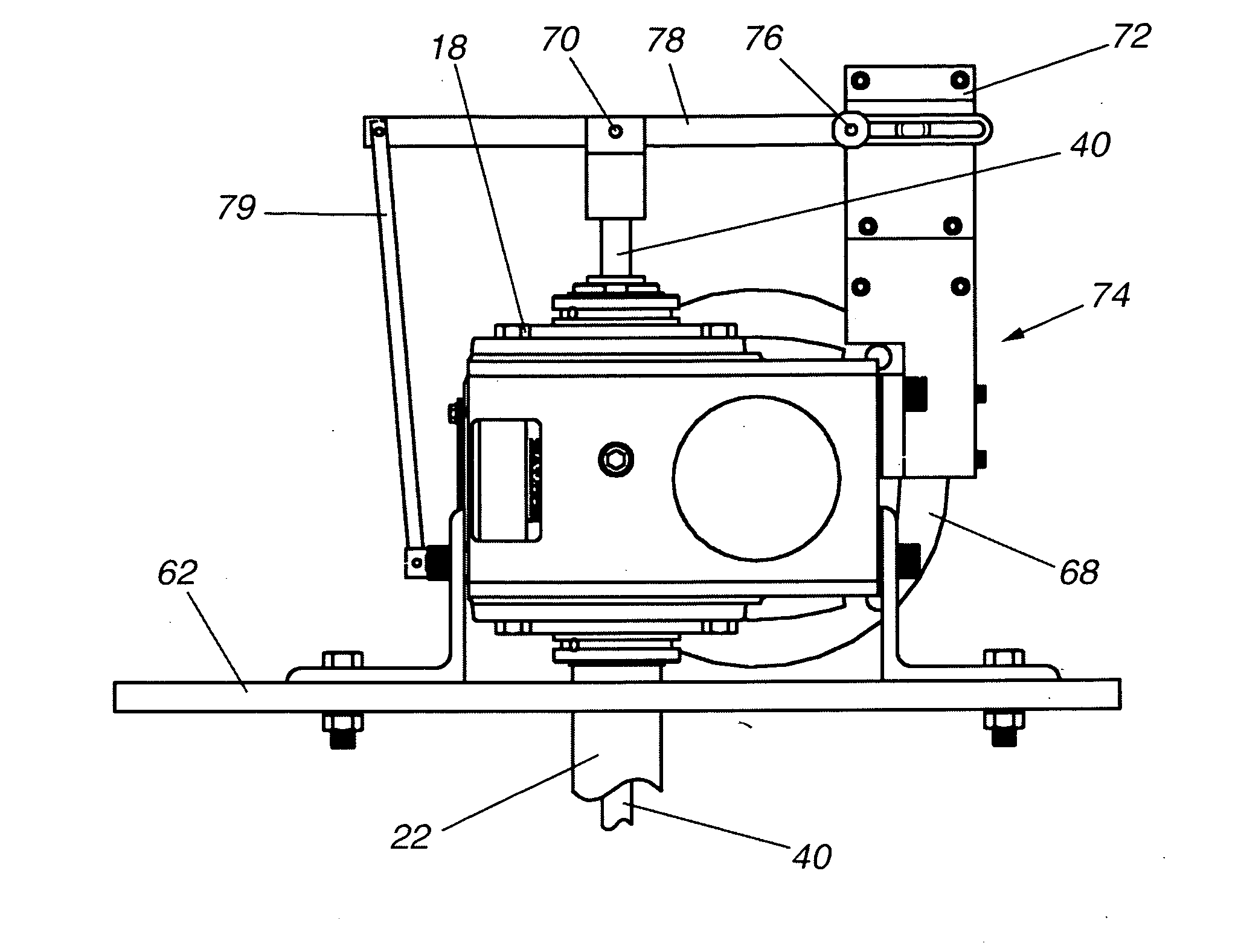

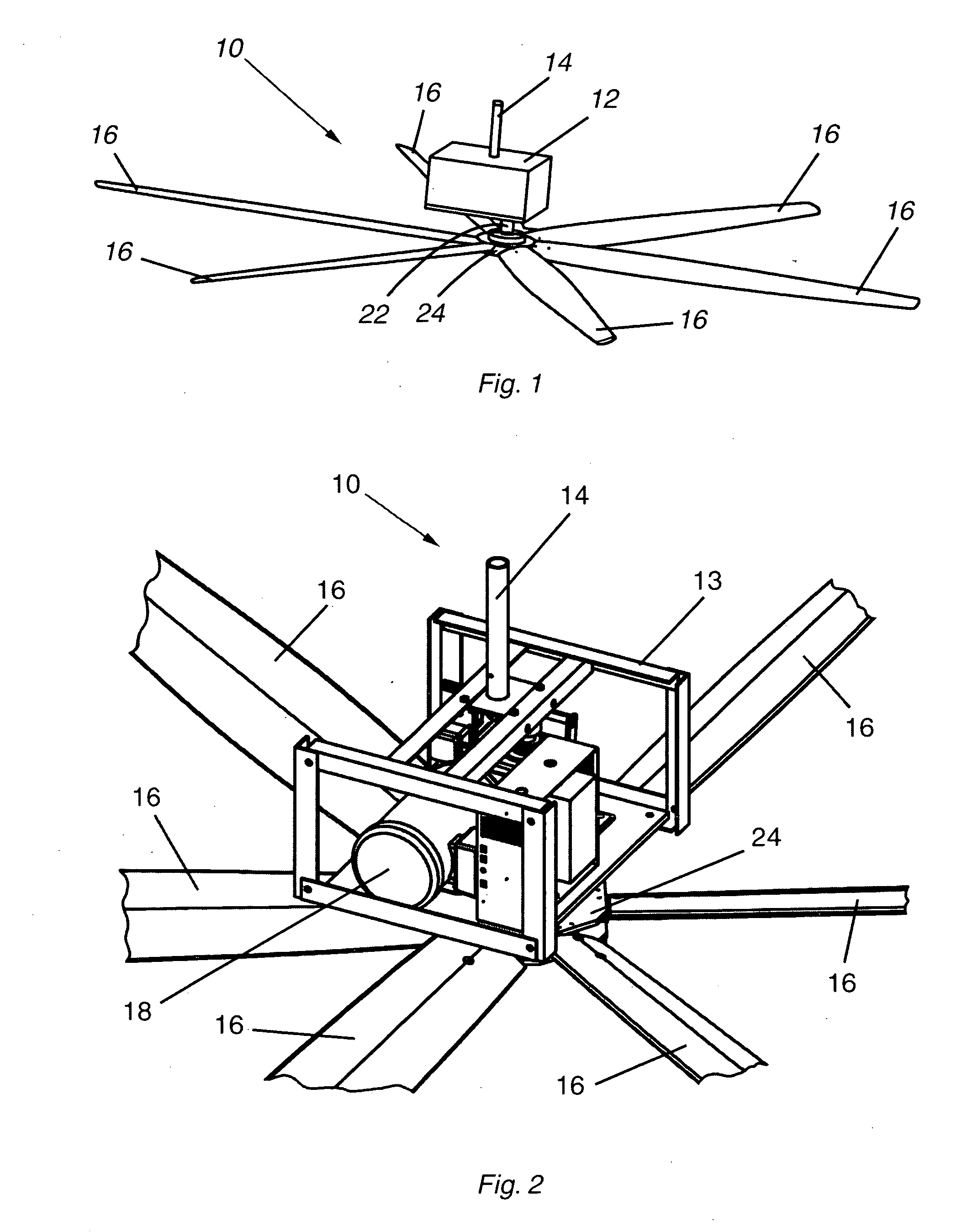

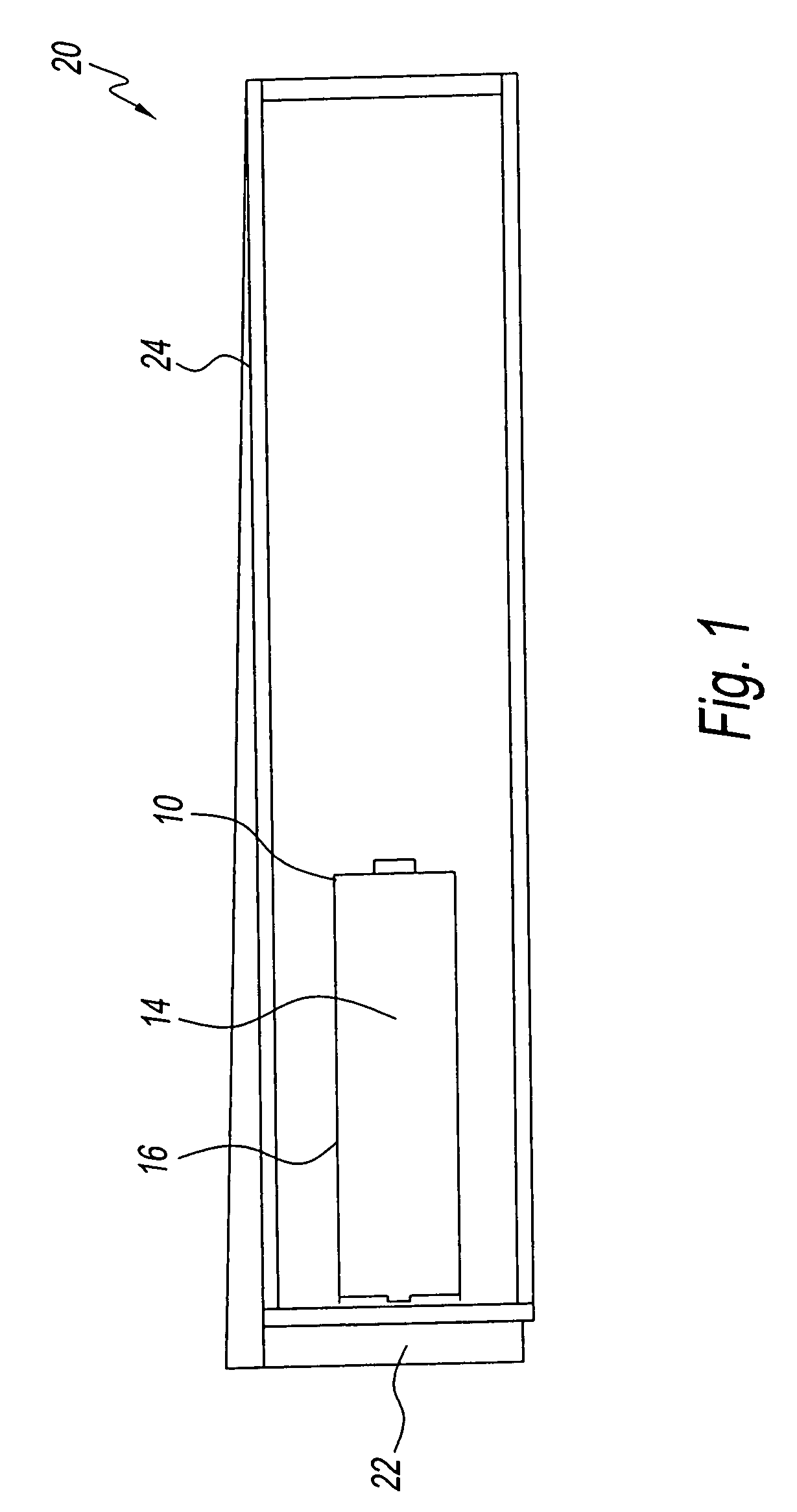

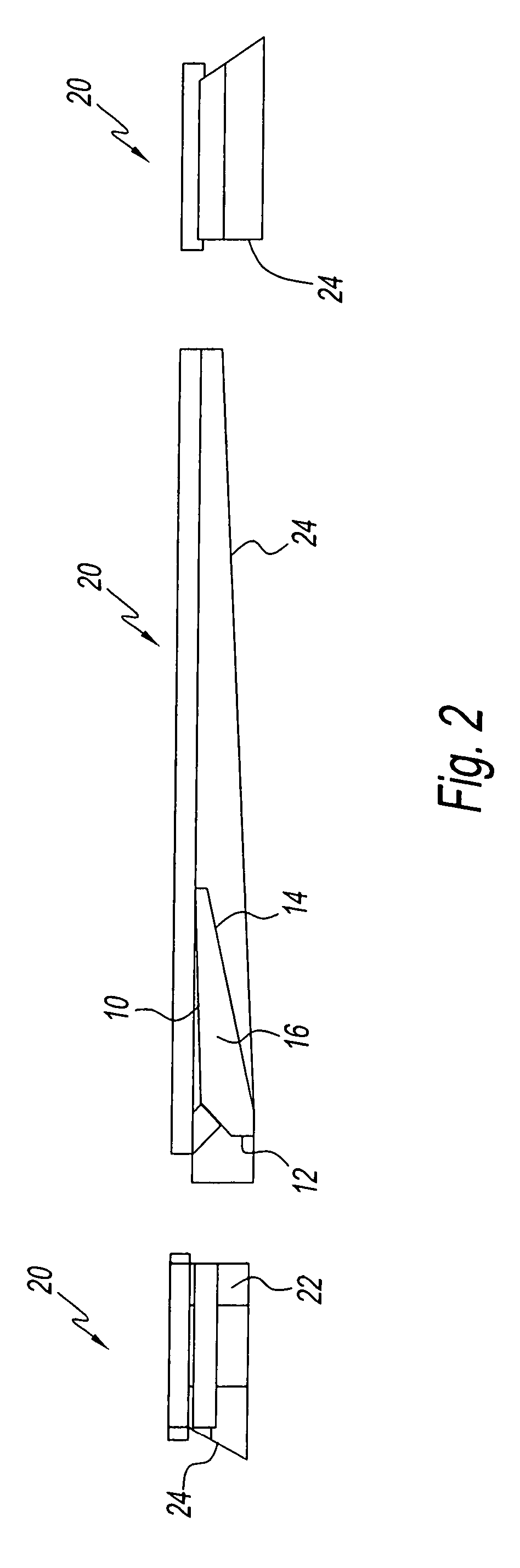

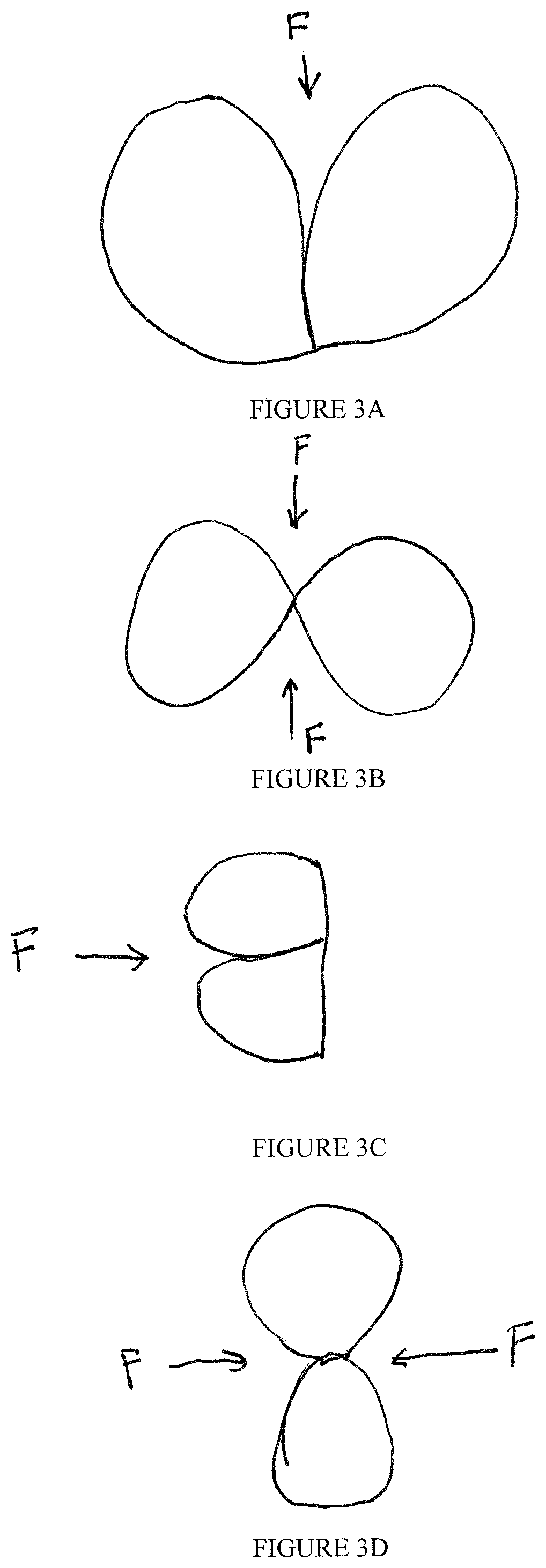

High volume low speed fan

ActiveUS20090123284A1Improve airflow efficiencyPromote circulationDynamo-electric brakes/clutchesPropellersAerospace engineeringAirflow

A high volume low speed (HVLS) fan provides improved air circulation and thermal control in a building by incorporating composite fan blades pivotable to both positive and negative pitch angles. The blades are molded of polymer material over a metal tube core for strength and ease of attachment to the fan hub, and have a symmetrical airfoil shape to produce an efficient bi-directional conical airflow. The fan includes a control unit providing manual and automated intelligent control over blade angle and rotational speed, as well as startup with approximately zero blade angle for more economical power consumption and less motor wear. The fan structure and mounting system allows the fan to be installed at an optimal height inside a variety of buildings to provide increased efficiency of air destratification and air mixing. An array of multiple HVLS fans with alternating directions of airflow can further increase efficiency of air movement.

