Patents

Literature

34results about How to "Various molding methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

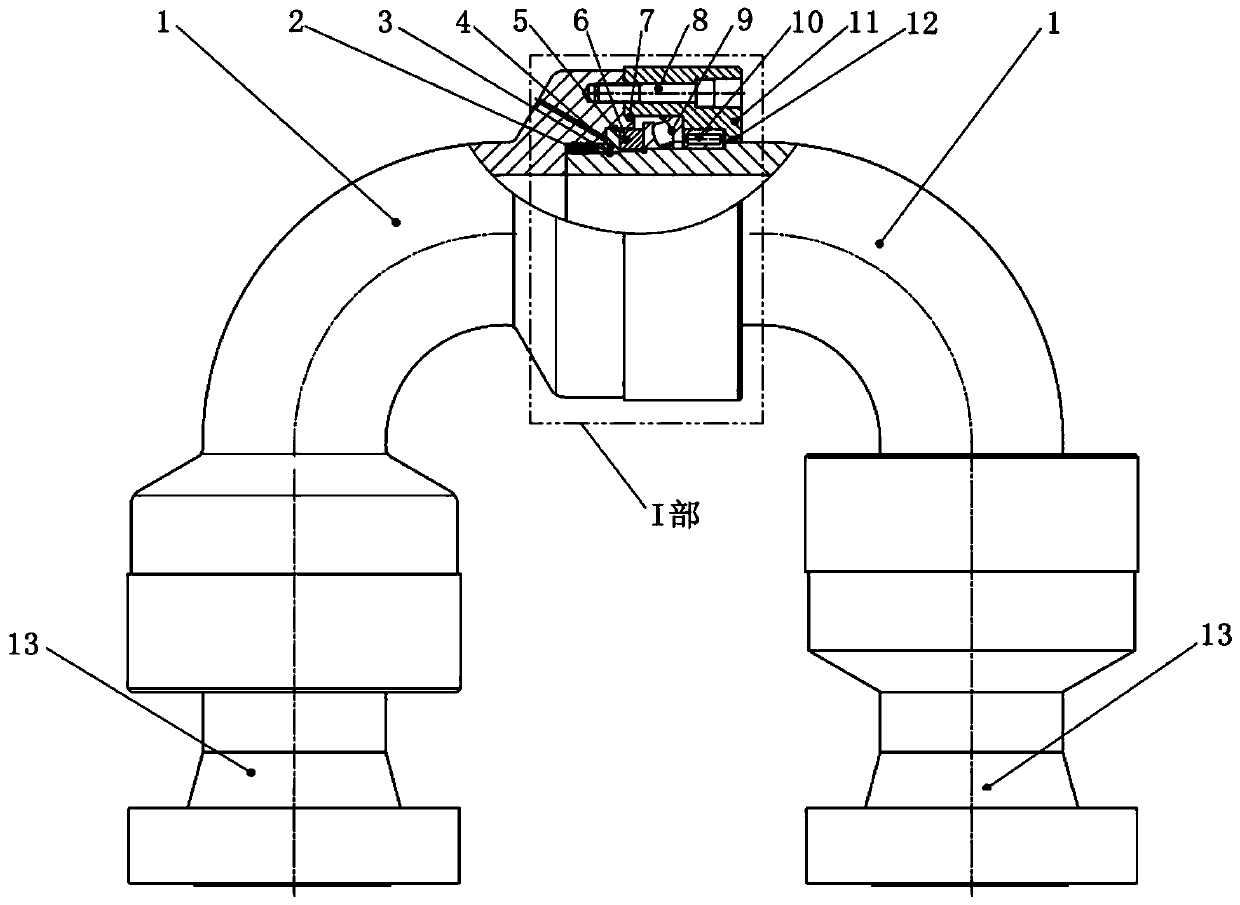

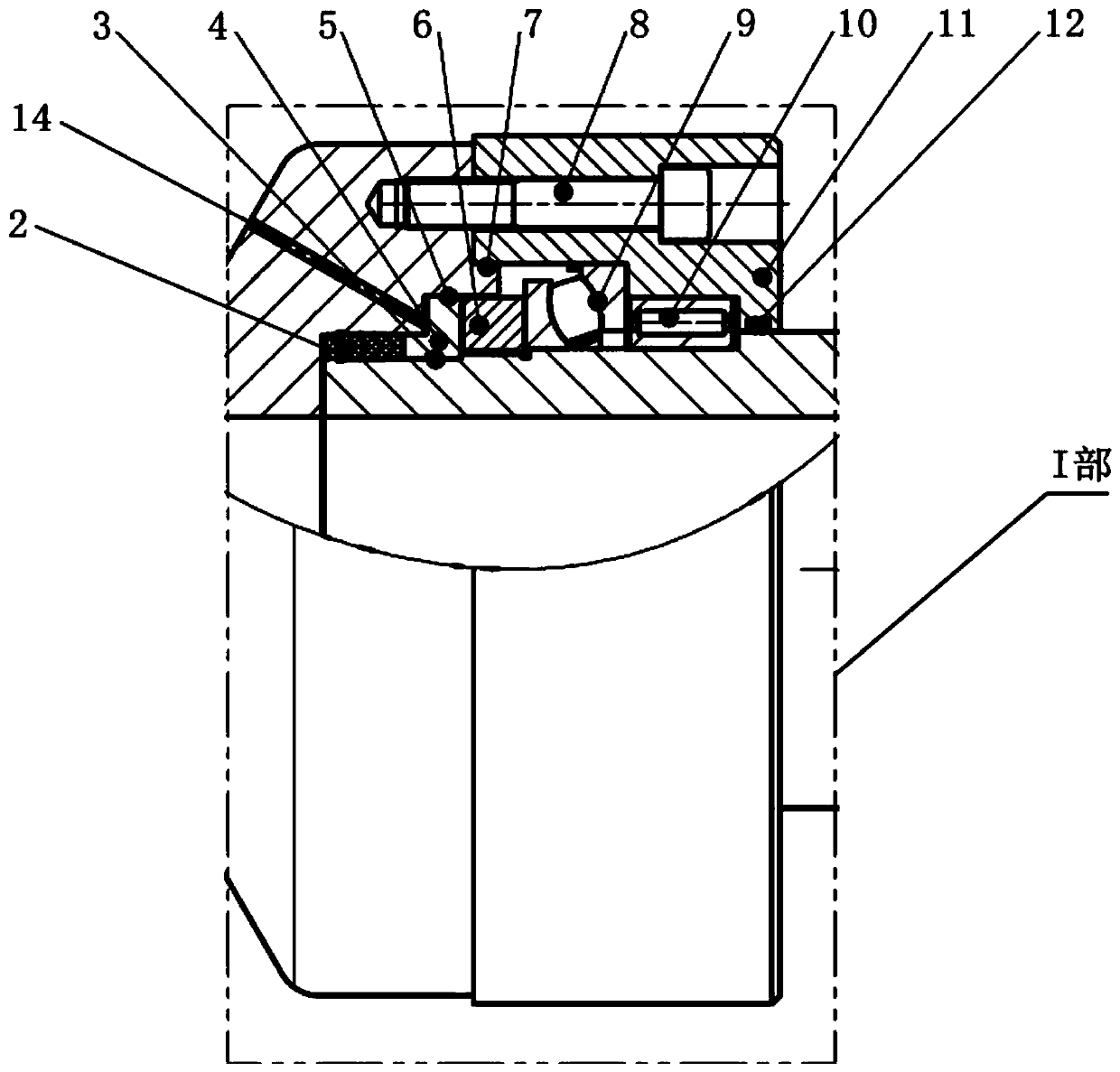

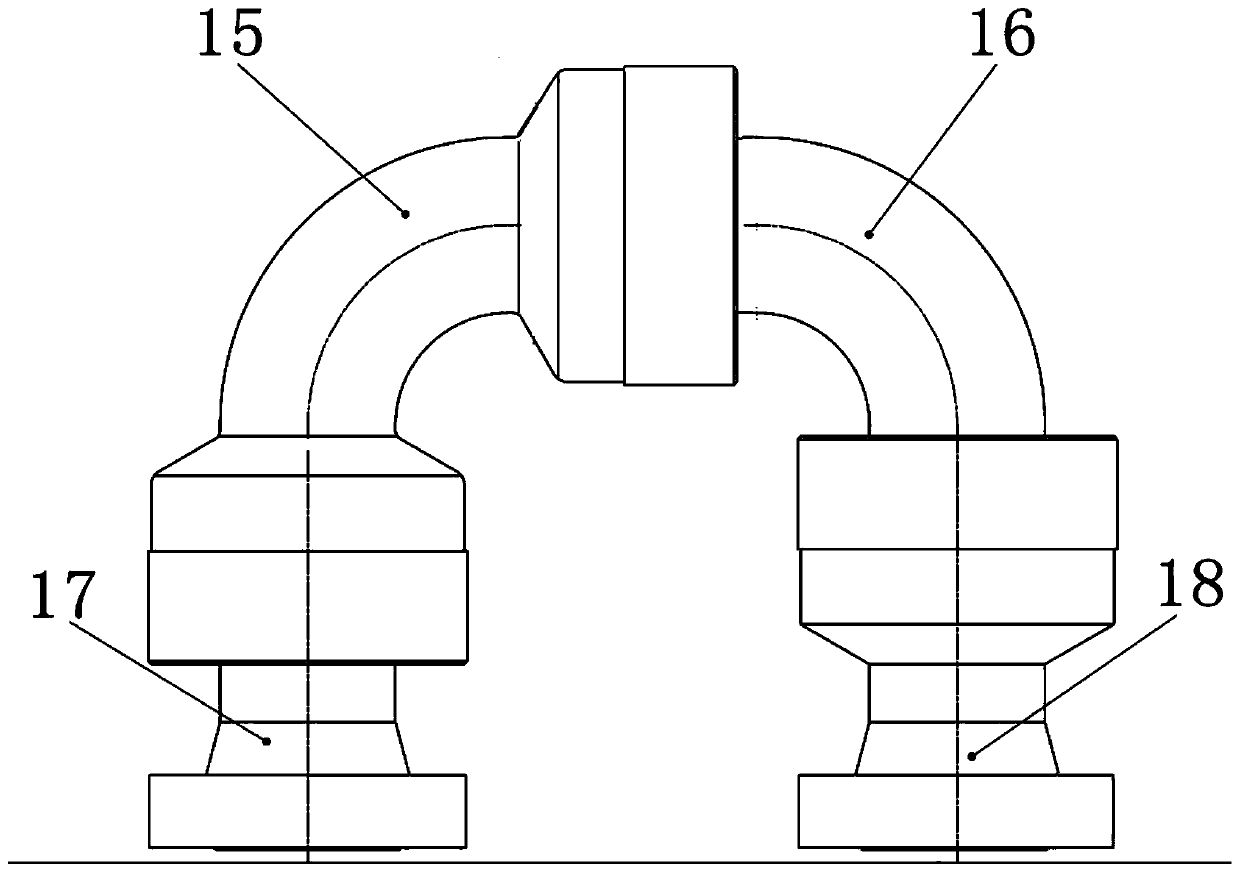

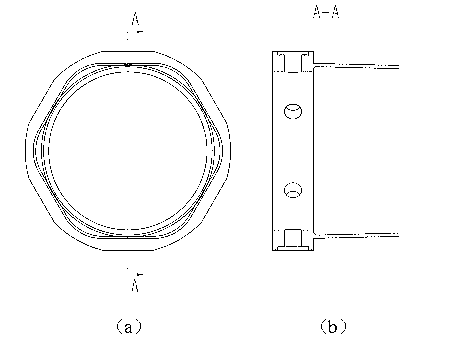

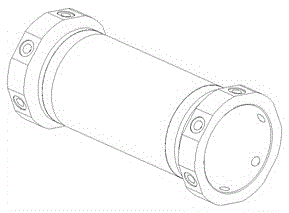

Combination bearing type large-specification movable elbow mechanism

PendingCN111594059ASimple structureReduce volumeDrilling rodsSealing/packingThrust bearingStructural engineering

The invention discloses a combination bearing type large-specification movable elbow mechanism. The combination bearing type large-specification movable elbow mechanism comprises elbows, connection heads, a pressing cover, a packing seal component and a rotating component, wherein positions between the elbows and the connection heads as wall as between the elbows are fixedly connected through thepressing cover and are sealed through the packing seal component, cavities are formed at the positions between pressing cover and the connection heads as wall as between the pressing cover and the elbows and are internally provided with the rotating component, the rotating component is used for relative rotating of the connection heads or the elbows and comprises a centripetal bearing and a thrustbearing, and the elbows and the connection heads as wall as the elbows are flexibly connected. The combination bearing type large-specification movable elbow mechanism has the beneficial effects thatthe combination bearing type large-specification movable elbow mechanism is flexible in connection, smooth in rotating, simple in structure, not limited by the pipe diameter, also not limited by theelbow structure molding method, small in volume and diversified in molding method.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

