Composite grille louvers

a technology of composite grille and louvers, which is applied in the direction of protective equipment, armoured vehicles, weapons, etc., can solve the problems of projectile damage to the engine or other components, air can easily flow through the non-linear path, and projectiles cannot easily navigate the non-linear path, so as to maintain improve the protective ability of the grille, and improve the airflow through the circuitous path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

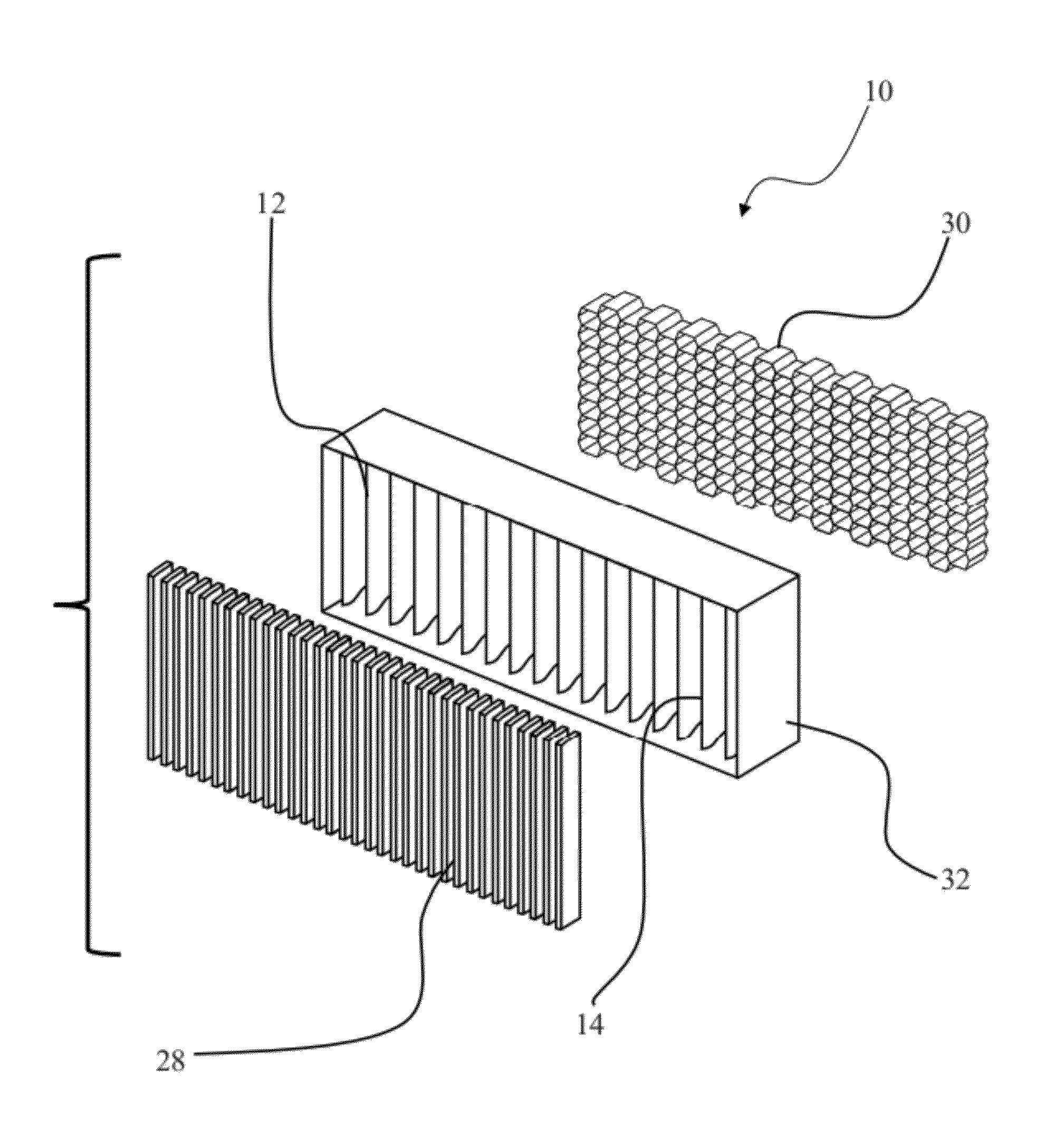