Owner:AIRMOTION SCI

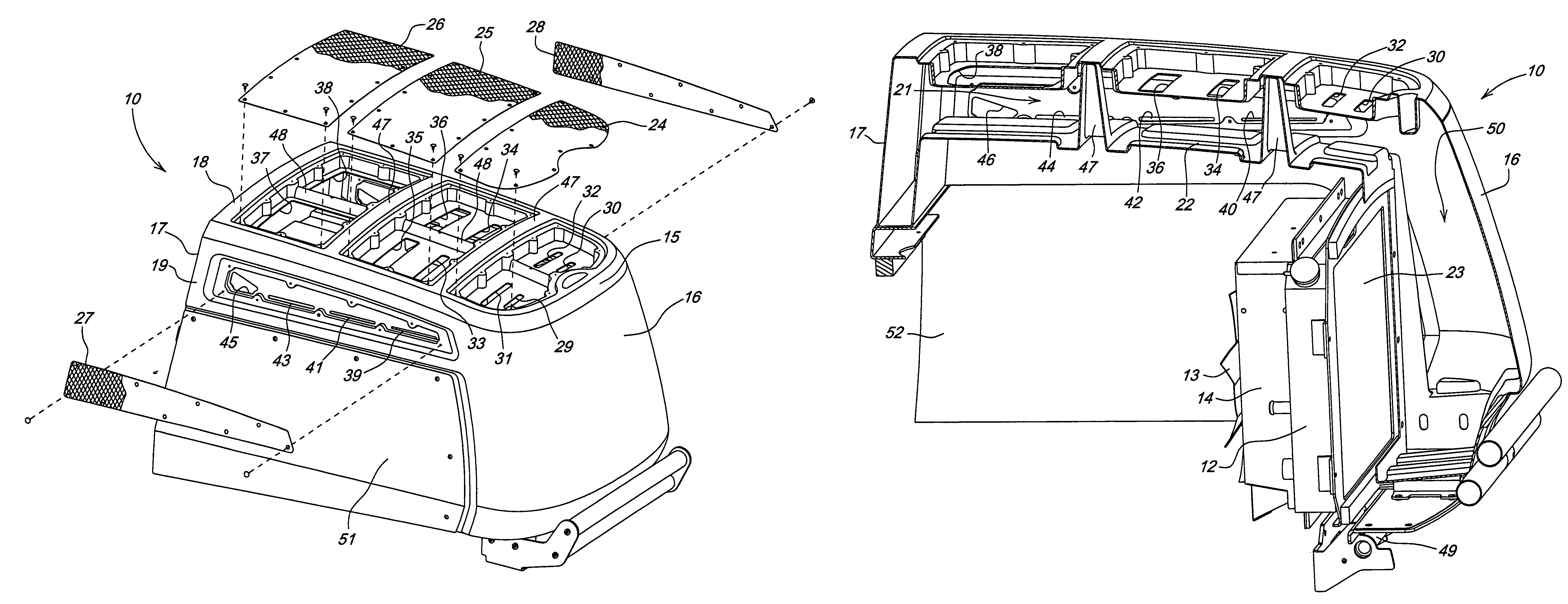

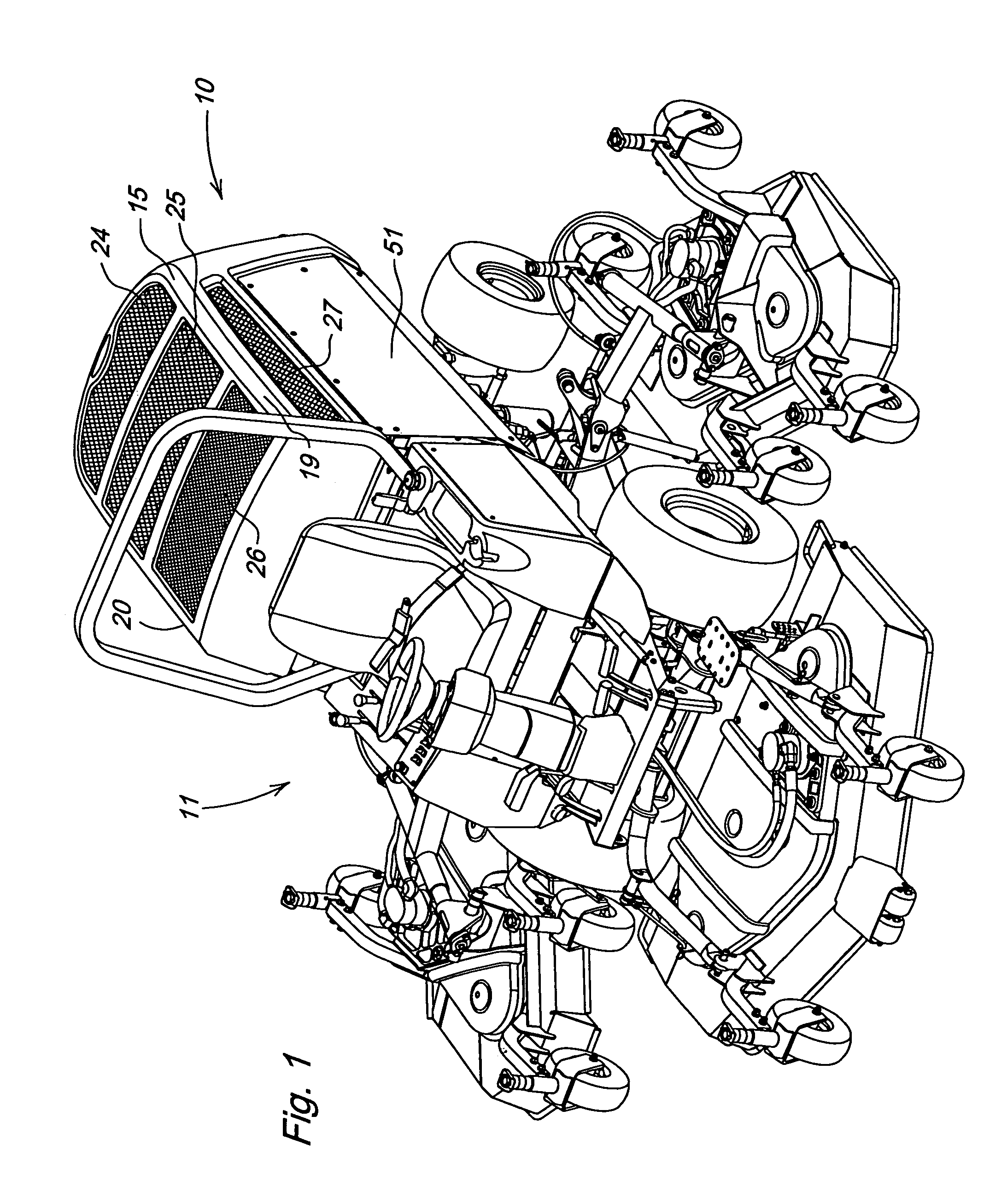

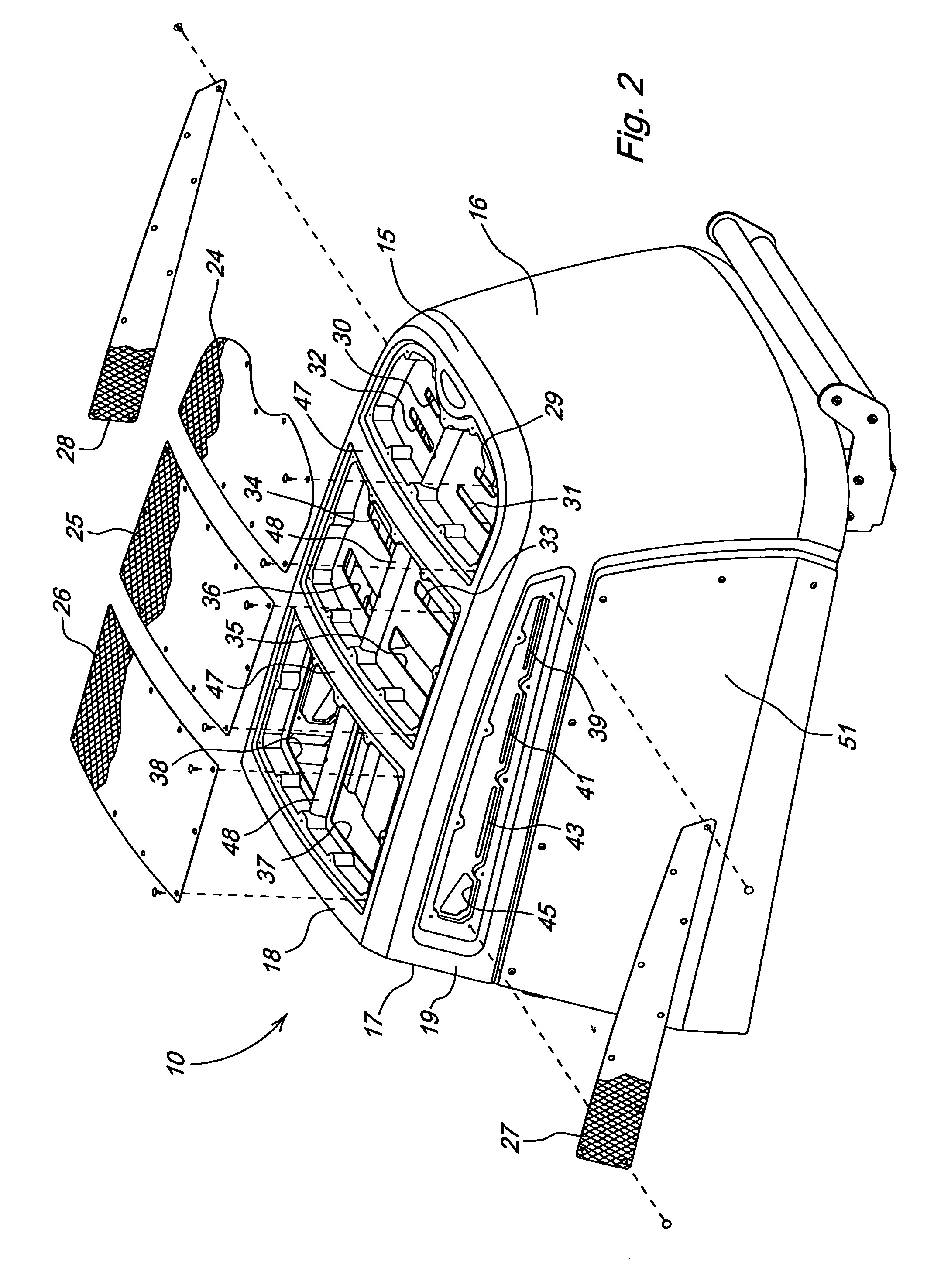

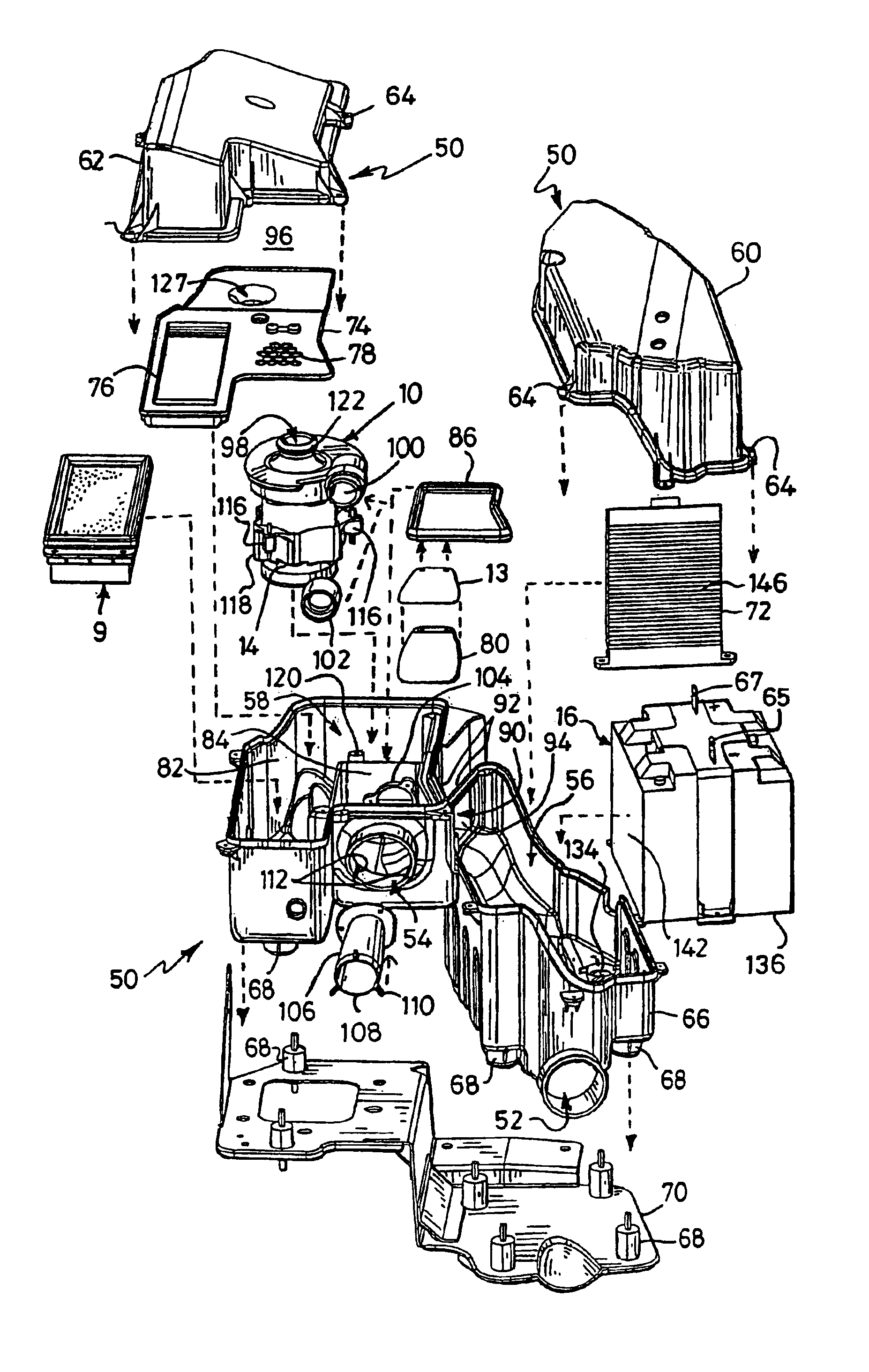

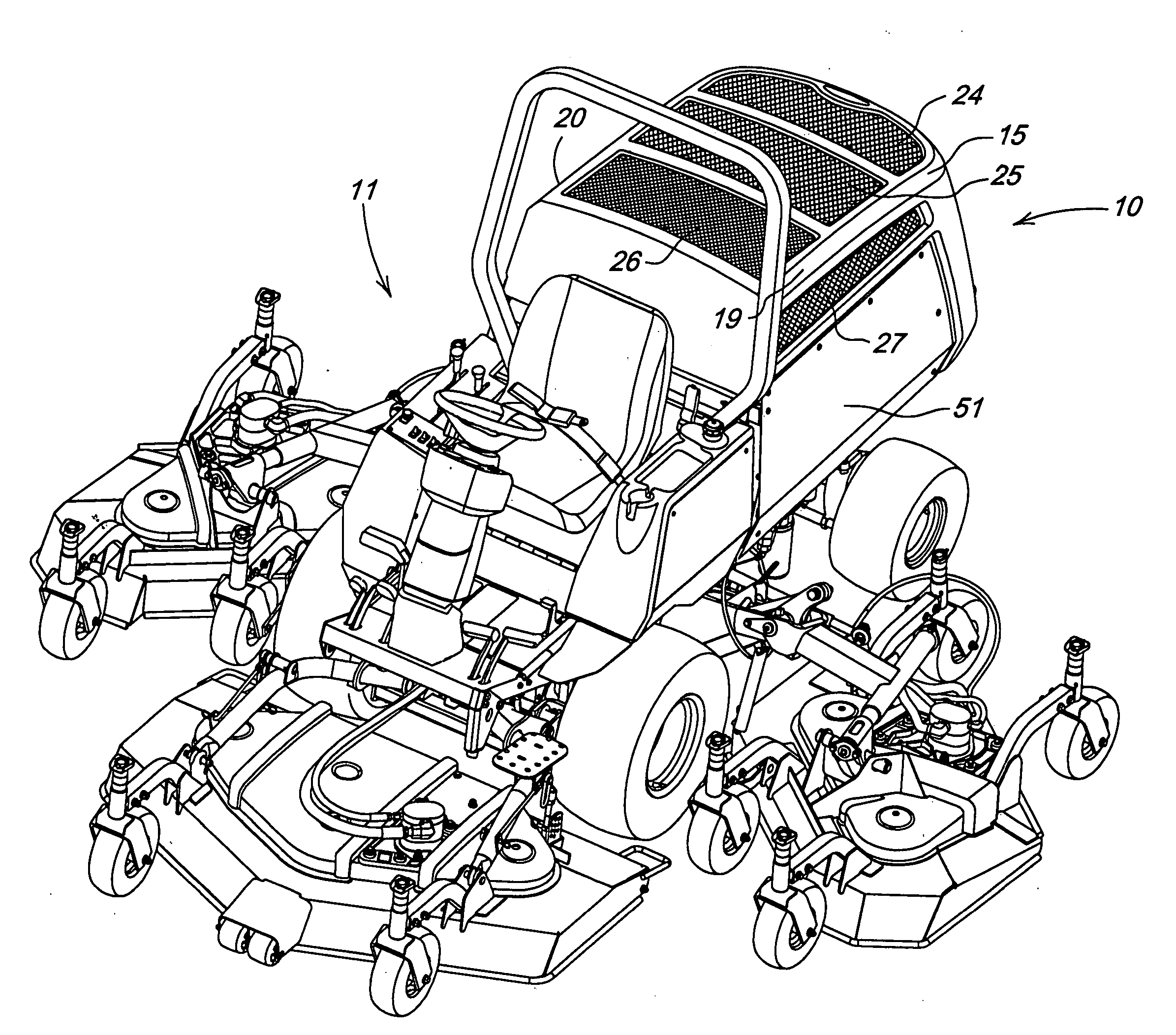

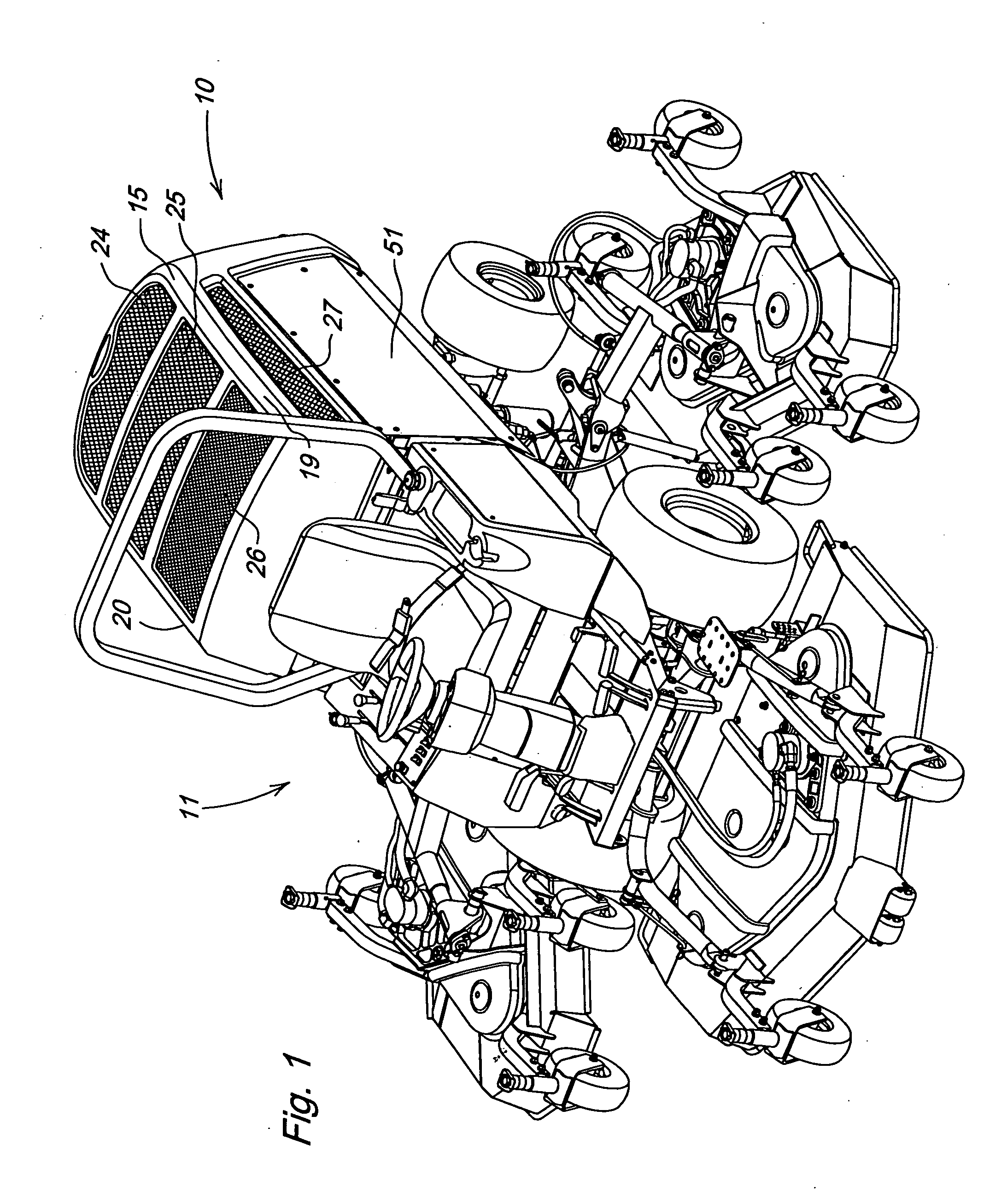

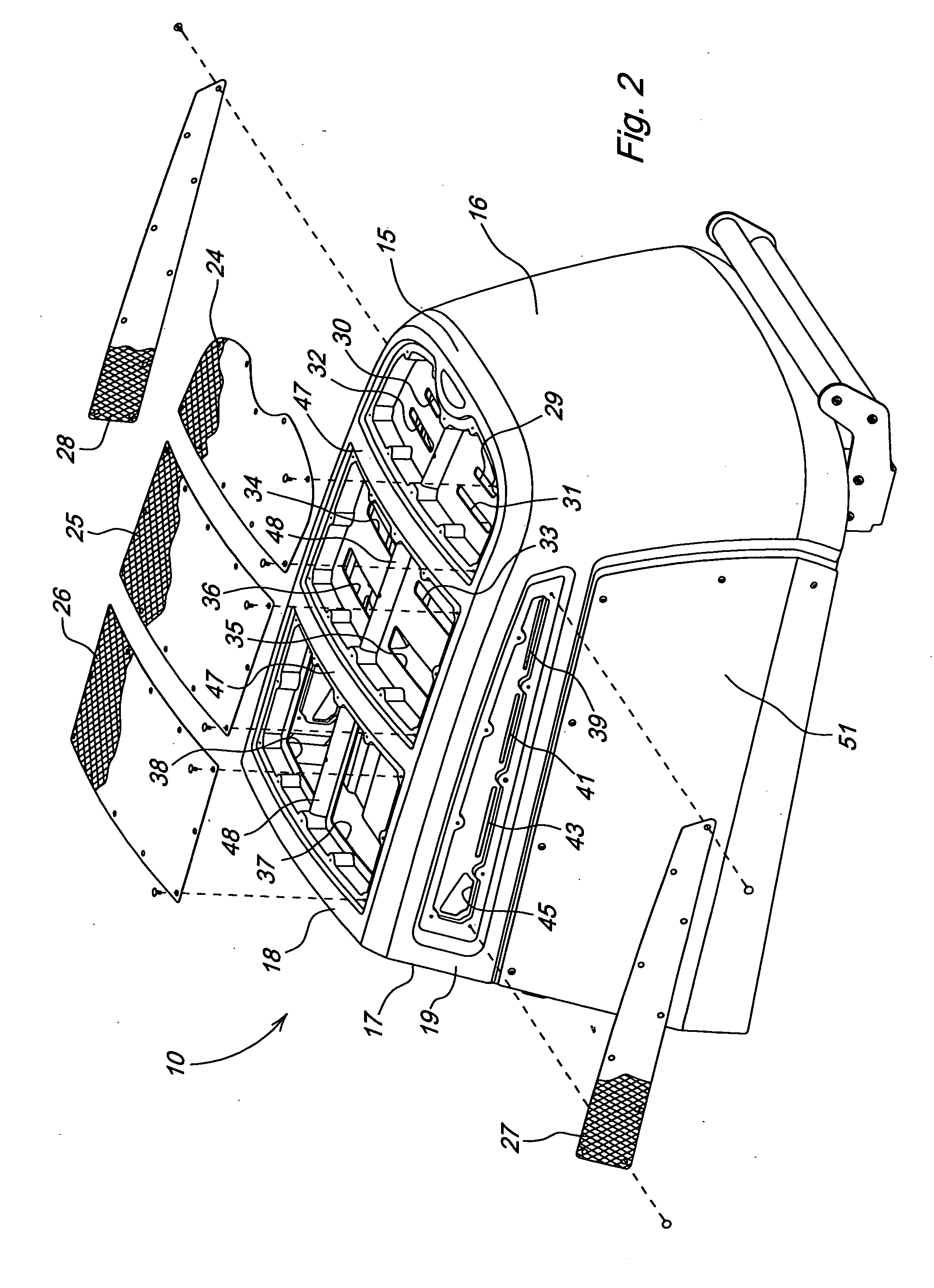

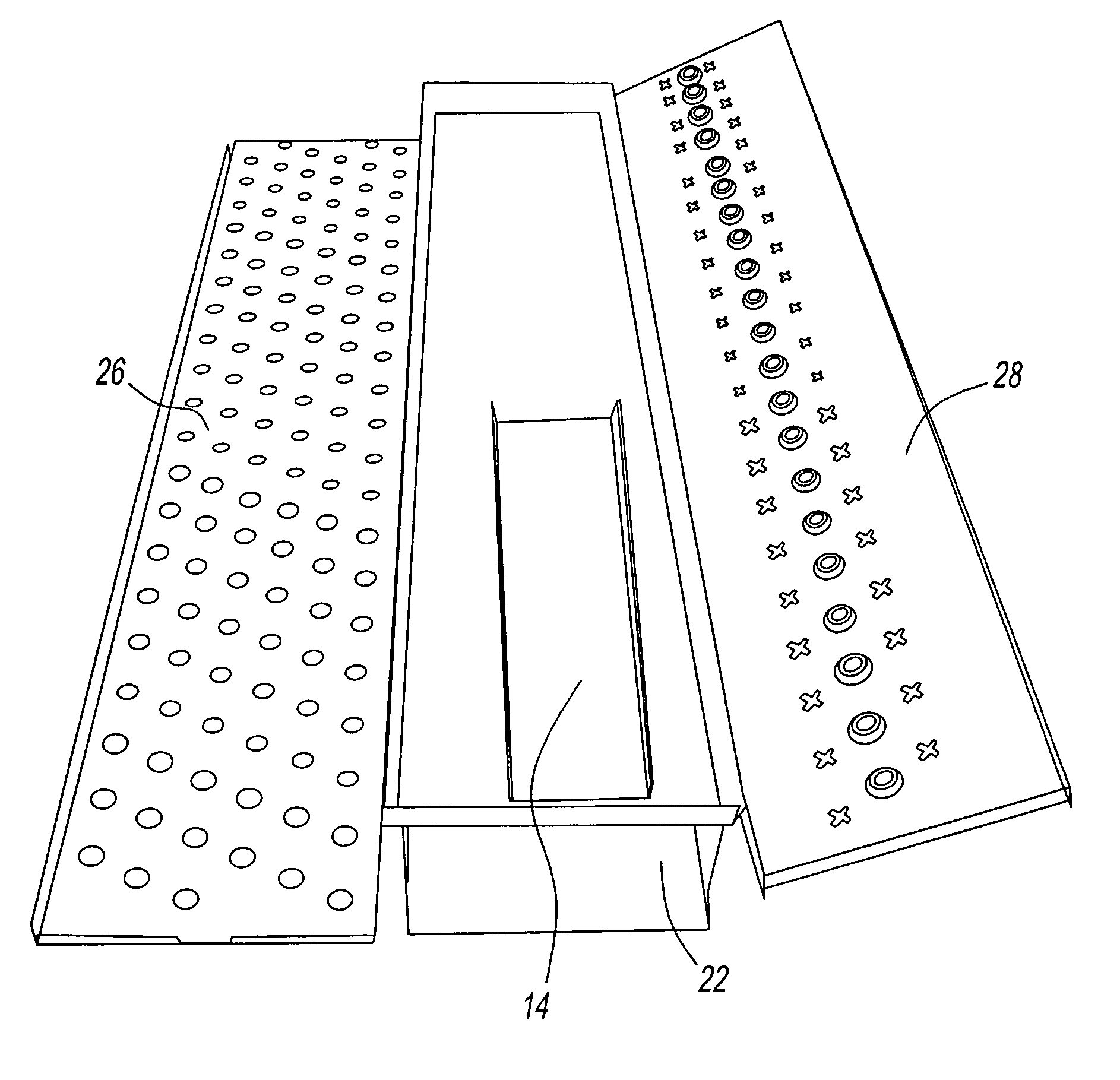

Hood with integral air duct

ActiveUS7370718B2Uniform air velocityEven airflowLiquid coolingCoolant flow controlEngineeringInternal combustion engine

A hood covers an internal combustion engine on the rear of a grass mowing machine. The hood has a top surface with a plurality of air intake openings recessed below the top surface, and an integral air duct. The integral air duct extends over the engine between the air intake openings and an air inlet side of the radiator and / or oil cooler adjacent the rear of the grass mowing machine. The air intake openings closest to the air inlet side of the radiator and / or oil cooler are dimensioned to limit the air intake velocity and prevent buildup of debris on screens or grilles over the openings.

Owner:DEERE & CO

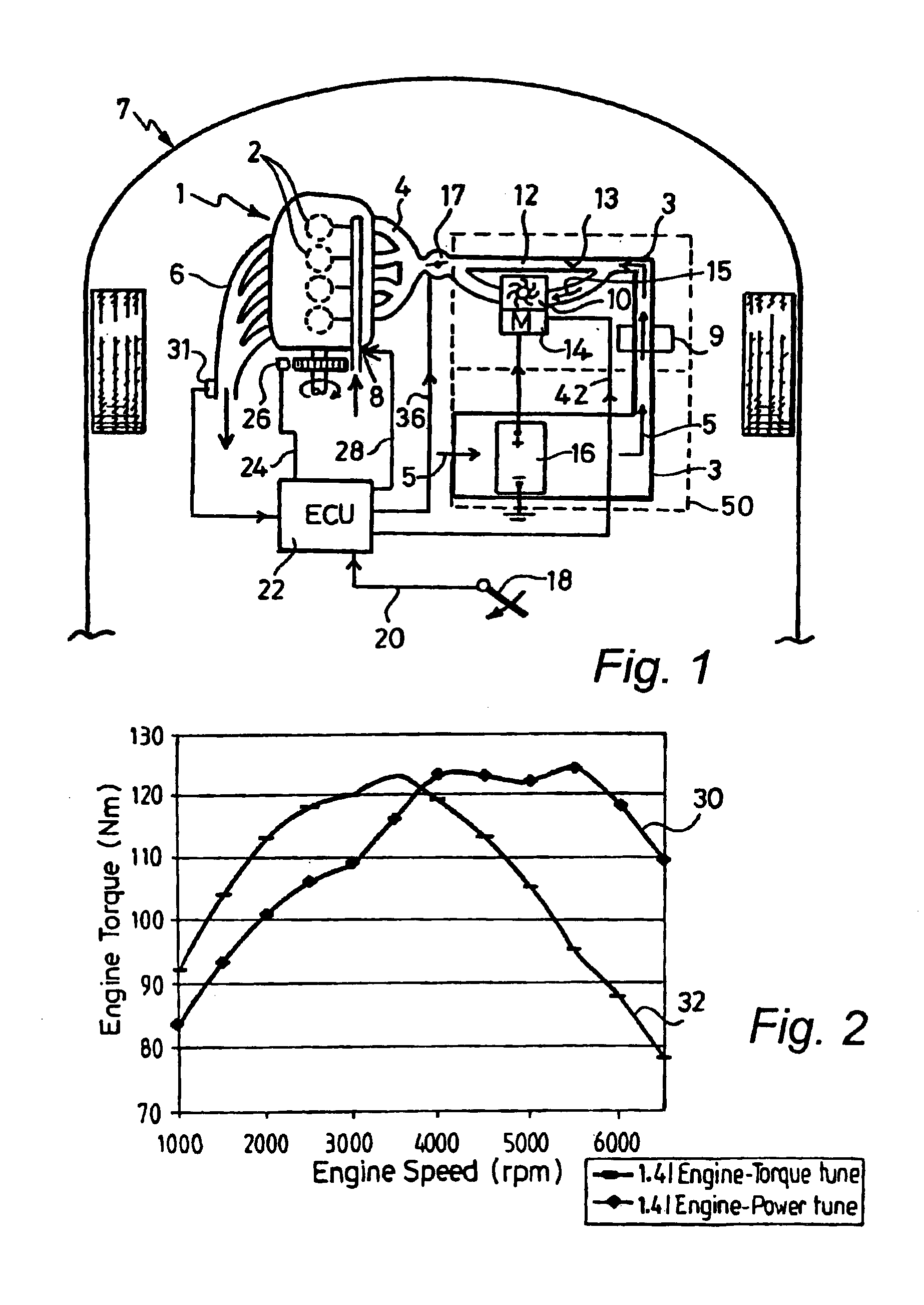

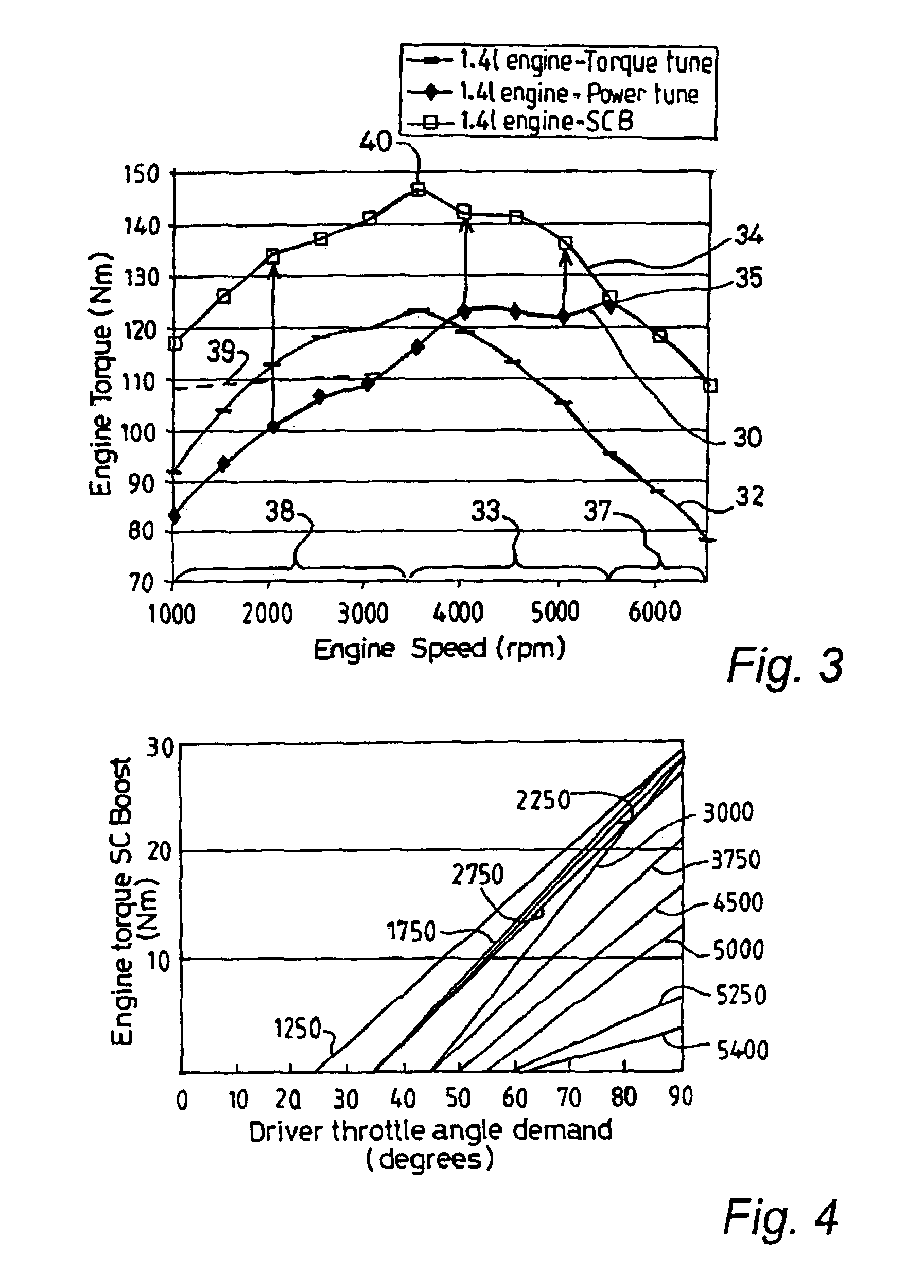

Air intake arrangement for an internal combustion engine

InactiveUS6892713B2Increase efficiencyCool efficiency be maximiseInternal combustion piston enginesAir cleaners for fuelForced inductionElectronics

The present invention relates to an air intake apparatus for an internal combustion engine of an automobile. The apparatus has an enclosure with an air supply path running throughout. Within the enclosure is an electrically driven supercharger, an automotive battery arid possibly other electronics. The enclosure is divided by a partition with an air passage into a battery compartment and a supercharger compartment. The battery compartment is upstream of the supercharger compartment. Air enters the battery compartment through an inlet, travels through the air passage in the partition, enters the supercharger and leaves through an outlet in the supercharger compartment to feed the engine. When the supercharger is running it draws in additional cool air from outside the enclosure through the inlet. This maximizes the cooling of all components upstream of the supercharger, in particular the battery which can heat up significantly when the supercharger is drawing maximum current

Owner:VALEO AIR MANAGEMENT UK

Mid-section of a can-annular gas turbine engine with a cooling system for the transition

InactiveUS20130219921A1Improvements in the operating efficiency, cost efficiency and/or cooling efficiencyReduce manufacturing costContinuous combustion chamberEngine manufactureInterior spaceEngineering

A cooling system is provided for a transition (420) of a gas turbine engine (410). The cooling system includes a cowling (460) configured to receive an air flow (111) from an outlet of a compressor section of the gas turbine engine (410). The cowling (460) is positioned adjacent to a region of the transition (420) to cool the transition region upon circulation of the air flow within the cowling (460). The cooling system further includes a manifold (121) to directly couple the air flow (111) from the compressor section outlet to an inlet (462) of the cowling (460). The cowling (460) is configured to circulate the air flow (111) within an interior space (426) of the cowling (460) that extends radially outward from an inner diameter (423) of the cowling to an outer diameter (424) of the cowling at an outer surface.

Owner:SIEMENS ENERGY INC

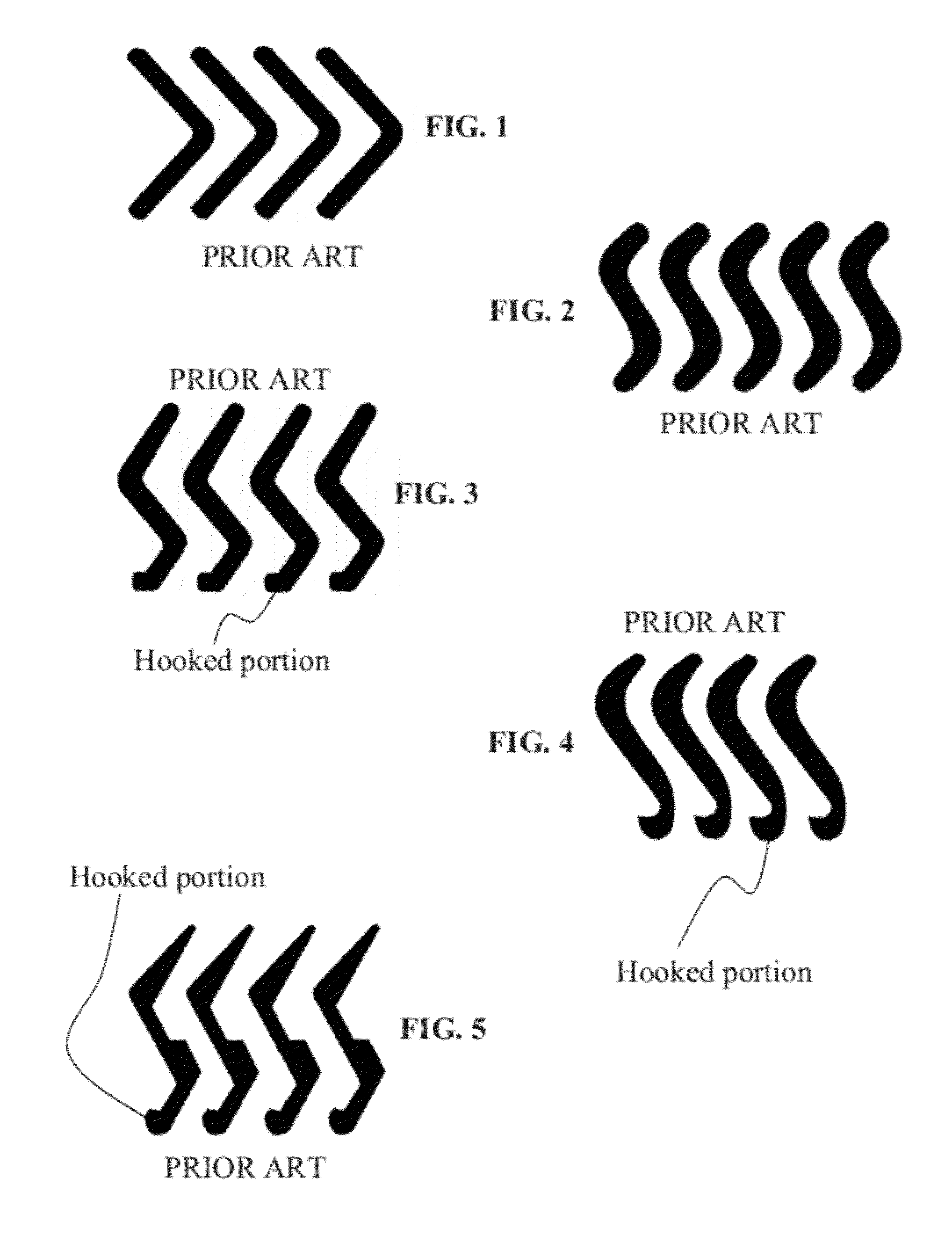

Composite grille louvers

InactiveUS20120240757A1Improve airflow efficiencyReduced effectivenessArmoured vehiclesArmour platesEngineeringMechanical engineering

A grille having a plurality of s-louvers shaped to increase the efficiency of air flow through the grille without decreasing the effectiveness of the louvers at stopping or deflecting projectiles. Each louver has a hooked portion at the end of the louver to present a ballistic hook for stopping projectiles ricocheting through the circuitous path defined between the louvers. An insert having a closeout for covering the ballistic hook is positioned within each hooked shape portion to eliminate the eddy or stall created at the end of the circuitous path by ballistic hook. The closeout can be penetrated by projectiles ricocheting through the circuitous path such that the ballistic hook can still capture projectiles within the inlet.

Owner:BAE SYSTEMS LAND & ARMAMENTS LP

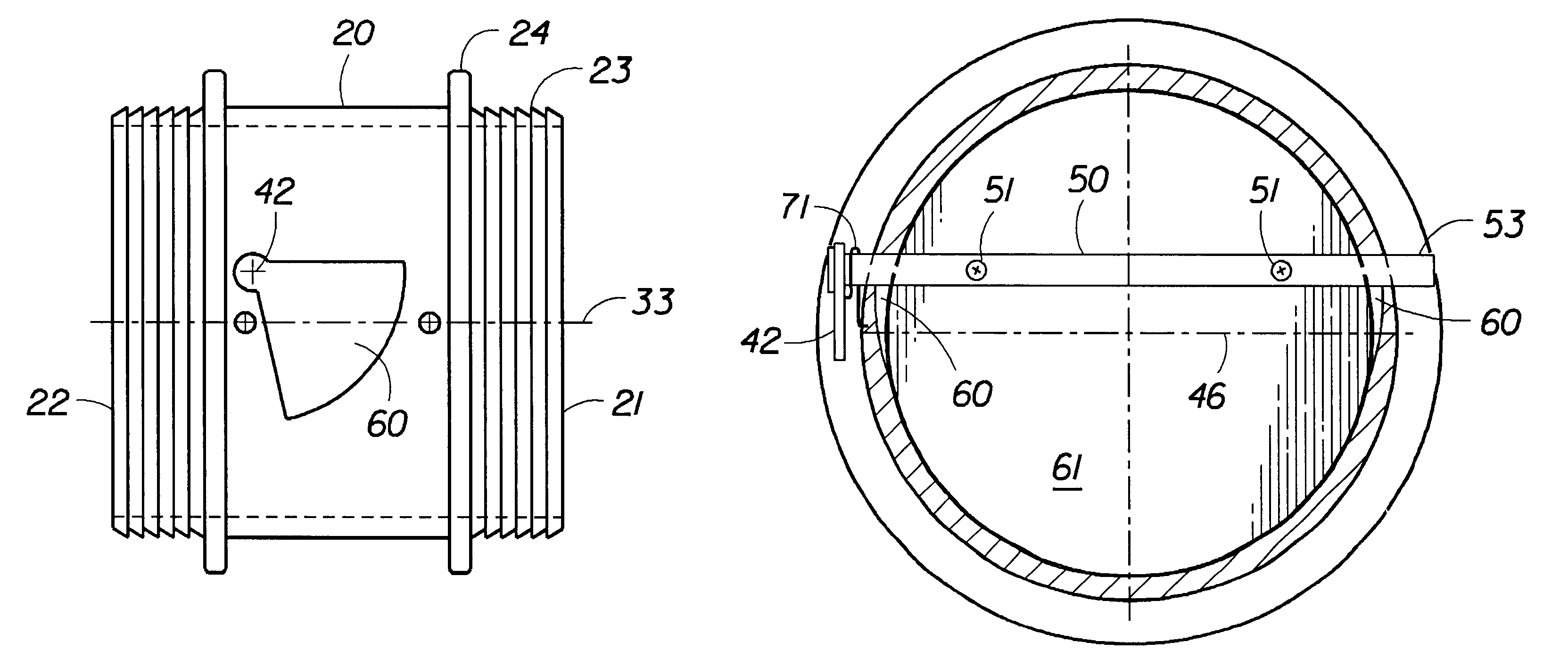

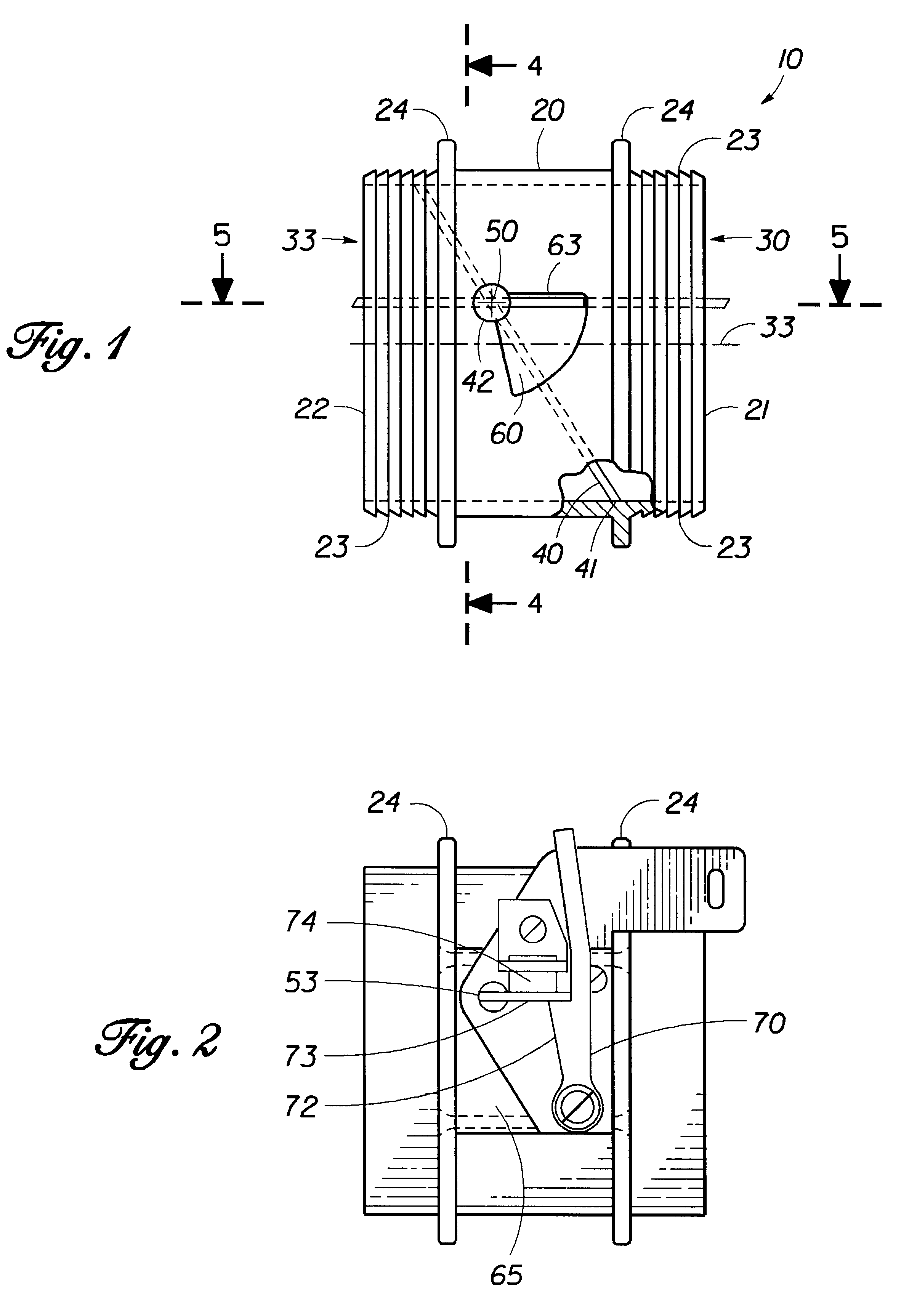

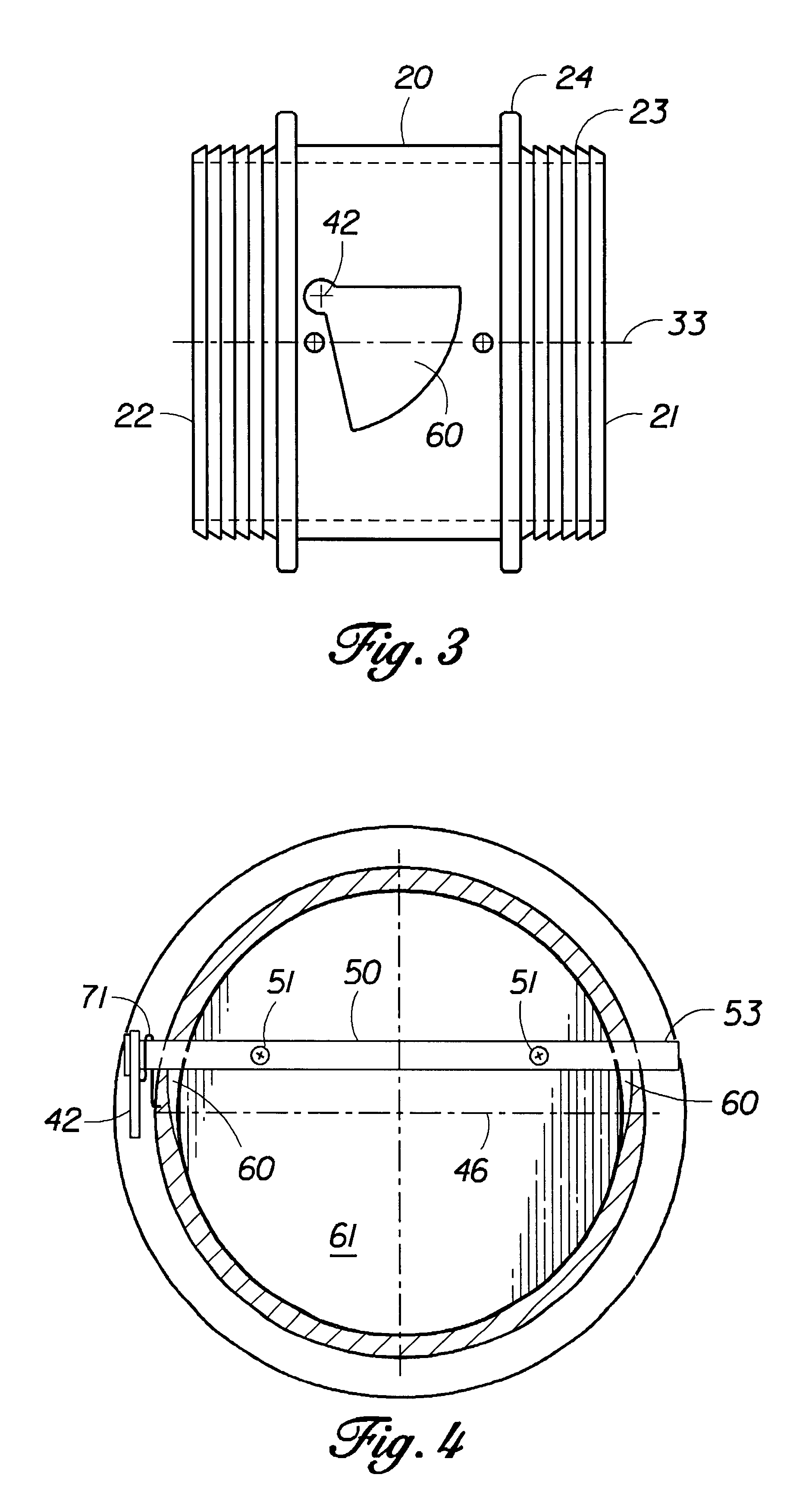

Offset butterfly valve

InactiveUS6283448B1Improve airflow efficiencyPlug valvesOperating means/releasing devices for valvesMaximum diameterEngineering

An offset butterfly valve with a valve body, air flow conduit extending there through, and an offset rotatably mounted valve plate. The air flow conduit has with no interruptions to impede air flow there through. Cross sections along any location of the conduit are essentially round and of equal diameter while the valve plate is the shape of an oblique cross section of the conduit and rotatably mounted therein. The valve plate axis of rotation is offset with respect to the center of the valve plate and further offset with respect to a center of the conduit. Rotation of the valve plate within the conduit is accomplished by providing two opposing indentations on the interior of the conduit which accommodate the maximum diameter dimension of the valve plate when the valve plate is rotated to an open position. The indentations do not interrupt air flow through the conduit or the sealing of the valve plate periphery which may be easily machined to seal with a sealing surface of the interior of the conduit. A valve plate shaft may be contained within the valve body or may be accesses by removable side mount blocks. Various activation, biasing, or latching mechanisms may be included on the valve plate shaft and the valve may be utilized as a check or a positive shut-off valve.