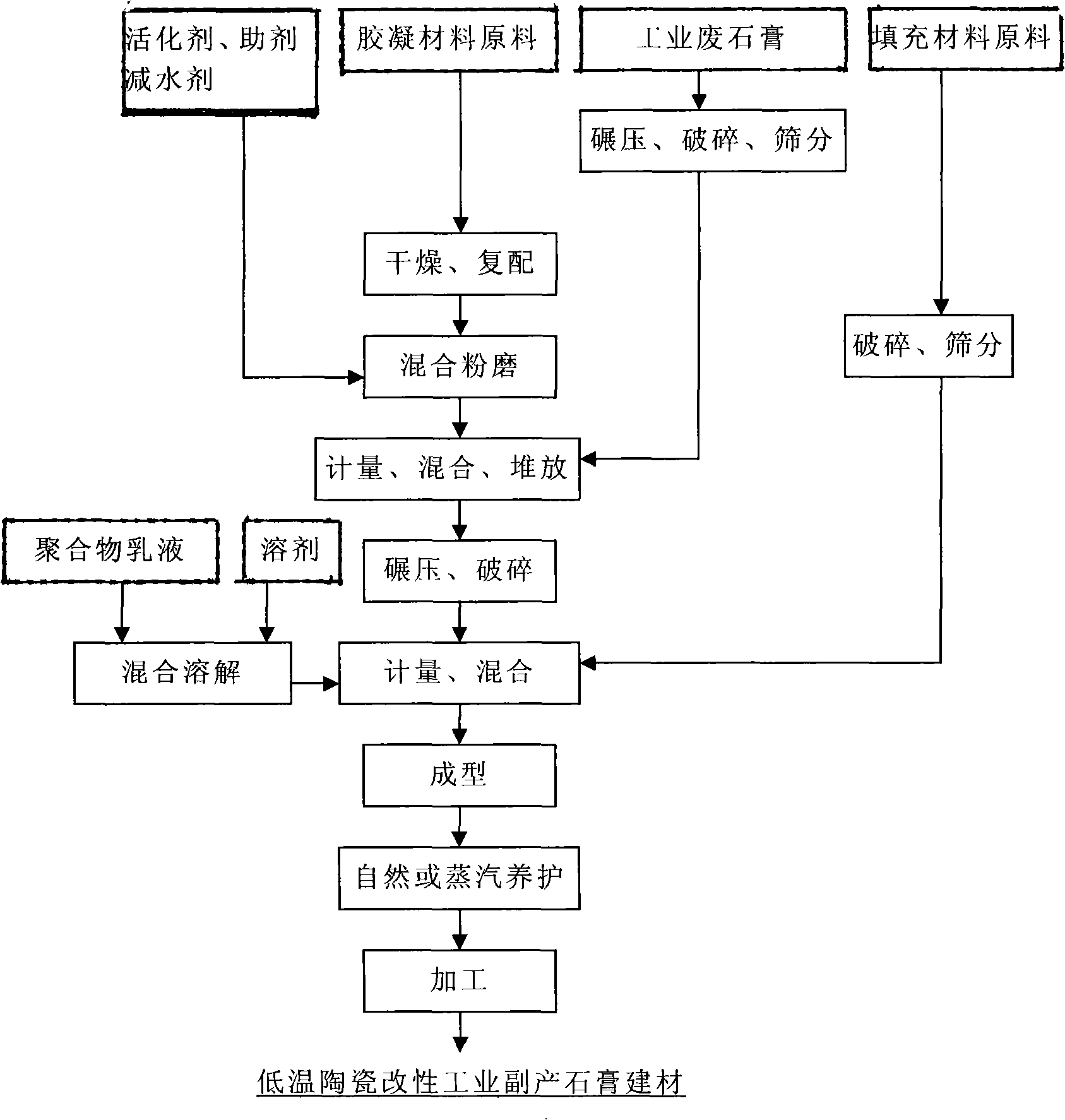

Method for producing building material with low-temperature ceramic modified industry by-product gypsum

InactiveCN101314530AImprove performanceVarious molding methodsSolid waste managementCement productionWork in processSolvent

The invention relates to a method for making a building material by low-temperature ceramic modified industrial side product gypsum, belonging to the building material technical field. The compositions adopted by the method are mixed according to the following mass ratio that: gelating material: side product gypsum: filler: activator: auxiliary agent: water reducing agent: polymer emulsion: solvent is equal to 100:300-900:50-500:80-150:12-30:1.0-10:0-50:50-500. The raw materials respectively undergoes raw material treatments such as gelating material powder preparation, waste gypsum treatment, filler crushing screening and polymer emulsion-solvent mixing and so on, and then are made into a building material which takes low-temperature ceramic mineral generated by the hydration of an inorganic waste residue gelating material as matrix phase and waste residue particle, waste gypsum and a hydration product thereof as disperse phase through the mixing, forming and maintenance working operation of a semi-finished product raw material. The building material has excellent mechanical property, high comprehensive utilization rate of wastes, more derivative products and stable performance.

