Counter rotating axial flow fan

An axial-flow fan and counter-rotating technology, applied in the field of machinery, can solve the problems of limited influence on work efficiency and limited diffusion layer of the rotary axial-flow fan, and achieve the effects of stable operation, obvious energy saving effect and reducing efficiency loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

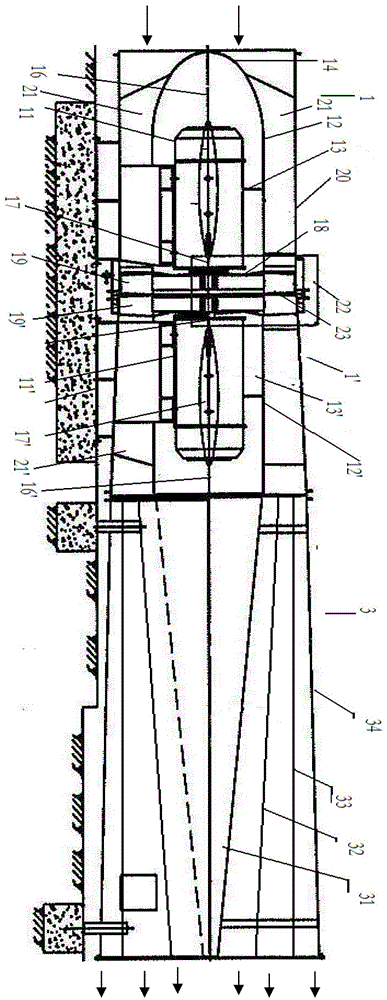

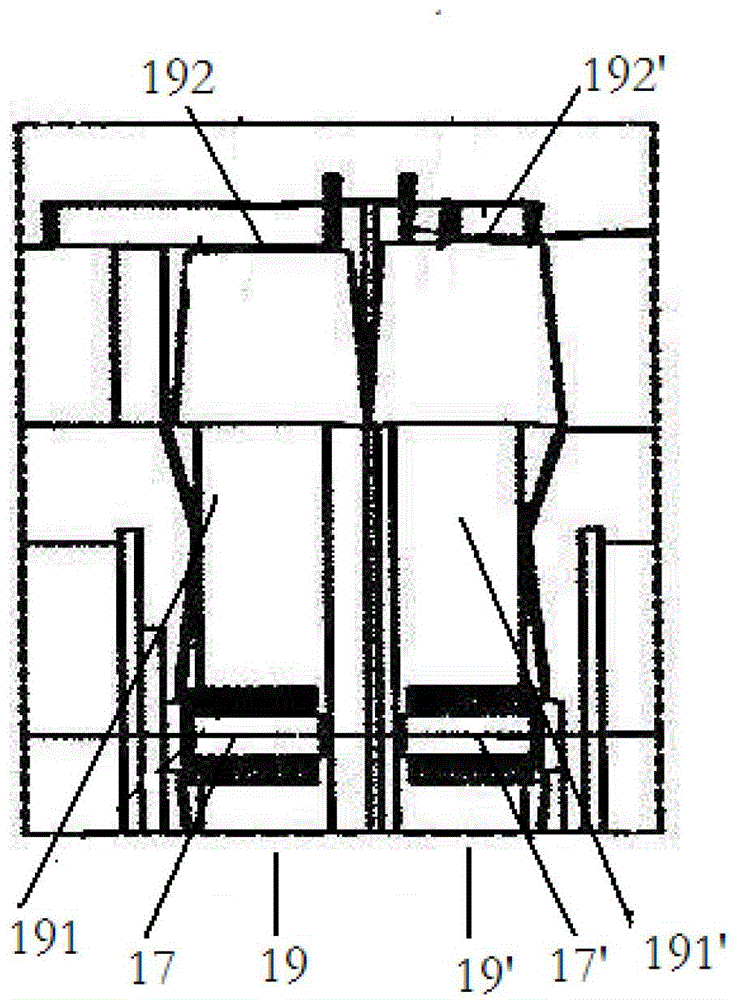

[0026] see figure 1 , The counter-rotating axial flow fan includes two sets of two-stage fans connected coaxially and a multi-layer diffuser connected to one end of the fan. From the air inlet of the fan to the end of the multi-layer diffuser, the first-stage fan 1, the second-stage fan 1' and the multi-layer diffuser 3 are sequentially included.