Owner:STERLING JAMES +1

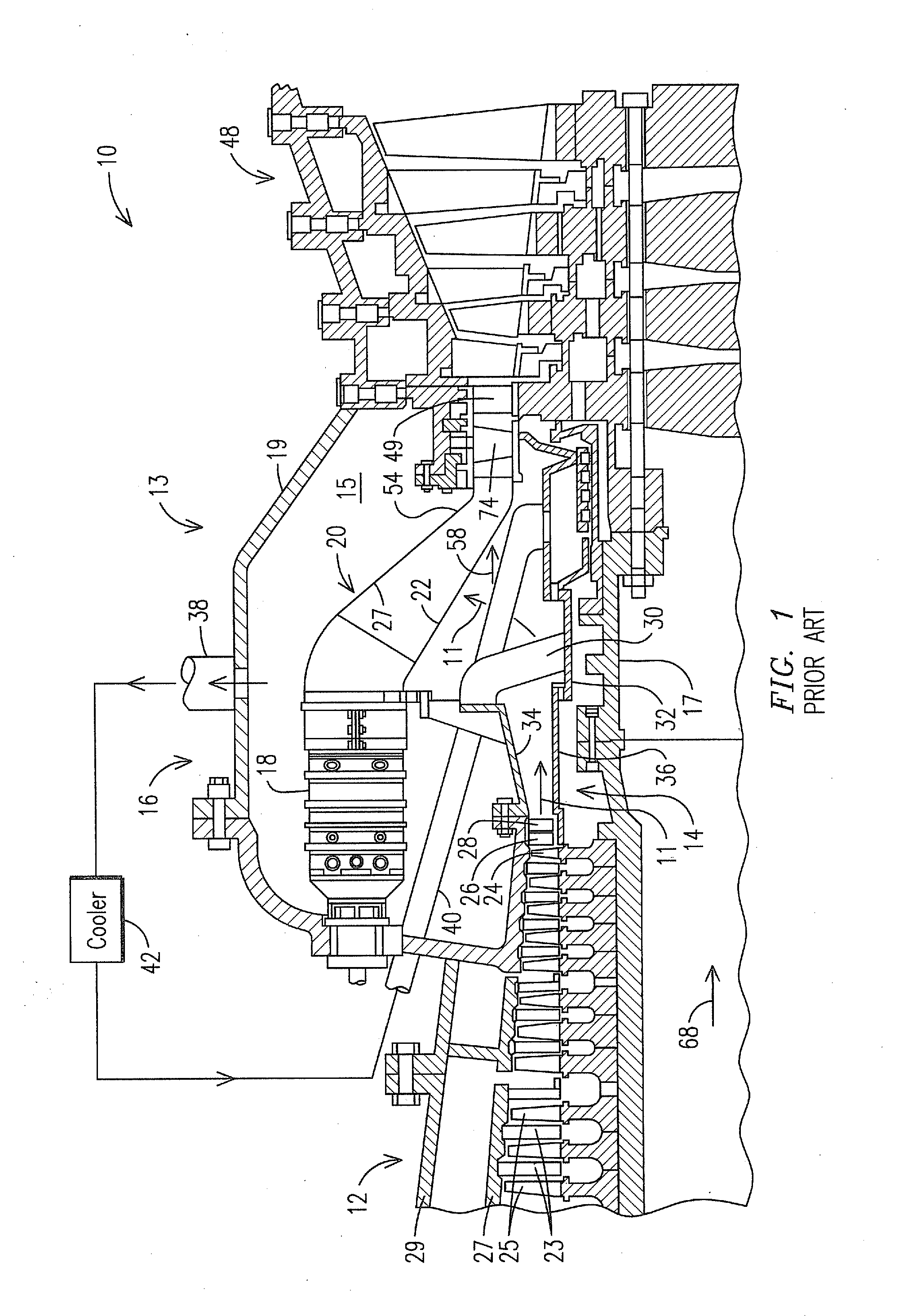

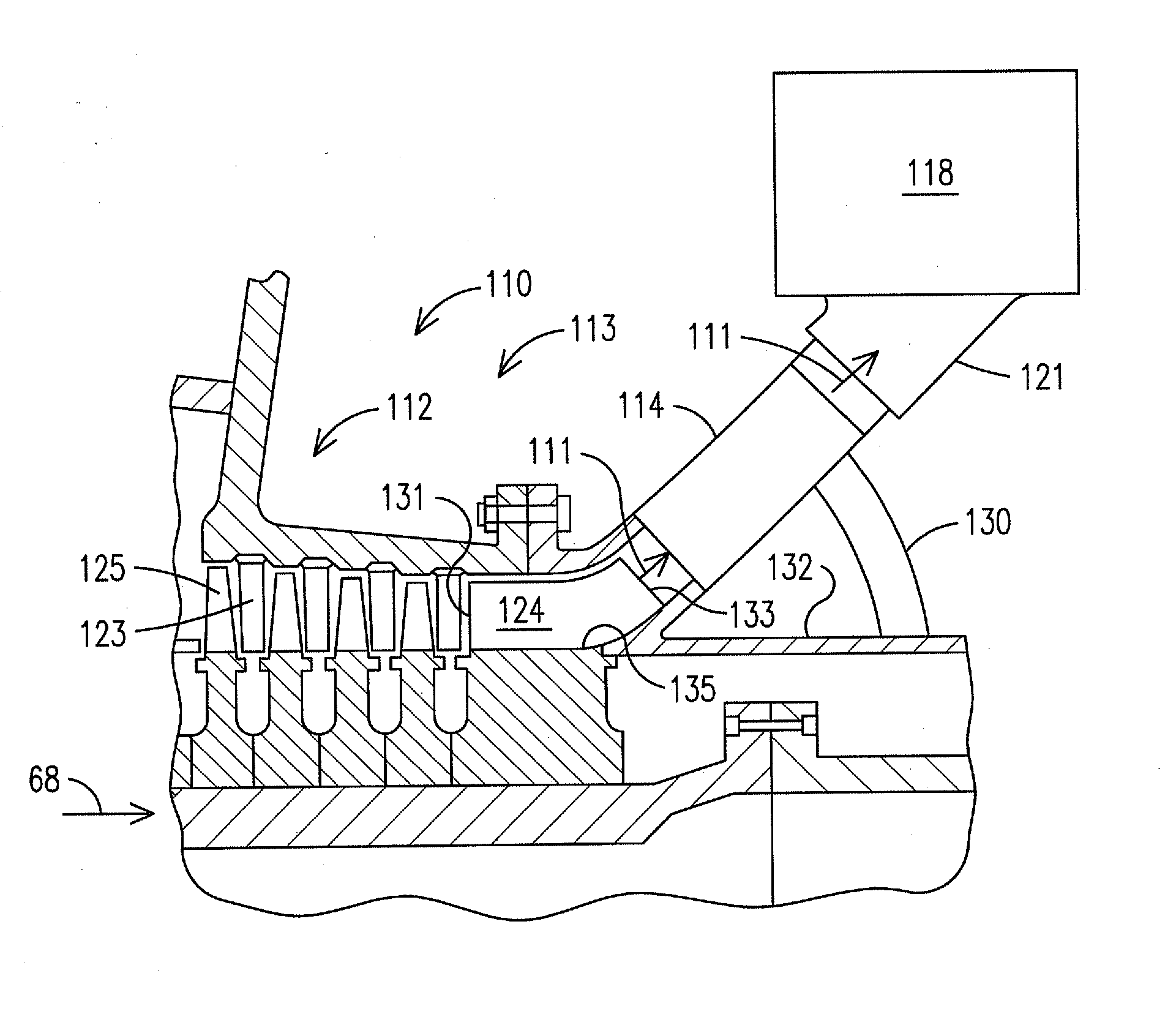

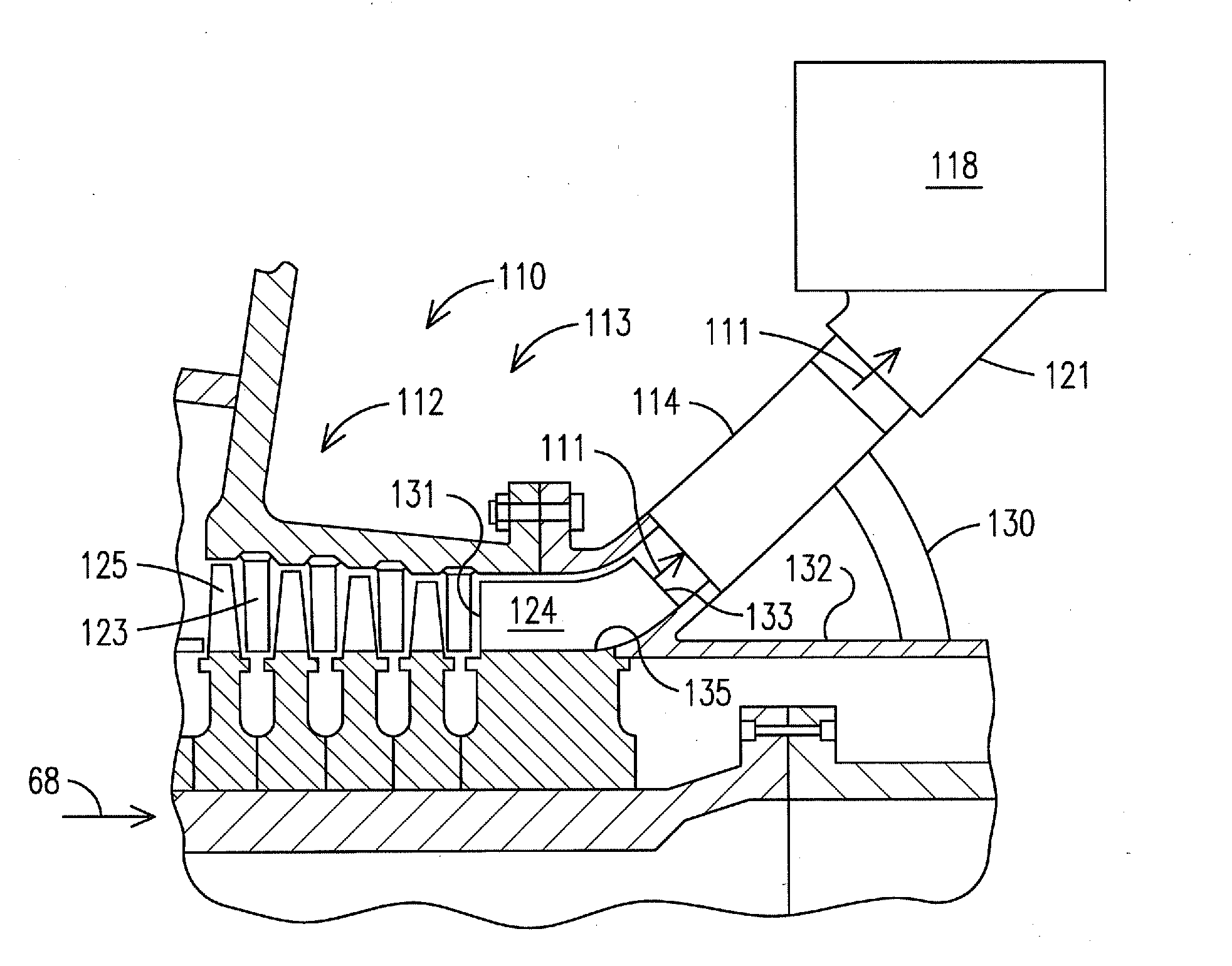

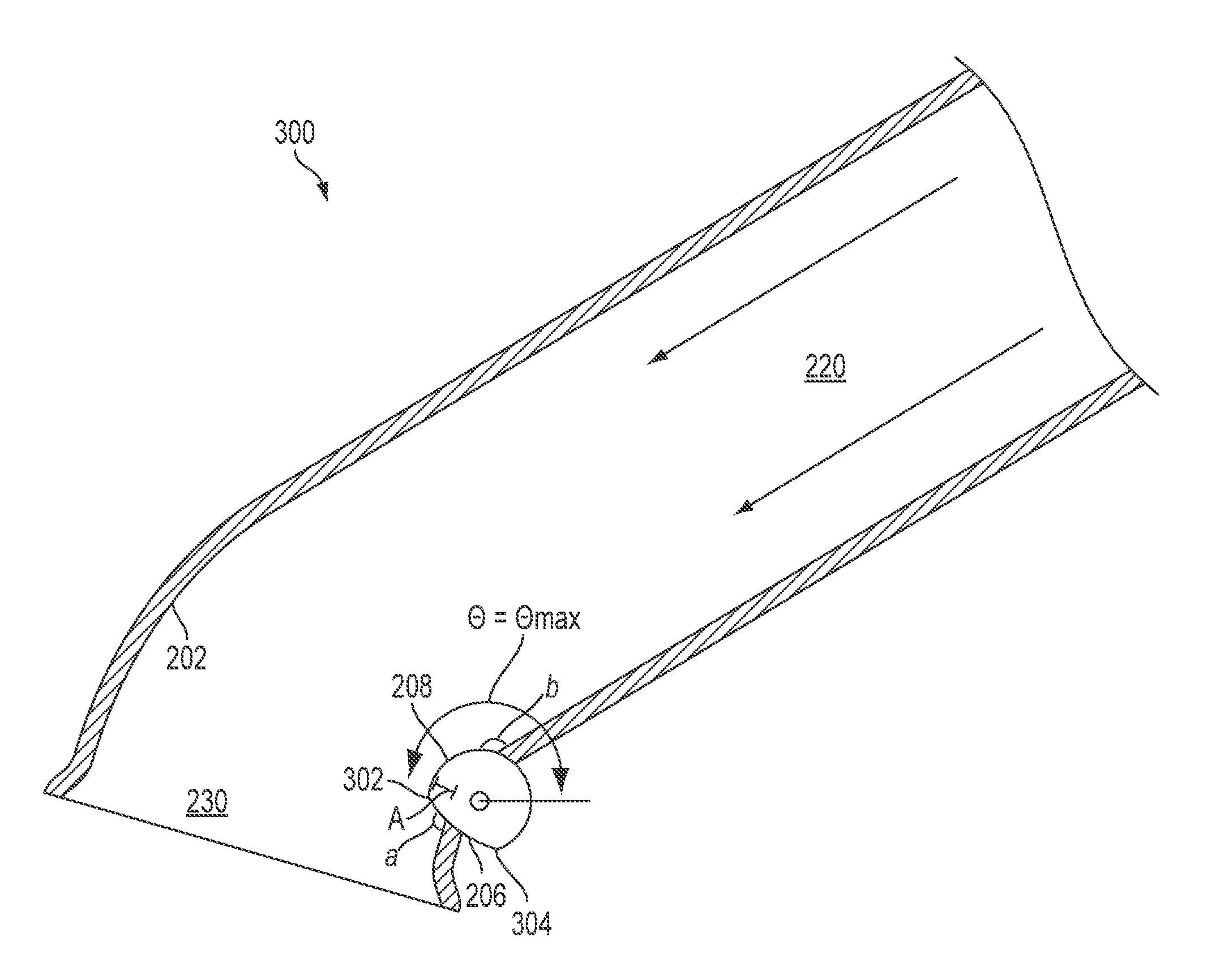

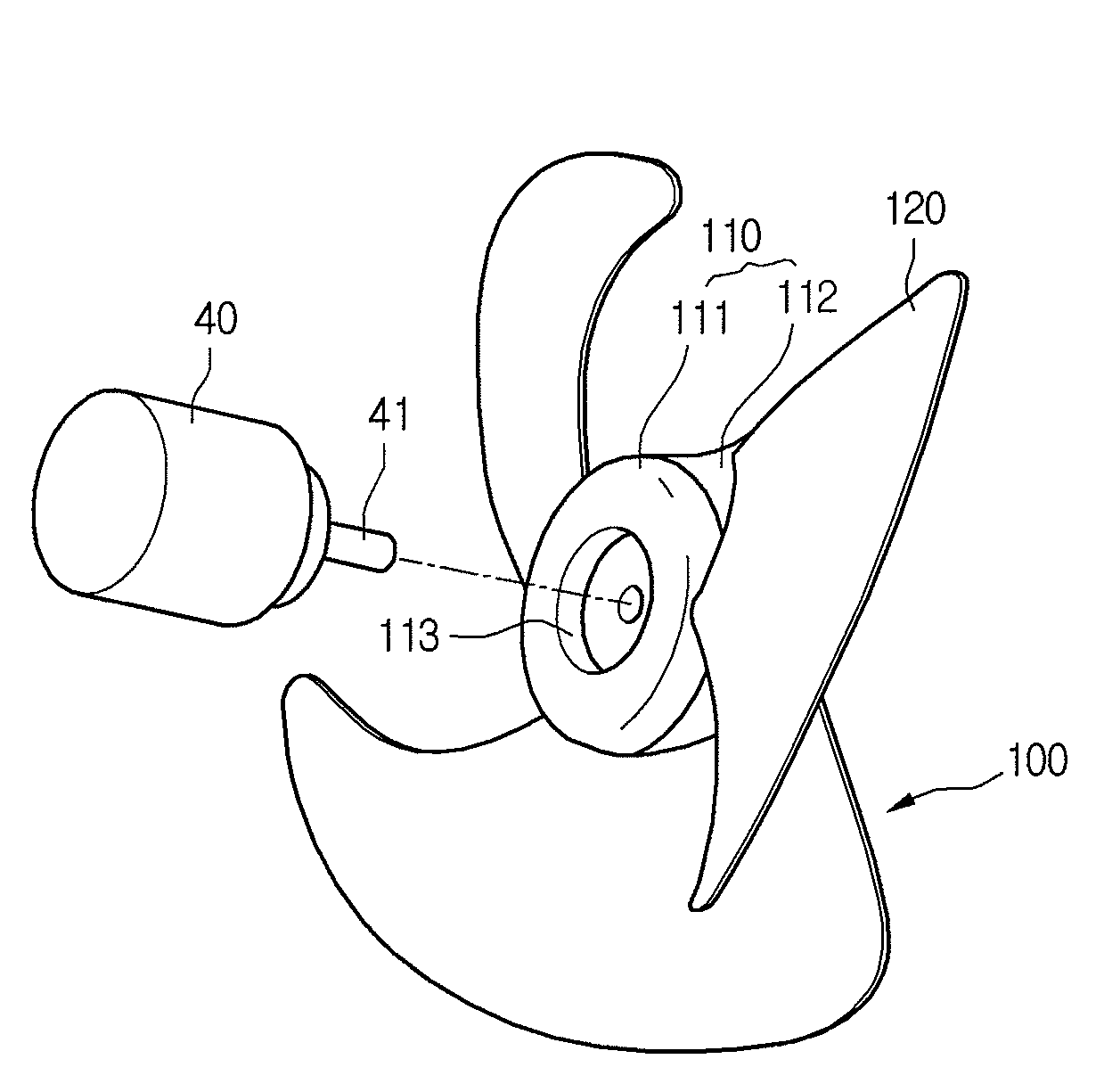

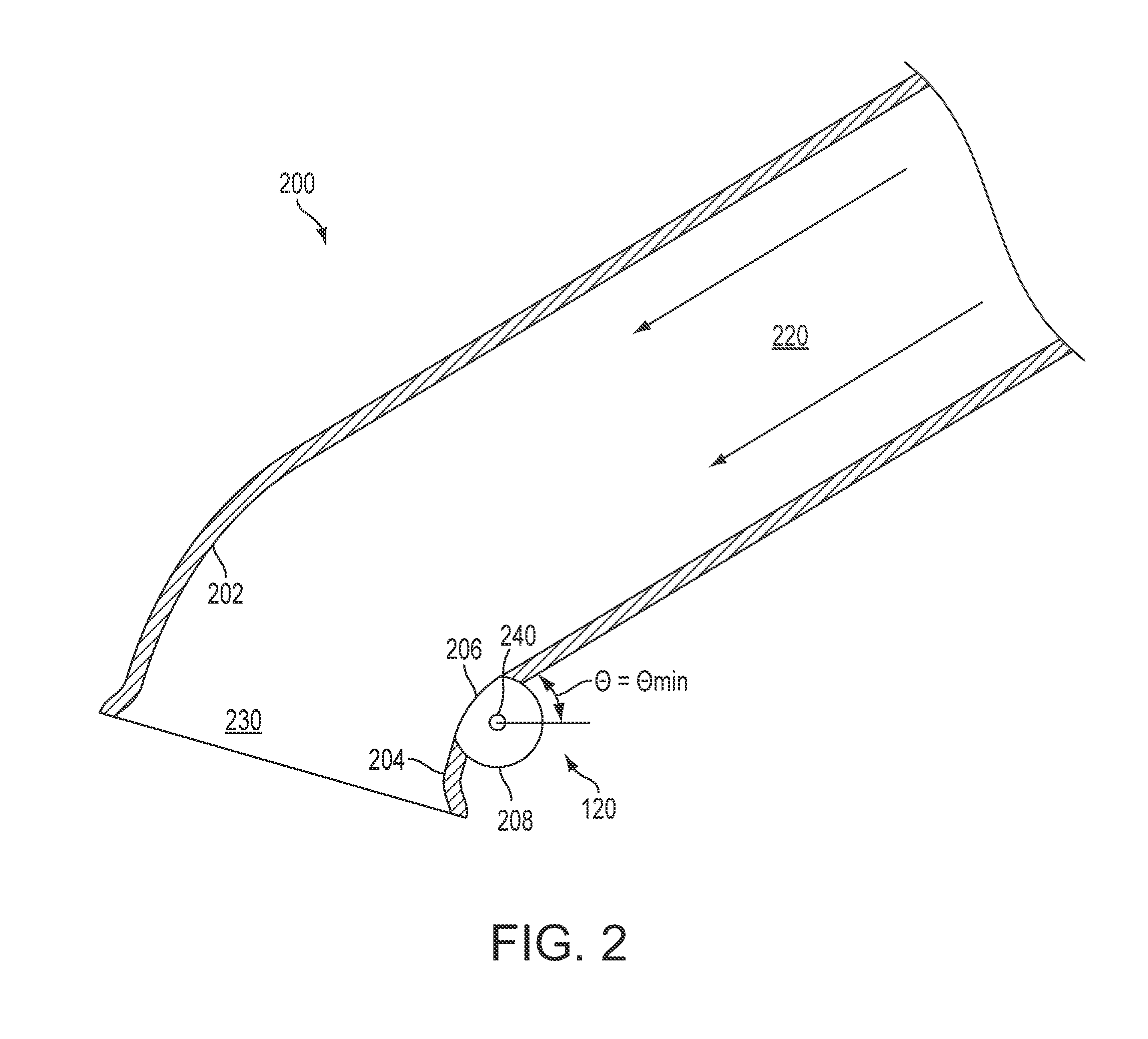

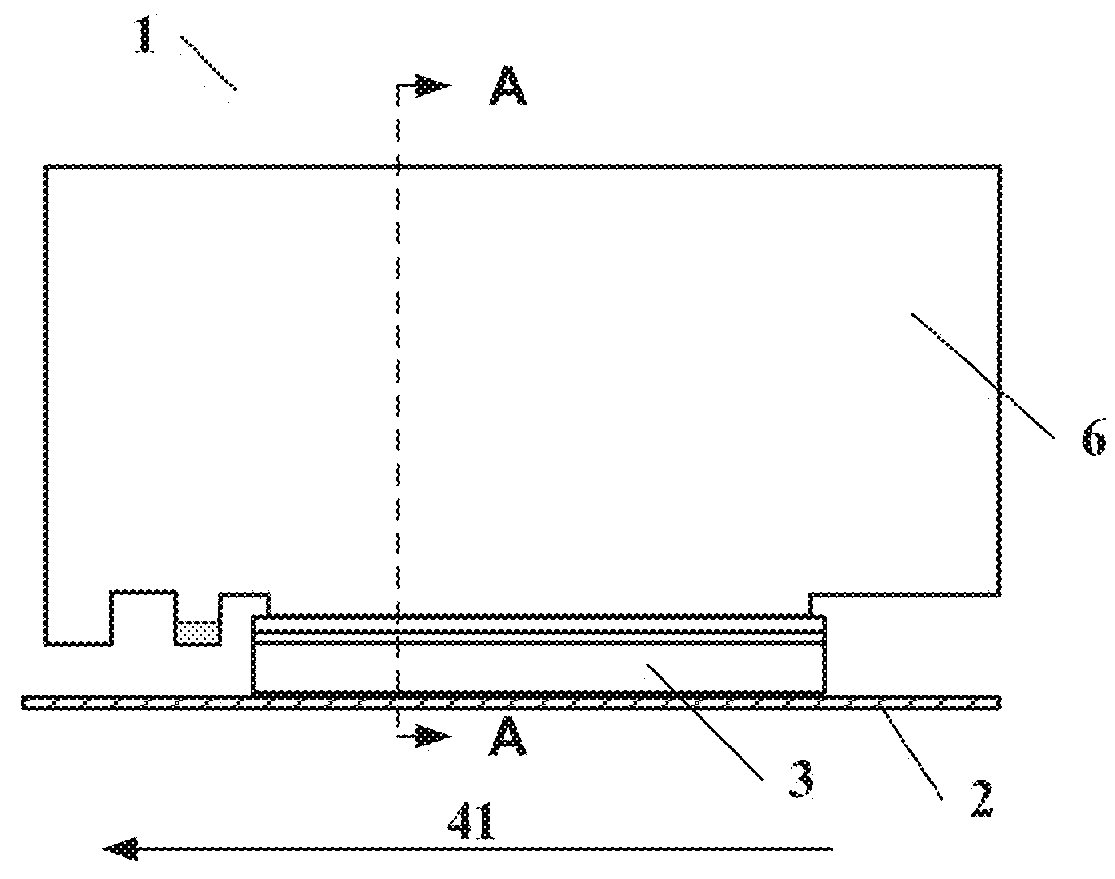

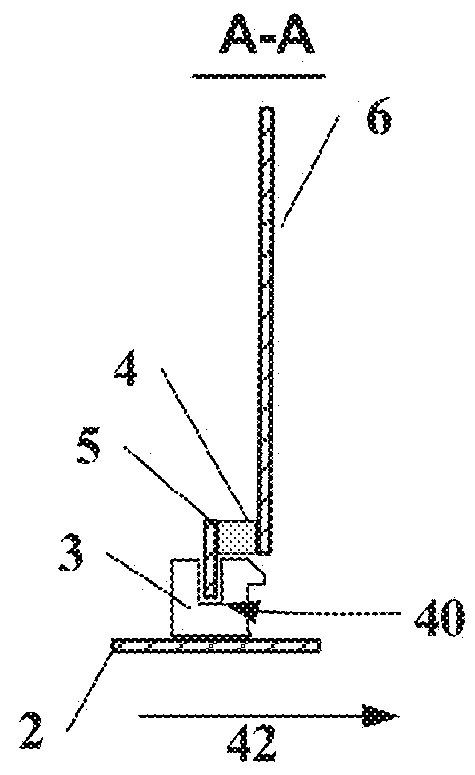

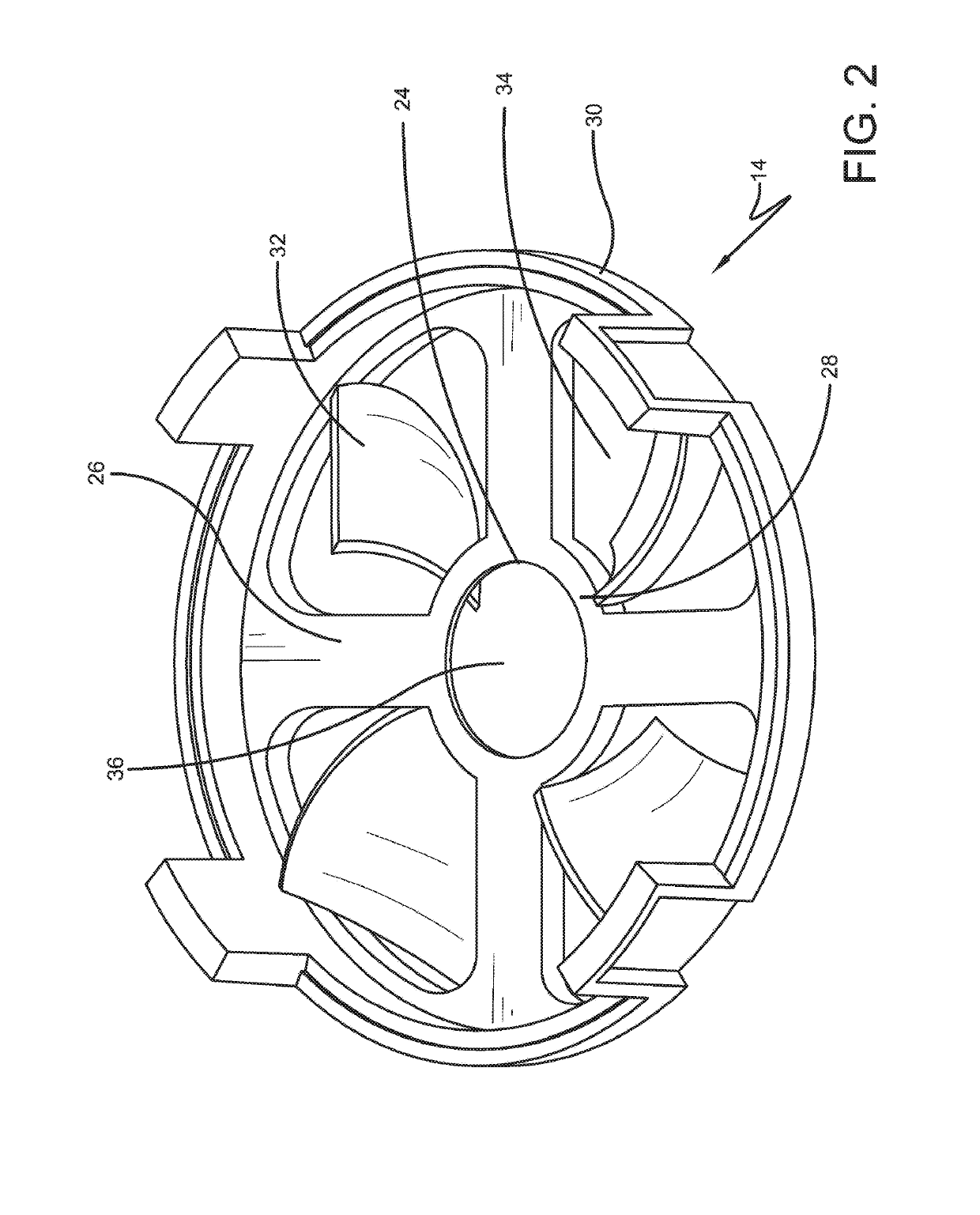

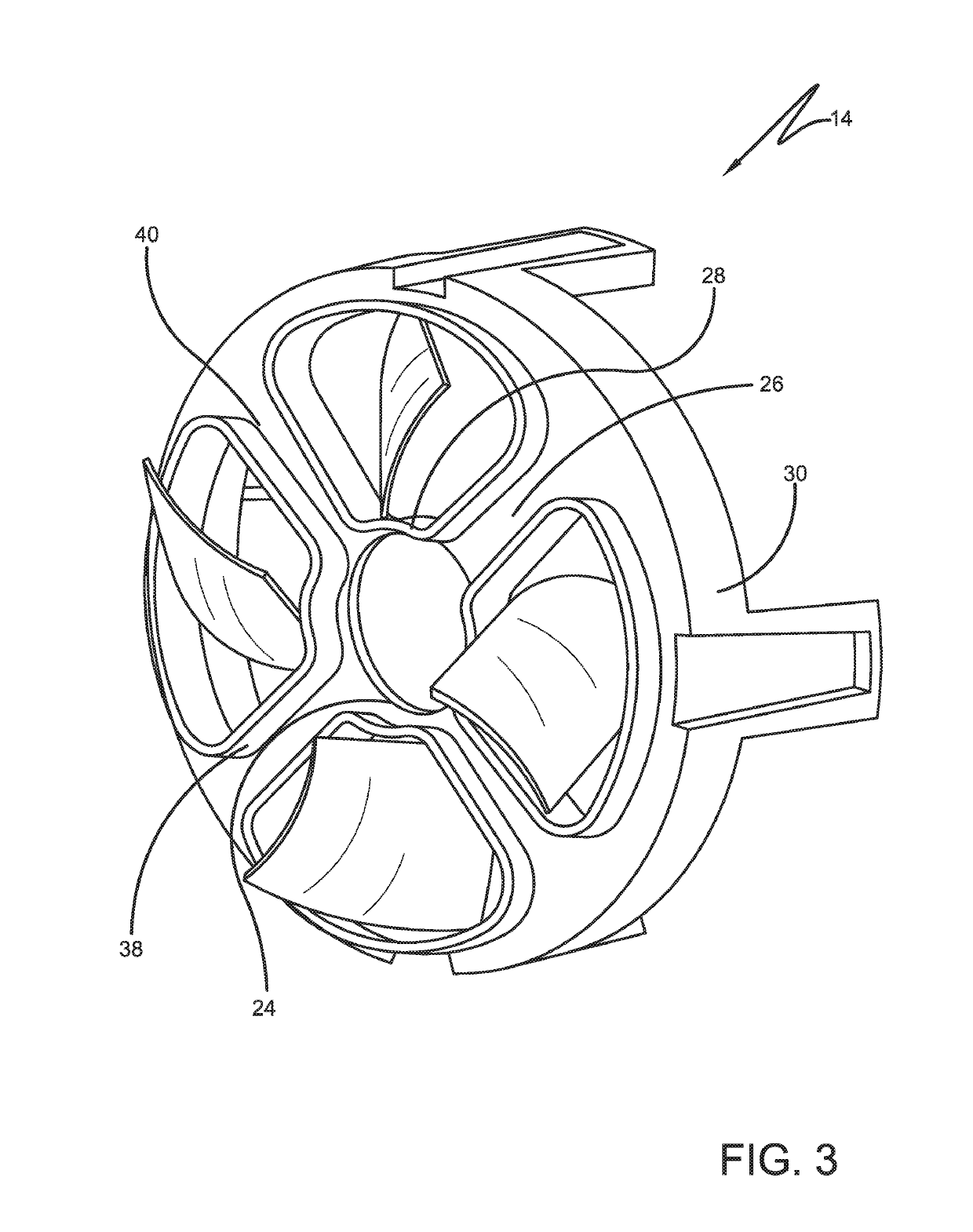

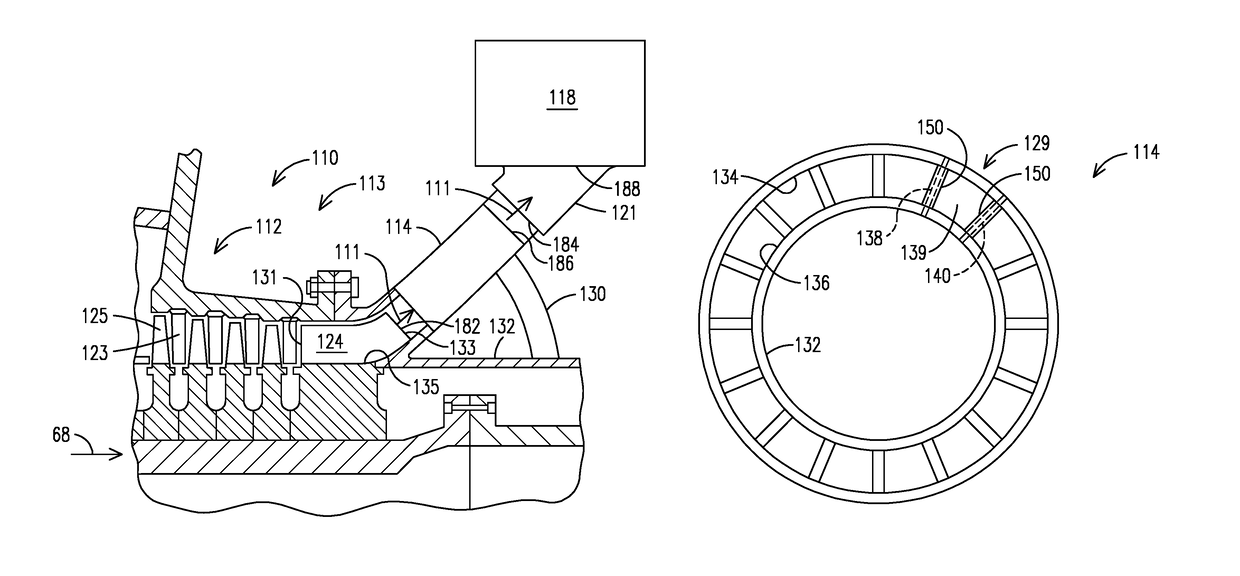

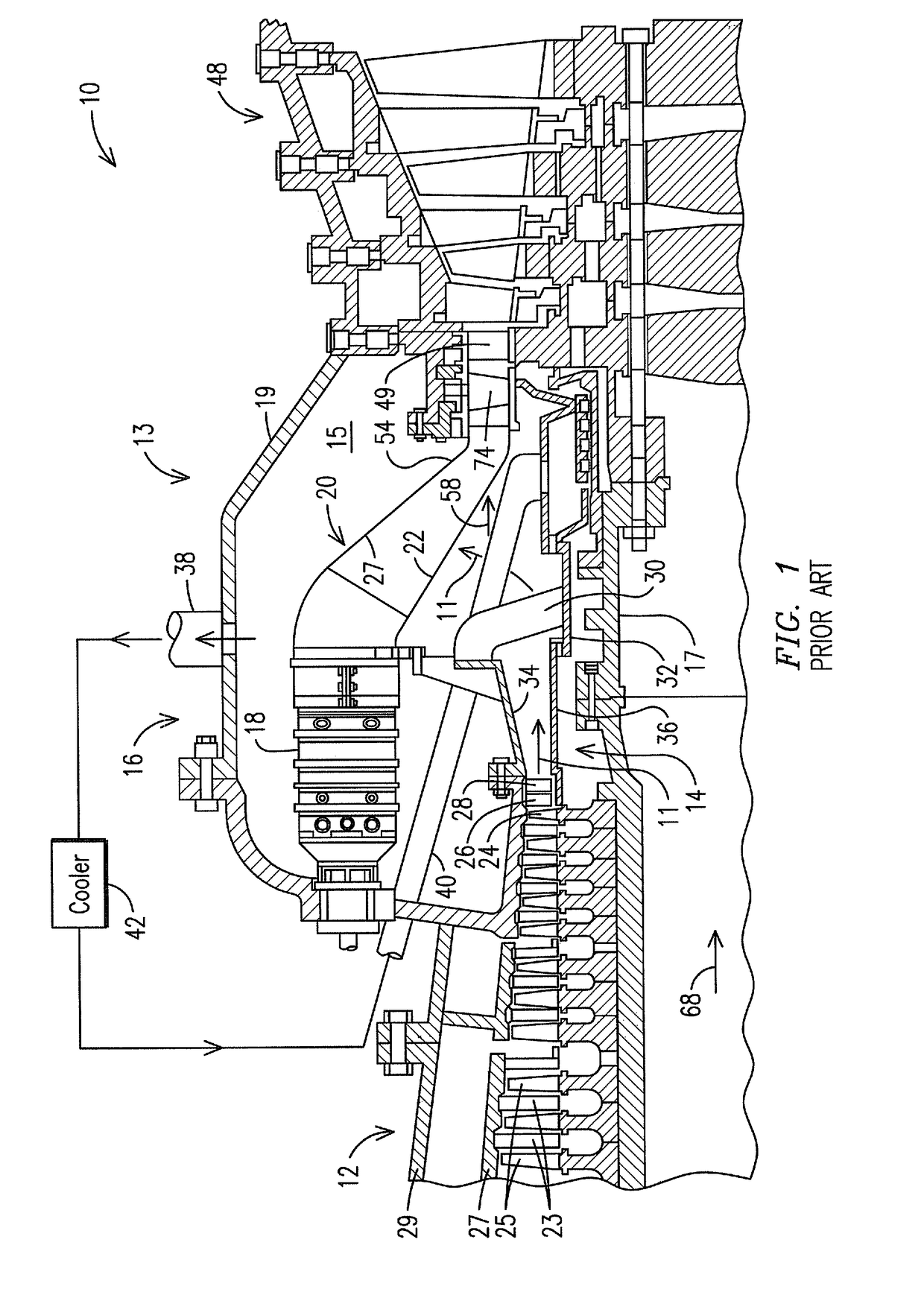

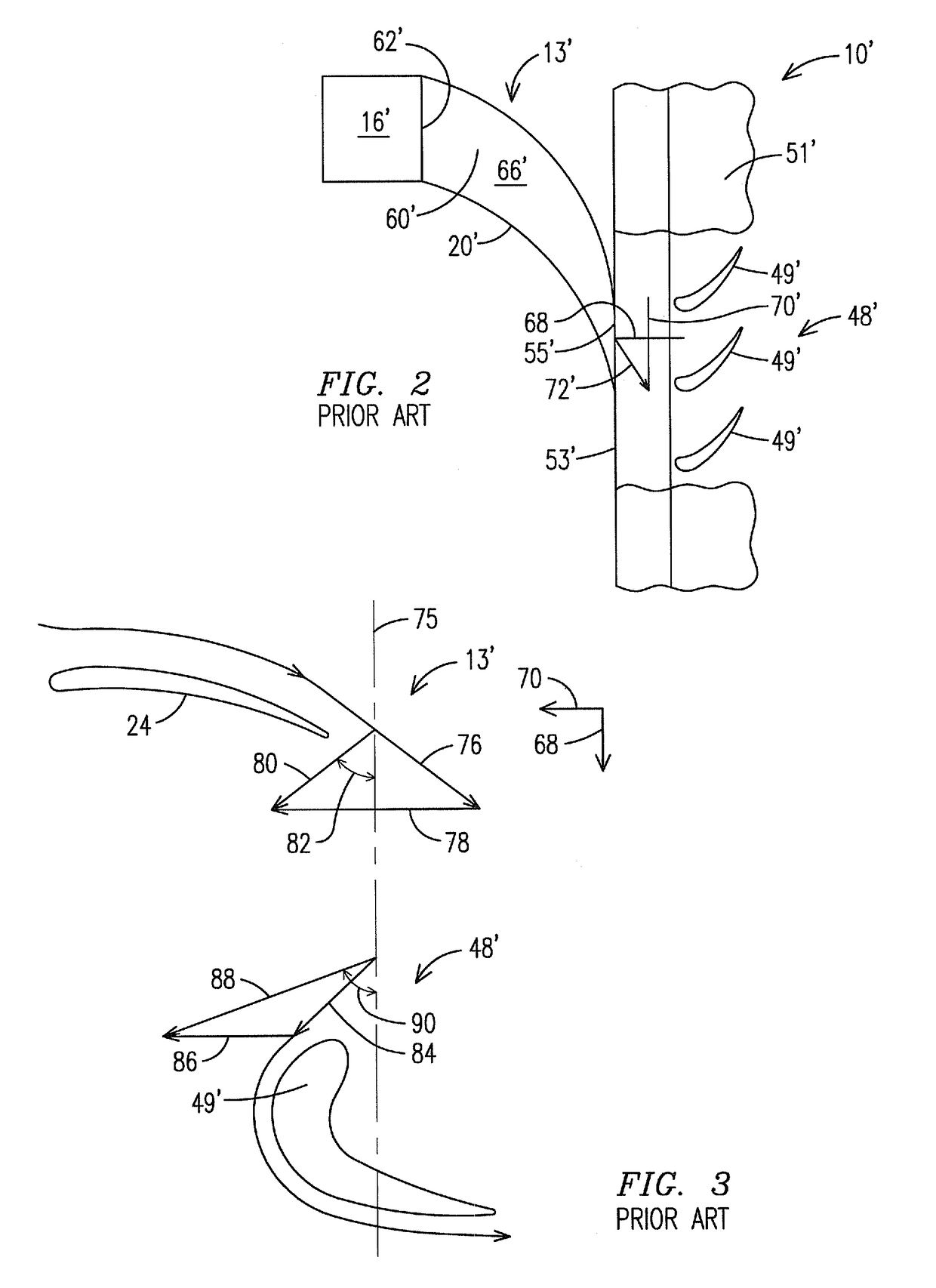

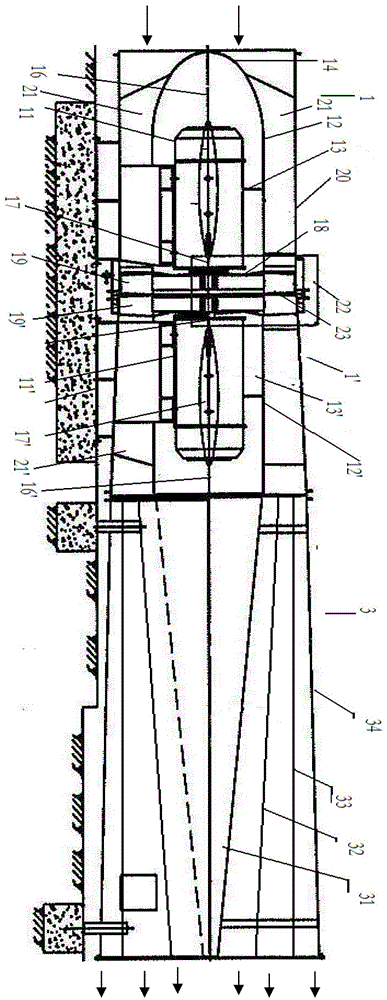

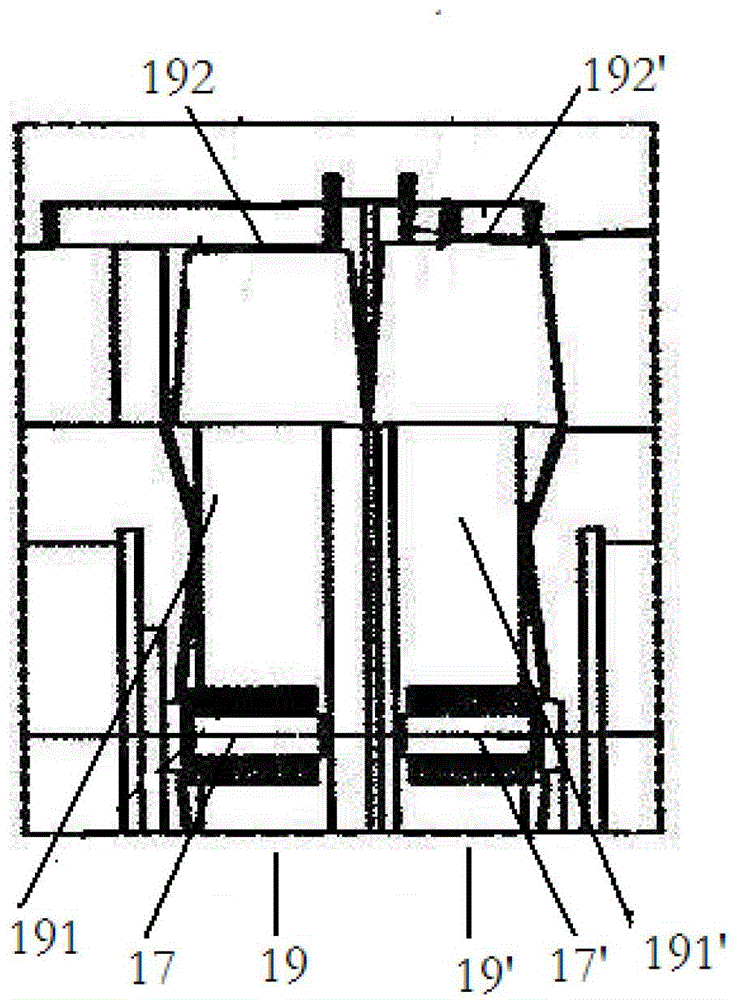

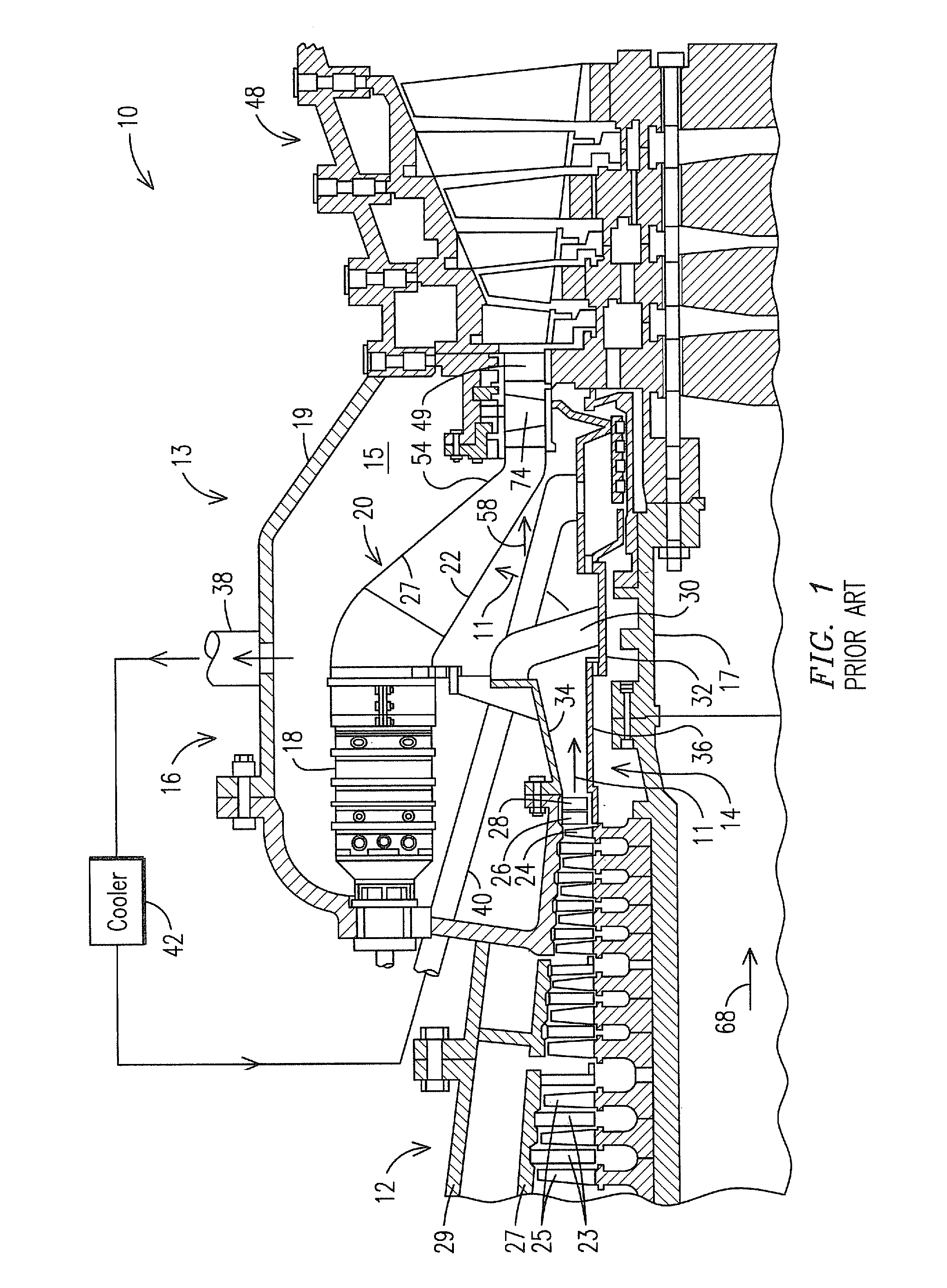

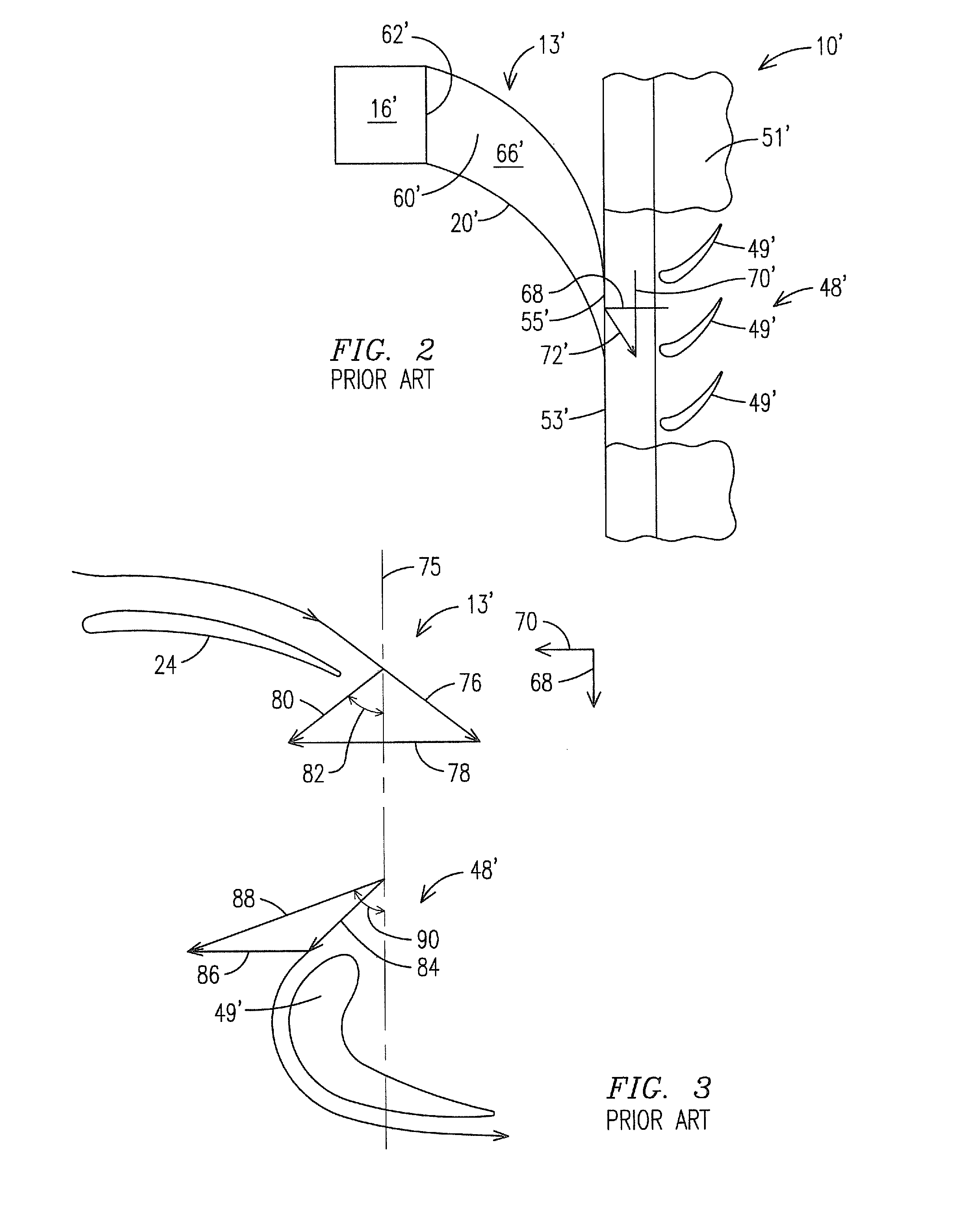

Mid-section of a can-annular gas turbine engine to introduce a radial velocity component into an air flow discharged from a compressor of the mid-section

InactiveUS20130224007A1Improvements in the operating efficiency, cost efficiency and/or cooling efficiencyReduce manufacturing costPump componentsGas turbine plantsCombustorTurbine

A midframe portion (113) of a gas turbine engine (110) is provided, including a compressor section (112) with a last stage blade (124). The compressor section (112) is configured to introduce a radial velocity component into an air flow (111) such that the air flow is discharged from the compressor section (112) at a mixed direction based on a combined longitudinal velocity component and radial velocity component. The midframe portion (113) further includes a manifold (121) to directly couple the air flow from an outlet of the compressor section (112) to an inlet of a respective combustor head (118) of the gas turbine engine (110).

Owner:SIEMENS ENERGY INC

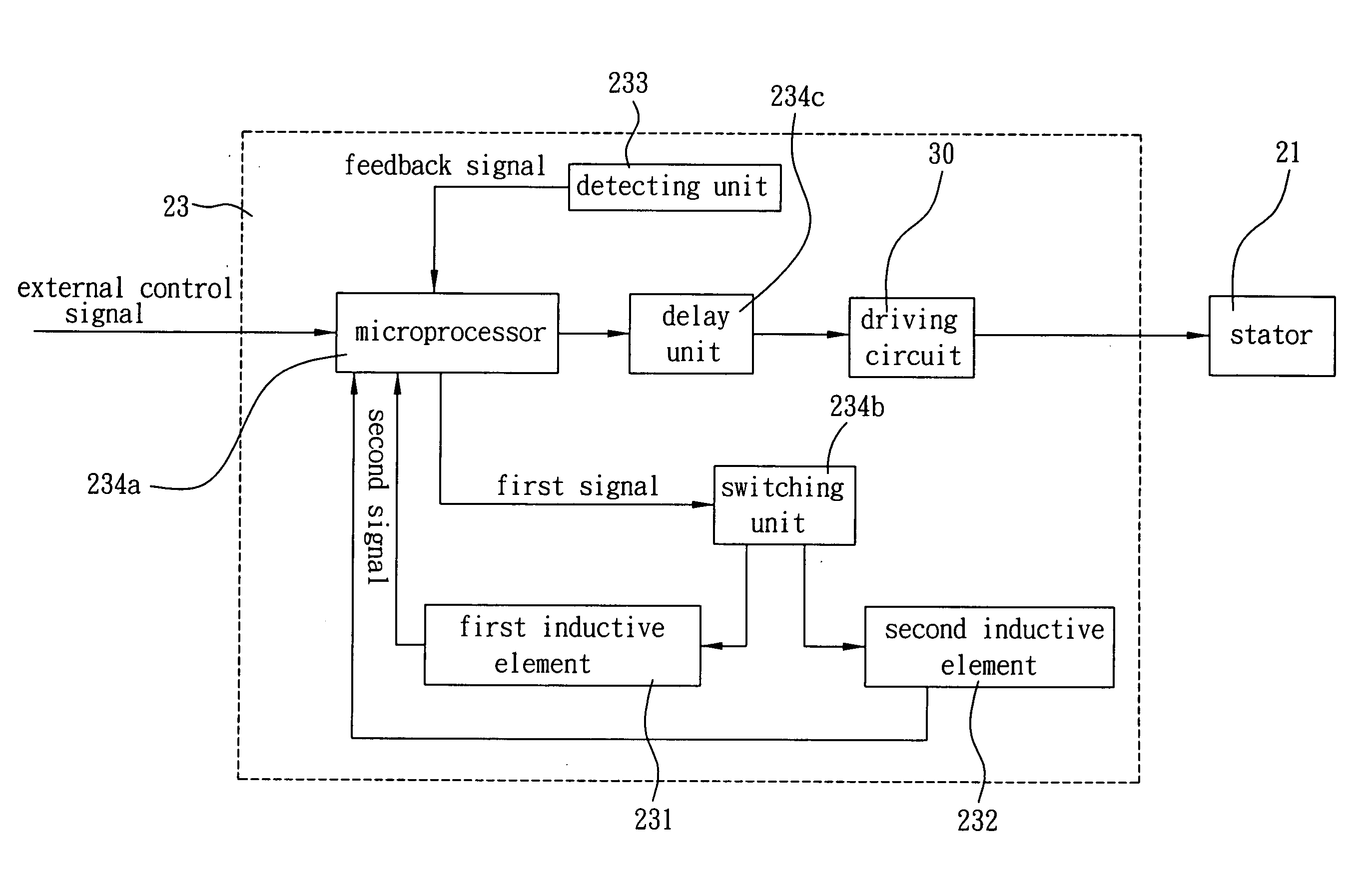

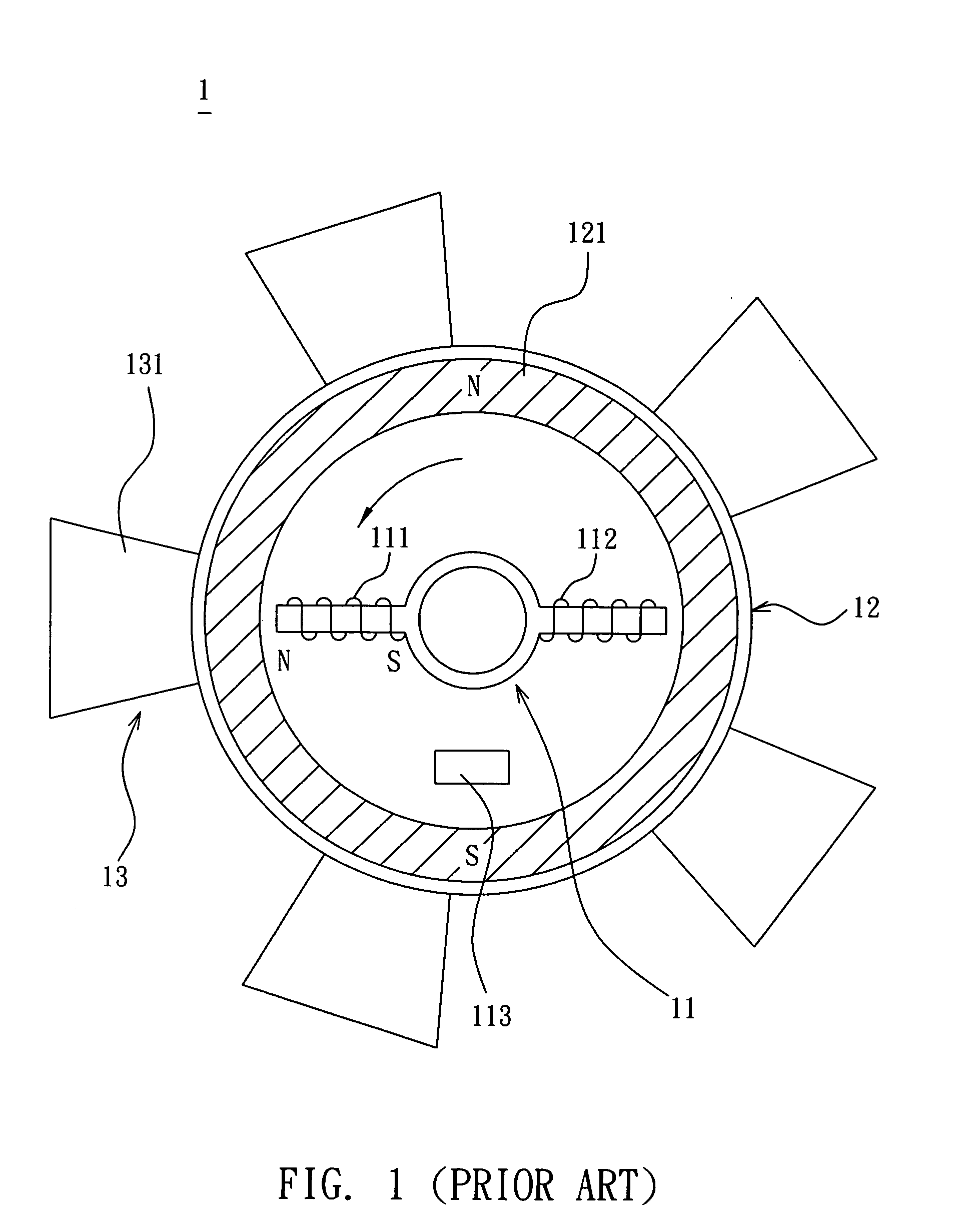

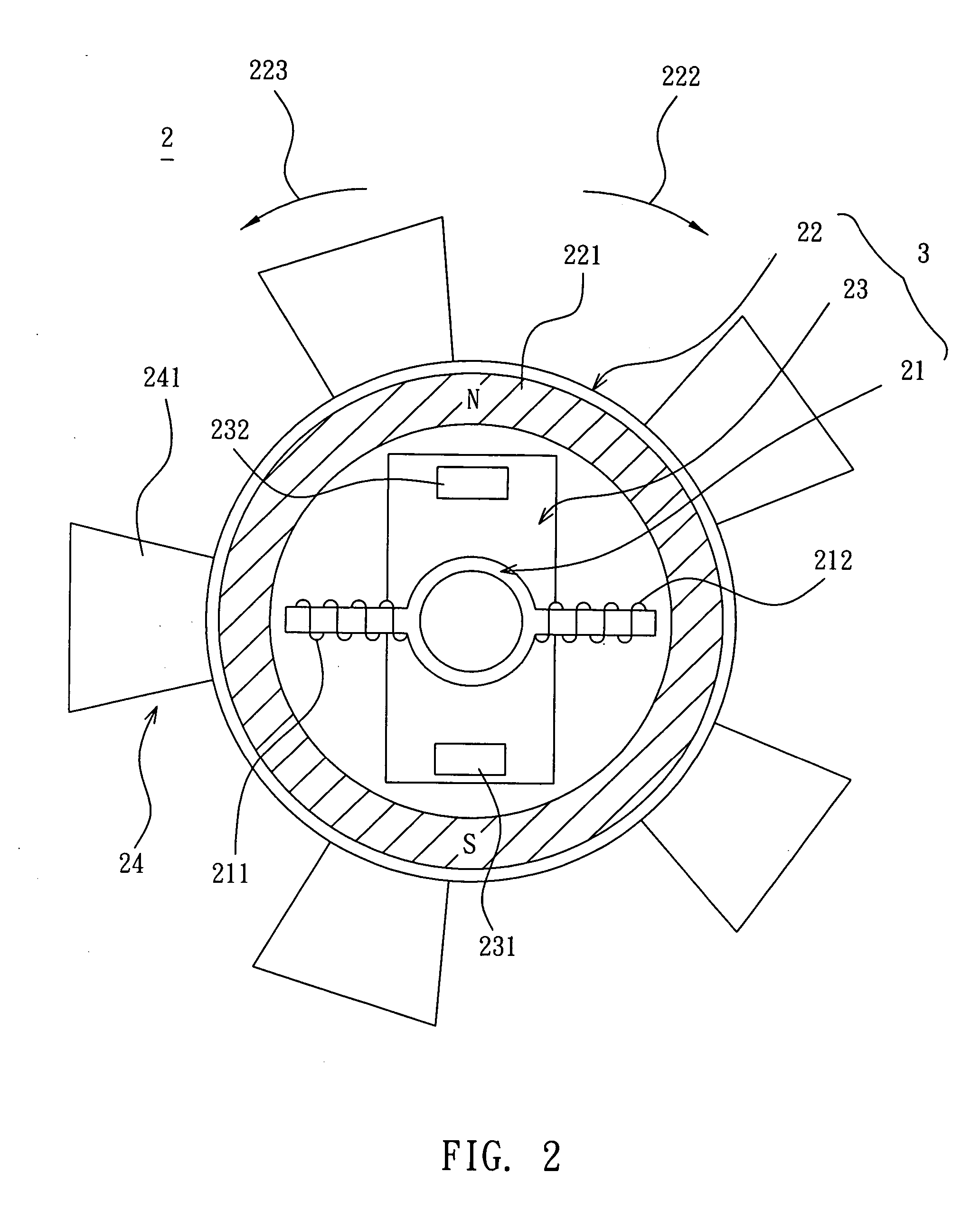

Bi-directional single-phase fan and motor thereof

InactiveUS20070001634A1Correctly detect magnetismImprove airflow efficiencyElectronic commutation motor controlMotor/generator/converter stoppersEngineeringInductor

A bi-directional single-phase motor includes a stator, a rotor and a control circuit. The rotor is coupled to the stator and rotates along a first direction or a second direction. The control circuit is disposed in the stator and has a first inductive element and a second inductive element. When the first inductive element is on and the second inductive element is off, the rotor rotates along the first direction. When the first inductive element is off and the second inductive element is on, the rotor rotates along the second direction.