Owner:KUNMING UNIV OF SCI & TECH

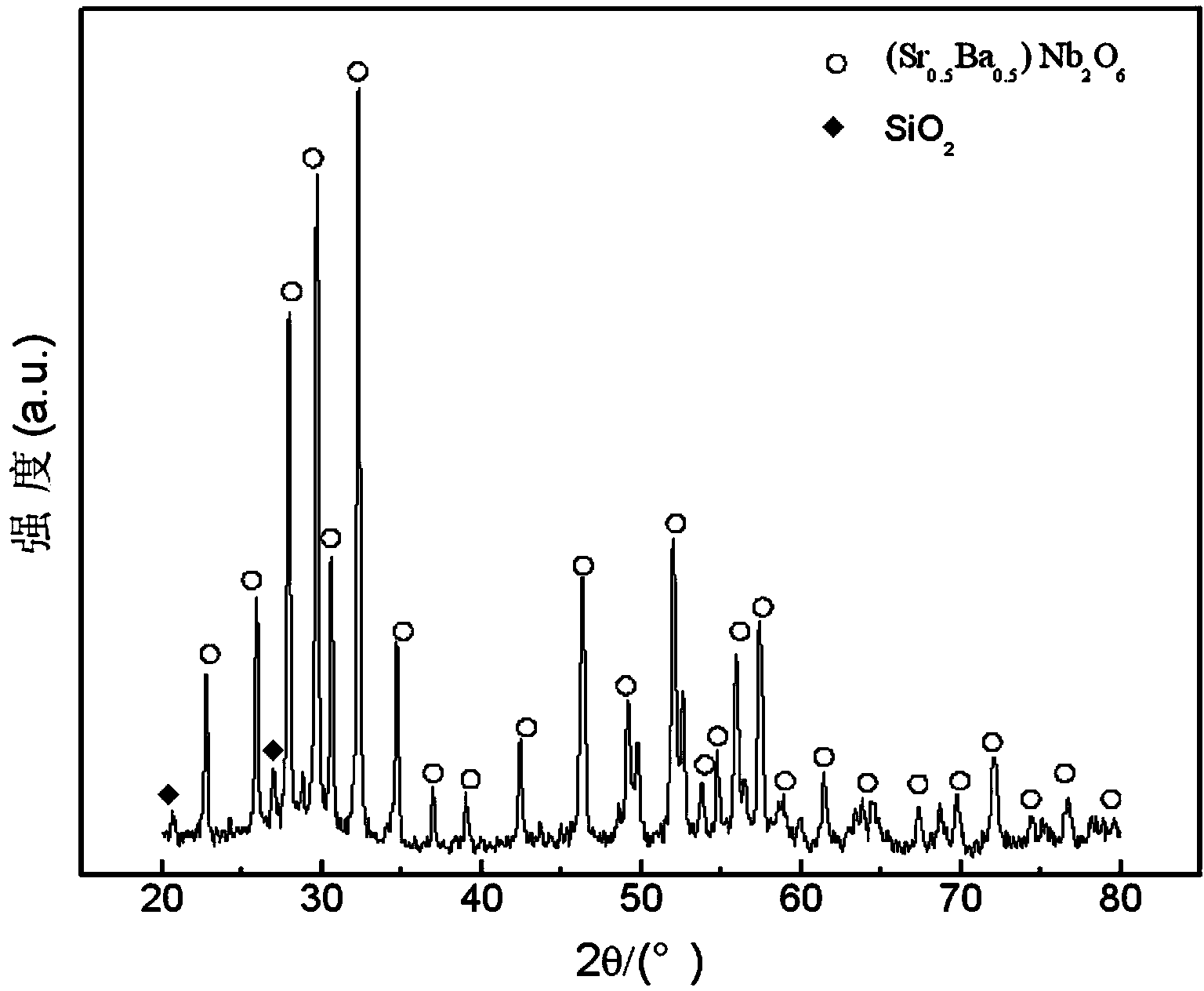

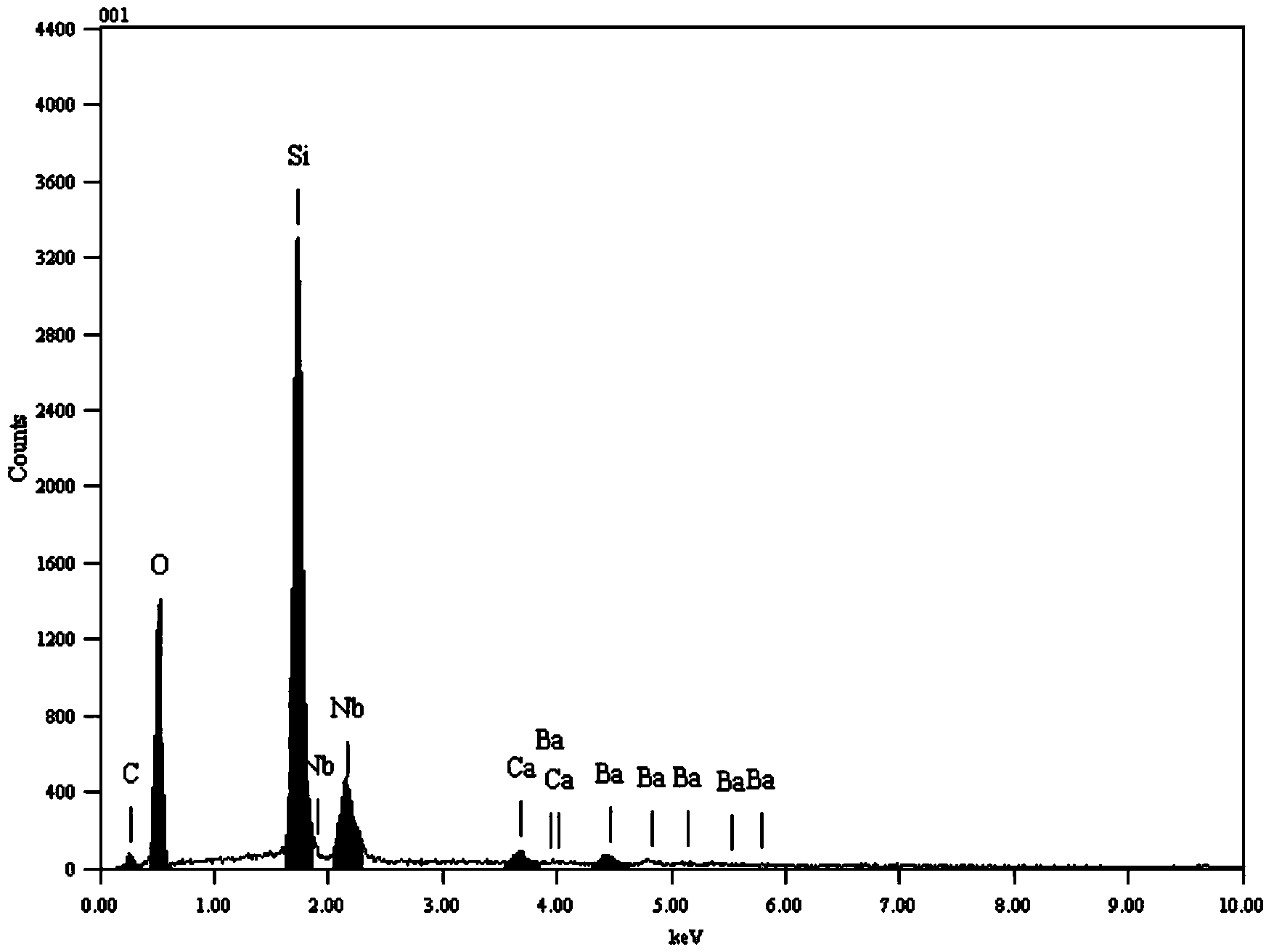

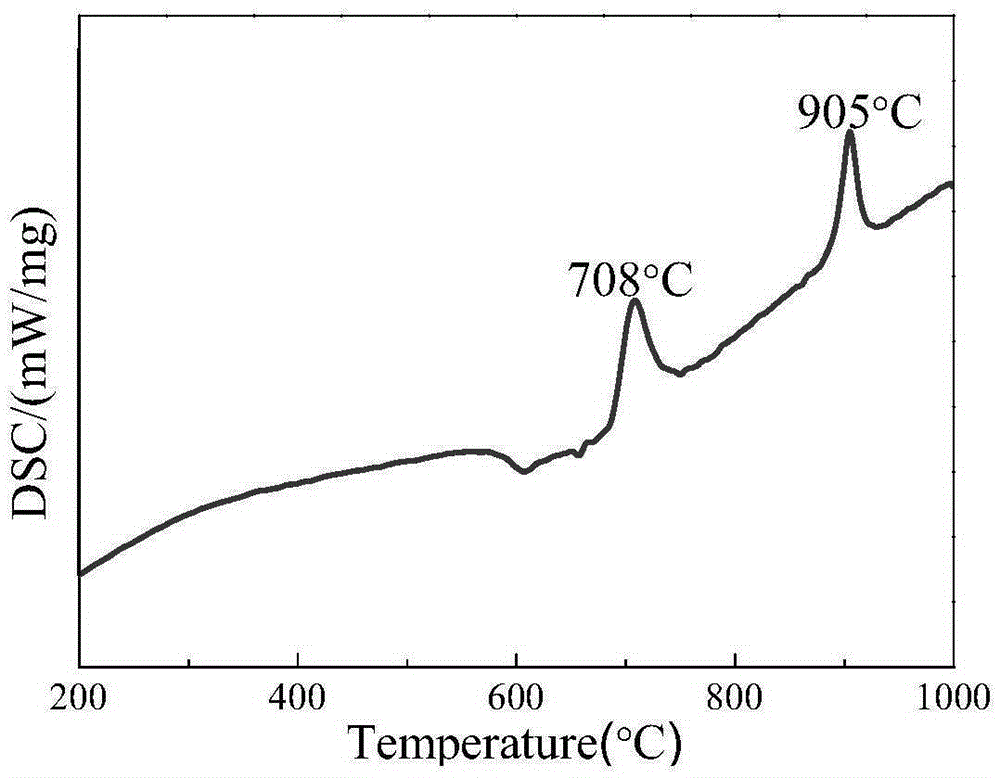

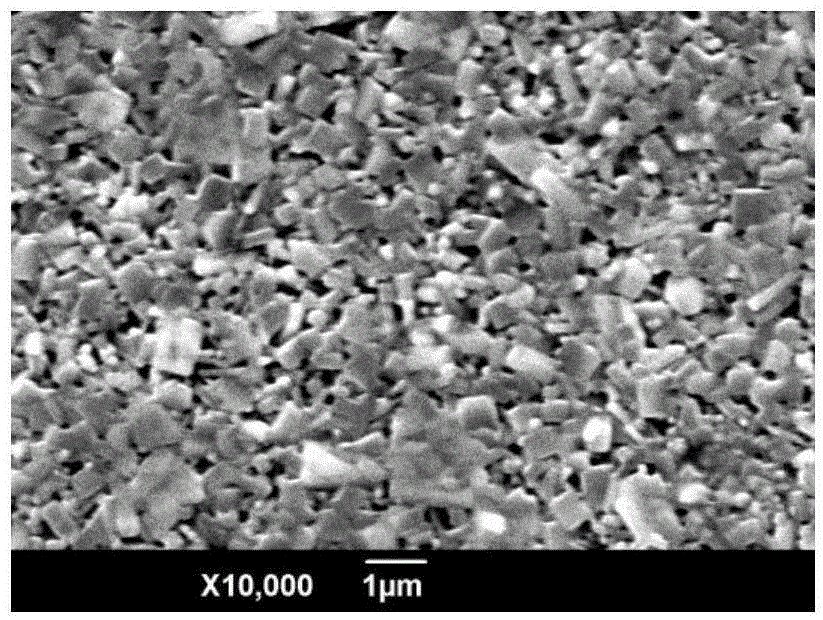

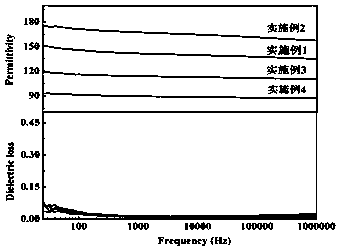

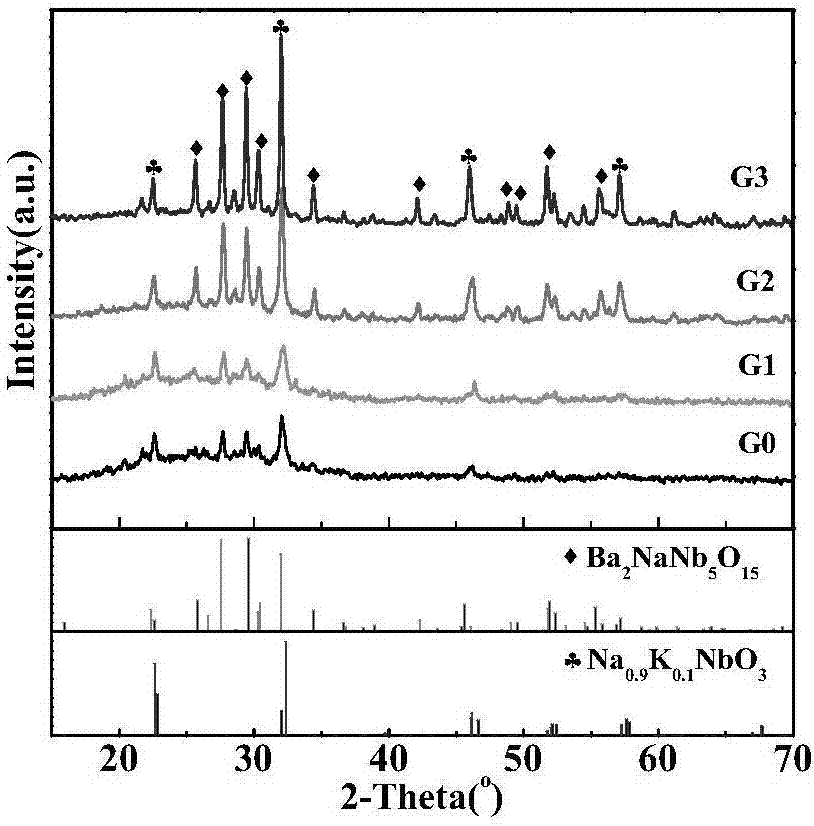

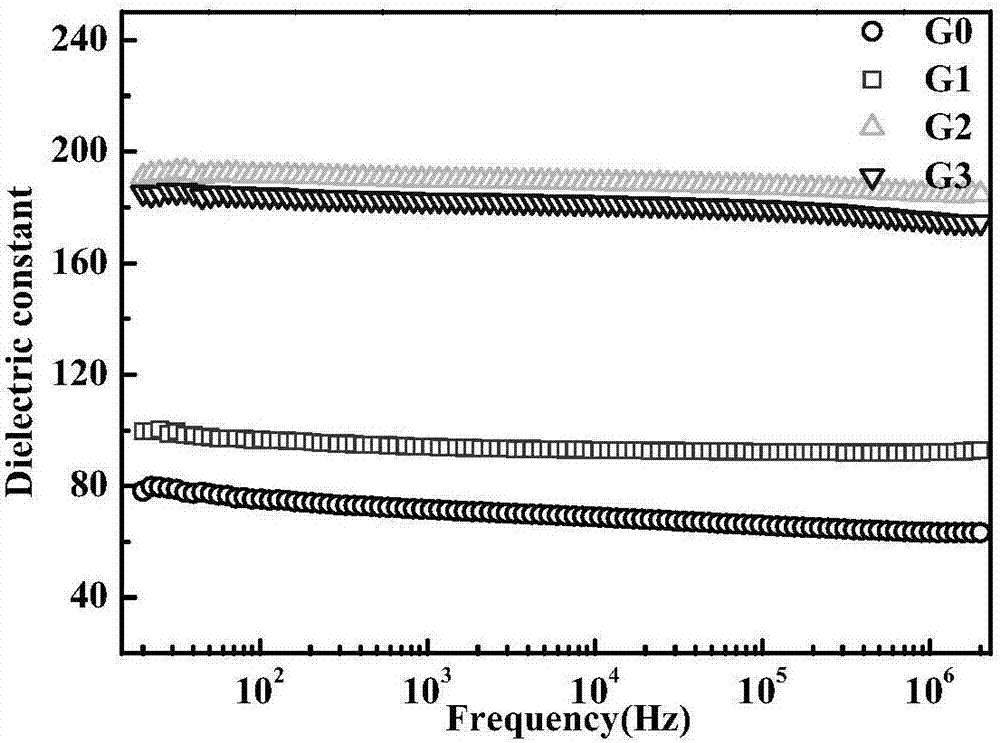

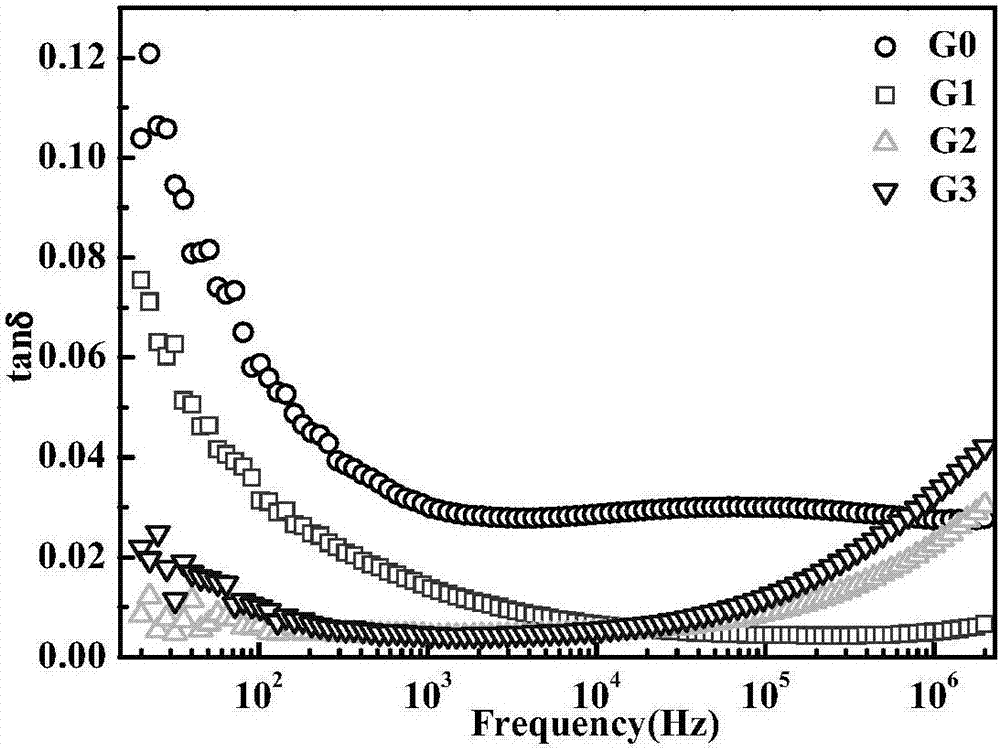

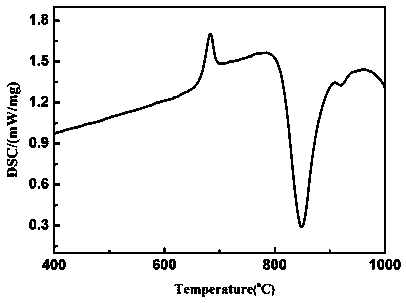

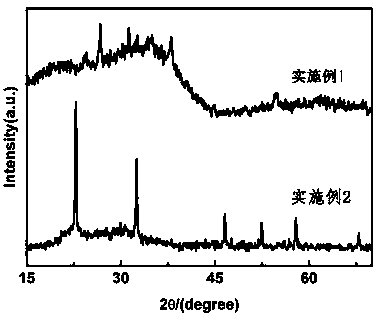

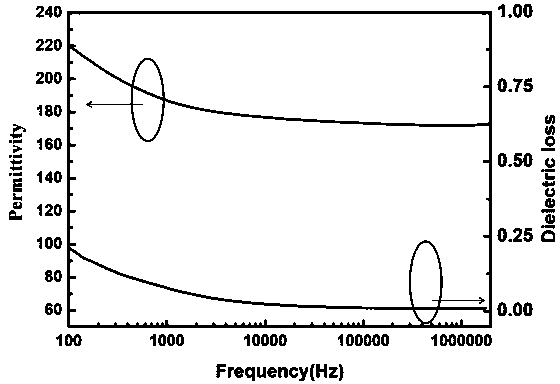

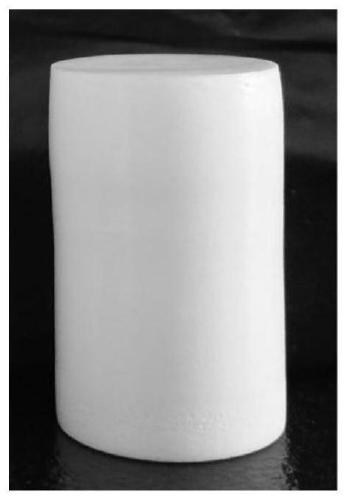

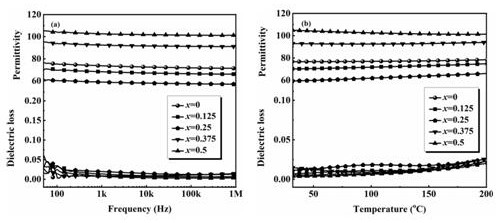

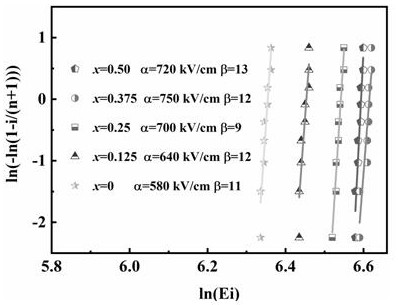

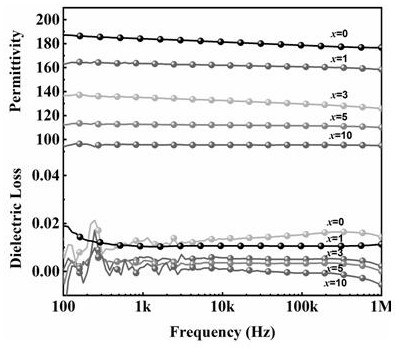

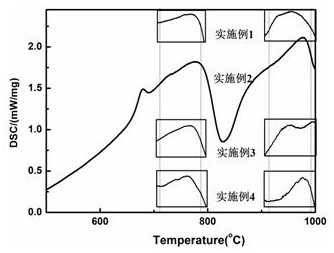

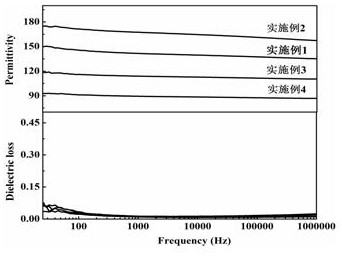

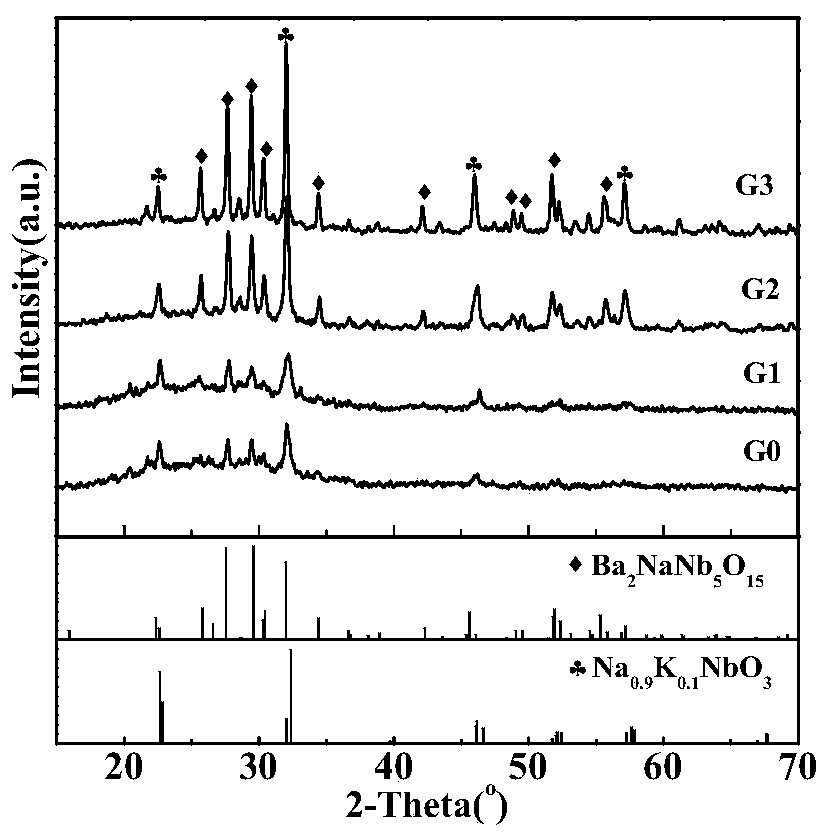

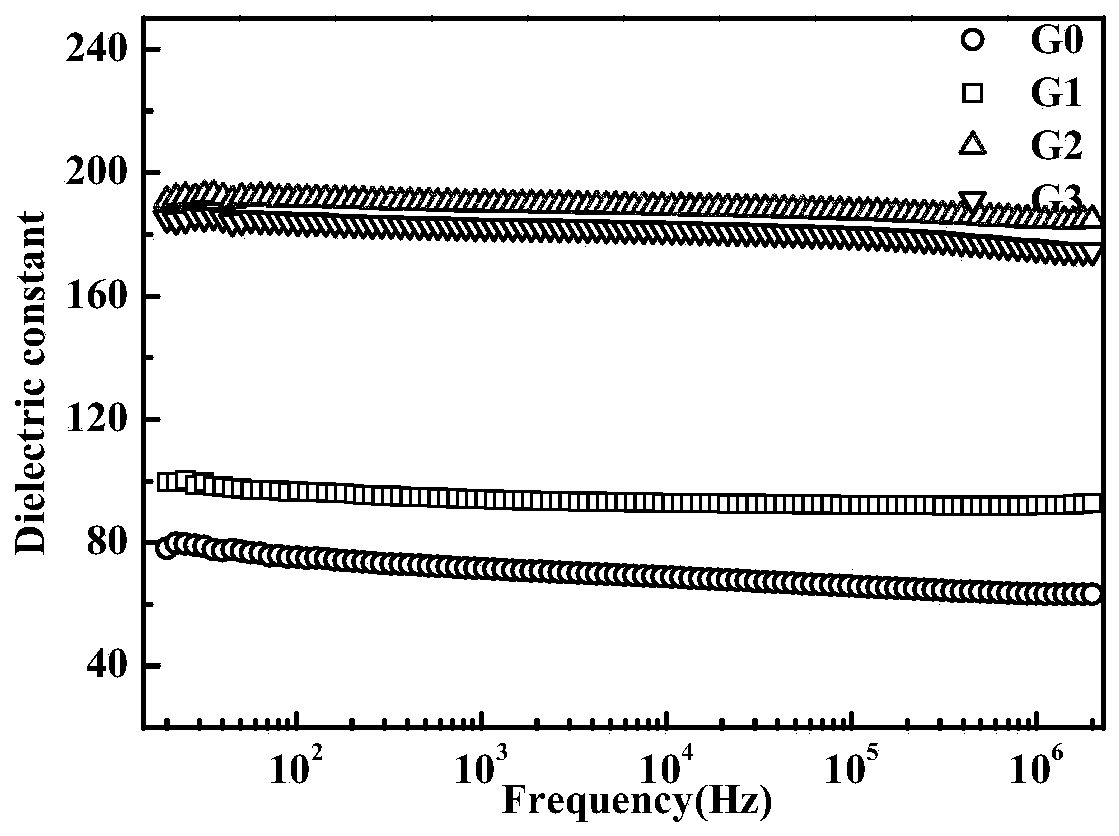

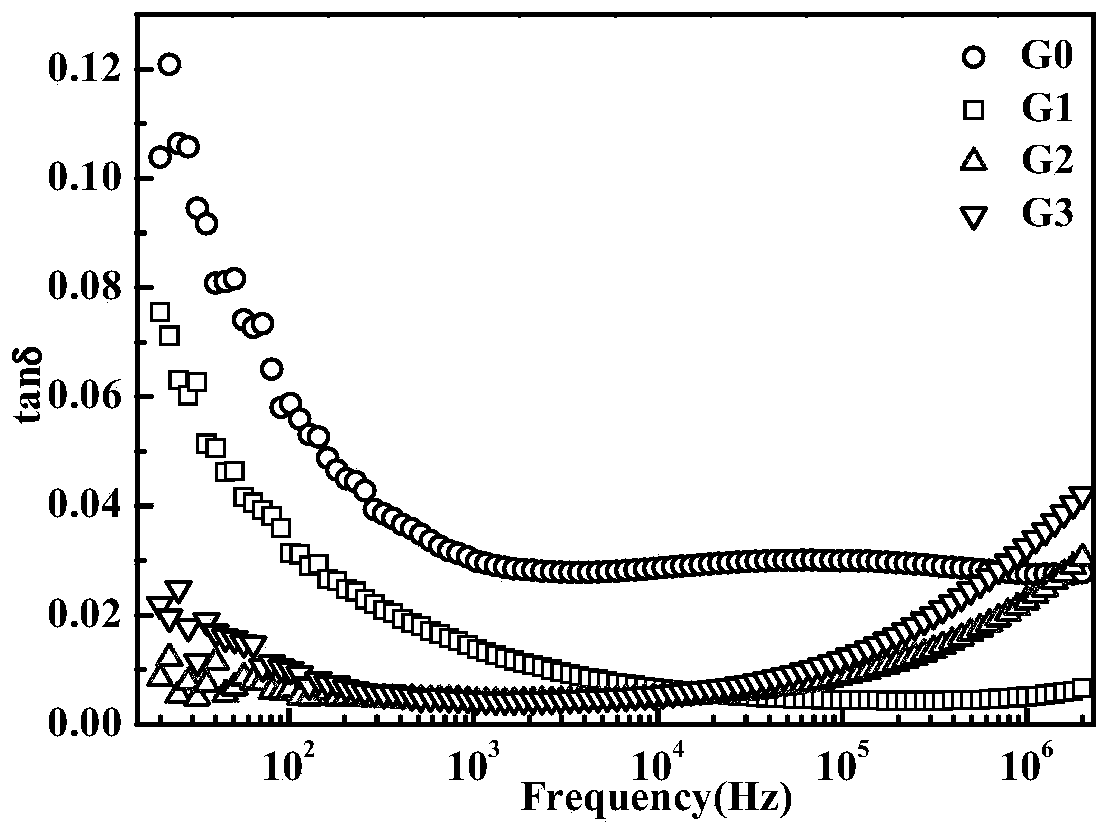

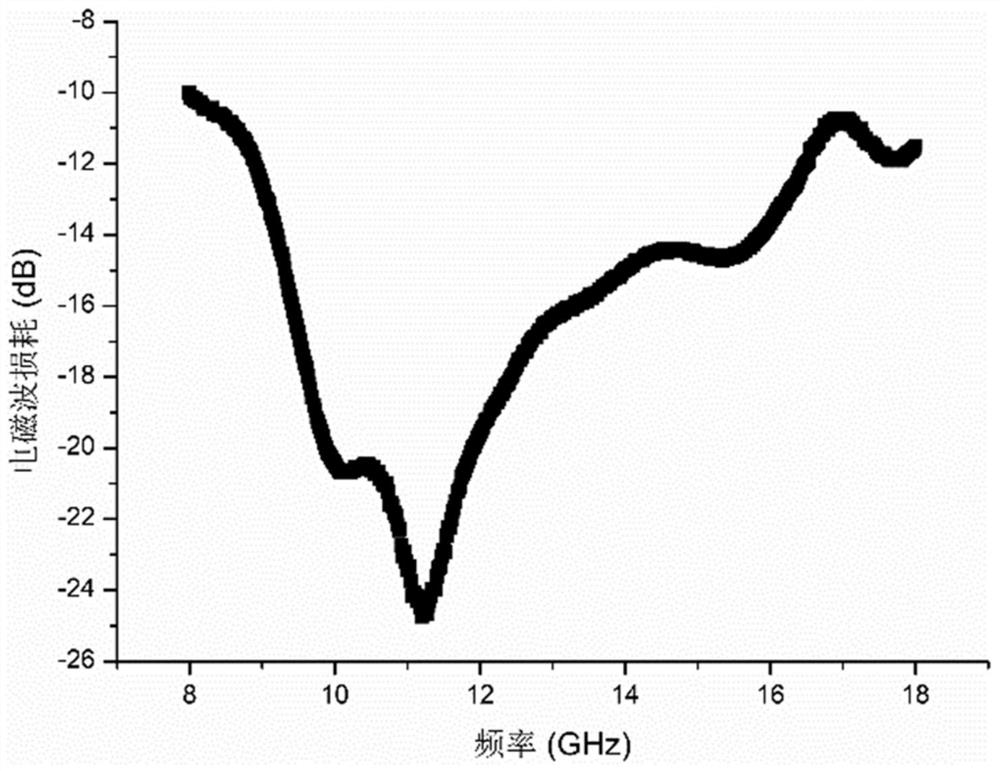

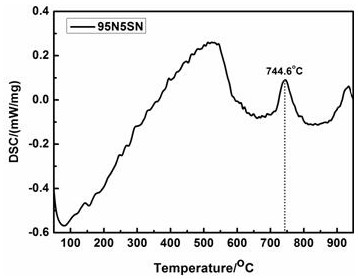

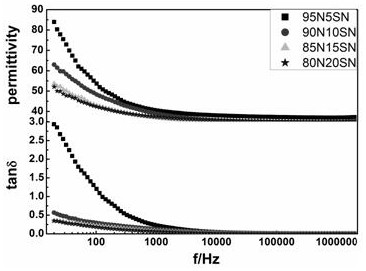

Strontium barium niobate glass ceramic material with high dielectric constant and high breakdown field strength and preparation method thereof

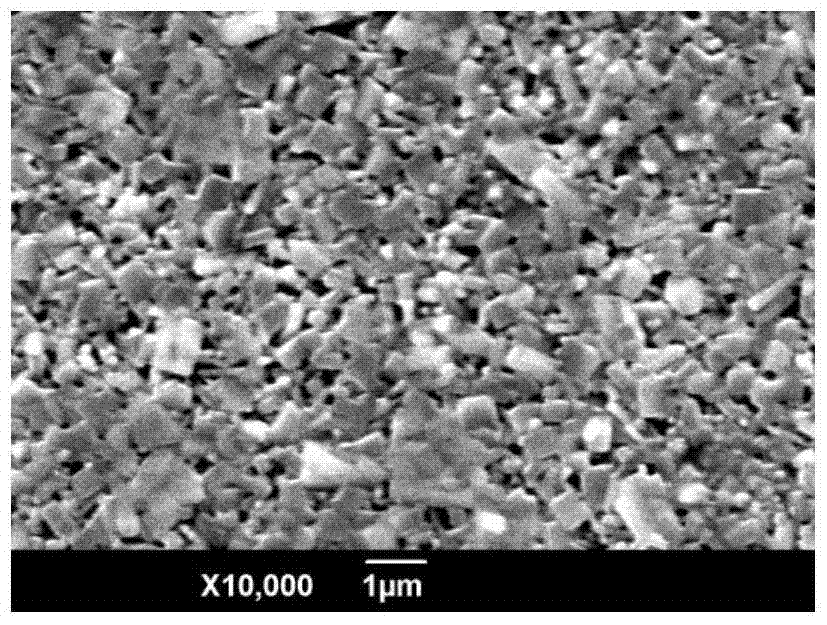

ActiveCN103880288AReduce porosityExperiment operation is simpleStrontium barium niobateDielectric loss

The invention discloses a strontium barium niobate glass ceramic material with high dielectric constant and high breakdown field strength and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing SrCO3, BaCO3, Nb2O5, CaCO3, SiO2, H3BO3 and BaF2, uniformly melting at 1300-1400 DEG C, molding and rapidly annealing to obtain annealed glass; crystalizing the annealed glass at the crystallization temperature and then cooling in a furnace to obtain the strontium barium niobate glass ceramic material. By adopting a melting method to prepare the strontium barium niobate glass ceramic material, the method is simple and convenient, and various molding methods are available. The strontium barium niobate glass ceramic material is treated at first and then is subjected to XRD (X-Ray Diffraction), SEM and EDS tests, and the test results prove that the strontium barium niobate glass ceramic material prepared by the method disclosed by the invention is ferroelectric glass ceramic with high dielectric constant, high breakdown field strength and low dielectric loss.