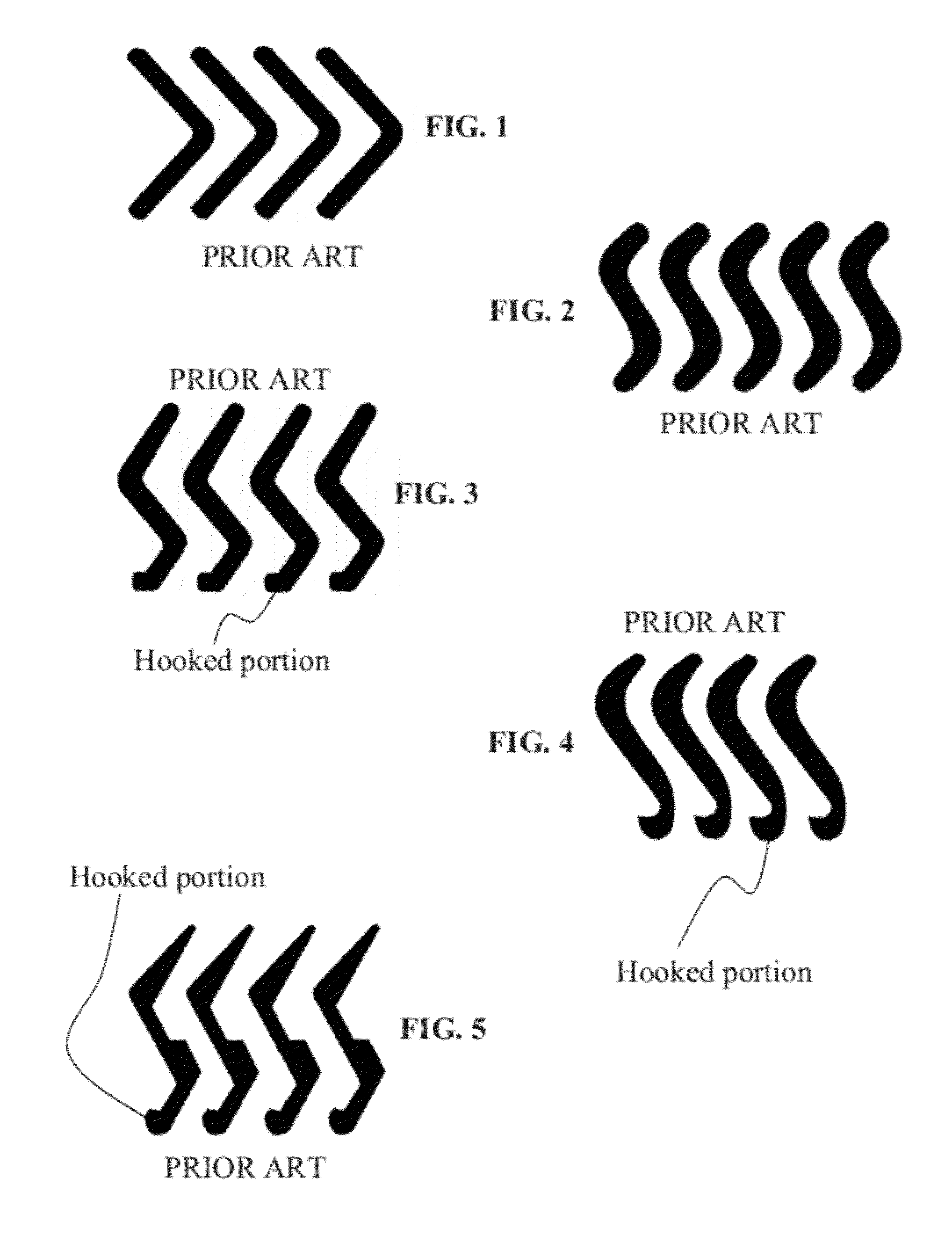

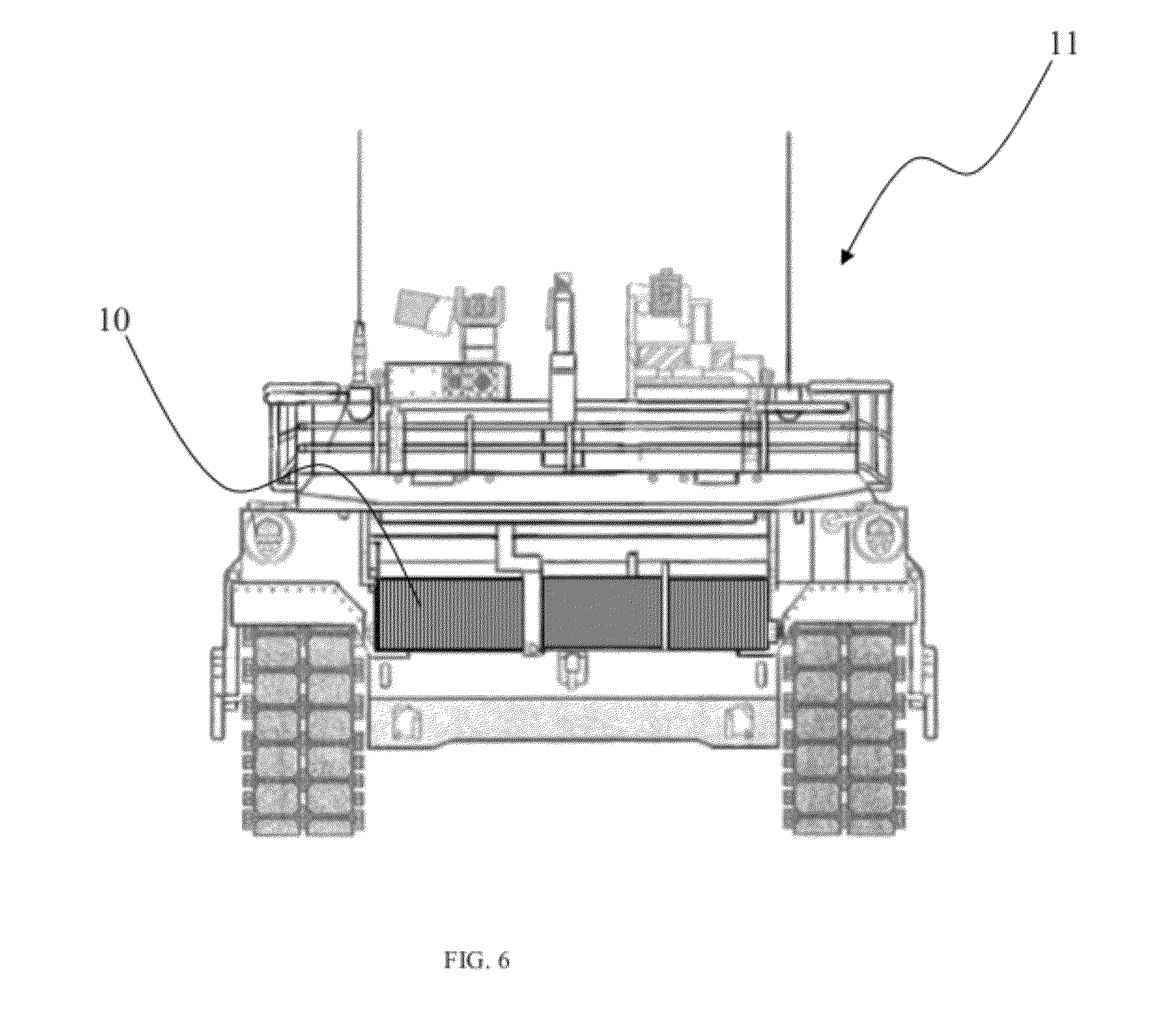

[0025]As shown in FIGS. 6-9, a grille 10, according to an embodiment of the present invention, comprises a plurality of S-shaped louvers 12 each having an exterior end 14 and an interior end 16. In one aspect, the exterior end 14 can comprise a tapered shape to minimize disruption of the airflow through the grille 10. The interior end 16 further comprises a hooked portion 18 defining an inlet 20 in the louver 12 and a ballistic hook 22 generally perpendicular to the louver 12. Each louver 12 further comprises an insert 22 shaped to fit within the inlet 20 and comprising a foam core 24 and a closeout 26. In another aspect, the louver 12 can only comprise the closeout 26 to define an air pocket in the inlet 20. In one aspect, the louvers can be about 3 inches long.

[0026]In one aspect, the louvers 12 can comprise a composite material rather than a metal to reduce the overall weight of the grille 10 while improving the ballistic protection of the grille 10. The composite material can ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com