Owner:DELTA ELECTRONICS INC

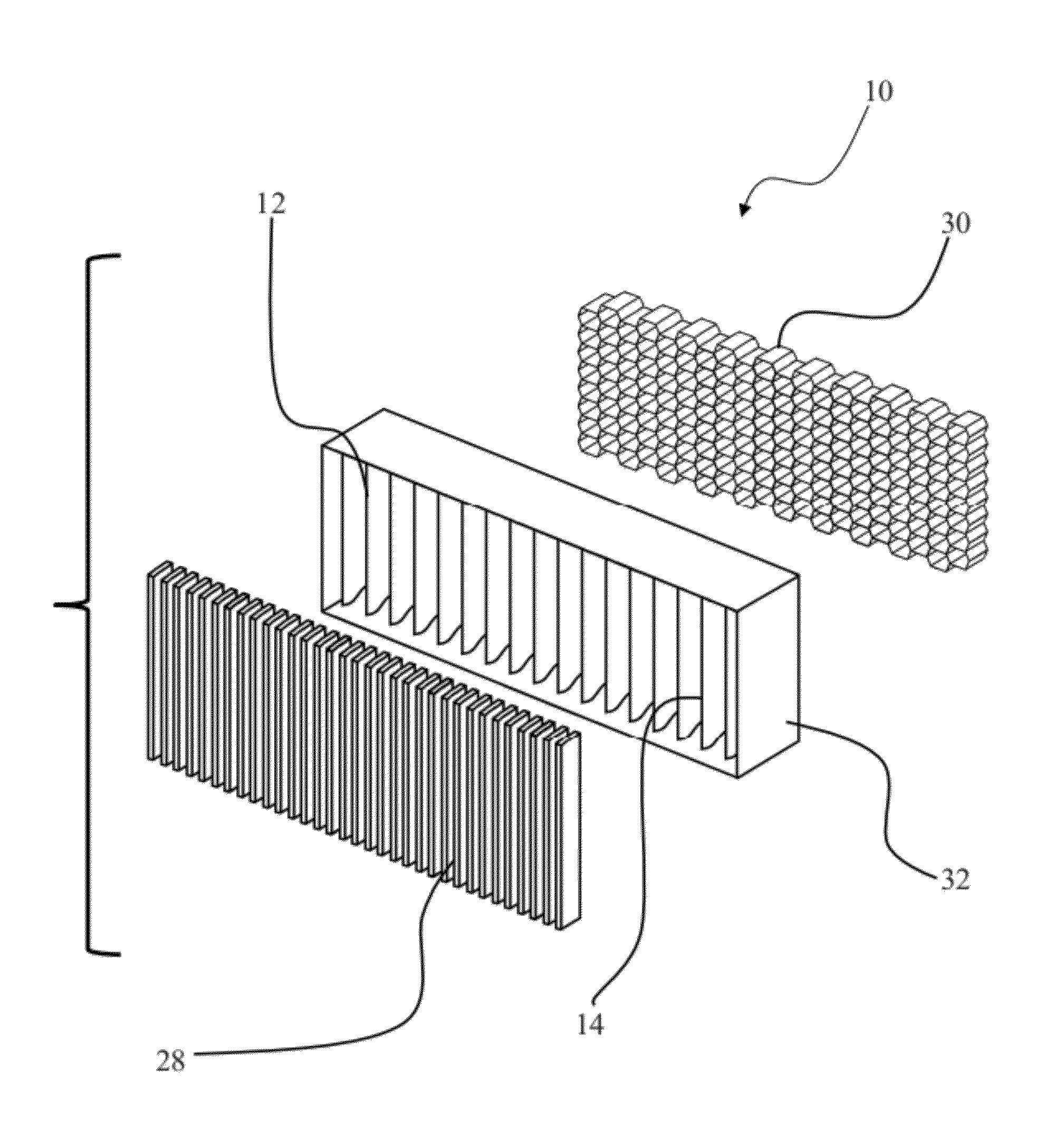

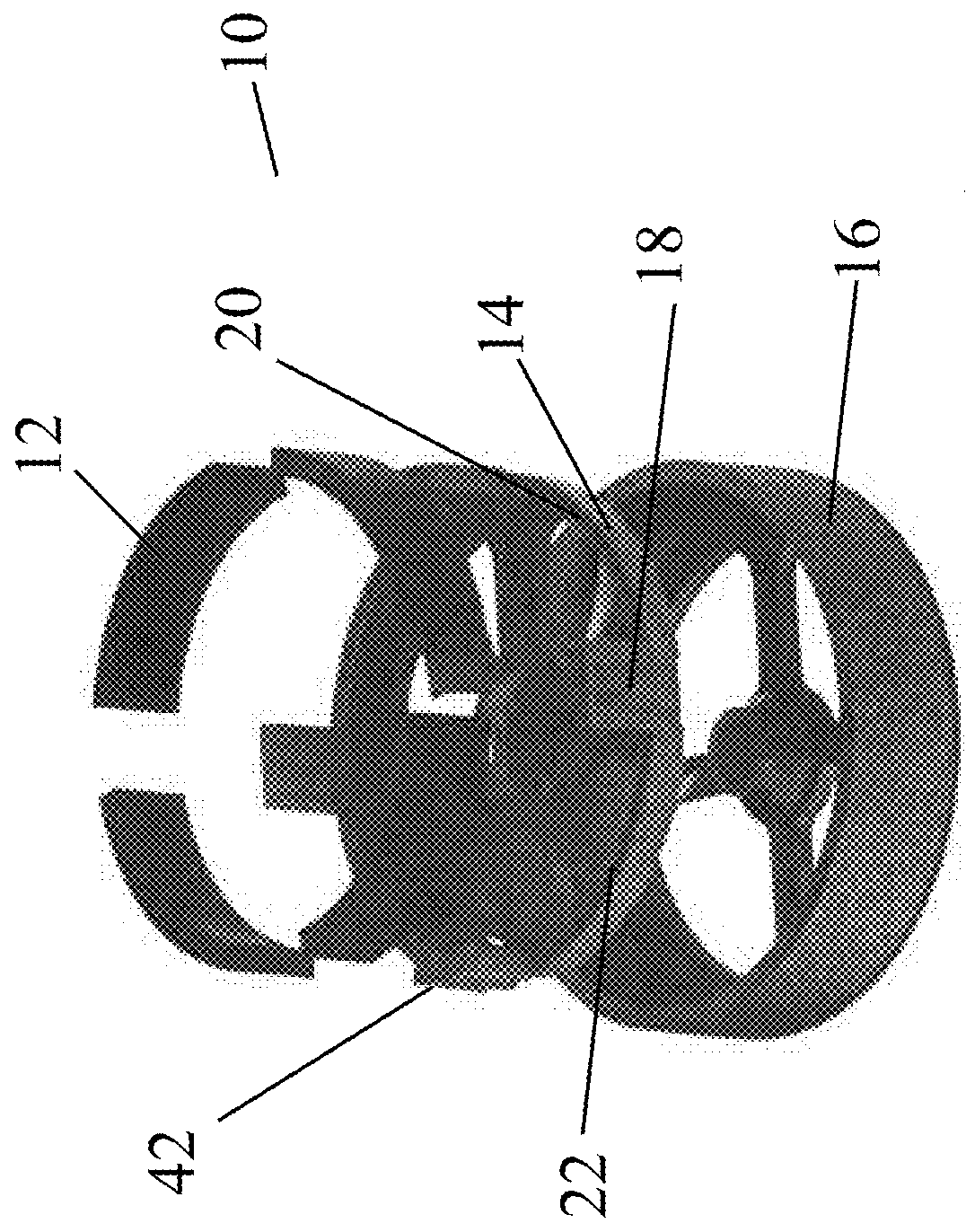

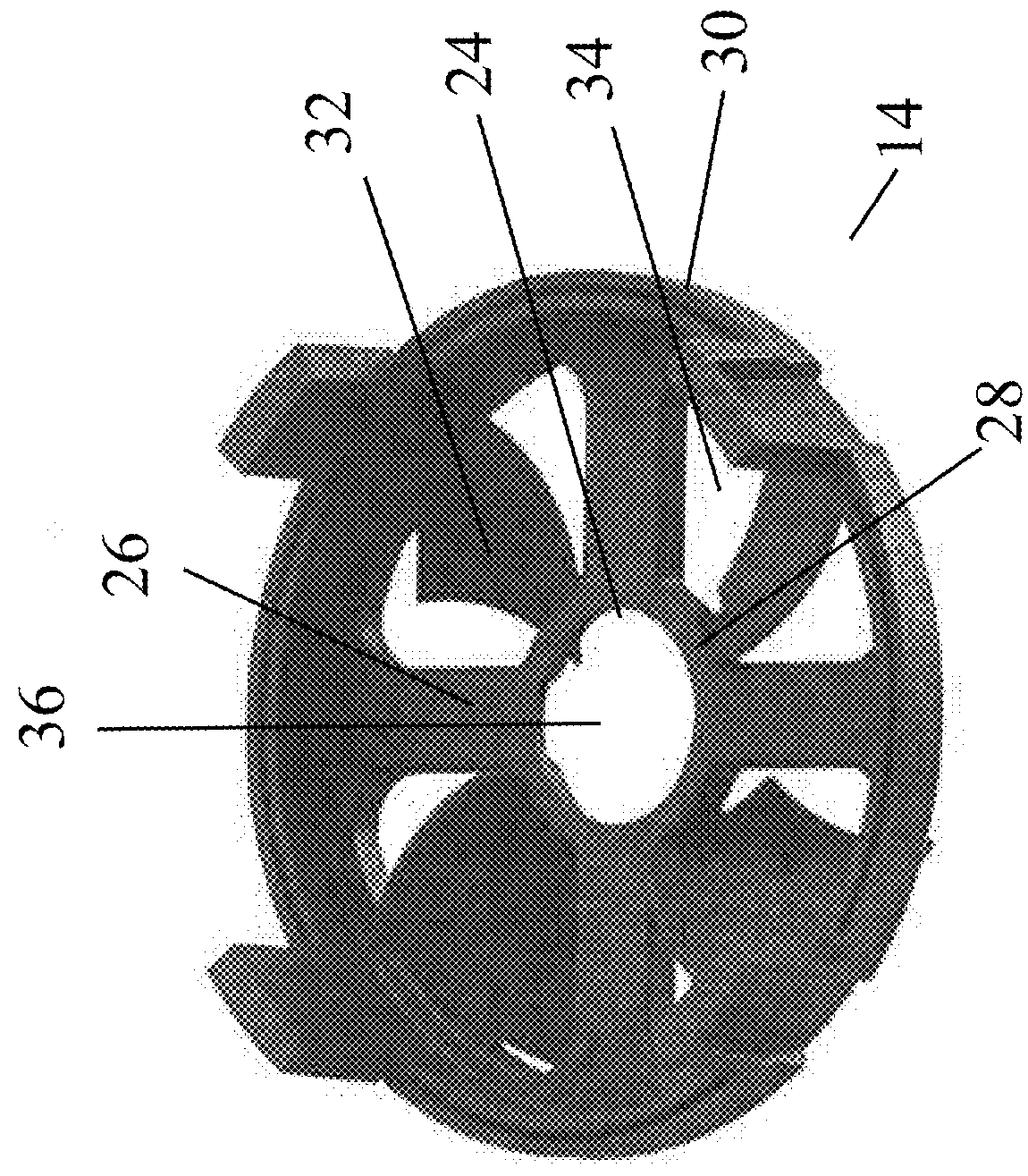

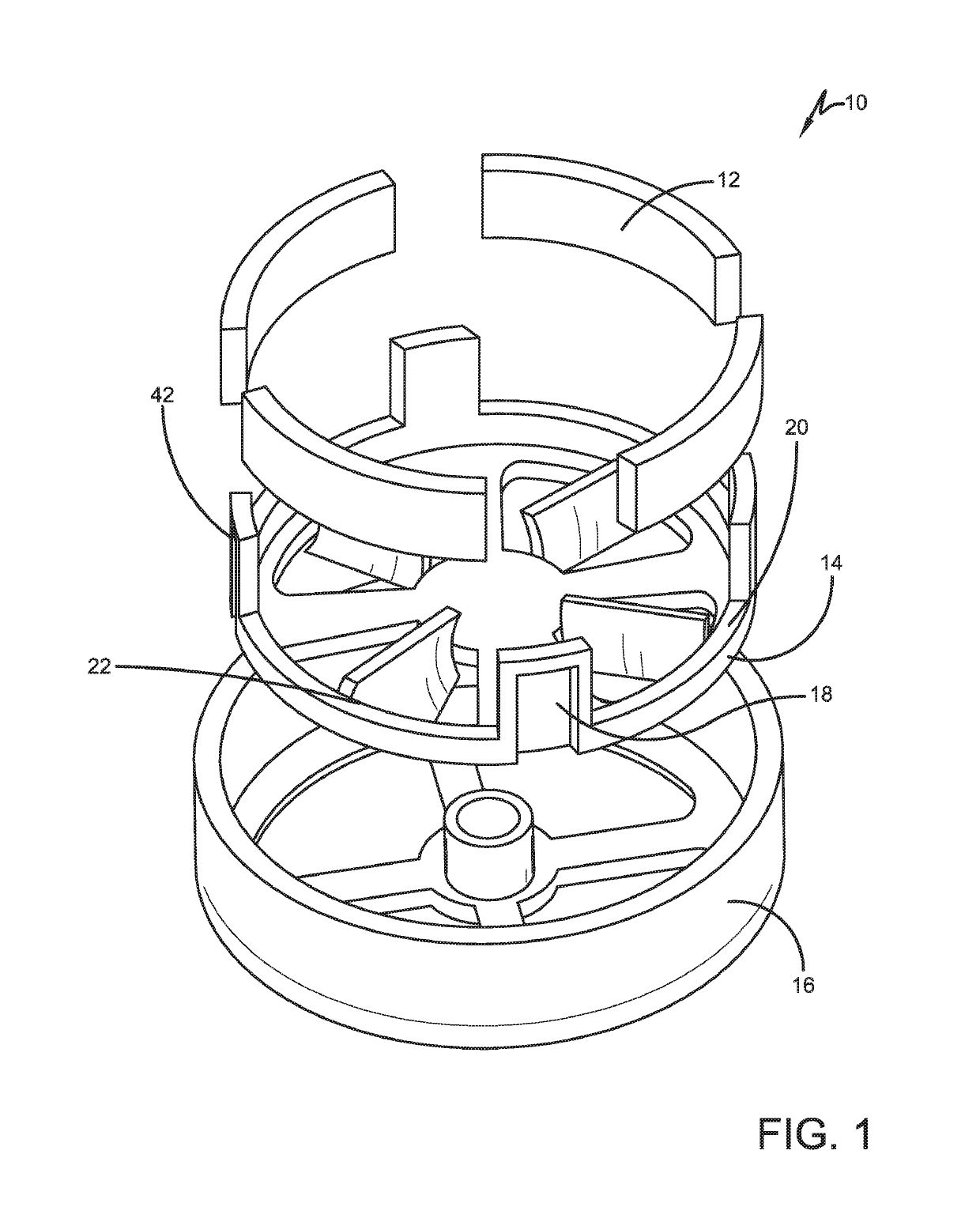

Brushless Direct Current Motor with Integrated Fan

ActiveUS20180109164A1Improve airflow efficiencyReduce resistanceMagnetic circuitManufacturing stator/rotor bodiesAdhesiveEngineering

Provided is a rotor assembly for a brushless direct current motor. The rotor assembly includes an insert which fits within an outer rotor cup. The insert locates the position of the magnets and secures them with extended features. Curved fan blades are integrated into the insert to provide improved airflow and cooling during rotation. The insert has features incorporated to reduce overall noise caused by air flow by having smooth transitions between mating surfaces and joints. A trench is incorporated within the insert to provide an overflow catch for excess adhesive when the magnet segments are “glued” into place.

Owner:SFEG CORP

Hood with integral air duct

ActiveUS20060213708A1Uniform air flow velocityUniform air flowLiquid coolingCoolant flow controlLawn mowerEngineering

A hood covers an internal combustion engine on the rear of a grass mowing machine. The hood has a top surface with a plurality of air intake openings recessed below the top surface, and an integral air duct. The integral air duct extends over the engine between the air intake openings and an air inlet side of the radiator and / or oil cooler adjacent the rear of the grass mowing machine. The air intake openings closest to the air inlet side of the radiator and / or oil cooler are dimensioned to limit the air intake velocity and prevent buildup of debris on screens or grilles over the openings.