Owner:SHAANXI UNIV OF SCI & TECH

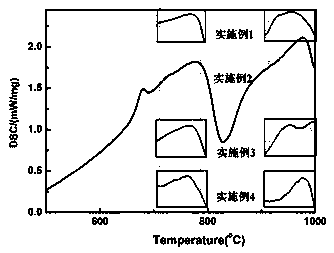

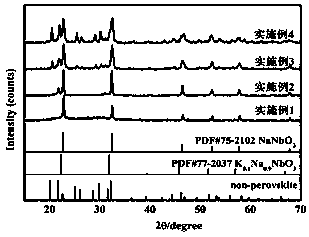

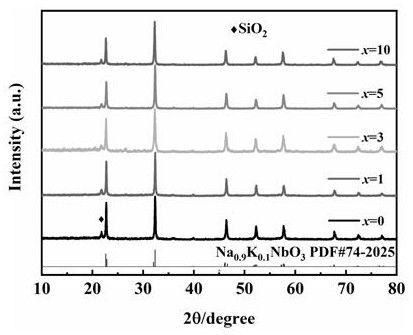

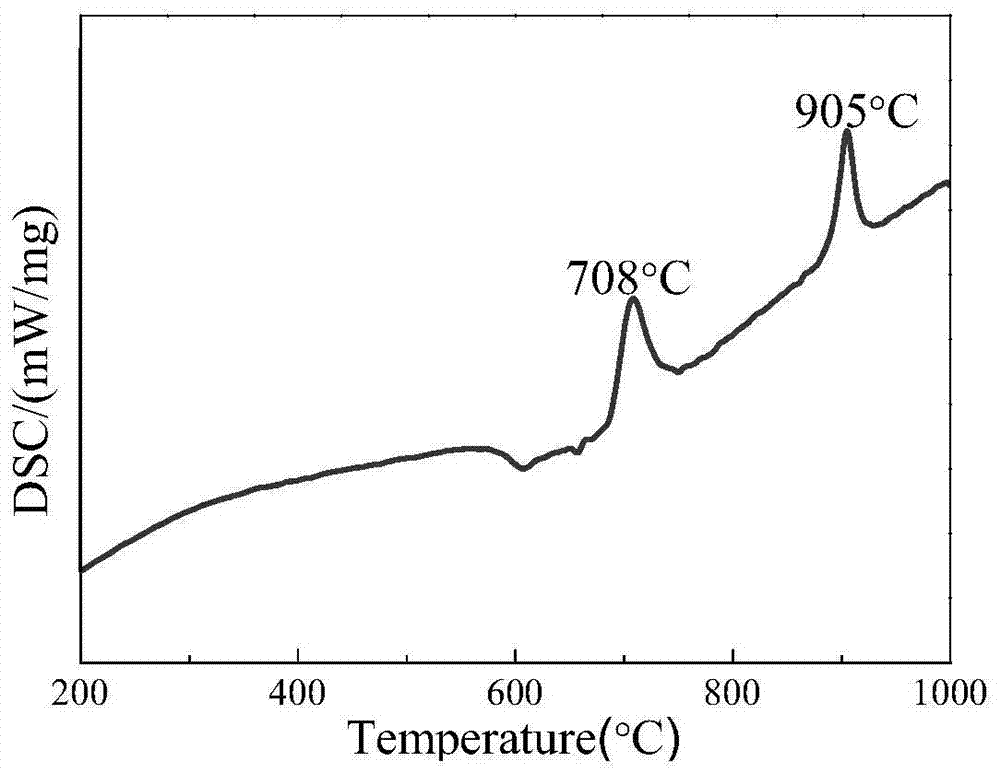

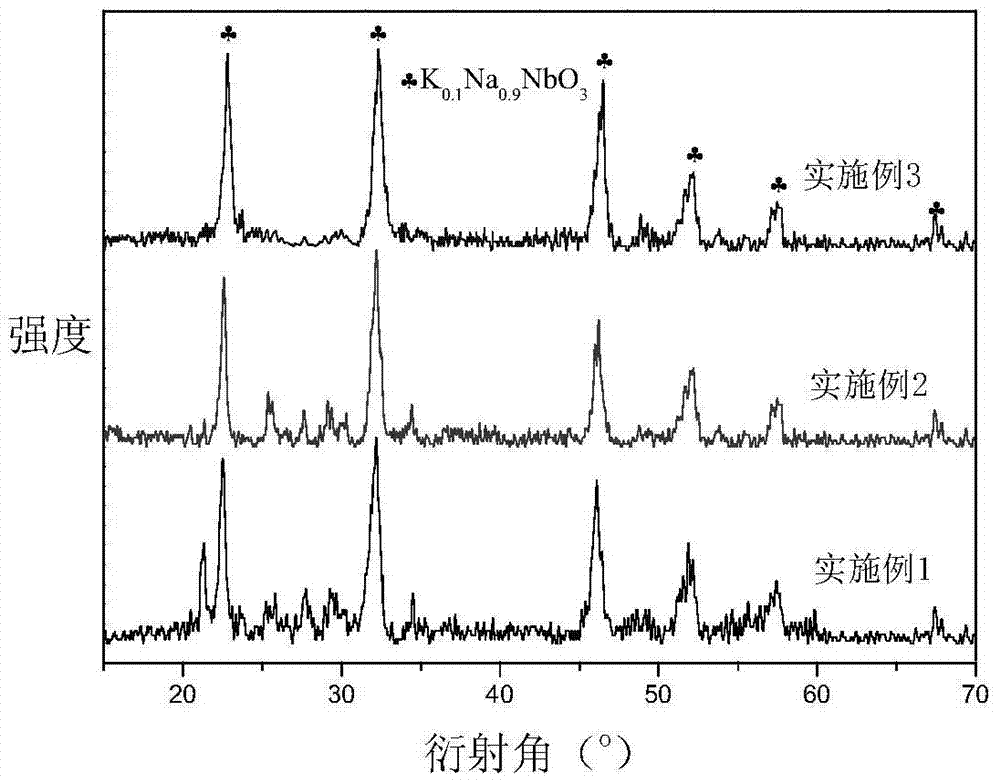

K2O-Na2O-Nb2O5-SiO2-B2O3 system glass ceramic material used for energy storage, and preparation method thereof

The invention relates to a K2O-Na2O-Nb2O5-SiO2-B2O3 system glass ceramic material used for energy storage, and a preparation method thereof. The method comprises the following steps: mixing K2CO3, Na2CO3, Nb2O5, SiO2, H3BO3 and BaF2 according to a molar ratio of 15:15:30:4.2:(2-5), fusing, molding, annealing, and crystallizing to prepare the material. Alkali metal oxides in raw materials exist in the glass system as a network modifier to destroy the network structure of glass, so the formula of the glass is simplified, the cost is reduced, and the quantity of kinds of precipitated impure phases is fundamentally reduced; a fusion technology is adopted, so the raw materials highly and uniformly react, and the experiment operation is simple; annealing can effectively eliminate internal stress; and segment heat insulation is adopted in the crystallization treatment process, so a crystal phase completely grows, crystal precipitation is thorough, and obtaining of glass ceramic with fine internal crystal grins, high homogenization degree and high energy storage density is facilitated.

Owner:SHAANXI UNIV OF SCI & TECH

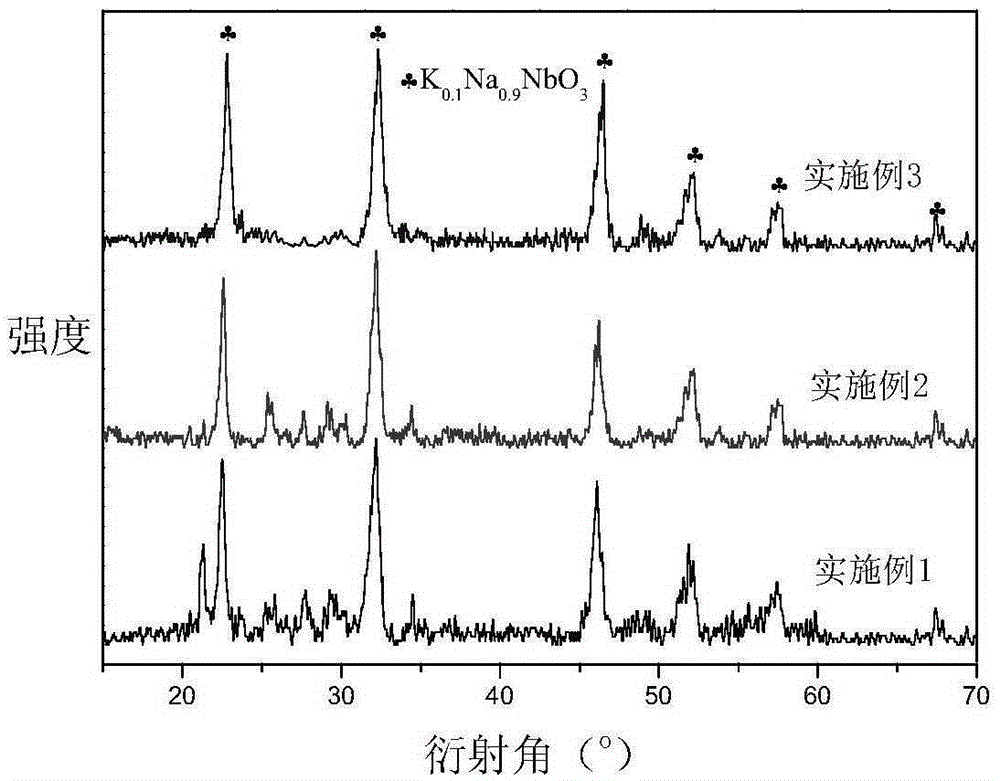

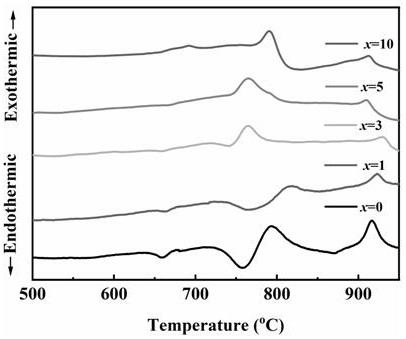

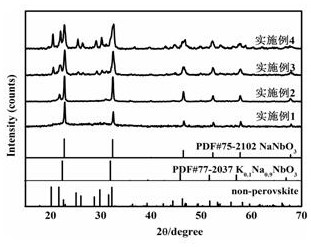

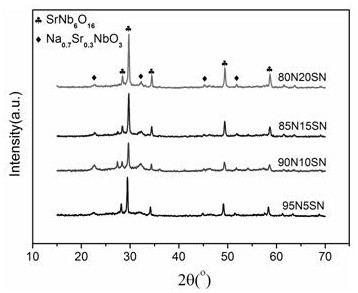

NaNbO3 phase containing Na2O-K2O-Nb2O5-SiO2 low dielectric loss energy storage glass ceramic

The invention relates to a NaNbO3 phase containing Na2O-K2O-Nb2O5-SiO2 low dielectric loss energy storage glass ceramic material, the microcrystal glass material is prepared by mixing a glass phase and a crystal phase, fusing, cooling and molding, annealing, and conducting crystallization heat treatment; wherein the glass phase accounts for 20% according to mole percent, and the balance is the crystal phase; the crystal phase is prepared by heating and fusing Na2CO3, K2CO3 and Nb2O5 at the molar ratio of x:(1-x):1, wherein x is more than or equal to 0.7 and less than or equal to 1. The dielectric loss of the prepared potassium-sodium niobate based energy storage microcrystal glass material is low; the added Na2CO3 not only has an effect on regulating the composition of the crystal phase ofa potassium-sodium niobate system, but also has a certain effect on promoting the crystallization process, the NaNbO3 phase favorable for the high energy storage density is formed, and the high energy storage density glass ceramic material is finally obtained.

Owner:SHAANXI UNIV OF SCI & TECH

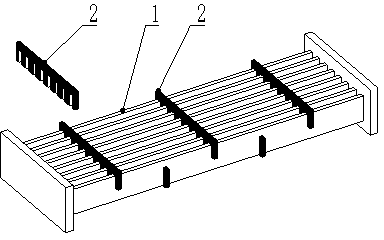

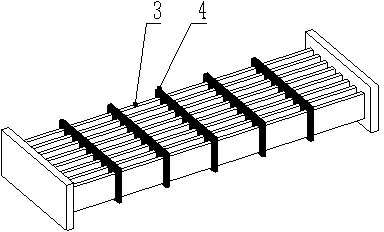

Electrostatic precipitator

InactiveCN104785371ANo discharge phenomenonVarious molding methodsElectrostatic separation detailsElectricityDie casting

The present invention provides an electrostatic precipitator, comprising an electrically charged unit and an electrostatic dust collection unit, and the electrostatic precipitator is characterized in that: the electrostatic dust collection unit adopts a spacer made from a metal material or an inorganic conductive material to keep a certain distance between dust collection plates and sheets. The air contact surface of the dust collection plates and sheets is made from an insulation material, so that adjacent dust collection plates and sheets may not be conducted. The spacer can be prepared by stamping molding of a metal plate such as an aluminum plate and a copper plate, also can be prepared by die-cast molding, metal bar pressing molding, and other manners, and an inorganic conductive material also can be used. Compared with a traditional electrostatic precipitator, electrostatic precipitator has the advantages of high efficiency, no arc discharge, low ozone and higher security.