[0027] The first-stage fan 1 includes a first-stage motor 11 from the inside to the outside, and a first-stage explosion-proof cover 12 is arranged outside the first-stage motor 11 , and the first-stage motor 11 and the first-stage explosion-proof cover 12 are connected by a rib 13 . The first-stage explosion-proof cover 12 is semi-ellipsoidal, coaxially connected with the first-stage motor 1, the end 14 of the first-stage explosion-proof cover 12 with a small diameter faces the air inlet 15 of the first-stage blower fan 1, and the first-stage motor is installed 1 Inside the first-stage explosion-proof cover 12, there is a gap be...

Embodiment 2

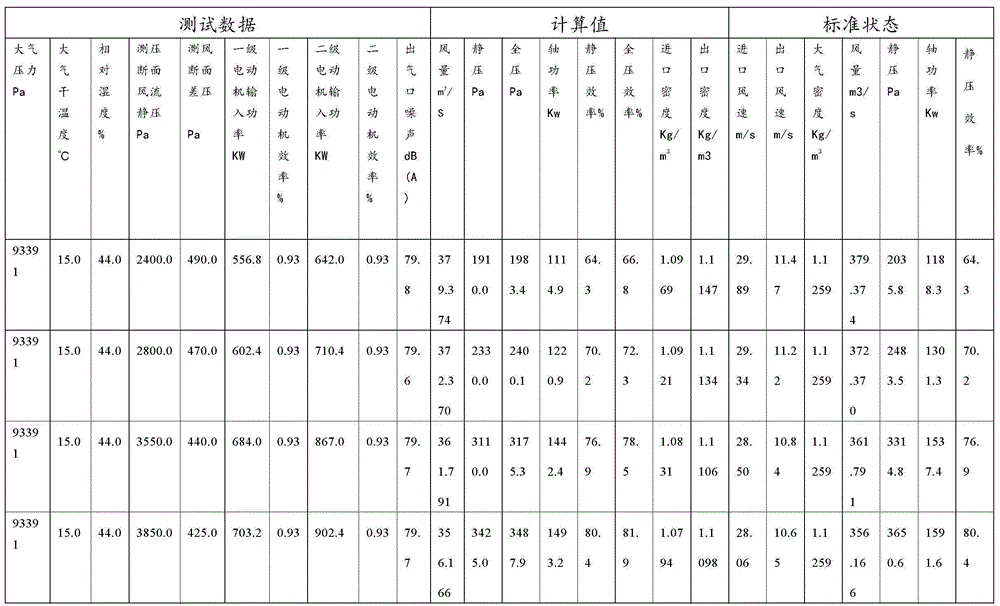

[0033] Using the counter-rotating axial flow fan of the present invention, the aerodynamic performance test is carried out, and the test results are shown in the following table: the matching motor model YBF800-10-1120, the rated power of the motor: 1120kw*2, the speed of the motor: 592r / min, two-stage operation , wind pressure test section area: 12.6923m 2 , Air volume test section area: 12.6923m 2 , Test method: on-site shutdown, short circuit test, blade installation angle: 35 。 / 30 。 (Level 1 / Level 2), fan outlet area: 32.5410m 2 , the test structure is shown in the table below:

[0034]

[0035]

[0036] It can be seen from the above table: the air volume test results are 379.4-330.2m 3 / s, the static pressure is 2035.8-5084.1Pa, the highest static pressure efficiency is 89.3%, the shaft power is 1188.3-1840.2kw, and the outlet noise is 79.1-79.9dB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com