Blade, axial flow fan blade and fan

A technology of axial flow blades and blades, which is applied in the field of blades, axial flow blades and fans, can solve the problems of increased motor costs, etc., and achieve the effects of improving aerodynamic performance, increasing outlet wind speed, and improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

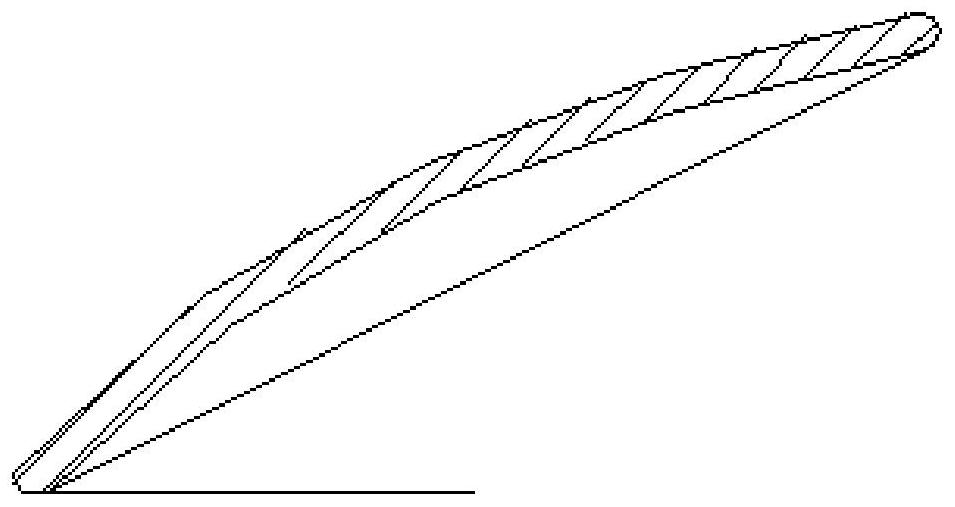

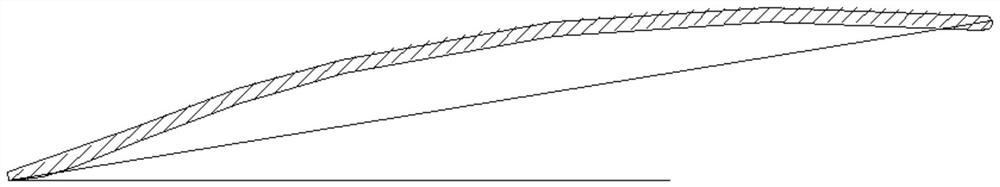

[0053] This embodiment provides a blade, which can be applied to axial flow blades. In one embodiment, such as Figure 4 to Figure 11 As shown, the blade 2 includes a pressure surface, a suction surface 26, a blade root portion 23, a blade top portion 24, a leading edge portion 21, and a trailing edge portion 22, and the cylindrical surface where the blade root portion 23 is defined is the blade root element surface 31. The cylindrical surface where the leaf top 24 is located is the blade top primitive surface 34, and the cylindrical surface located in the middle of the blade root primitive surface 31 and the blade top primitive surface 34 is the 1 / 2 primitive surface 32, which is located at the blade top The cylindrical surface between the primitive surface 34 and the 1 / 2 primitive surface 32 is the 3 / 4 primitive surface 33 .

[0054] The maximum distance between the leading edge portion 21 and the trailing edge portion 22 at the base element surface 31 of the blade root is l...