Owner:QUALITY AIR SHENZHEN TECH CO LTD

KNN-based (sodium potassium niobate-based) energy storage microcrystalline glass material with ultralow dielectric loss and preparation method

The invention relates to a KNN-based (sodium potassium niobate-based) energy storage microcrystalline glass material with ultralow dielectric loss and a preparation method. The microcrystalline glass material is prepared from a glass phase and a crystal phase through mixing, fusing, cooling and molding, annealing, carrying out crystallization heat treatment, wherein according to mol percent, the glass phase accounts for 20 percent to 50 percent and the balance is the crystal phase; the crystal phase is composed of K2CO3, Na2CO3, Nb2O5 and BaCO3 at a mol ratio of (3-x) to (3-x) to 6 to 2x and x is more than 0 and less than or equal to 2.5. The KNN-based energy storage microcrystalline glass material prepared by the preparation method has extremely low dielectric loss; BaO is introduced, has the effect of adjusting the composition of the crystal phase of a sodium potassium niobate system and also has a certain promotion effect on a devitrification process and devitrification is accelerated by rare-earth metal ions; the BaO can also generate a pinning effect, and adverse impacts, caused by interface polarization, on breakdown and worsening are weakened; finally, the microcrystalline glass material with a high dielectric constant is obtained.

Owner:SHAANXI UNIV OF SCI & TECH

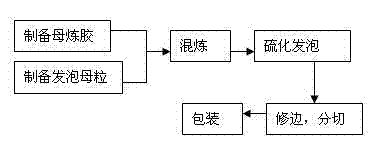

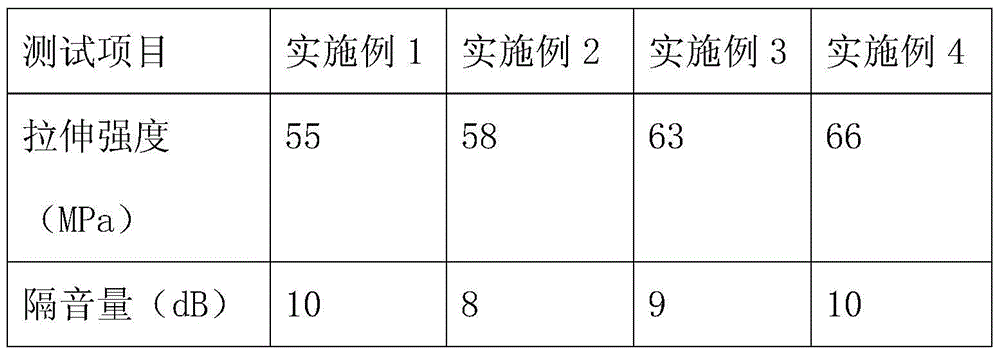

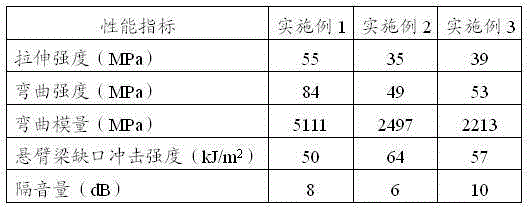

Composite foam sound insulation material and preparation method thereof

The invention discloses a composite foam sound insulation material. The material is composed of the following components in parts by weight: 49 parts of halogenated butyl rubber sulfurization system, 120 parts of sound insulation material master batch, and 40 parts of foaming master batch; wherein the halogenated butyl rubber sulfurization system comprises the following components in parts by weight: 30 parts of halogenated butyl rubber, 12 parts of promoter, 2 parts of promoter, 2 parts of anti-coking agent, 1 part of promoter, and 3 parts of sulfurization agent; the foaming master batch comprises the following components in parts by weight: 20 parts of halogenated butyl rubber and 20 parts of foaming agent; the sound insulation material master batch comprises the following components in parts by weight: 50 parts of halogenated butyl rubber, 50 parts of sound insulation material, and 20 parts of plasticizer. The invention also discloses a preparation method of the composite foam sound insulation material. The composite foam sound insulation material has the advantages of good sound insulation and sound absorbing property, light weight, and excellent heat insulation property, and at the same time has the characteristics of adaptability to various appearances in the actual use, excellent elasticity, fire retardant property, environment-friendliness, and chemical corrosion resistance.

Owner:李巍巍 +1

NaNbO3-based Na2O-Nb2O5-SiO2 high-dielectric-constant energy-storage glass ceramic and preparation method

InactiveCN109626828AReduce porosityLow dielectric lossGlass shaping apparatusElectricityDielectric loss

The invention relates to a NaNbO3-based Na2O-Nb2O5-SiO2 high-dielectric-constant energy-storage glass ceramic and a preparation method of the glass ceramic. The glass ceramic material is prepared through the steps that a glass phase and a crystal phase are subjected to mixing, fusion, cooling formation, annealing and heat treatment for crystallization, wherein the glass phase accounts for, by mole, 0.1%, and the balance is the crystal phase; the crystal phase is formed by heating and fusing Na2CO3 and Nb2O5 in a mole ratio of 1:1. The NaNbO3-based energy-storage glass ceramic mateiral is low in dielectric loss; due to the addition of the NaCO3, the composition of the crystal phase of the potassium-sodium niobate system can be adjusted, moreover, a certain of promoting effect on the crystallization process is achieved, the NaNbO3 phase high in storage energy density is easily formed, and finally, the high-storage-energy-density glass ceramic material is obtained.

Owner:SHAANXI UNIV OF SCI & TECH

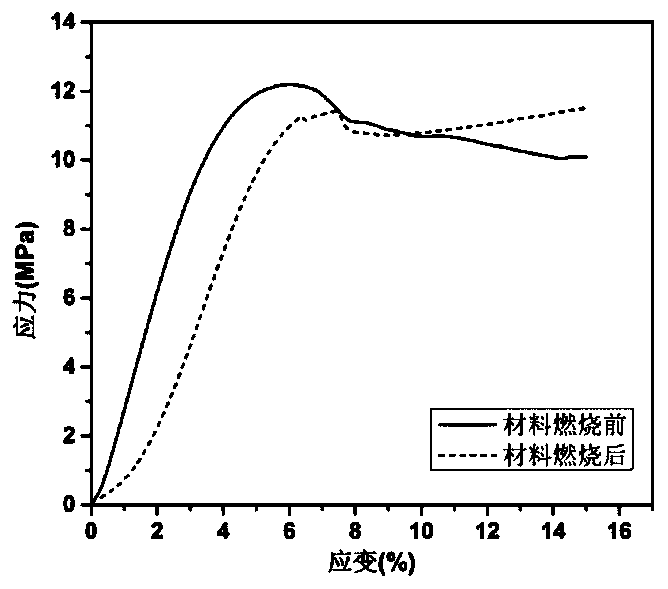

Flame-retardant smoke-inhibition light-weight high-strength high-molecular material, and preparation method thereof

The invention provides a flame-retardant smoke-inhibition light-weight high-strength high-molecular material, and a preparation method thereof. The flame-retardant smoke-inhibition light-weight high-strength high-molecular material comprises following steps: 1, a gelatinizing agent, an oil phase reaction monomer, an oil phase crosslinking agent, an initiator, and a composite flame-retardant smoke-inhibition agent are mixed, and are stirred to be uniform, a dispersion phase is added for emulsification so as to form a uniform fine gel emulsion which is stagnant in upside down position; the gel emulsion is subjected to thermal induced polymerization reaction, and after reaction drying is carried out so as to obtain the flame-retardant smoke-inhibition light-weight high-strength high-molecularmaterial. The flame resistance of the flame-retardant smoke-inhibition light-weight high-strength high-molecular material is capable of reaching V-0 grade or higher only with slightly reduced mechanical performance.

Owner:SHAANXI NORMAL UNIV

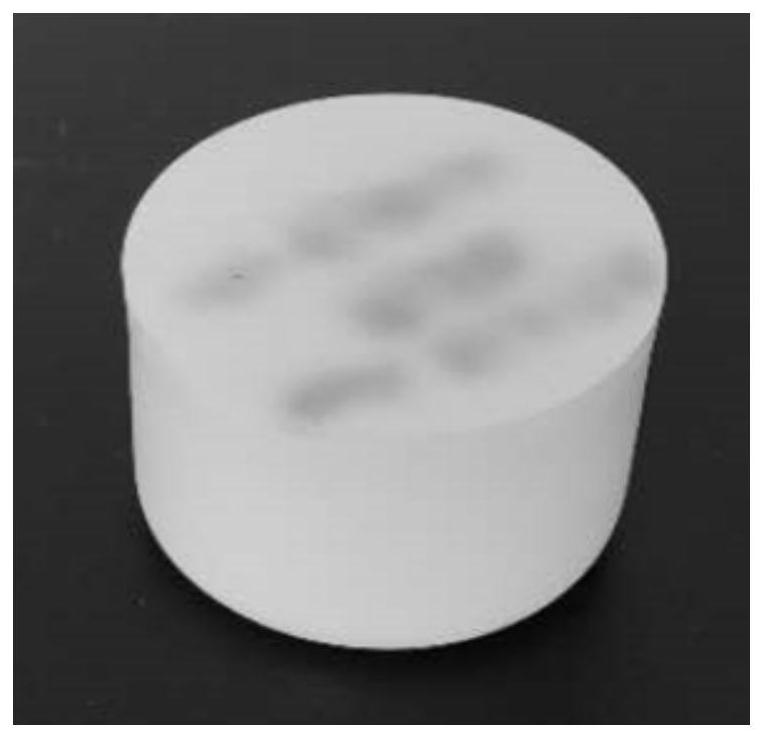

Novel sustained-release material and preparation method thereof

ActiveCN111607044AVarious molding methodsRelease noneBiocidePest repellentsEmulsionPore distribution

The invention discloses a novel sustained-release material and a preparation method thereof, and belongs to the field of sustained-release materials. According to the method, the variety and using amount of a stabliizing agent are adjusted, the volume ratio of adispersionphase to acontinuous phase is controlled, a water-in-oil type gel emulsion which is uniform in foam pore distribution, high in closed pore rate, relatively thick in pore wall and about 20-100 microns in pore size is prepared, completely embedding of a sustained-release agent into the closed pore structure is realized, andheating polymerization is carried out to obtain a novel green sustained-release material. As the sustained-release agent is completely embedded in the dispersion phase with the closed-pore structure, the sustained-release agent can only be slowly released from the free volume of the continuous-phase high polymer material through three steps of adsorption, permeation and desorption, and the problem thatthe sustained-release time is too short due to external light and heat is effectively avoided. The novel sustained-release material disclosed by the invention is diversified in molding method and rich in application form.

Owner:SHAANXI NORMAL UNIV

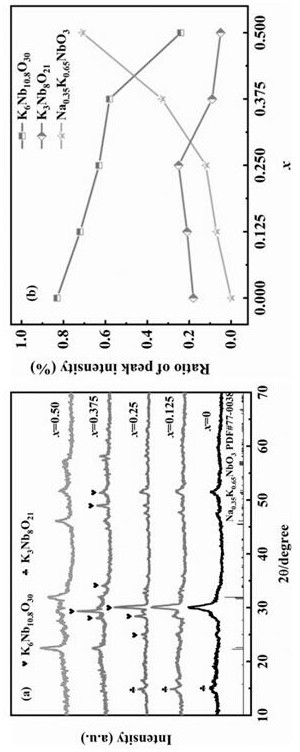

Niobate glass ceramic with alkali metal oxide substitute, low dielectric loss and high energy storage density as well as preparation method and application thereof

ActiveCN112225460AImprove compactnessReduce porosityGlass shaping apparatusAlkali metal oxideHigh energy

The invention relates to a glass ceramic material which substitutes K2ONb2O5SiO2 with alkali metal oxide Na2O and has low dielectric loss and high energy storage density. A preparation method of the material comprises the following steps: firstly, taking K2CO3, Na2CO3, Nb2O5 and SiO2 as raw materials according to a chemical formula of 40[(1-x)K2O-xNa2O]-40Nb2O5-20SiO2 (the x is less than or equalto 0.500), uniformly mixing the powder through mechanical ball milling, and performing annealing; and performing melting, cooling molding and annealing to obtain a glass block, and performing heat preservation at 800 DEG C for 2 h, and performing crystallization treatment to obtain the glass ceramic material. The method is simple in preparation process, the raw materials are low in price, the manufacturing cost is low, a linear hysteresis loop can be obtained at the room temperature, the energy storage density reaches 2.44 J / cm<3> to the maximum, the dielectric loss is lower than 0.02, and theenergy storage efficiency is guaranteed to be 94% or above at the high temperature of 200 DEG C.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of sound insulation material for building and preparation method thereof

InactiveCN104326698BImprove sound insulationImprove mechanical propertiesFiberTrimethylene carbonate

The invention discloses a building sound insulation material and a preparation method thereof, the building sound insulation material comprises the following components by weight: 66-72 parts of polyethylene, 8-12 parts of organic fiber, 5-12 parts of coal gangue powder, 5-12 parts of fly ash, 8-10 parts of poly trimethylene carbonate, 5-8 parts of montmorillonite and 0.05-1 part of sodium humate. The invention also provides the preparation method of the building sound insulation material, and the method comprises the following steps: (1) weighing 66-72 parts by weight of polyethylene, 8-12 parts by weight of organic fiber, 5-12 parts by weight of coal gangue powder, 5-12 parts by weight of fly ash, 8-10 parts by weight of poly trimethylene carbonate, and 5-8 parts by weight of montmorillonite; (2) putting the component into a high pressure homogenizer, stirring for 30min at 65-70 DEG C under 21.5-22MPa; and (3) sequentially adding the 0.05-1 part of sodium humate, stirring evenly, and firing 2-3 hours at 780-850 Deg C to obtain the building sound insulation material.