Owner:DEERE & CO

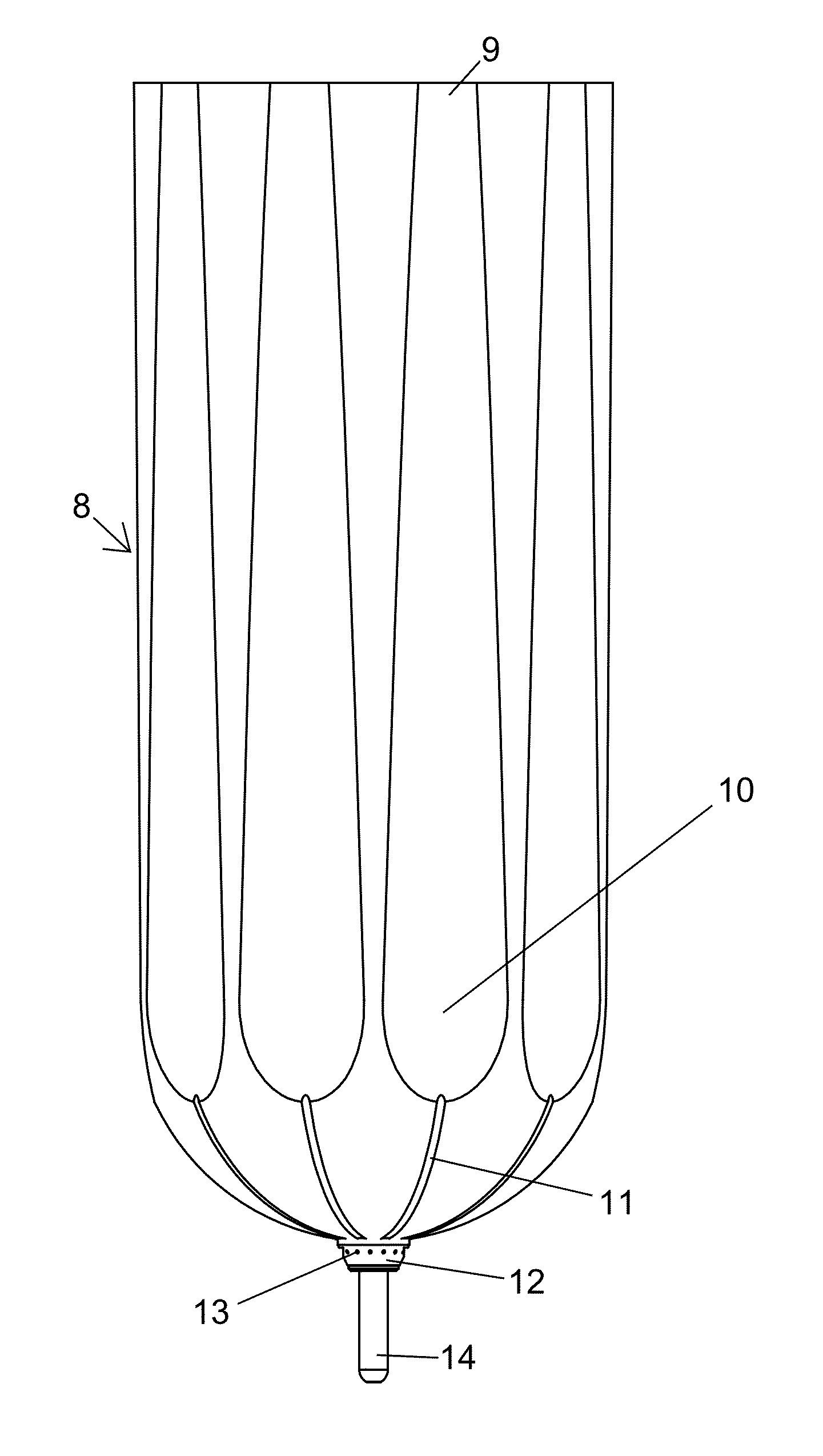

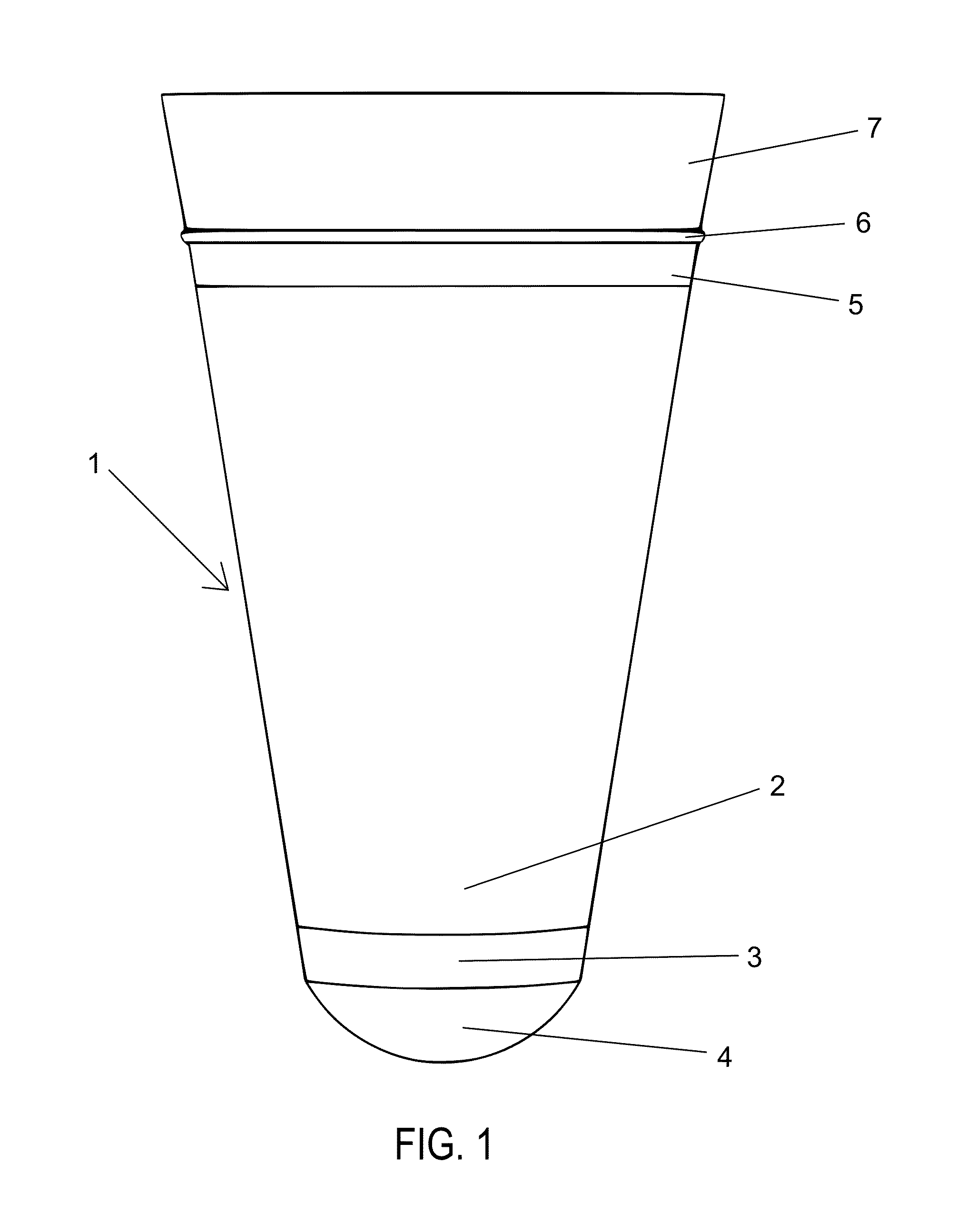

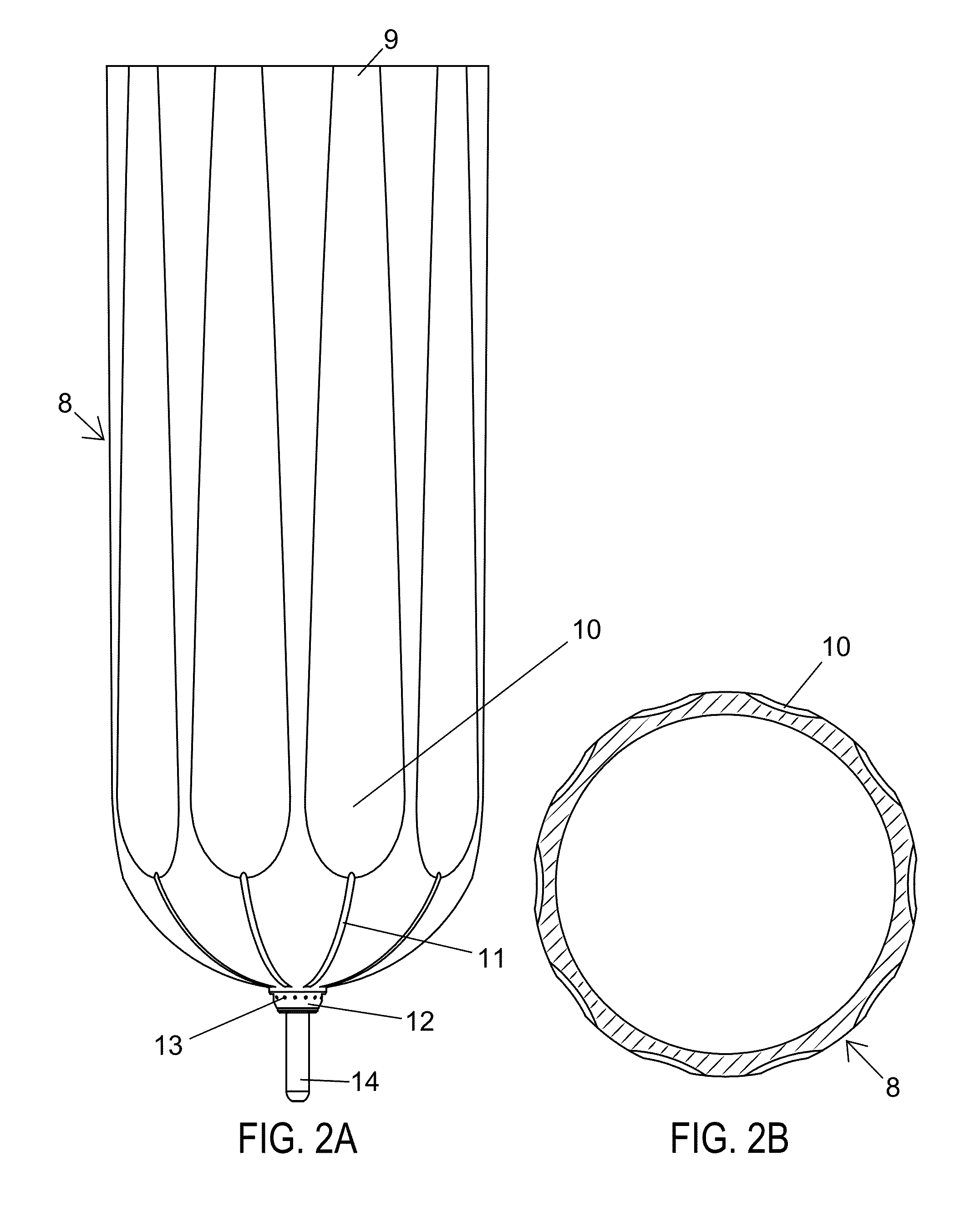

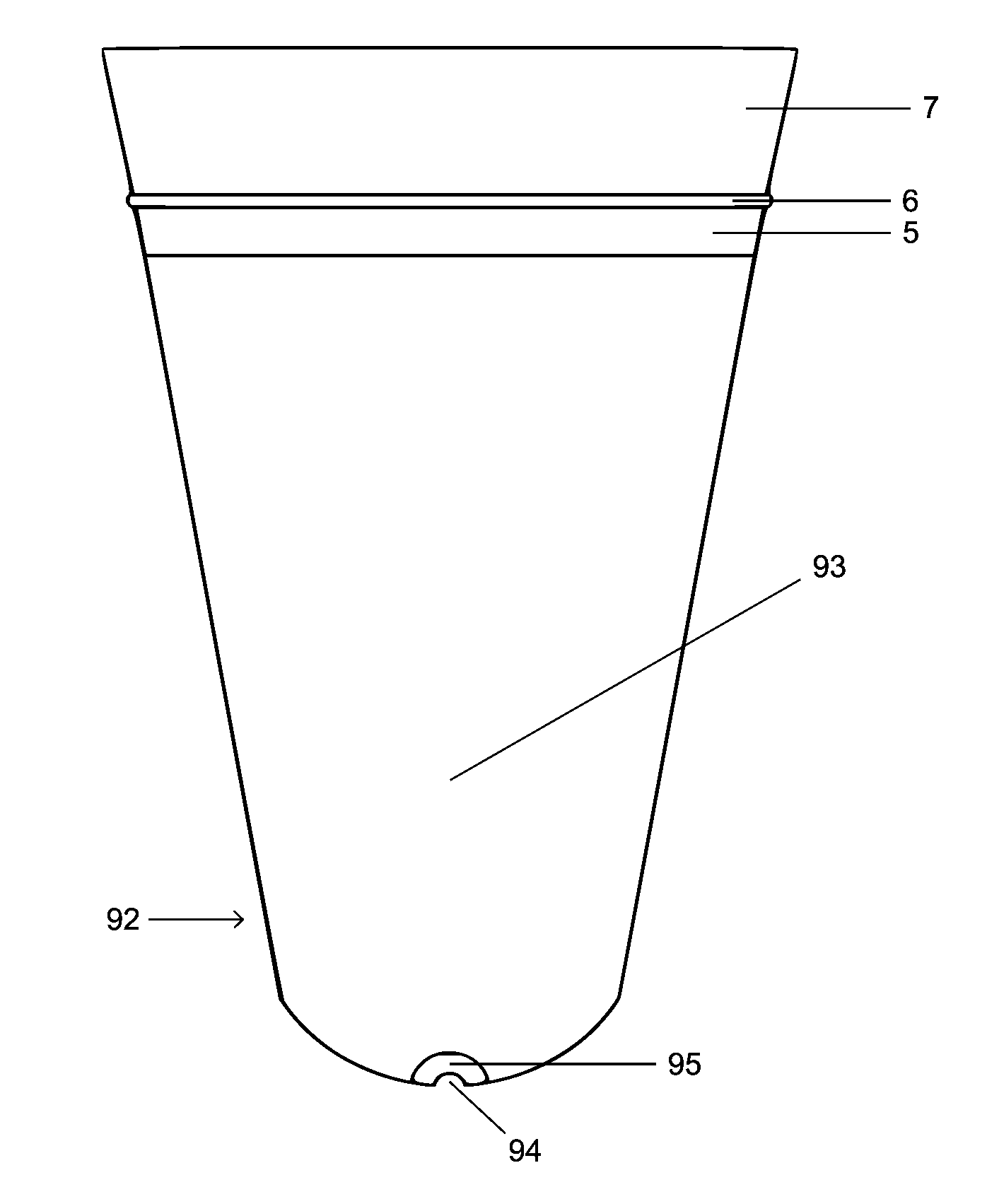

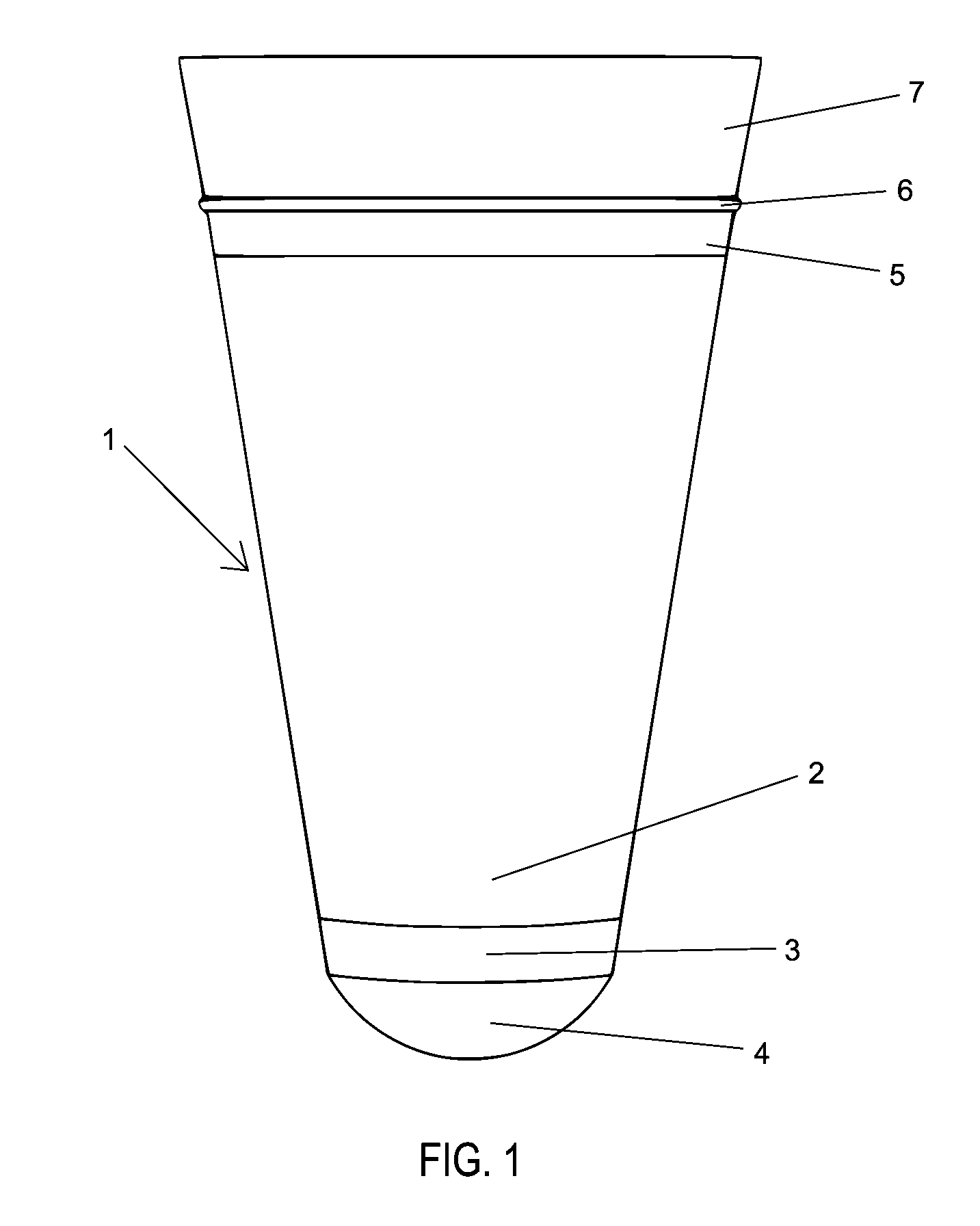

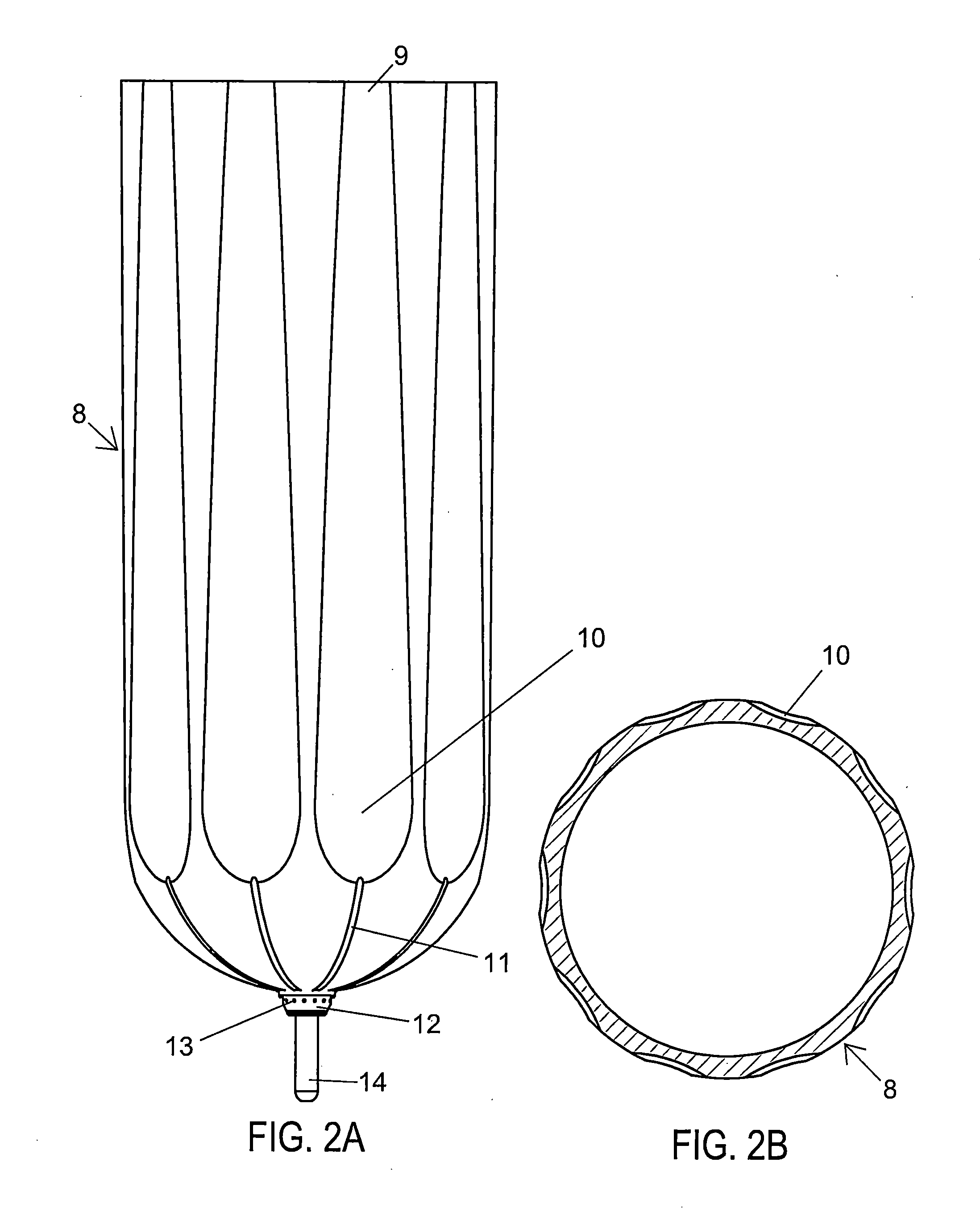

Negative gauge pressure dynamic convection system for artificial limb and associated methods

ActiveUS9398963B2Reduce the amount requiredExcess buildupArtificial legsThermal energyDifferential pressure

The negative gauge pressure dynamic convection system for artificial limb system is to be attached to a residual limb of an amputee. The device provides thermal energy transfer from within an artificial limb to the ambient atmosphere through regulated cyclical differential pressure airflow into the sealed environment between both the residuum and the inside of the suspension liner of an artificial limb and as an alternate embodiment between the rigid socket and the outside of the suspension liner or a combination of both. The system may include a multi-ply surface area multiplying textile layer; a limb-conformable convection suspension liner; an artificial limb socket with an over-molded enclosure for system components; a convection manifold assembly; a convection control system, which includes a continuously operating airflow generation device, and a rising edge triggered negative gauge pressure regulation device, such as an electromechanical binary airflow proportioning device, or an alternate mechanical binary airflow proportioning device.

Owner:KING CHARLES RUSSELL

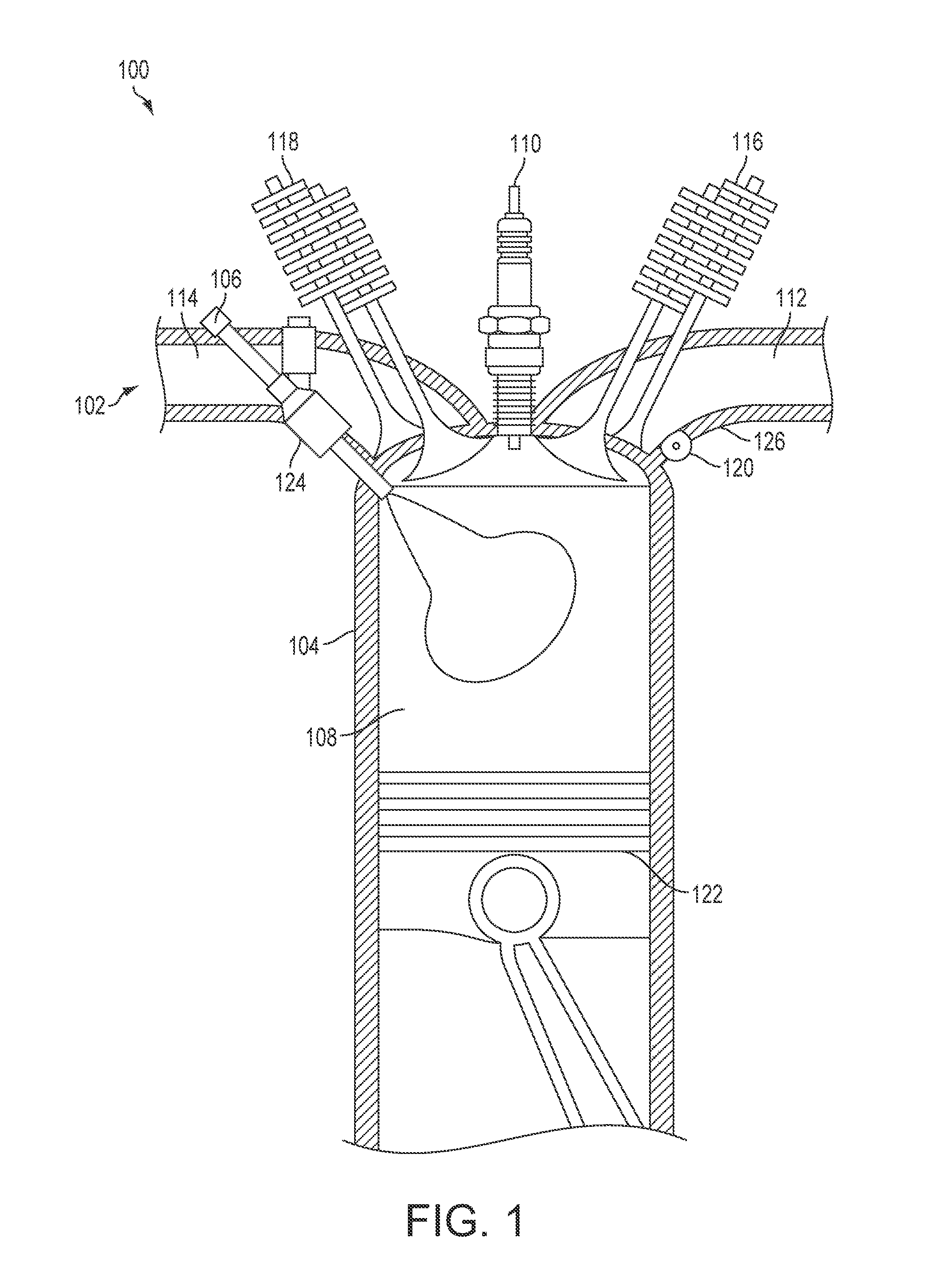

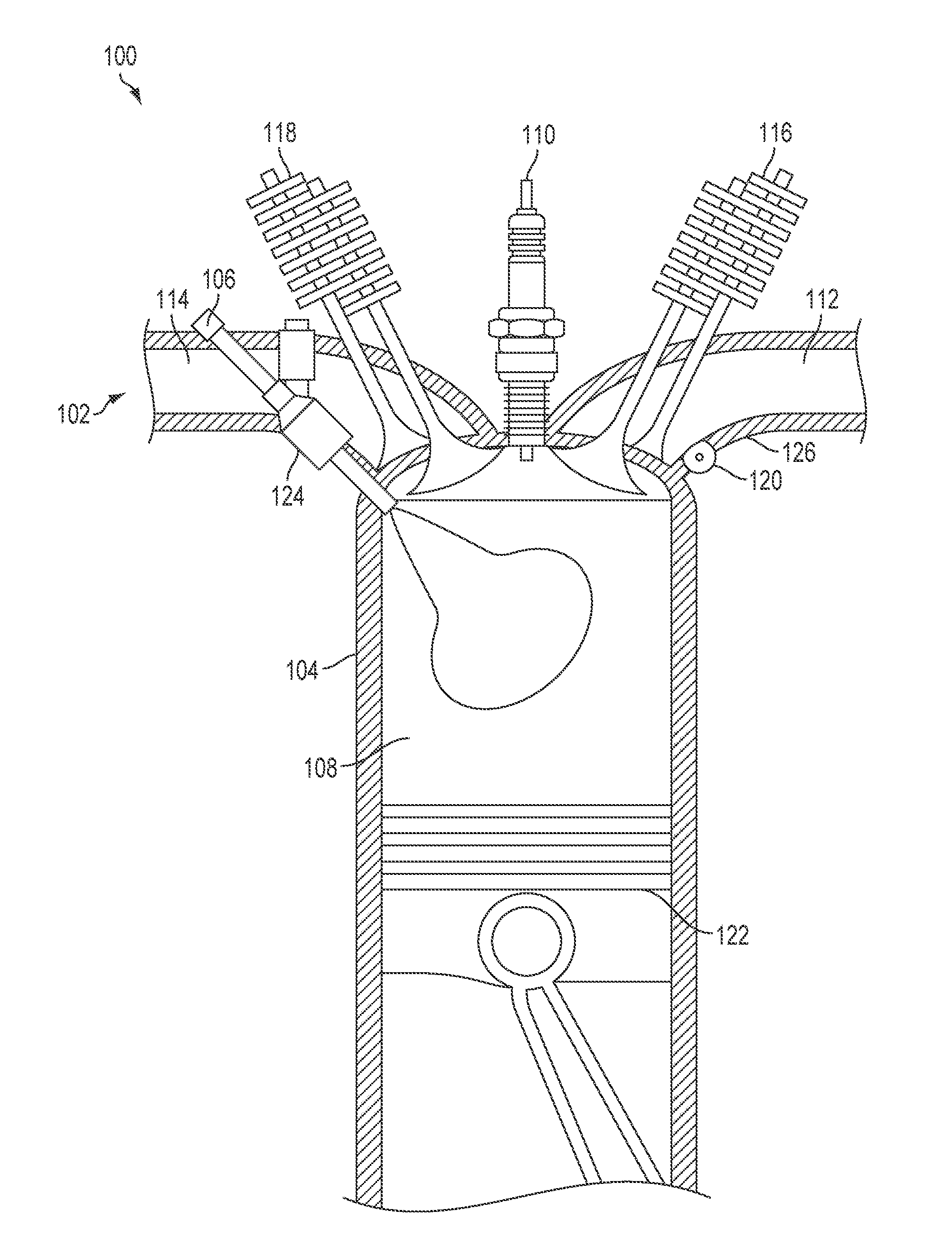

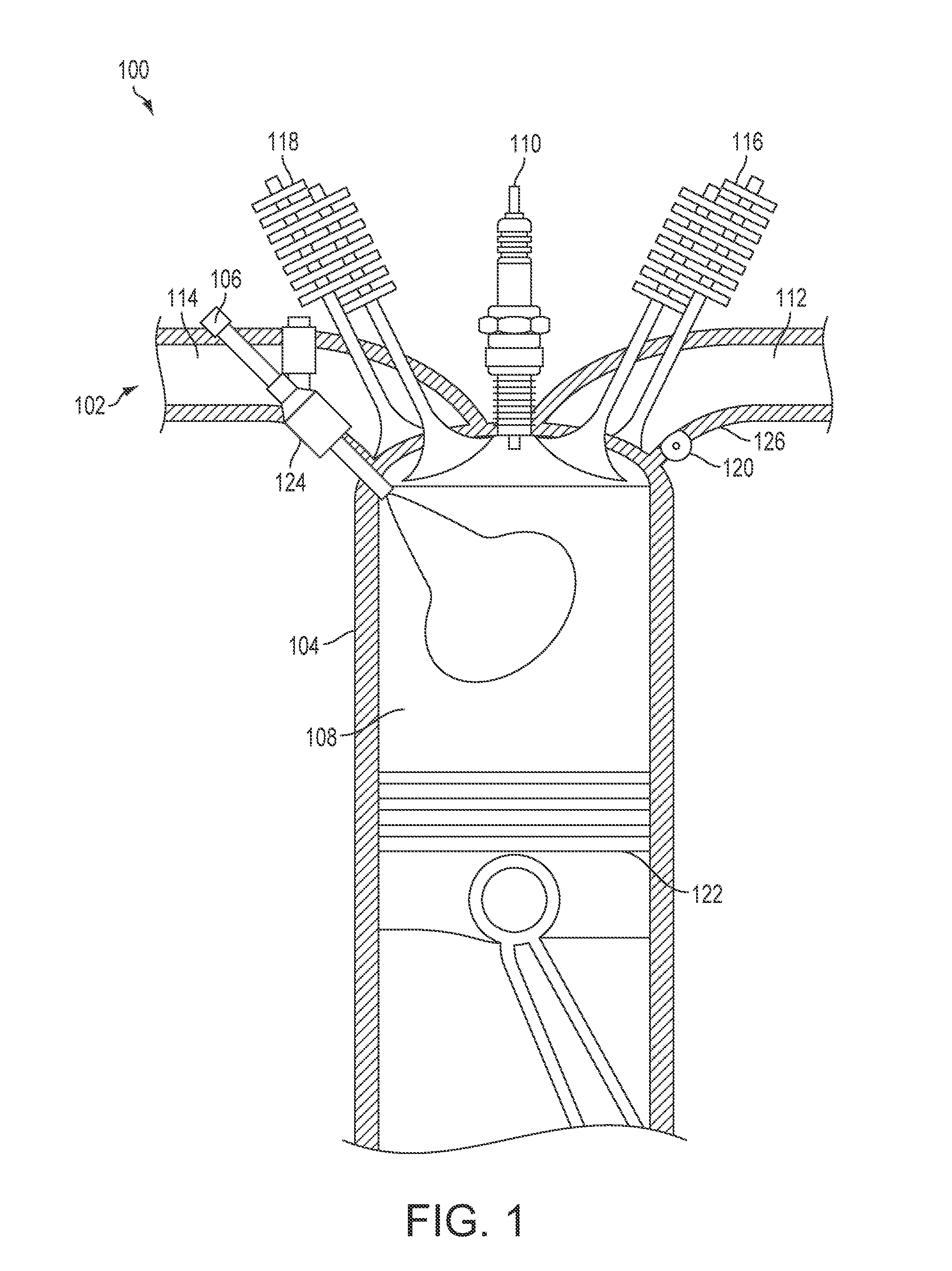

Rotatable valve in a cylinder intake duct

ActiveUS8430074B2Increase burn rateImprove combustion stabilityInternal combustion piston enginesCylinder headsEngineeringOperant conditioning

A spark ignition direct injection fuel cylinder for an engine includes a rotatable valve at a curved wall of an intake duct. The rotatable valve provides a variable step in to adjust the degree of tumble airflow while reducing flow restriction to improve engine performance across operating conditions.

Owner:FORD GLOBAL TECH LLC

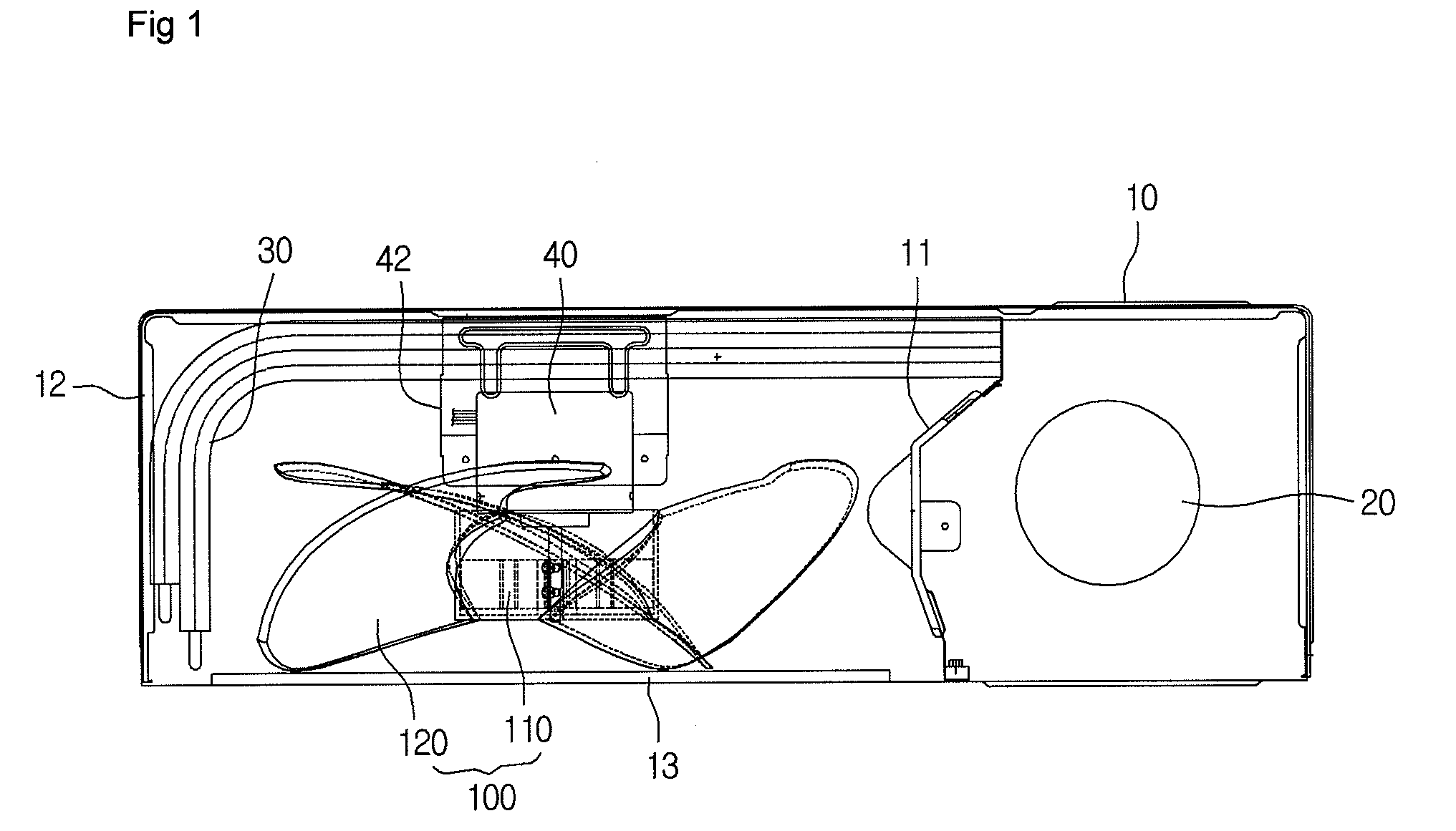

Air conditioner fan

InactiveUS20080159872A1Improve airflow efficiencyReduce noise levelPump componentsLighting and heating apparatusAerospace engineering

Owner:LG ELECTRONICS INC

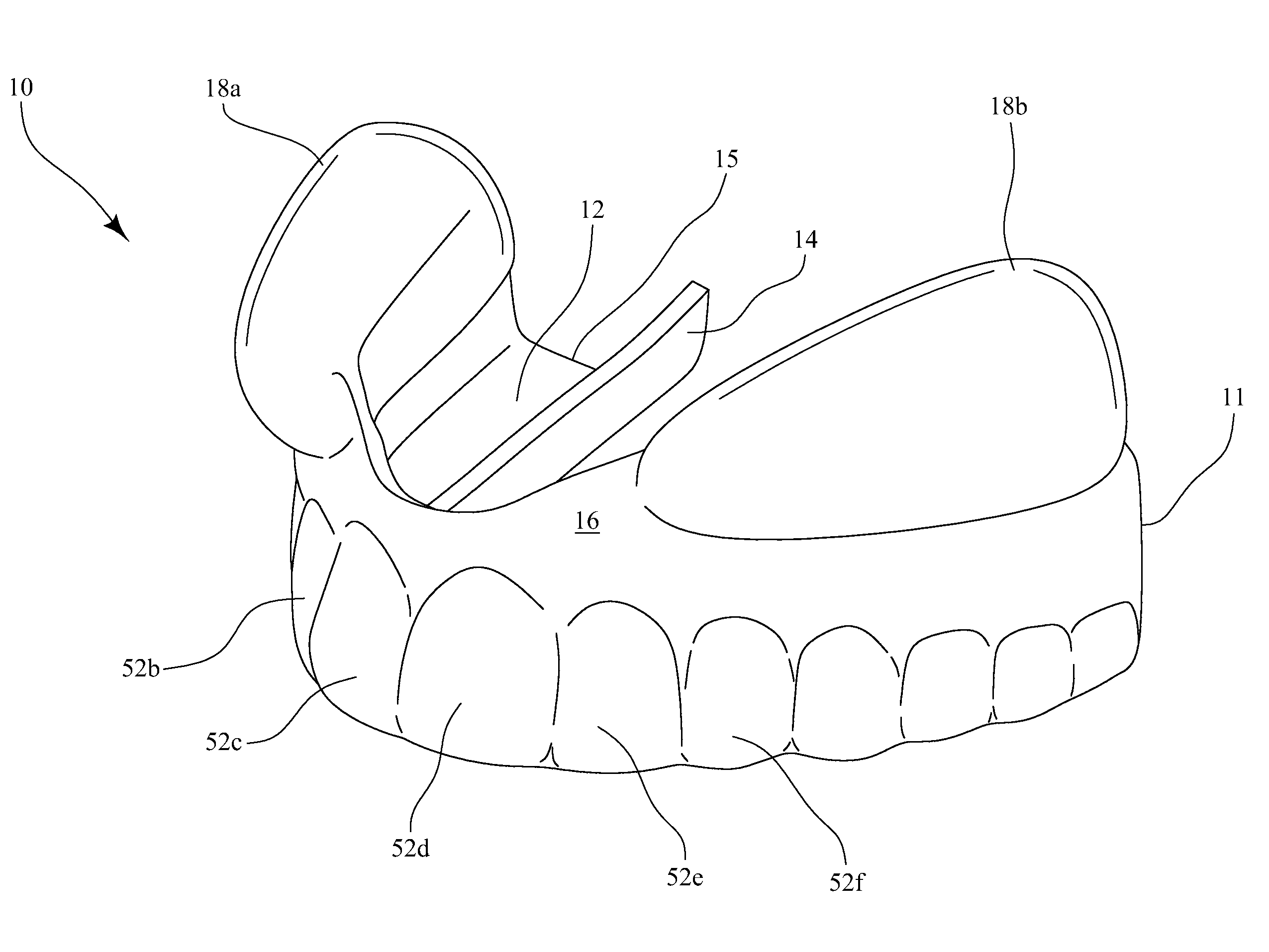

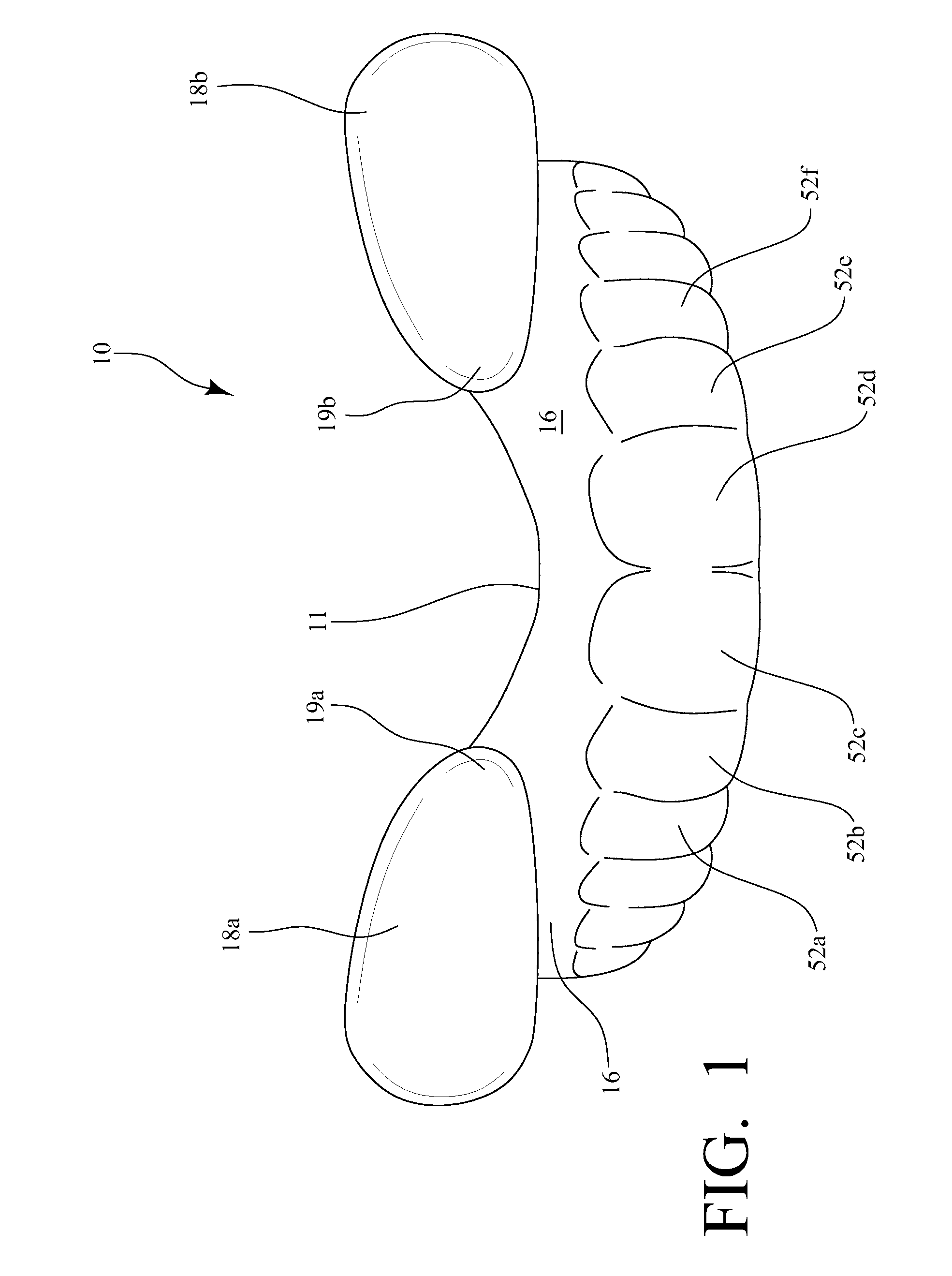

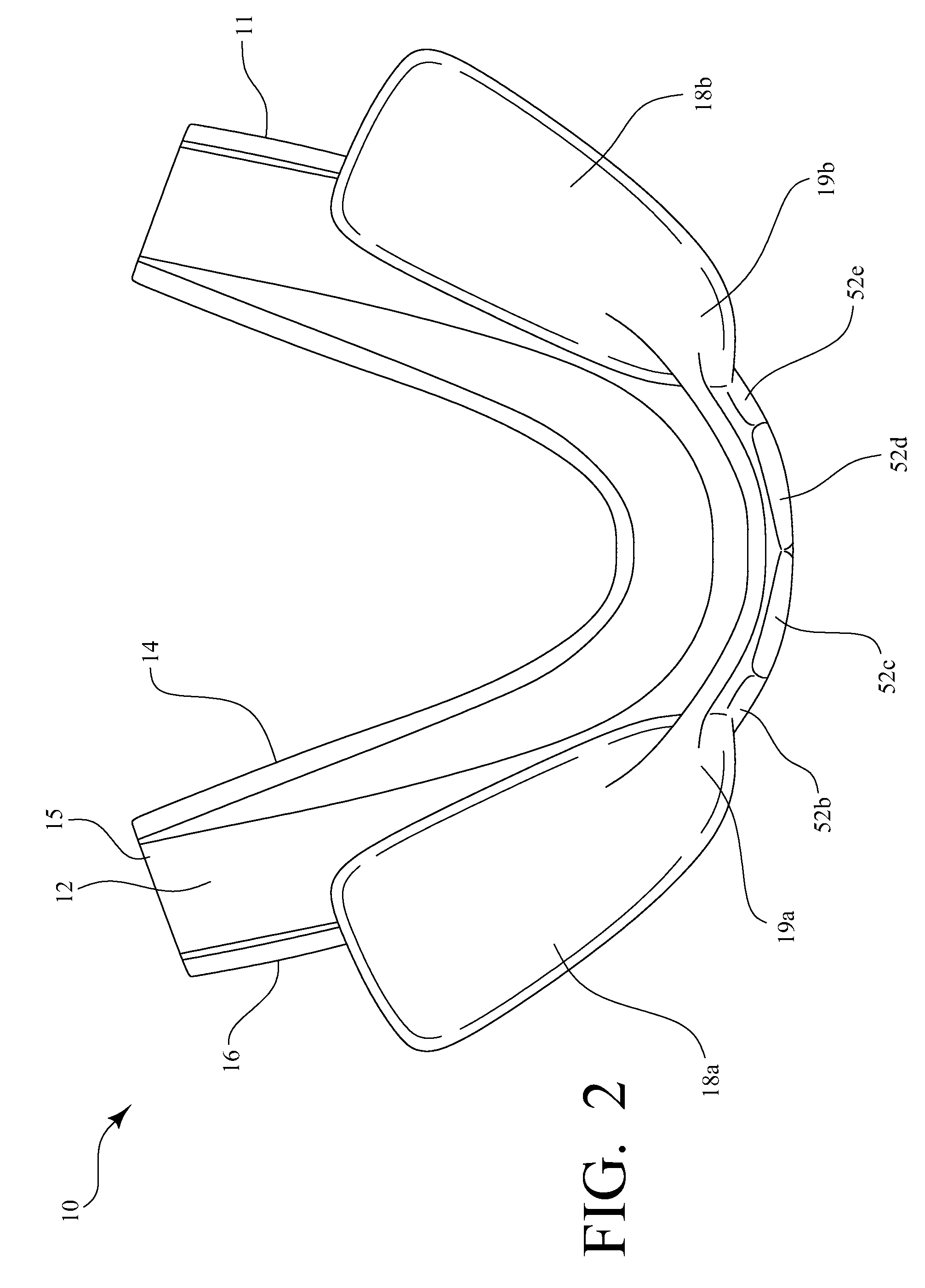

Mouthpiece for opening nasal passages

ActiveUS8151799B1Improve and increase respiratory functionReduce airflow resistanceTeeth fillingSnoring preventionNasal cavityNasal passage

A breathing device for intra-oral use particularly useful to increase the air flow through the nares, the nasal passages, pharynx, and larynx of a user includes a generally U-shaped member curved in an arch to conform to a user's upper dentition, edentulous maxillary ridges, or any prosthetic device. The U-shaped member is provided with at least one wall having a depth slightly greater than the vertical dimension of a user's upper dentition and a receptacle to receive the upper dentition, edentulous ridge, or prosthetic device. A pair of nasal passage expansion members is disposed along opposed sides of the U-shaped member and are positioned to extend into the muco-buccal and muco-labial vestibule of a user distally from the lateral extent of the nares to the zygoma whereby upon insertion of the breathing device into the mouth of a user, the walls of the muco-buccal and muco-labial vestibule engage the muscles of facial expression thereby enlarging the nares and nasal passages of a user resulting in an increase of air flow and air velocity into the nasal passages, pharynx, larynx and respiratory system.