Embodiment 2

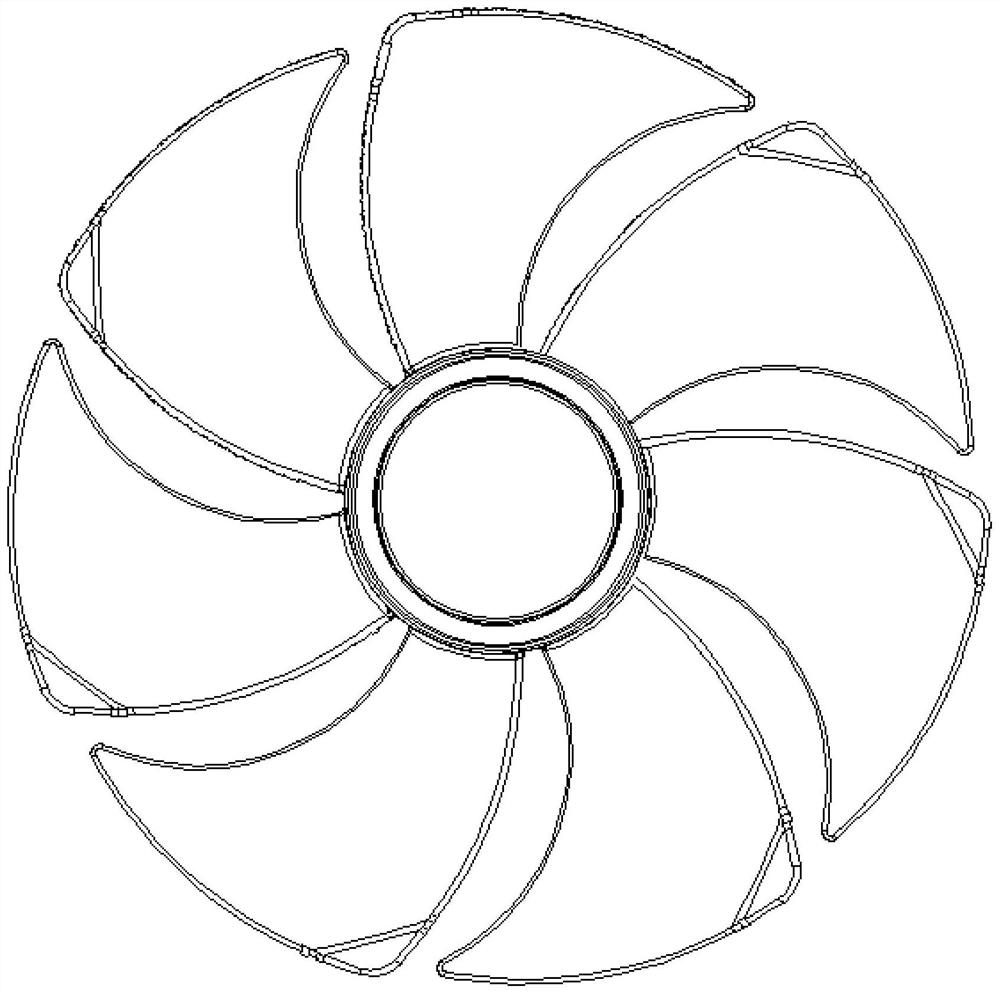

[0068] This embodiment provides an axial fan blade, including a hub 1 and a plurality of blades as provided in Embodiment 1 uniformly distributed along the circumference of the hub 1 .

[0069] Tests have proved that compared with the common fan blades in the prior art, the axial-flow fan blade provided by this embodiment can significantly increase the wind speed at the center of the fan blade by 1m / s and the air volume by 2m 3 / min. At 1100rpm, the power of the motor is reduced by 2W, and the temperature rise of the motor is reduced, which is beneficial to control the cost. The axial-flow fan blade can be matched with the motor to improve energy efficiency and reduce the cost of the motor. At the same time, it can effectively reduce the humming sound during high-speed rotation and improve the sound quality.

[0070] In one embodiment, the diameter of the hub 1 is d, the outer diameter of the axial flow blade is D, and 0.25≤d / D≤0.3. Can reasonably control air separation and ...

Embodiment 3

[0073] This embodiment provides a fan, including the axial flow blade provided in the above embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com