Owner:JIANGSU MAOLONG MACHINERY MFG

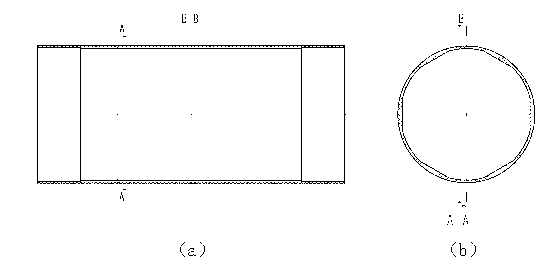

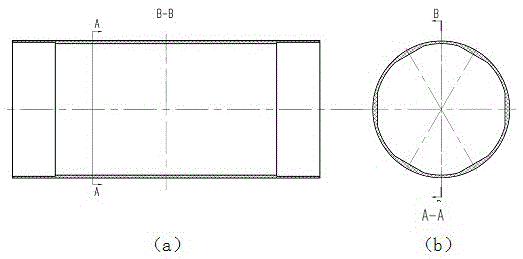

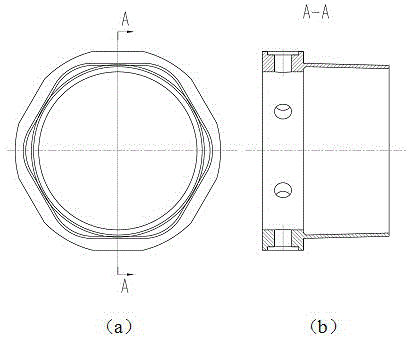

Profile-matched bonding glass fiber reinforced plastic transmission shaft and its production technology

The invention discloses a profile-matched bonding glass fiber reinforced plastic transmission shaft and its production technology. The profile-matched bonding glass fiber reinforced plastic transmission shaft comprises a metal flange and a glass fiber reinforced plastic intermedium tube, which are adhered together. The metal flange and the glass fiber reinforced plastic intermedium tube have a bonding matching surface. The metal flange and the glass fiber reinforced plastic intermedium tube both have a polygonoun and arc transition matching profile. The bonding matching surface of the metal flange and the glass fiber reinforced plastic intermedium tube is a polygonoun and arc transition bonding structure. Through the profile-matched bonding surface, torsional rigidity for self-locking between the matched profile will be greatly increased; bonding strength reliability is greatly raised; and by the adoption of the conical surface matched bonding surface, during the bonding process, matching between the metal flange and the glass fiber reinforced plastic intermedium tube has a self-centering effect, bonding operation difficulty can be reduced, and bonding manufacturability is raised.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

A kind of high tenacity sound insulation composite material and preparation method thereof

ActiveCN103160018BHigh form factor design freedomImprove sound insulationCoatingsMasterbatchPolypropylene composites

The present invention discloses a high toughness sound insulation composite material, which is prepared from the following components, by weight, 30-50 parts of an organic fiber toughened polypropylene composite material, and 50-70 parts of a sound insulation material masterbatch, wherein the organic fiber toughened polypropylene composite material comprises the following components, by weight, 46-67.4 parts of polypropylene, 30-50 parts of organic fibers, 2-3 parts of a compatibilizing agent, and 0.6 part of an antioxidant, and the sound insulation material masterbatch comprises the following components, by weight, 49.7-59.7 parts of polypropylene, 40-50 parts of a sound insulation filling material, and 0.3 part of an antioxidant. The invention further discloses a high toughness sound insulation composite material preparation method. The high toughness sound insulation composite material has characteristics of good sound insulation, excellent mechanical property, convenient processing molding, high product shape design freedom degree, excellent elasticity, chemical corrosion resistance and the like.

Owner:HEFEI GENIUS NEW MATERIALS

Glass ceramic for realizing high dielectric constant and high breakdown performance by regulating glass network structure and preparation method thereof

ActiveCN113233772AHigh energy storageSuppression of interfacial polarizationGlass matrixBreakdown strength

The invention relates to a glass ceramic capable of regulating and controlling a glass network structure to realize high dielectric constant and high breakdown performance and a preparation method thereof. The glass ceramic material is prepared by compounding a crystal phase and a glass phase, wherein the crystal phase is prepared from raw materials through mixing, melting, cooling molding, annealing and crystallization heat treatment; the crystal phase is prepared from La2O3, Na2CO3, K2CO3 and Nb2O5 in a molar ratio of x: (35-x): 5: 40 (x is equal to 0, 1, 3, 5 and 10); the glass phase is SiO2; the molar ratio of the crystal phase to the glass phase is 4: 1. The potassium-sodium niobate-based dielectric glass ceramic material prepared by the invention is high in dielectric constant and high in breakdown strength. According to the invention, La2O3 is added, so that a glass matrix obtains a compact glass network structure, and then the dielectric constant is improved through a reasonable crystallization treatment system.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing fully-compact TiN/Cu material with golden yellow surface through two-step sintering

ActiveCN114289713ASolve the difficult problem of sintering and densificationAchieve full densificationNitrogen atmosphereNitrogen gas

The invention discloses a method for preparing a fully-compact TiN / Cu material with a golden yellow surface through two-step sintering, and belongs to the field of powder metallurgy. Titanium powder and copper powder are evenly mixed according to a certain proportion, and the fully-compact TiN / Cu material with the golden yellow surface is obtained through forming and sintering. According to the method, in the nitrogen atmosphere sintering process, nitrogen reacts with titanium powder, and the TiN material with the golden yellow metal luster is generated in situ. Meanwhile, low-melting-point Cu serves as a binding phase and can be fully converted into a liquid phase in the high-temperature sintering process, combination between the binding phase and a hard phase is enhanced, and therefore full compactness of the TiN / Cu material is achieved. And finally, the TiN / Cu material is prepared through a powder metallurgy process, so that complexity and liberalization of the shape of a process product can be achieved, the utilization rate of raw materials can be increased, near-net forming is achieved, and the process cost is reduced.

Owner:UNIV OF SCI & TECH BEIJING +1

Nanometer air guide fiber membrane for improving fiber composite material appearance and preparation method and application thereof

InactiveCN106364117AEasy to prepareShort processSynthetic resin layered productsLaminationFiberProduct gas

The invention relates to a nanometer air guide fiber membrane for improving fiber composite material appearance and a preparation method and application thereof. The nanometer air guide fiber membrane comprises release layers which are arranged on the upper surface and the lower surface respectively, a nanometer air guide membrane layer and a fiber cloth layer which are arranged between the upper release layer and the lower release layer. According to the nanometer air guide fiber membrane for improving the fiber composite material appearance, the phenomena that the appearance in the original product is out of flatness, lack of glue and has pinholes are overcome, excess gas is exported by the nanometer air guide membrane, at the same time, by means of the composite structure of the nanometer air guide membrane and the fiber cloth, the introduction of the gas between layers is effectively reduced, the preparation method is simple, the technological process is short, the forming way is diversified, and it is beneficial to obtaining a full and smooth appearance, the quality and yield rate of the product are improved.

Owner:XIAMEN HOWER MATERIAL

A nano air-conducting fiber membrane for improving the appearance of fiber composites, its preparation method and application

InactiveCN106364117BReduce the introductionImprove qualitySynthetic resin layered productsLaminationFiberProduct gas

The invention relates to a nanometer air guide fiber membrane for improving fiber composite material appearance and a preparation method and application thereof. The nanometer air guide fiber membrane comprises release layers which are arranged on the upper surface and the lower surface respectively, a nanometer air guide membrane layer and a fiber cloth layer which are arranged between the upper release layer and the lower release layer. According to the nanometer air guide fiber membrane for improving the fiber composite material appearance, the phenomena that the appearance in the original product is out of flatness, lack of glue and has pinholes are overcome, excess gas is exported by the nanometer air guide membrane, at the same time, by means of the composite structure of the nanometer air guide membrane and the fiber cloth, the introduction of the gas between layers is effectively reduced, the preparation method is simple, the technological process is short, the forming way is diversified, and it is beneficial to obtaining a full and smooth appearance, the quality and yield rate of the product are improved.

Owner:XIAMEN HOWER MATERIAL

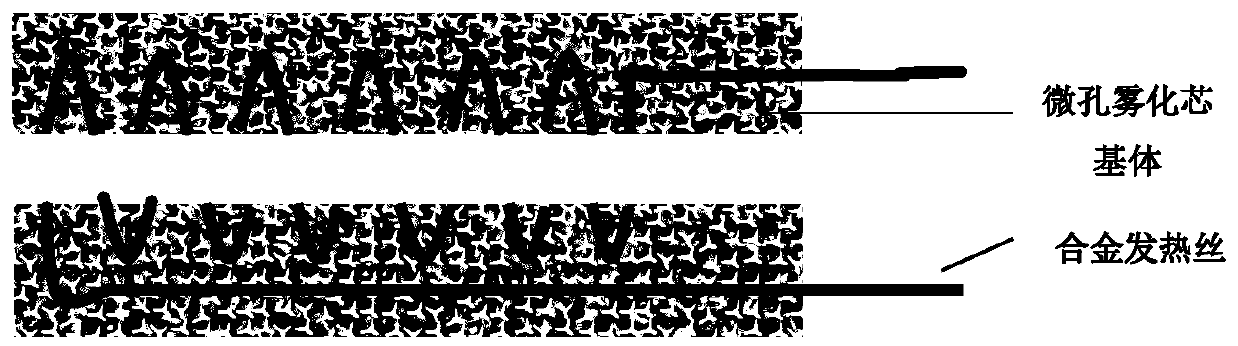

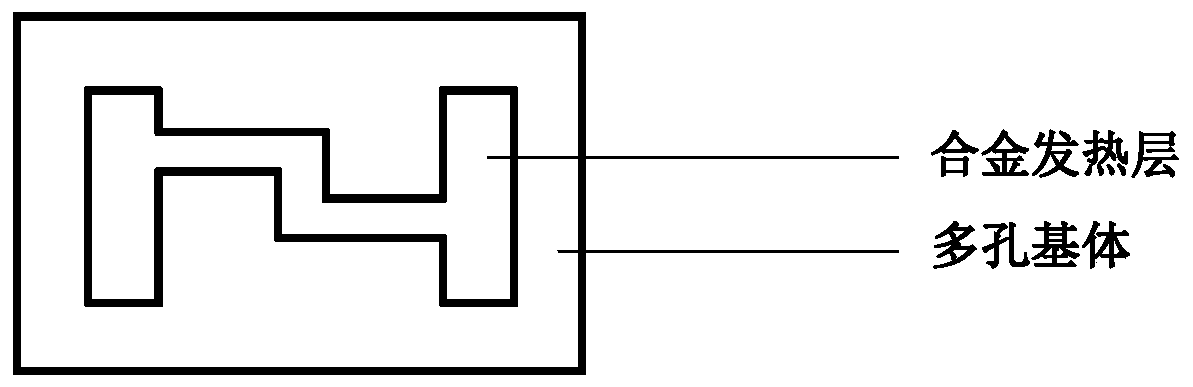

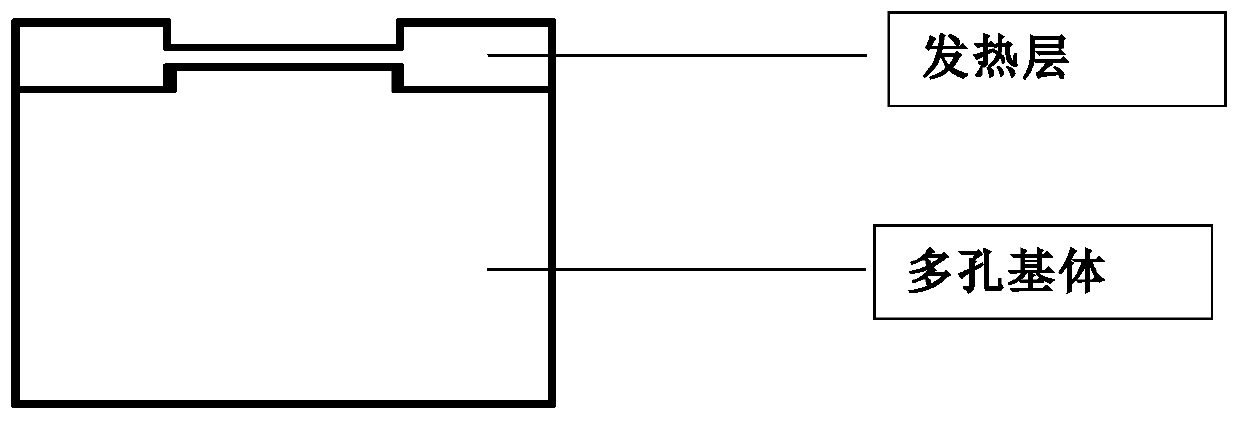

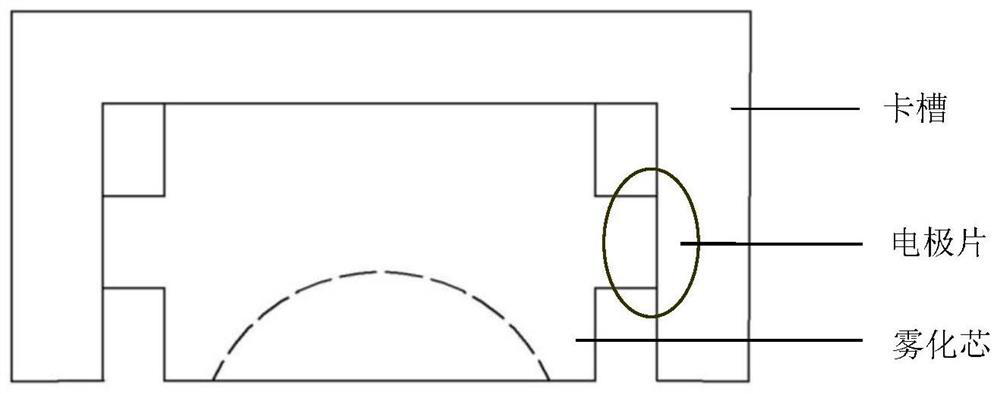

Preparation method of silicate-based microporous drug delivery atomizing core and heating component thereof