Owner:HAZARD JAMES T +1

Negative gauge pressure dynamic convection system for artificial limb and associated methods

ActiveUS20150265432A1Reduce the amount requiredExcess buildupArtificial legsThermal energyControl system

The negative gauge pressure dynamic convection system for artificial limb system is to be attached to a residual limb of an amputee. The device provides thermal energy transfer from within an artificial limb to the ambient atmosphere through regulated cyclical differential pressure airflow into the sealed environment between both the residuum and the inside of the suspension liner of an artificial limb and as an alternate embodiment between the rigid socket and the outside of the suspension liner or a combination of both. The system may include a multi-ply surface area multiplying textile layer; a limb-conformable convection suspension liner; an artificial limb socket with an over-molded enclosure for system components; a convection manifold assembly; a convection control system, which includes a continuously operating airflow generation device, and a rising edge triggered negative gauge pressure regulation device, such as an electromechanical binary airflow proportioning device, or an alternate mechanical binary airflow proportioning device.

Owner:KING CHARLES RUSSELL

Rotatable valve in a cylinder intake duct

ActiveUS20120145121A1Increase combustion burn rateImprove combustion stabilityInternal combustion piston enginesCylinder headsEngineeringOperant conditioning

A spark ignition direct injection fuel cylinder for an engine includes a rotatable valve at a curved wall of an intake duct. The rotatable valve provides a variable step in to adjust the degree of tumble airflow while reducing flow restriction to improve engine performance across operating conditions.

Owner:FORD GLOBAL TECH LLC

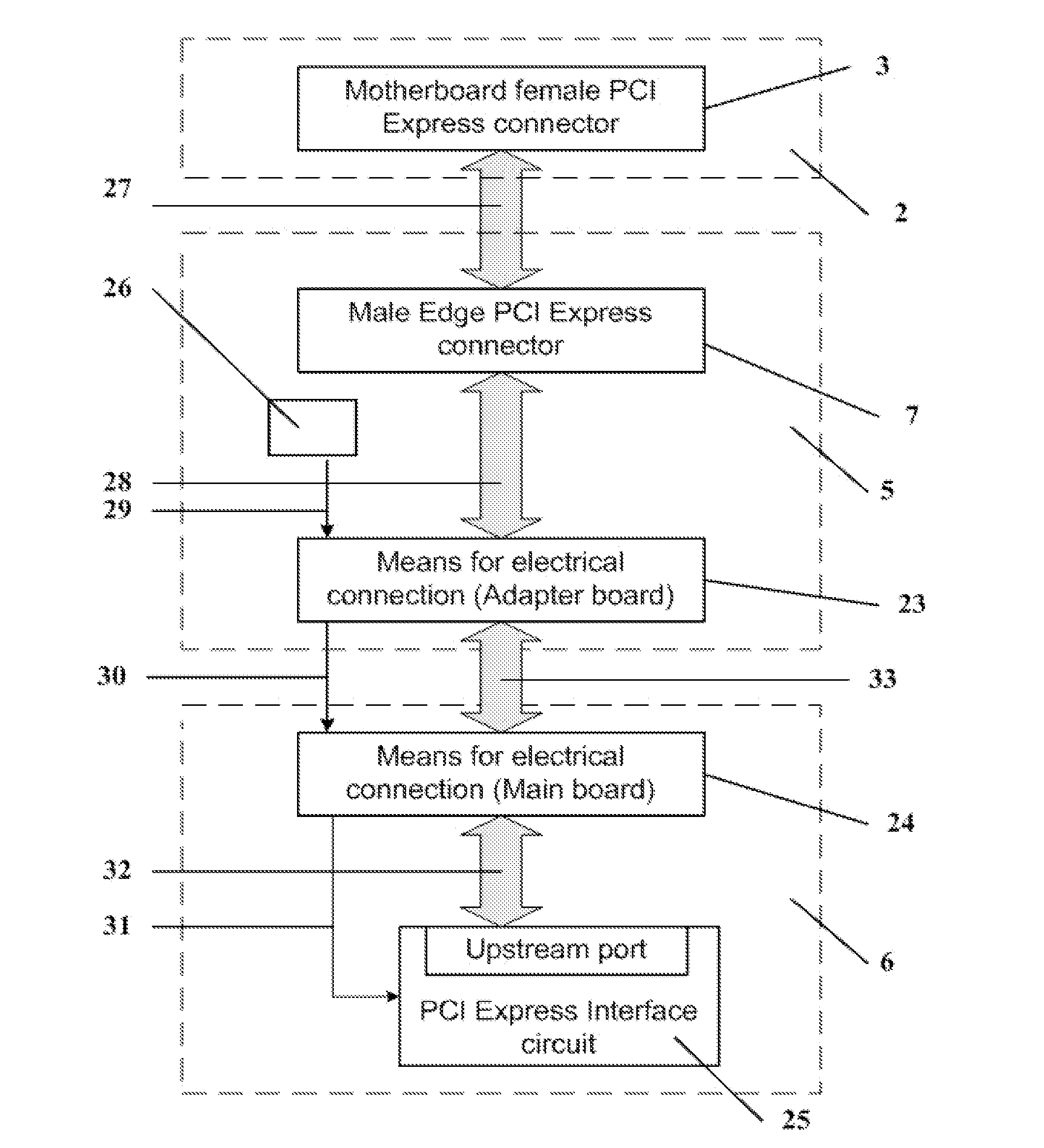

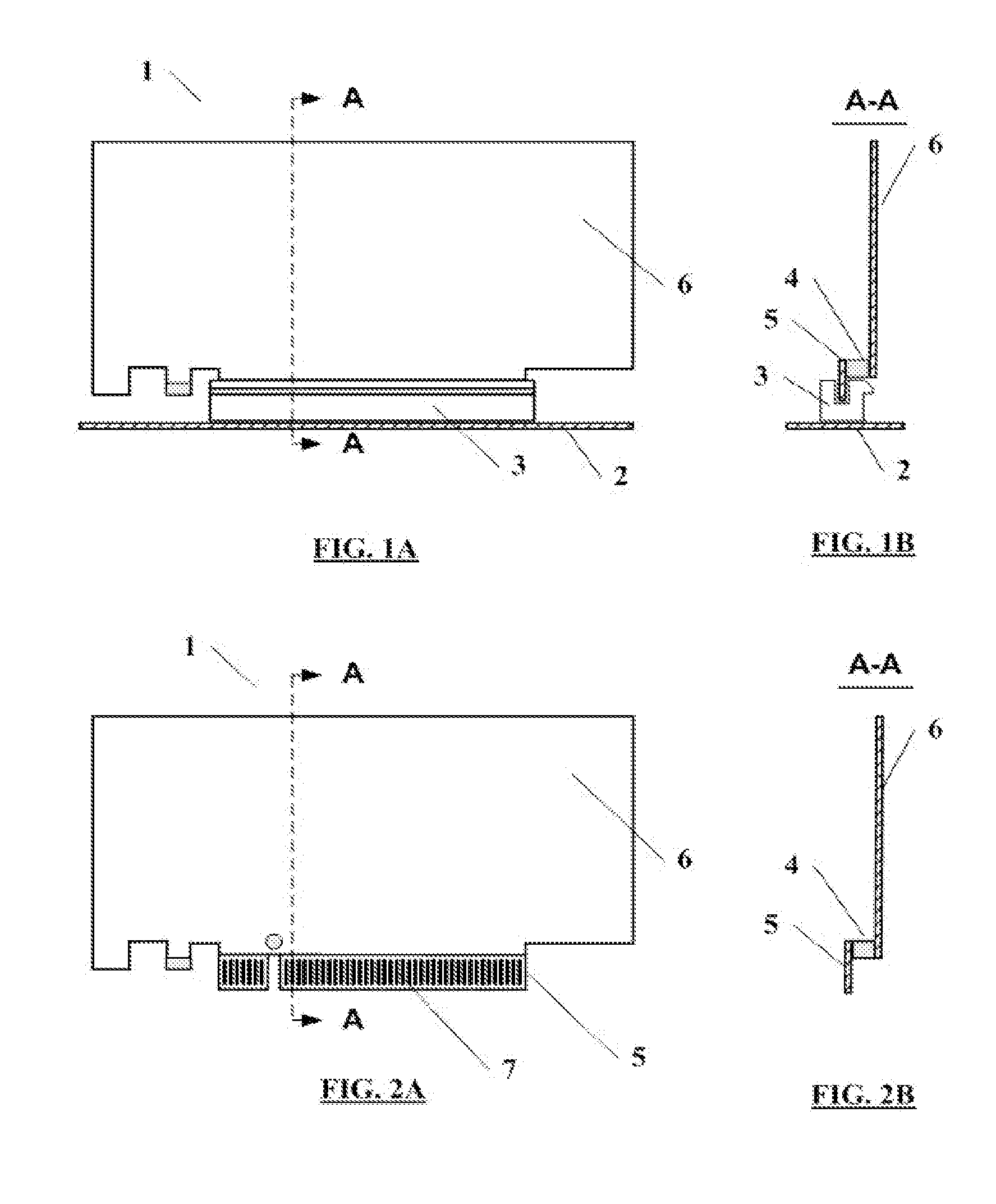

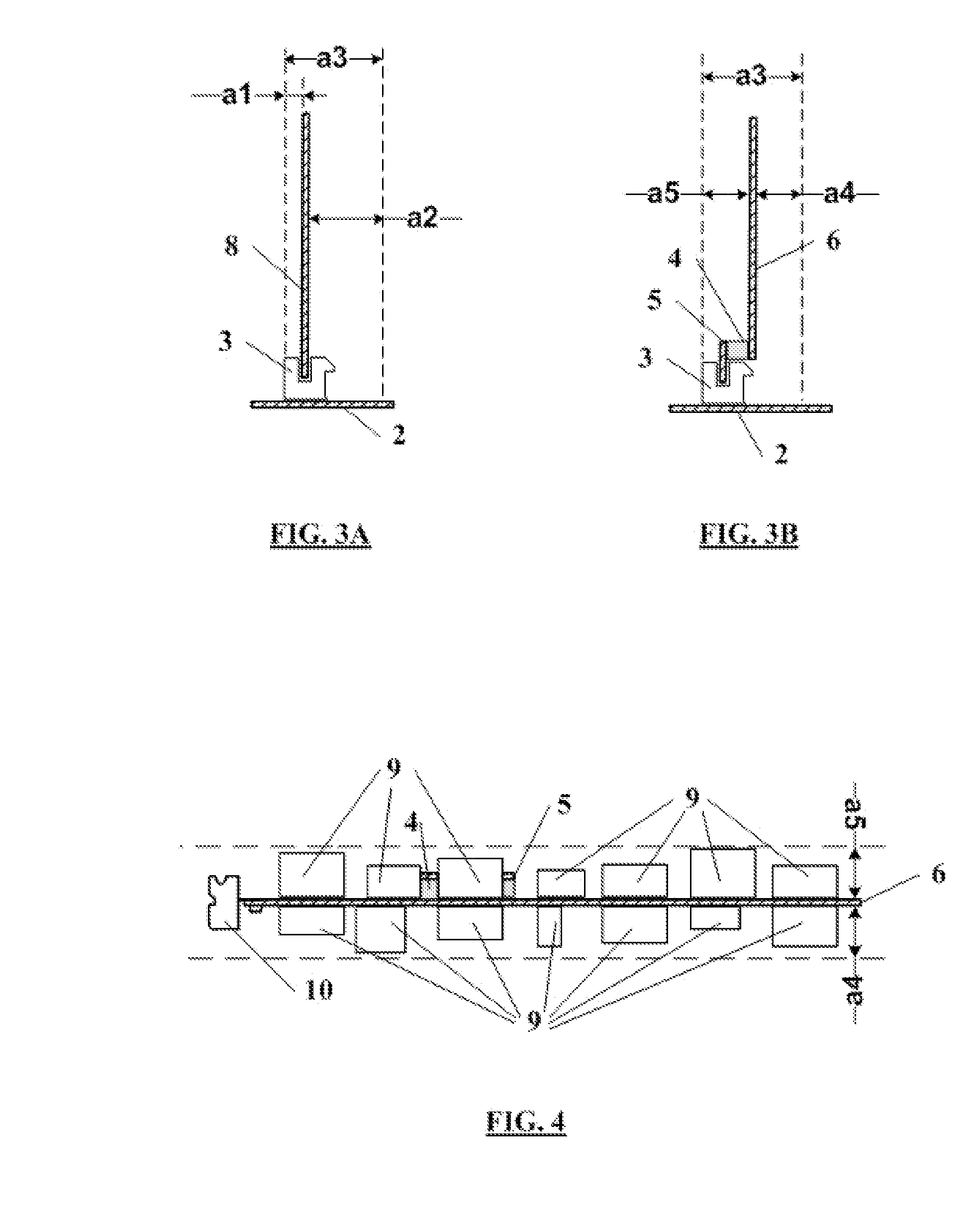

Advanced PCI Express Board Assembly

ActiveUS20160299863A1Increase the number ofImprove airflow efficiencyElectric digital data processingEngineeringPCI Express

An advanced PCI Express board assembly is intended for efficiently placing more electronic components or modules having a large height (up to 8.57 mm) in comparison with traditional PCI Express add-in boards. This assembly comprises two PCBs connected together. The first one has the minimum possible sizes. This PCB includes a PCI Express male edge connector and is intended to be plugged in to motherboard female PCI Express connector. The second PCB is parallel to first one and is located in the middle of the space (slot) defined for one add-in PCI Express board. This position makes possible to place high electronic components or modules on the both sides (top and bottom) of the second PCB.

Owner:FELDMAN MICHAEL +1

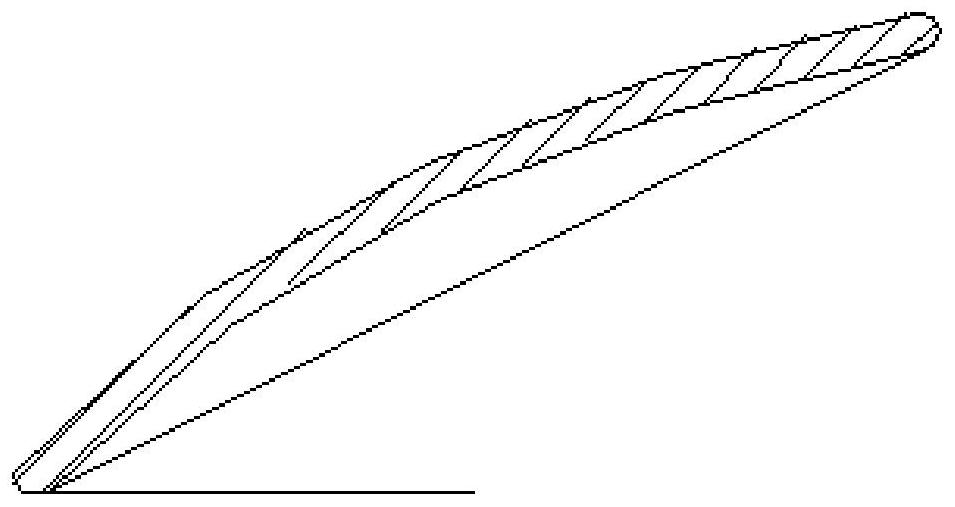

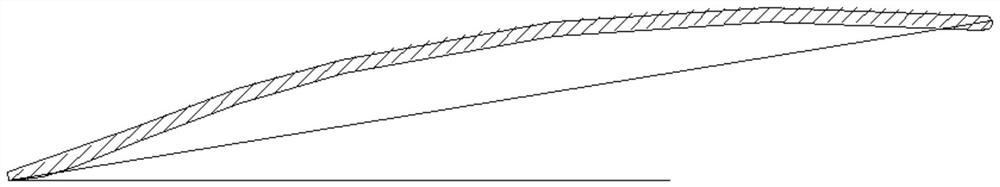

Blade, axial flow fan blade and fan

PendingCN111980964AGuaranteed air volumeIncrease the outlet wind speedPump componentsPumpsAir velocitySuction force

The invention relates to the technical field of fans, and particularly relates to a blade, an axial flow fan blade and a fan. The blade comprises a pressure surface, a suction surface, a blade root part, a blade top part, a front edge part and a rear edge part, wherein a cylindrical surface where the blade root part is located is defined as a blade root element surface, a cylindrical surface wherethe blade top part is located is defined as a blade top element surface, a cylindrical surface located between the blade root element surface and the blade top element surface is a 1 / 2 element surface, and a cylindrical surface located between the blade top element surface and the 1 / 2 element surface is a 3 / 4 element surface; and the maximum distance between the front edge part and the rear edgepart at the blade root element surface is l1, the maximum distance between the front edge part and the rear edge part at the 1 / 2 element surface is l2, the maximum distance between the front edge partand the rear edge part at the 3 / 4 element surface is l3, the maximum distance between the front edge part and the rear edge part at the blade top element surface is l4, and the values of 11, 12, 13 and 14 gradually increases. The outlet air speed can be effectively increased, the pneumatic performance of the blade is matched with a motor, and the air volume of the fan made of the blade is guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

Advanced PCI express board assembly

ActiveUS9996495B2Increase the number ofImprove airflow efficiencyElectric digital data processingSoftware engineeringPCI Express

An advanced PCI Express board assembly is intended for efficiently placing more electronic components or modules having a large height (up to 8.57 mm) in comparison with traditional PCI Express add-in boards. This assembly comprises two PCBs connected together. The first one has the minimum possible sizes. This PCB includes a PCI Express male edge connector and is intended to be plugged in to motherboard female PCI Express connector. The second PCB is parallel to first one and is located in the middle of the space (slot) defined for one add-in PCI Express board. This position makes possible to place high electronic components or modules on the both sides (top and bottom) of the second PCB.

Owner:FELDMAN MICHAEL +1

Brushless direct current motor with integrated fan

ActiveUS10291103B2Improve airflow efficiencyReduce resistanceMagnetic circuitManufacturing stator/rotor bodiesAdhesiveFan blade

Provided is a rotor assembly for a brushless direct current motor. The rotor assembly includes an insert which fits within an outer rotor cup. The insert locates the position of the magnets and secures them with extended features. Curved fan blades are integrated into the insert to provide improved airflow and cooling during rotation. The insert has features incorporated to reduce overall noise caused by air flow by having smooth transitions between mating surfaces and joints. A trench is incorporated within the insert to provide an overflow catch for excess adhesive when the magnet segments are “glued” into place.

Owner:SFEG CORP

Mid-section of a can-annular gas turbine engine to introduce a radial velocity component into an air flow discharged from a compressor of the mid-section

InactiveUS10012098B2Improvements in the operating efficiency, cost efficiency and/or cooling efficiencyReduce manufacturing costPump componentsGas turbine plantsCombustorTurbine

A midframe portion (113) of a gas turbine engine (110) is provided, including a compressor section (112) with a last stage blade (124). The compressor section (112) is configured to introduce a radial velocity component into an air flow (111) such that the air flow is discharged from the compressor section (112) at a mixed direction based on a combined longitudinal velocity component and radial velocity component. The midframe portion (113) further includes a manifold (121) to directly couple the air flow from an outlet of the compressor section (112) to an inlet of a respective combustor head (118) of the gas turbine engine (110).

Owner:SIEMENS ENERGY INC

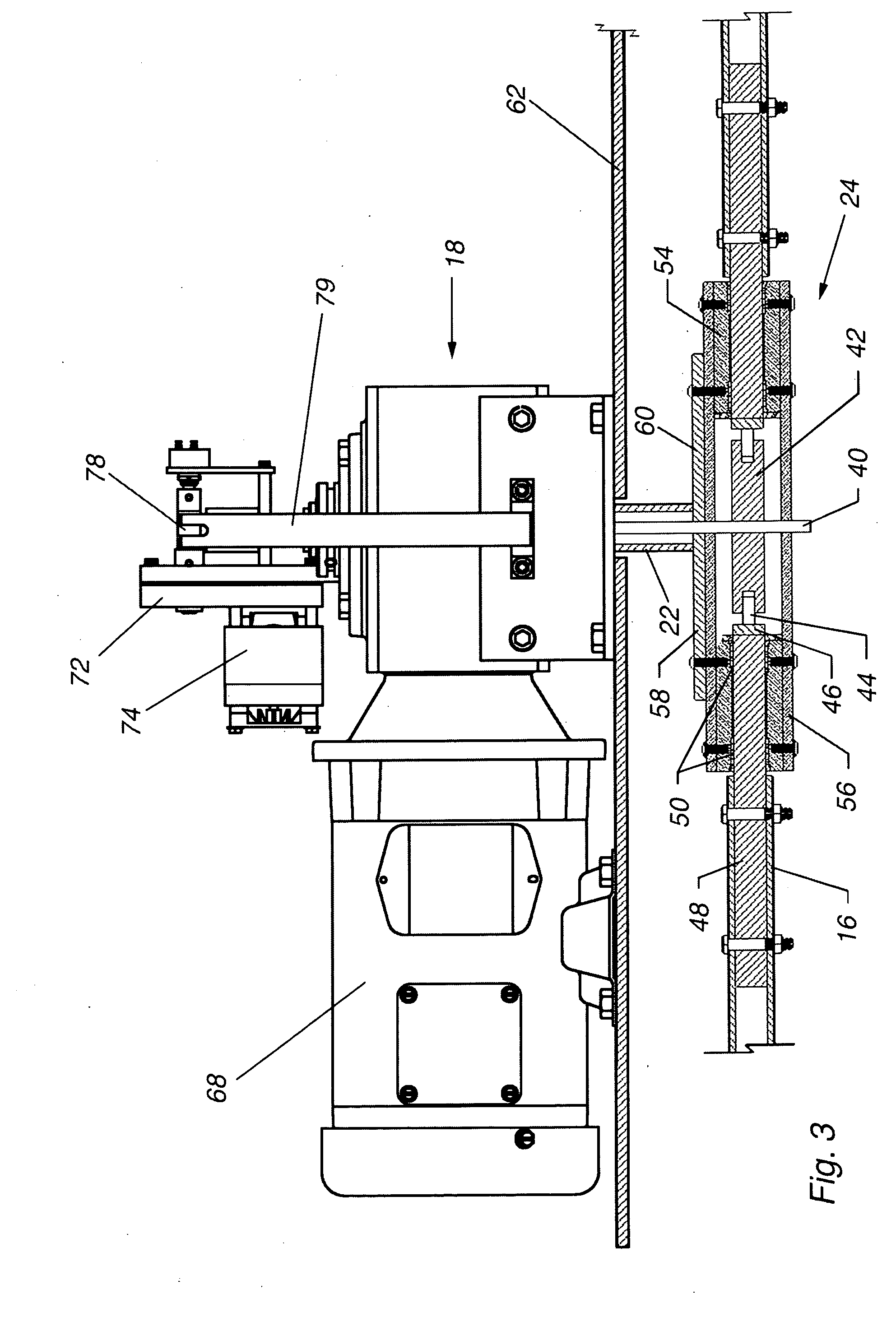

Air flow path for an air impingement finger duct

InactiveUS7882855B2Improve airflow efficiencyIncrease pressureFluid heatersDomestic stoves or rangesWaste management

Owner:LINCOLN FOODSERVICE PRODS

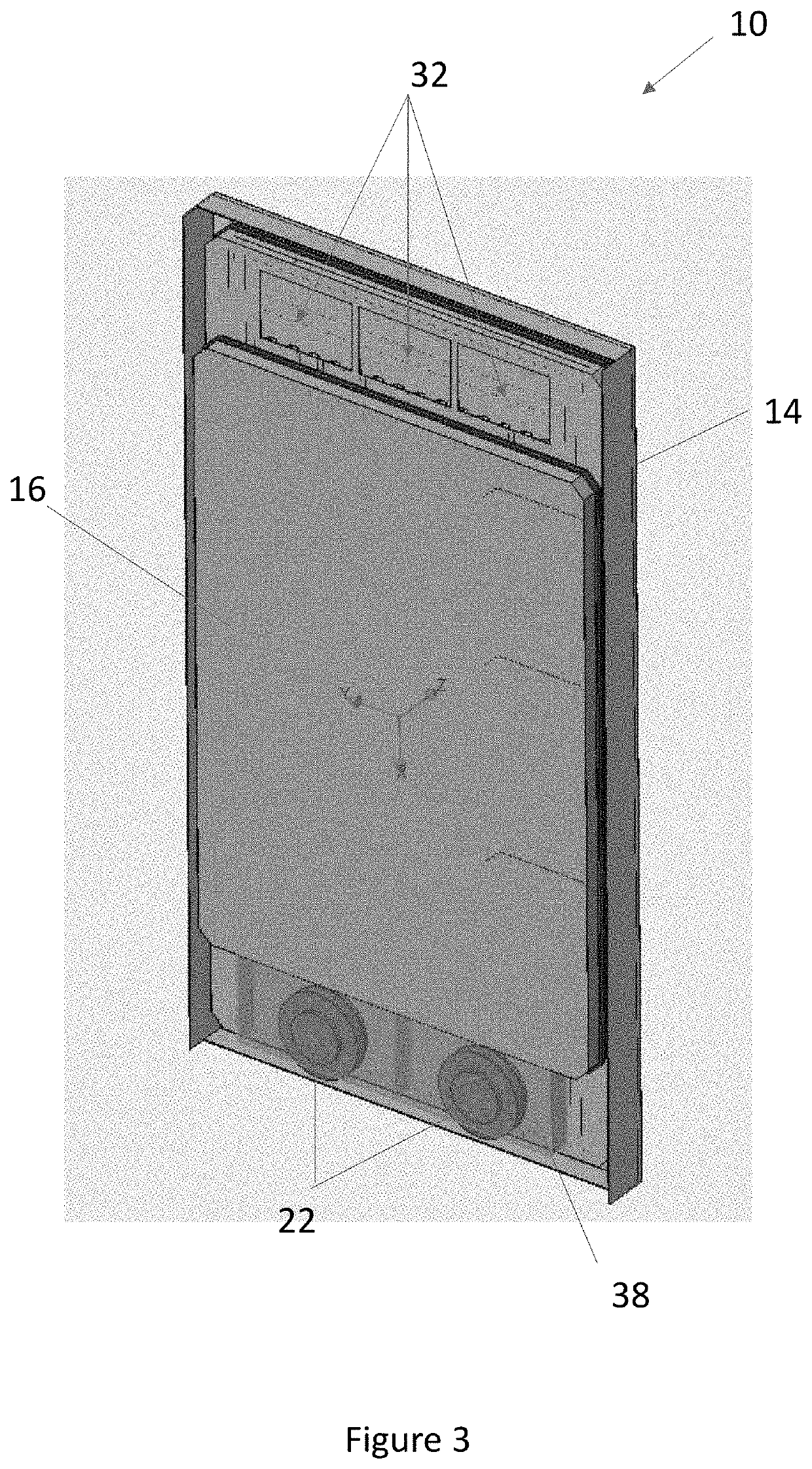

Display assemblies incorporating electric vehicle charging equipment

ActiveUS20220132681A1Improve airflow efficiencyEven air distributionCharging stationsCasings with display/control unitsElectric carsElectric vehicle

A display assembly with integrated electric vehicle charging equipment includes a first and second side assembly connected to a structural frame, each including an electronic display subassembly located behind a cover. The electric vehicle charging equipment is connected to the structural frame between said first and second side assemblies in an at least partially recessed manner. Open or closed loops of air may be provided for cooling the first and second side assemblies and the electric vehicle charging equipment, which may all be connected to a common power source.

Owner:MFG RESOURCES INT INC

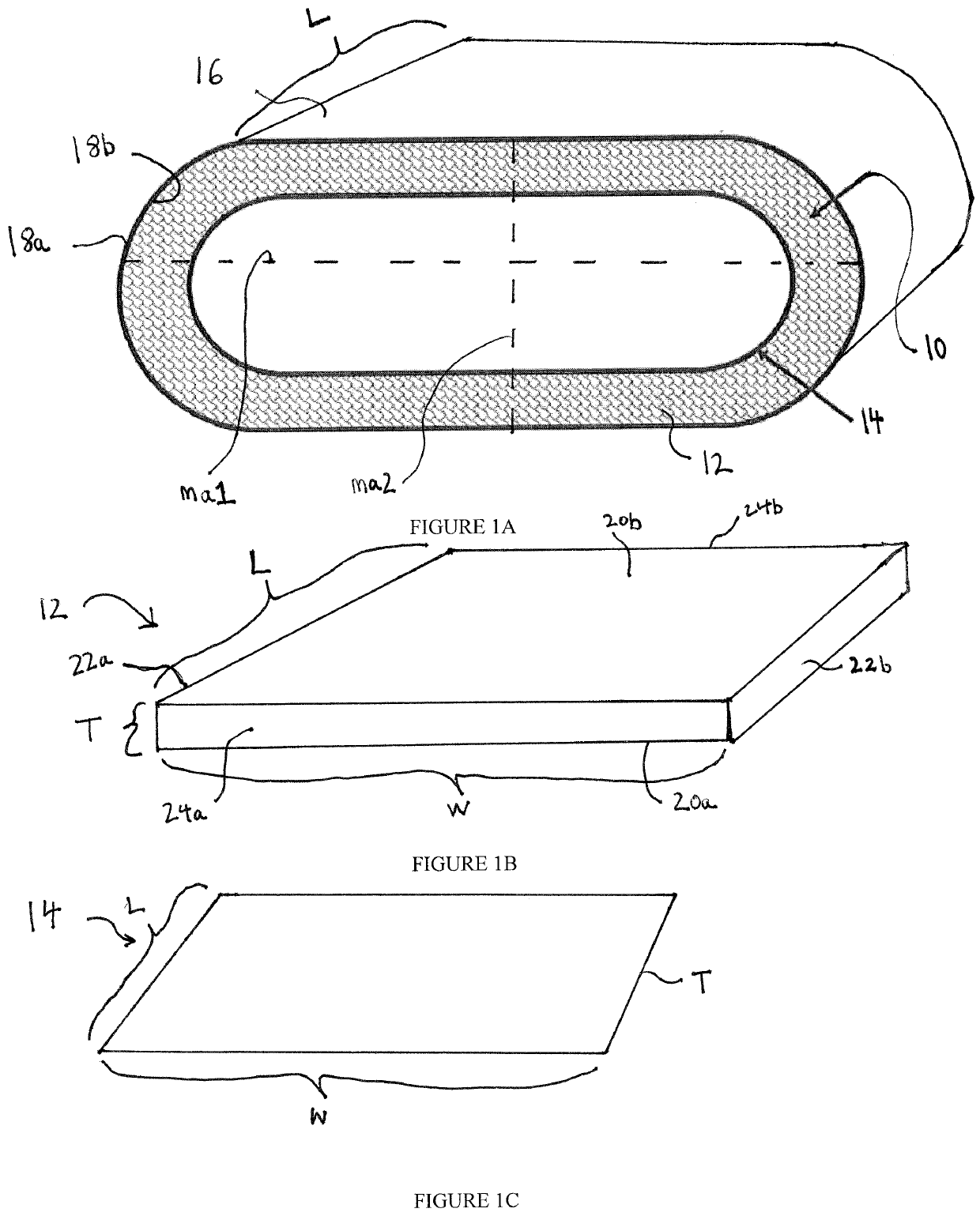

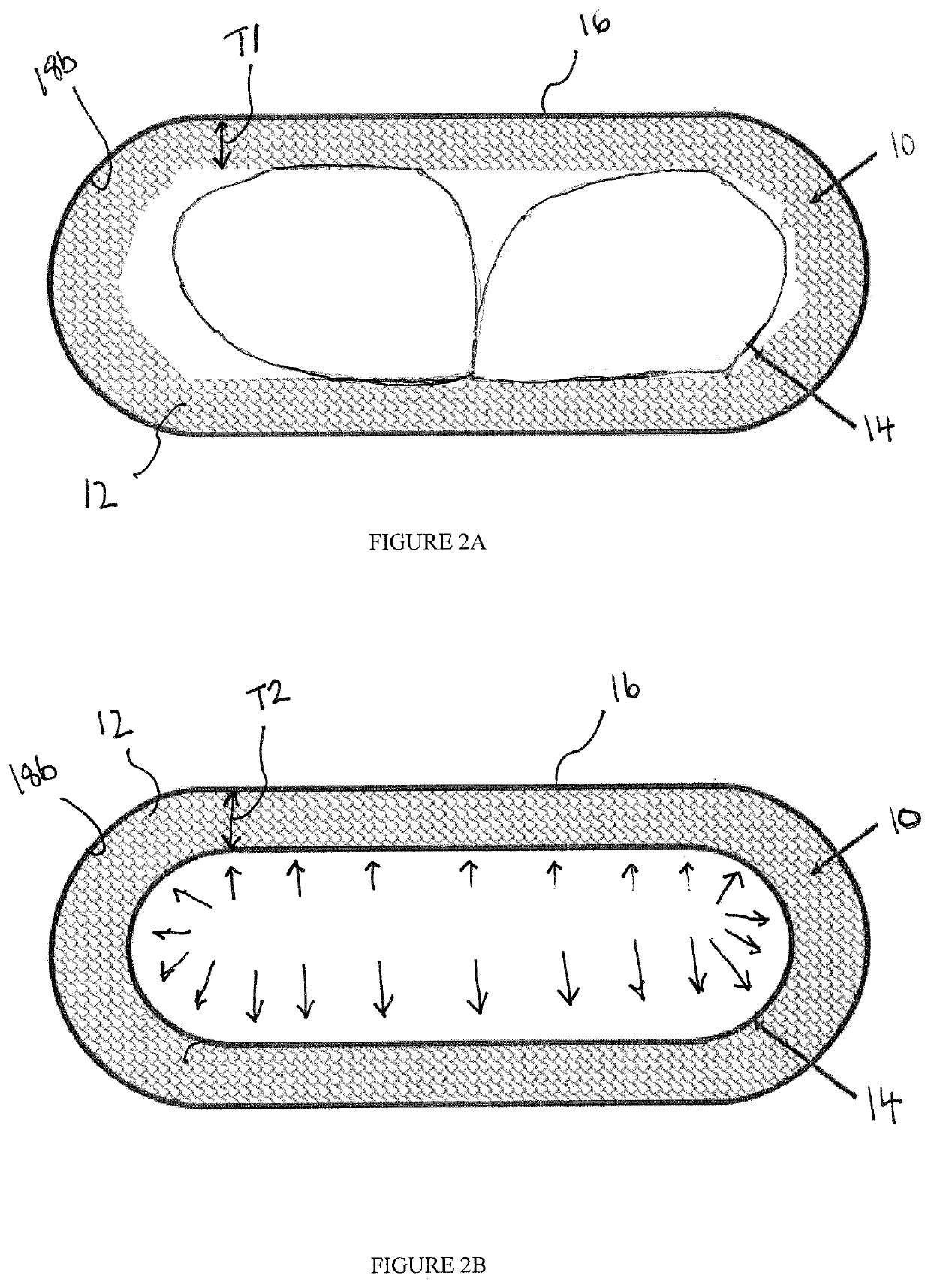

Methods and materials to universally fit duct liner insulation for oval HVAC duct systems

ActiveUS11333287B2Improve airflow efficiencyDucting arrangementsThermal insulationInsulation layerEngineering

The present disclosure relates generally to duct liner insulation products for curvilinear ducts, and more specifically relates to methods and materials to universally fit duct liner insulation for lining oval ducts in air conditioning, heating, and ventilating (HVAC) systems. A duct liner insulation for a curvilinear duct is provided that includes an insulation layer configured to line an interior surface of a curvilinear duct when installed within the curvilinear duct. The duct liner insulation also includes an elastically deformable layer configured to compress the insulation layer against the interior surface of the curvilinear duct when installed within the curvilinear duct such that the insulation layer extends substantially uniformly around an inner periphery of the curvilinear duct.

