Maintenance-free slide bearing with FEP or PFA in the adhesive layer

A technique for sliding bearings and adhesive layers, applied in the field of maintenance-free sliding bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

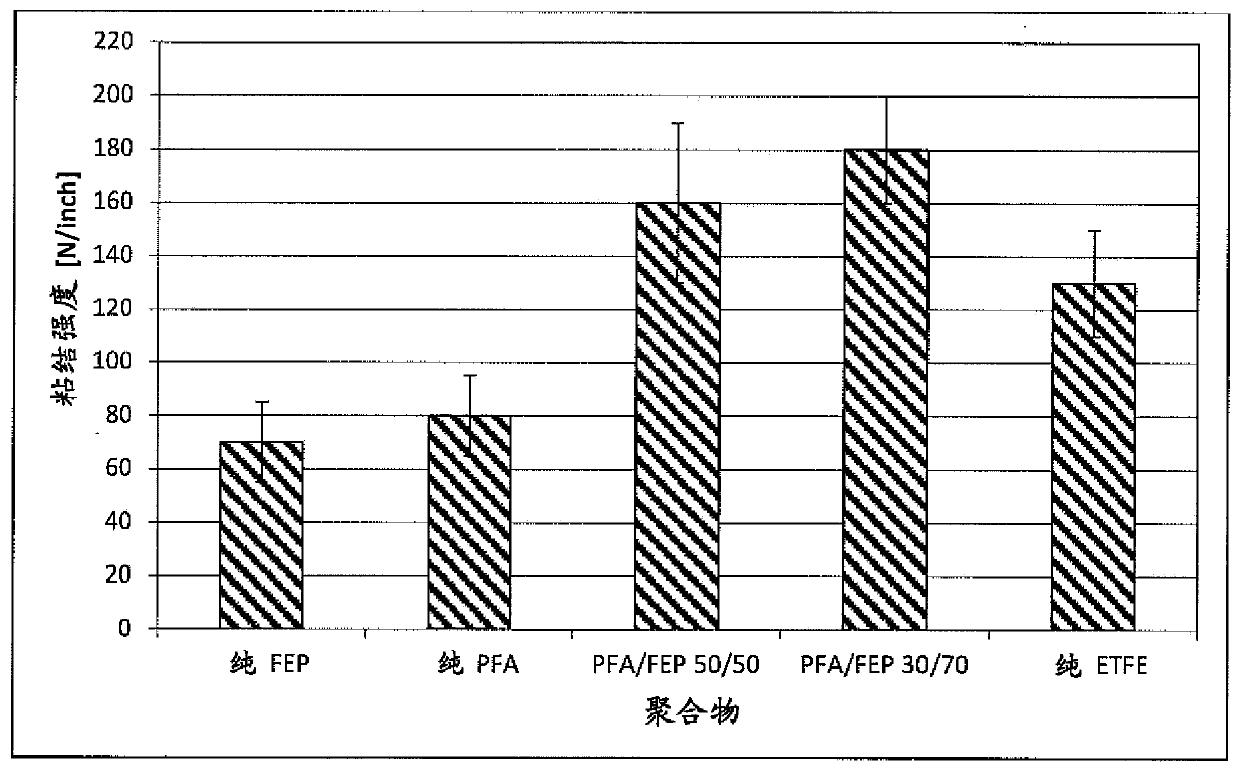

[0055] 180°T-peel test

[0056] The 180° T-peel test is described in DIN EN 1895, the entire content of which is hereby incorporated. Prepare sample strips with a five-layer structure. The settings for the layers are: Steel Backing, Adhesive, Slide Layer, Adhesive, Steel Backing. The width of the sample strips is 25mm. Fix the clamps at one end to opposing steel outer edges. The steel backing was pulled apart and the peel force to separate the steel backing was measured.

[0057]In one experiment, strips with pure FEP or pure PFA were selected as the material for the adhesive layer. In another experiment, blends of FEP and PFA in various ratios were chosen as the material for the adhesive layer. Cold-rolled steel grade 1.0338 was chosen as the metal backing layer and a PTFE compound tape with a filler content of 25% was chosen as the sliding layer.

[0058] Such as figure 2 As demonstrated by the experimental results shown, the blends of FEP and PEA have significantly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com