Owner:JOHNS MANVILLE CORP

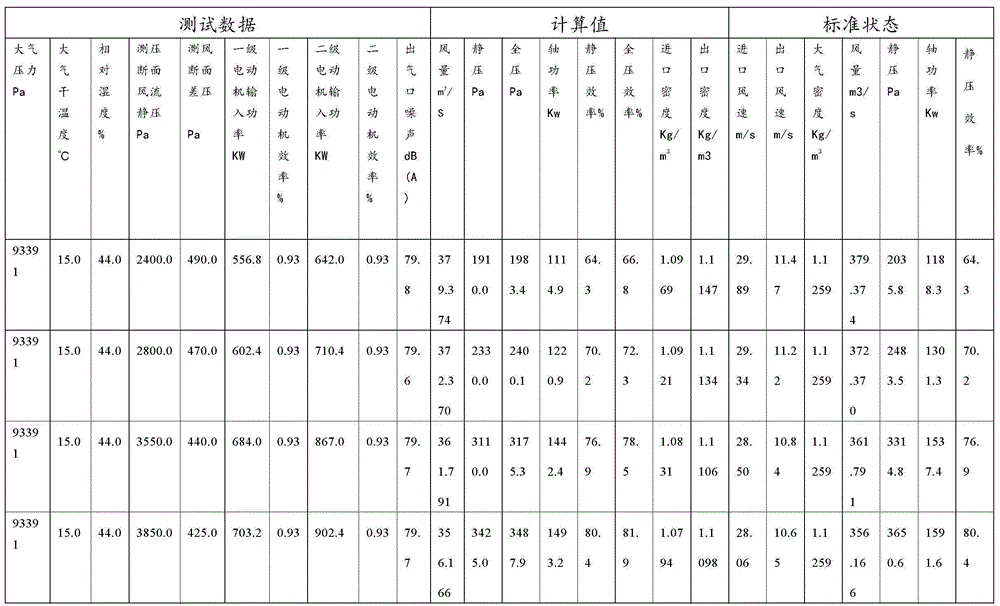

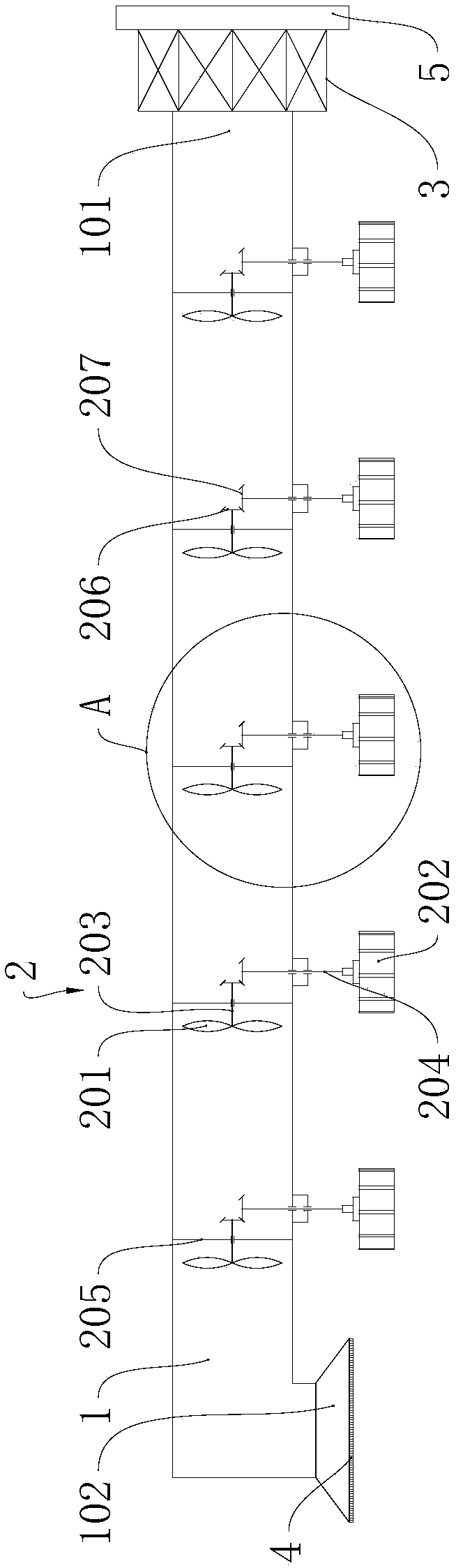

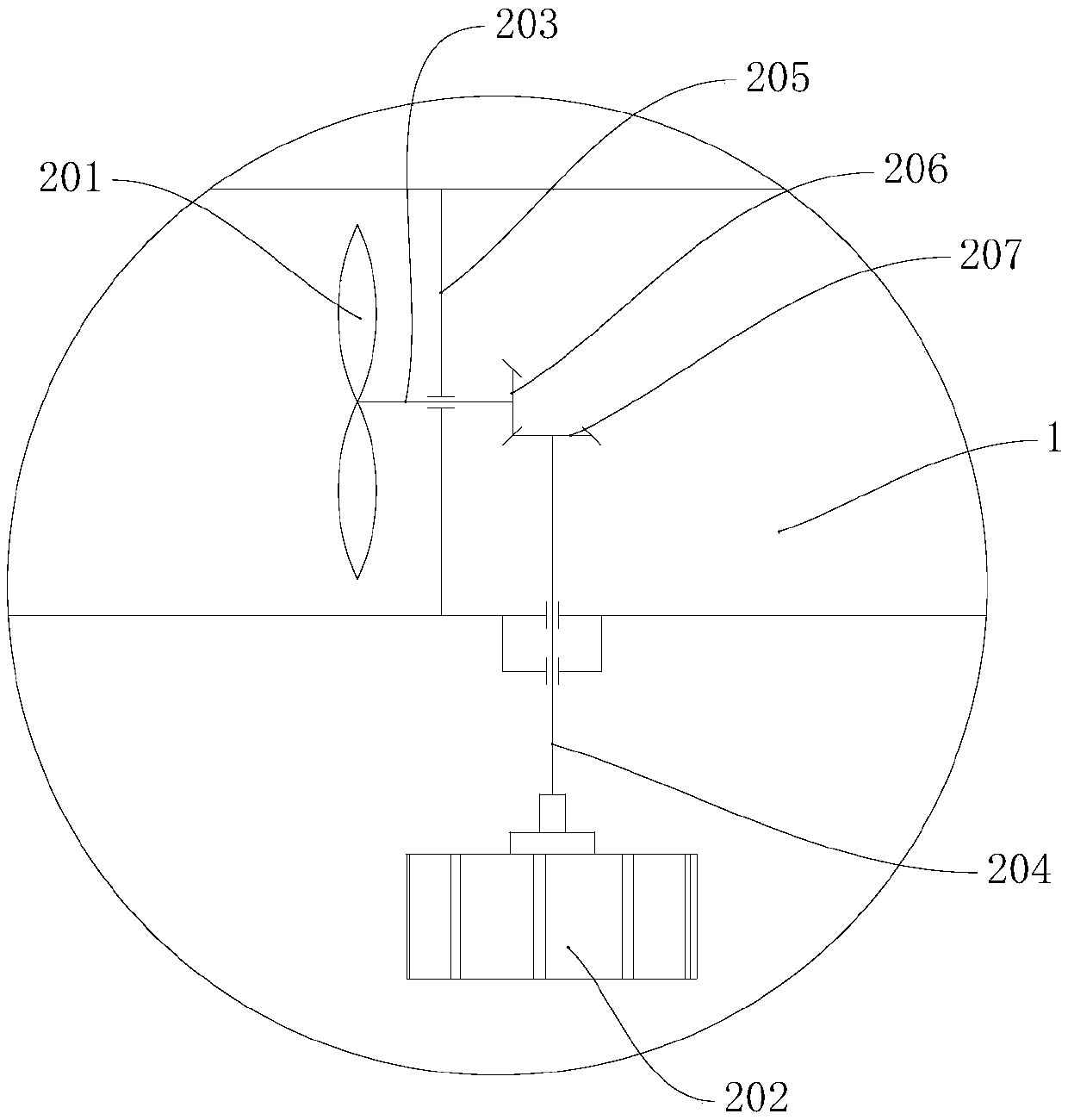

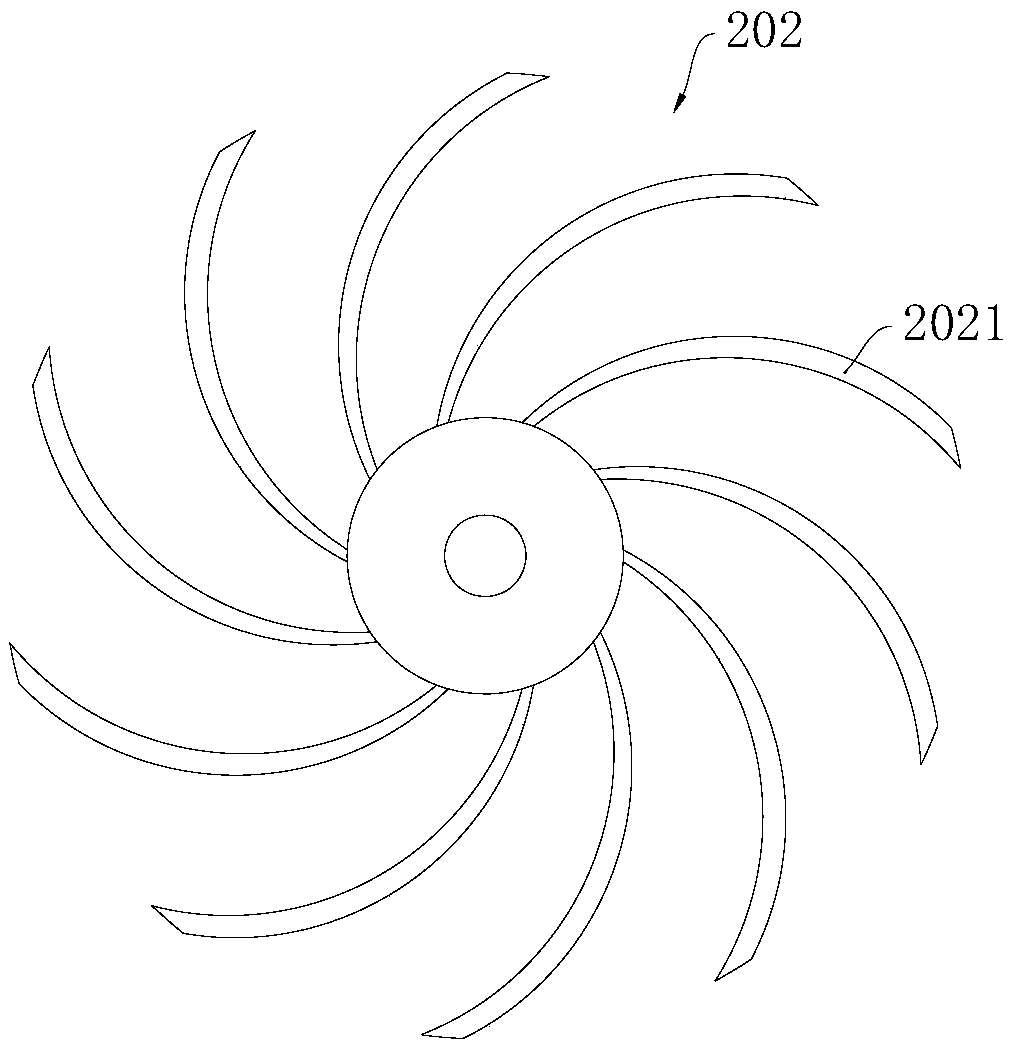

Counter rotating axial flow fan

ActiveCN102808793BImprove energy savingReduce efficiency lossPump componentsPump installationsImpellerEngineering

The invention provides a counter rotating axial flow fan, which includes a motor, an impeller, an explosion-proof cover, an air duct and a single-layer or multi-layer diffuser, wherein the outlet end of the single-layer or multi-layer diffuser extends in the direction away from the air duct; and the air duct sequentially includes a core duct, a first-stage inner duct, a second-stage inner duct and a diffused outer duct from outside to inside. Due to the special structure of the air duct, the counter rotating axial flow fan has very high static efficiency.

Owner:燕京装备制造有限公司

Unpowered ventilation device and tunnel

PendingCN109630182AStable hand directionRotational stabilityWind motor combinationsTunnel/mines ventillationImpellerEngineering

The invention relates to the technical field of ventilation of mines or tunnels, and provides an unpowered ventilation device and tunnel, which comprise a ventilation duct and a blower assembly, wherein a first air inlet and a second air inlet are arranged on the ventilation duct; the blower assembly comprises a rotary fan and a vortex impeller, the rotary fan is arranged in an inner cavity of theventilation duct, a fan direction of the rotary fan is in an extending direction of the ventilation duct, the vortex impeller is arranged outside the ventilation duct, and the rotary fan is in transmission connection with the vortex impeller; and the vortex impeller is driven by air flow of the ventilation duct to rotate unidirectionally, and the rotary fan is driven by the vortex impeller to rotate unidirectionally. The vortex impeller rotates along with the air flow outside the ventilation duct, so that the fan direction of the rotary fan is guaranteed to be stable, and an air flow direction in the ventilation duct is guaranteed to be stable; in addition, the blower assembly can transfer kinetic energy of the air flow in different directions outside the ventilation duct to the rotary fan, so that the efficiency of the blower assembly is improved and the ventilation efficiency in the ventilation duct is improved.

Owner:GUANGZHOU ENG CO LTD OF CHINA RAILWAY 19TH BUREAU GRP

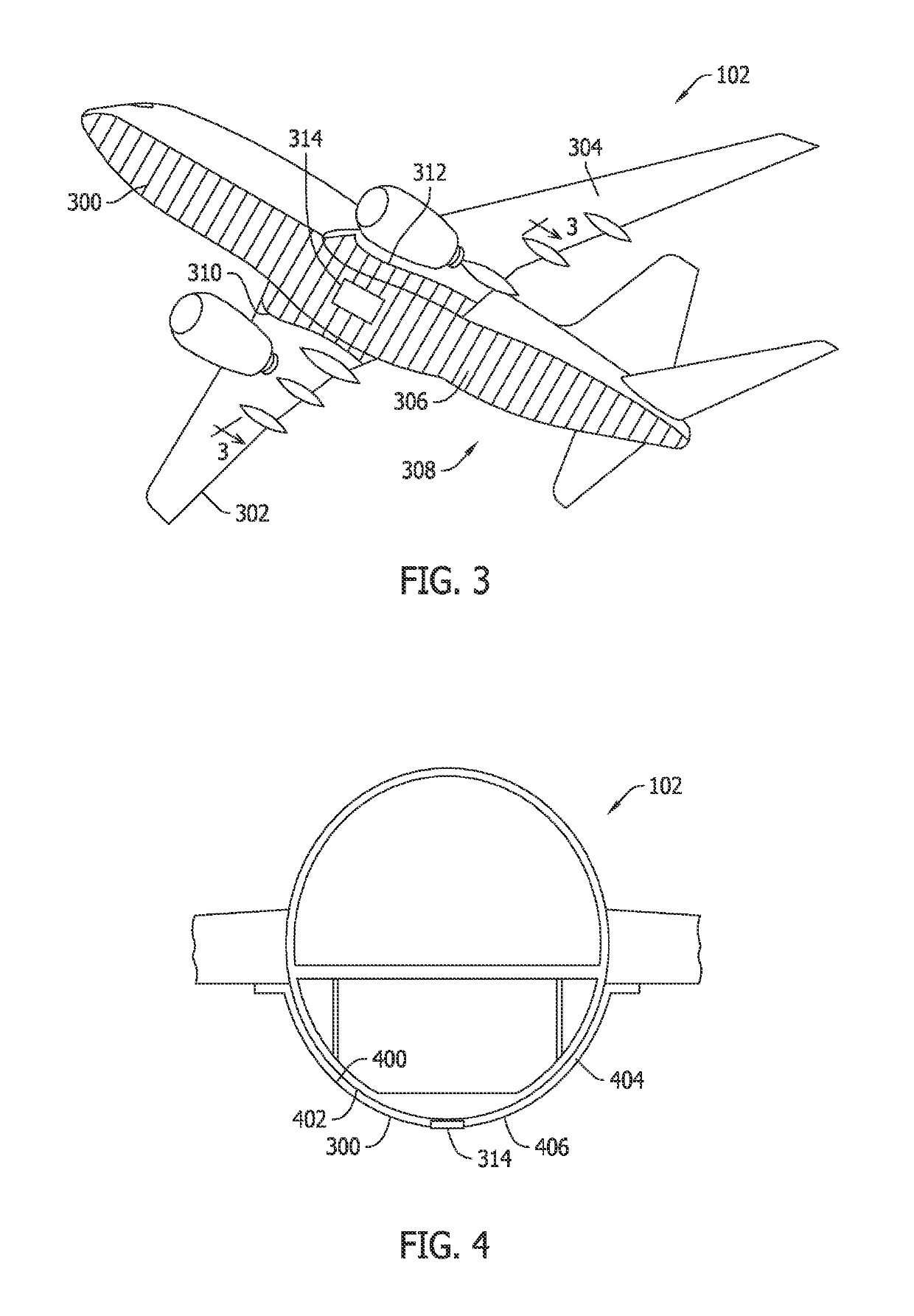

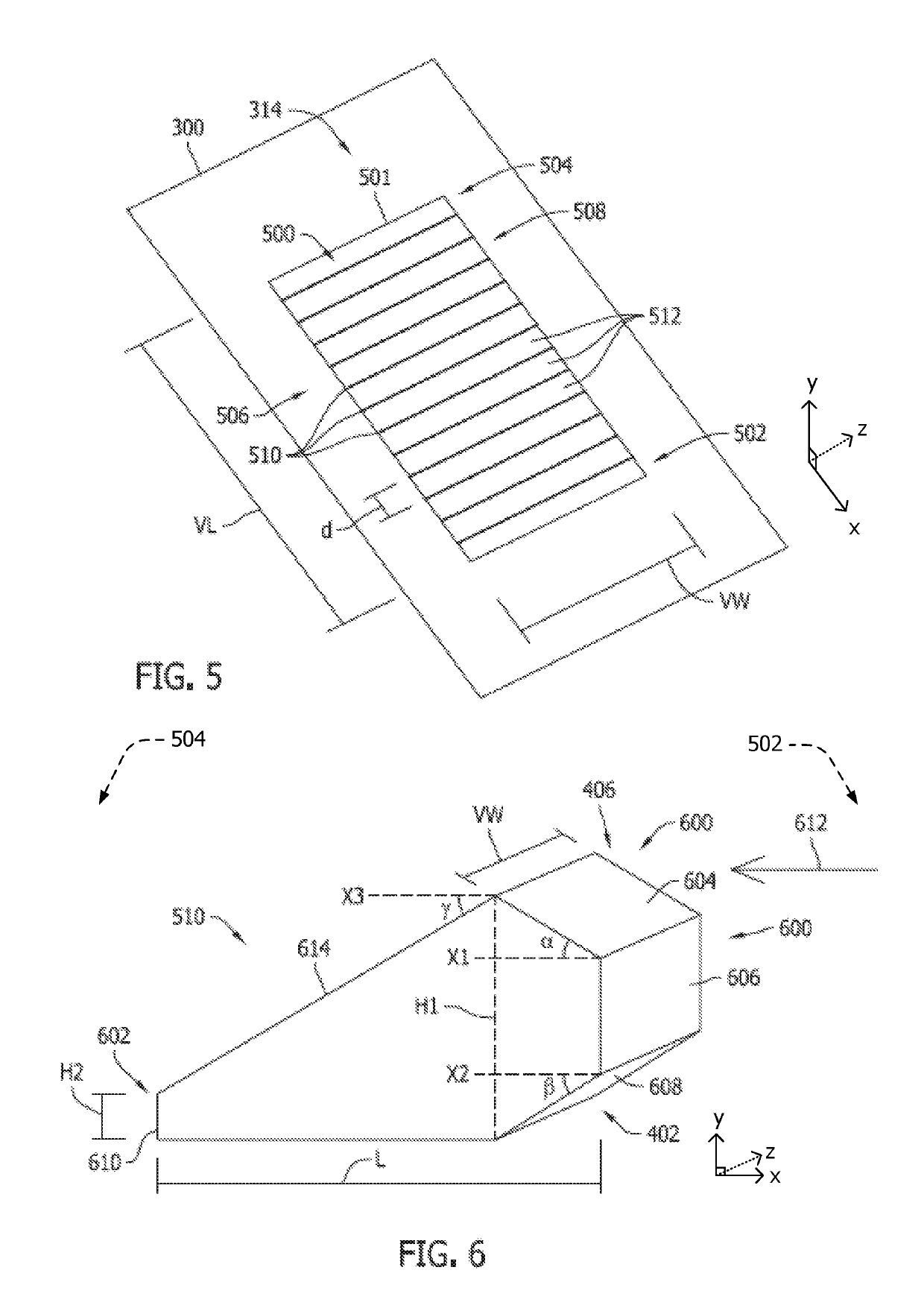

Pressure equalization vent for use in an aircraft assembly

InactiveUS10330334B2Improve airflow efficiencyAircraft accessoriesLighting and heating apparatusEngineeringEqualization

A pressure equalization vent for use in an aircraft assembly is provided. The pressure equalization vent includes an opening having a first end and a second end opposite the first end, and a first side and a second side opposite the first side. The vent further includes a plurality of louvers positioned within the opening. Each louver is positioned a predetermined distance from an adjacent louver to form a gap therebetween. Each louver includes an airfoil-shaped cross-section configured to increase airflow efficiency across the vent.

Owner:THE BOEING CO

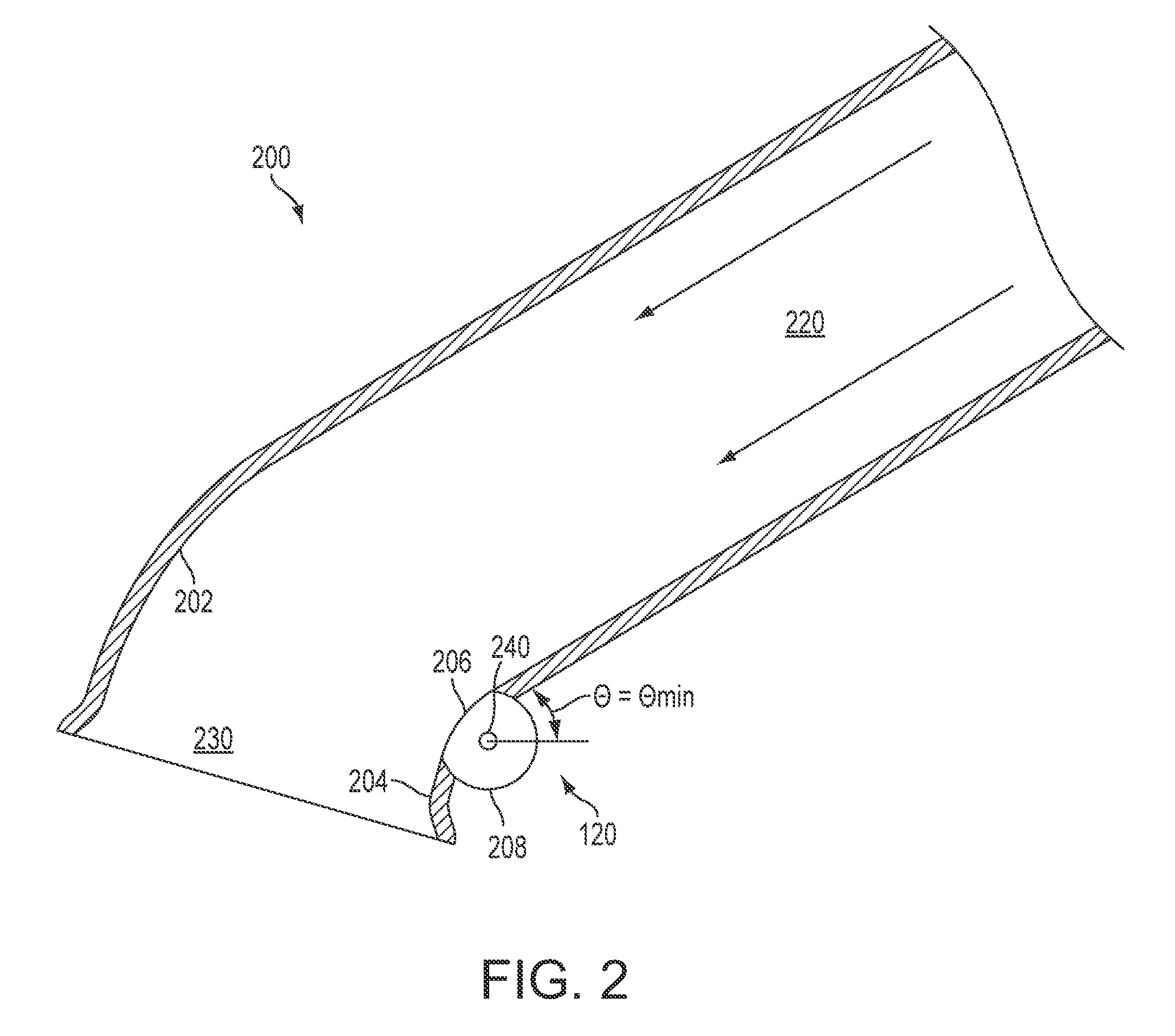

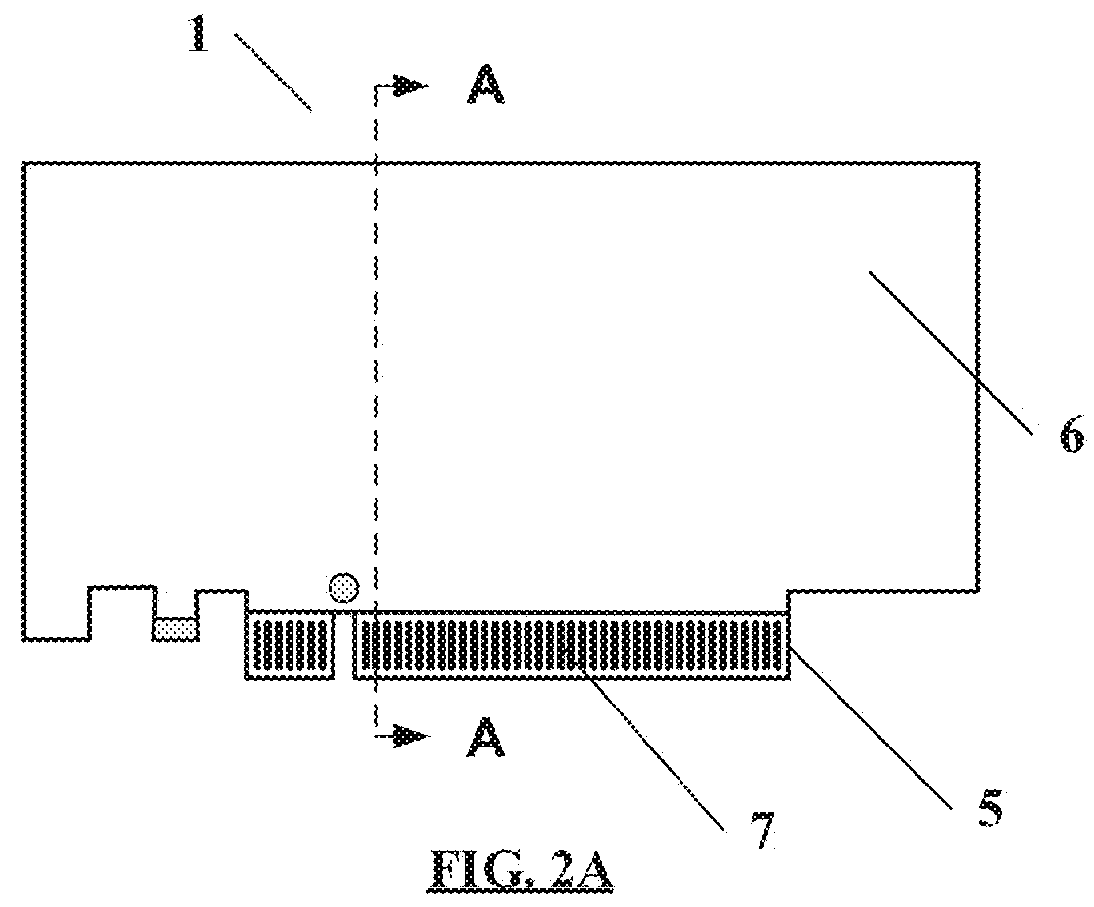

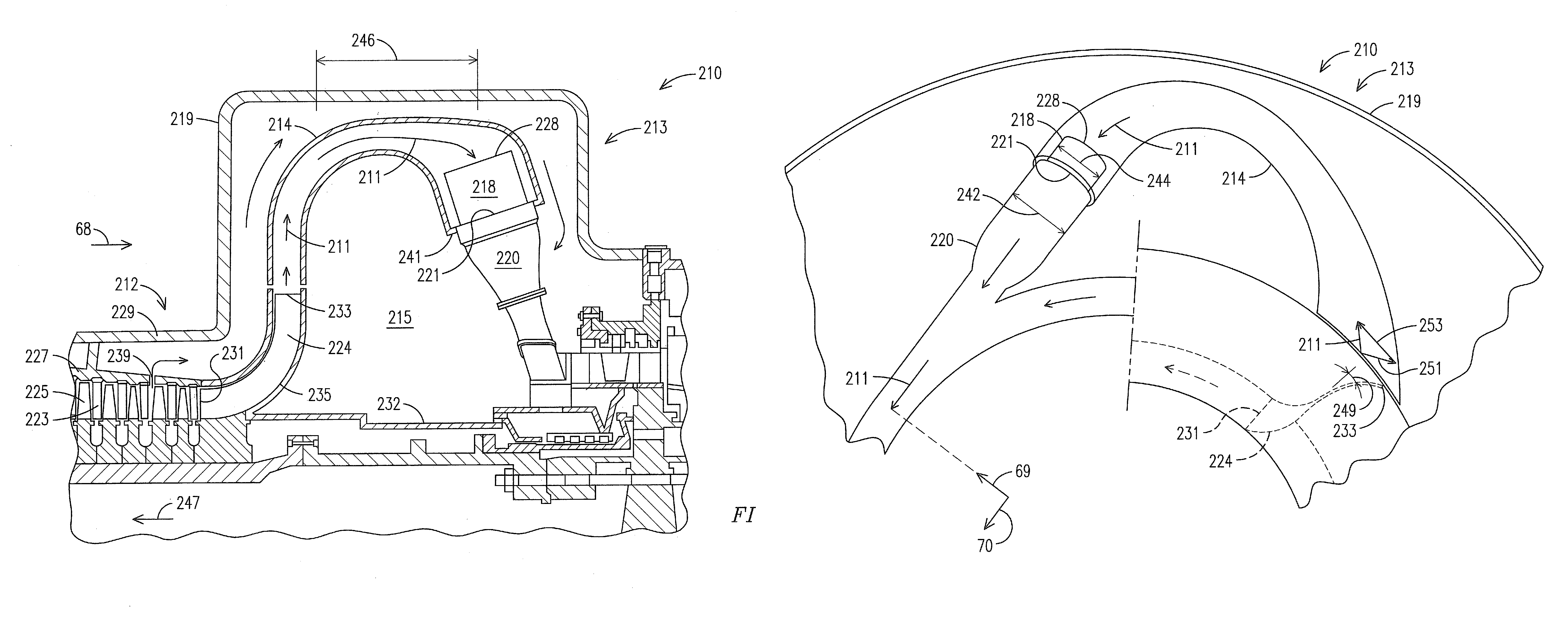

Mid-section of a can-annular gas turbine engine with a radial air flow discharged from the compressor section

InactiveUS9476355B2Cost efficientReduce manufacturing costPump componentsGas turbine plantsCombustorEngineering

A midframe portion (213) of a gas turbine engine (210) is presented, and includes a compressor section (212) configured to discharge an air flow (211) directed in a radial direction from an outlet of the compressor section (212). Additionally, the midframe portion (213) includes a manifold (214) to directly couple the air flow (211) from the compressor section (212) outlet to an inlet of a respective combustor head (218) of the midframe portion (213).

Owner:SIEMENS ENERGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com