InactiveCN110105015BConvenient sourceVarious molding methodsAdditive manufacturing apparatusAuxillary shaping apparatusPhysical chemistryMaterials science

The invention provides a silicate-based microporous drug-delivery atomizing core and a preparation method for a heating assembly of the atomizing core, and belongs to the field of microporous inorganic composite materials. A mixture of a silicate-based clinker, a pore-forming agent and water is used as a base material for preparing the drug-delivery atomizing core, firearmor and other alloy materials are used as the resistance heating assembly, and the silicate-based microporous drug-delivery atomizing core and preparation of the heating assembly of the atomizing core can be implemented by using various forming technologies. The microporous silicate base material is used as an atomizing core base body, the high-temperature material sintering process after green body formation can be omitted, the problem can be avoided that the heating assembly is oxidated, embrittled and the like in the high-temperature sintering process, the production cost is greatly saved, and the preparation technology of the atomizing core is simplified. The atomizing core produced by using the method has the advantages of being precise in size, high in formation speed and the like.

Owner:UNIV OF SCI & TECH BEIJING

Contains nanbo 3 Phase na 2 o-k 2 o-nb 2 o 5 -sio 2 Low dielectric loss energy storage glass ceramics

The present invention relates to containing NaNbO 3 Phase Na 2 O‑K 2 O‑Nb 2 o 5 ‑SiO2 2 Low dielectric loss energy storage glass-ceramic material, the glass-ceramic material is obtained by mixing glass phase and crystal phase, melting, cooling forming, annealing and crystallization heat treatment; wherein, the glass phase accounts for 20% by mole percentage %, the balance is the crystalline phase; the crystalline phase is obtained by molar ratio of x :(1- x ): 1 Na 2 CO 3 、K 2 CO 3 , Nb 2 o 5 Obtained by heating and melting, 0.7≤x≤1. The potassium sodium niobate base energy storage glass-ceramic material that the present invention makes is low in dielectric loss; The Na that the present invention adds 2 CO 3 , not only adjusts the crystal phase composition of the potassium sodium niobate system, but also promotes the crystallization process to a certain extent, forming NaNbO which is conducive to high energy storage density 3 Phase, finally get high energy storage density glass-ceramic material.

Owner:SHAANXI UNIV OF SCI & TECH

A k for energy storage 2 o na 2 o‑nb 2 o 5 ‑sio 2 -b 2 o 3 System glass ceramic material and preparation method thereof

The invention relates to a K2O-Na2O-Nb2O5-SiO2-B2O3 system glass ceramic material used for energy storage, and a preparation method thereof. The method comprises the following steps: mixing K2CO3, Na2CO3, Nb2O5, SiO2, H3BO3 and BaF2 according to a molar ratio of 15:15:30:4.2:(2-5), fusing, molding, annealing, and crystallizing to prepare the material. Alkali metal oxides in raw materials exist in the glass system as a network modifier to destroy the network structure of glass, so the formula of the glass is simplified, the cost is reduced, and the quantity of kinds of precipitated impure phases is fundamentally reduced; a fusion technology is adopted, so the raw materials highly and uniformly react, and the experiment operation is simple; annealing can effectively eliminate internal stress; and segment heat insulation is adopted in the crystallization treatment process, so a crystal phase completely grows, crystal precipitation is thorough, and obtaining of glass ceramic with fine internal crystal grins, high homogenization degree and high energy storage density is facilitated.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of porous titanium-based drug atomization core and heating component for atomization

ActiveCN109590473BIncrease profitVarious molding methodsMedical devicesMedical atomisersNichromeMetallic materials

Owner:UNIV OF SCI & TECH BEIJING

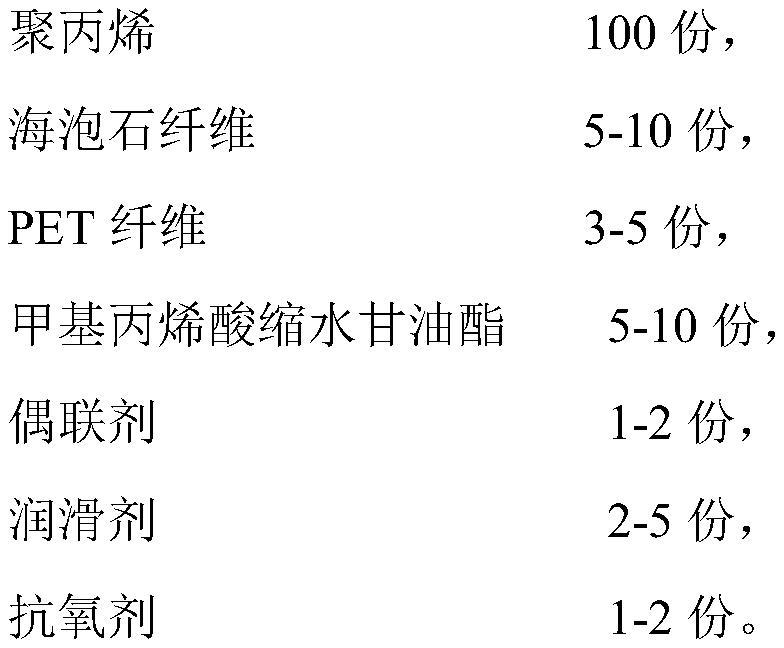

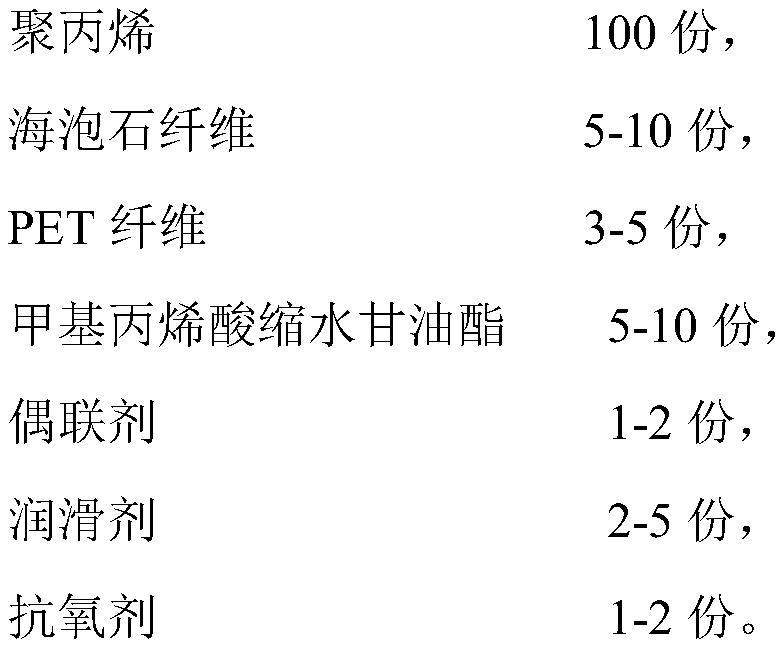

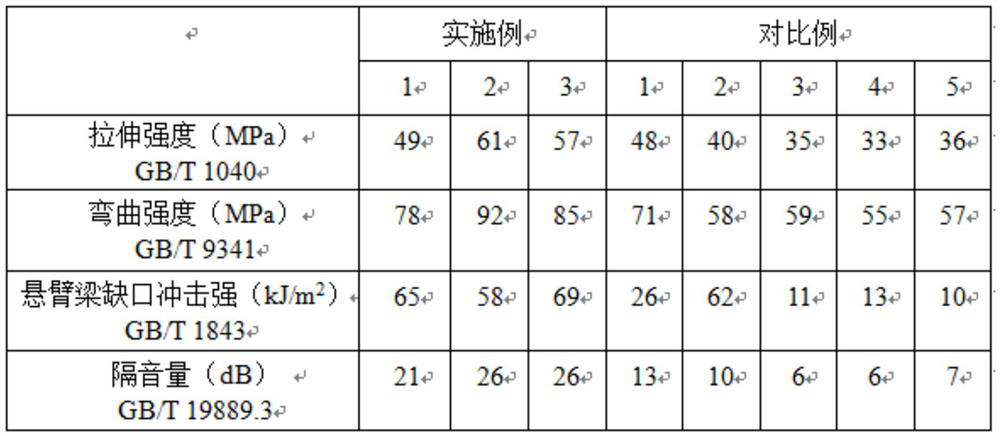

Sound insulation composite material with excellent mechanical property and preparation method thereof

The invention discloses a sound insulation composite material with excellent mechanical properties, which is prepared from, by weight, 100 parts of polypropylene, 5-10 parts of sepiolite fibers, 3-5 parts of PET fibers, 5-10 parts of glycidyl methacrylate, 1-2 parts of a coupling agent, 2-5 parts of a lubricant and 1-2 parts of an antioxidant. The invention also discloses a preparation method of the sound insulation composite material. The prepared sound insulation composite material has excellent sound insulation performance and also has good mechanical performance. By compounding the sepiolite fibers and the PET fibers, the mechanical property and sound insulation performance of the composite material are superior to those of a composite material in which the sepiolite fibers or the PET fibers are independently used, and are far superior to those of a common filler as a sound insulation material in the field.

Owner:HEFEI GENIUS NEW MATERIALS

A KNN-based energy storage glass-ceramic material with ultra-low dielectric loss and its preparation method

The invention relates to a KNN-based (sodium potassium niobate-based) energy storage microcrystalline glass material with ultralow dielectric loss and a preparation method. The microcrystalline glass material is prepared from a glass phase and a crystal phase through mixing, fusing, cooling and molding, annealing, carrying out crystallization heat treatment, wherein according to mol percent, the glass phase accounts for 20 percent to 50 percent and the balance is the crystal phase; the crystal phase is composed of K2CO3, Na2CO3, Nb2O5 and BaCO3 at a mol ratio of (3-x) to (3-x) to 6 to 2x and x is more than 0 and less than or equal to 2.5. The KNN-based energy storage microcrystalline glass material prepared by the preparation method has extremely low dielectric loss; BaO is introduced, has the effect of adjusting the composition of the crystal phase of a sodium potassium niobate system and also has a certain promotion effect on a devitrification process and devitrification is accelerated by rare-earth metal ions; the BaO can also generate a pinning effect, and adverse impacts, caused by interface polarization, on breakdown and worsening are weakened; finally, the microcrystalline glass material with a high dielectric constant is obtained.

Owner:SHAANXI UNIV OF SCI & TECH

A bonded glass fiber reinforced plastic drive shaft with form-surface fit and its production process

The invention discloses a profile-matched bonding glass fiber reinforced plastic transmission shaft and its production technology. The profile-matched bonding glass fiber reinforced plastic transmission shaft comprises a metal flange and a glass fiber reinforced plastic intermedium tube, which are adhered together. The metal flange and the glass fiber reinforced plastic intermedium tube have a bonding matching surface. The metal flange and the glass fiber reinforced plastic intermedium tube both have a polygonoun and arc transition matching profile. The bonding matching surface of the metal flange and the glass fiber reinforced plastic intermedium tube is a polygonoun and arc transition bonding structure. Through the profile-matched bonding surface, torsional rigidity for self-locking between the matched profile will be greatly increased; bonding strength reliability is greatly raised; and by the adoption of the conical surface matched bonding surface, during the bonding process, matching between the metal flange and the glass fiber reinforced plastic intermedium tube has a self-centering effect, bonding operation difficulty can be reduced, and bonding manufacturability is raised.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Phosphorus-based flame-retardant glass fiber reinforced plastic floor paint and construction method thereof

InactiveCN112226148AStable performance at high temperatureImprove corrosion resistanceFireproof paintsCovering/liningsGlass fiberWeather resistance

The invention discloses a phosphorus-based flame-retardant glass fiber reinforced plastic floor paint and a construction method thereof. The floor paint comprises the following components in parts byweight: 60-70 parts of phosphorus-based flame-retardant unsaturated polyester resin, 30-40 parts of chopped glass fibers, 0.5-1 part of an accelerant and 1-2 parts of a curing agent, wherein the phosphorus-based flame-retardant unsaturated polyester resin contains 2-methyl-1,2-oxaphosphepin-5-one-2-oxide. Compared with existing epoxy floor paint, the floor paint disclosed by the invention is prepared by compounding the phosphorus-based flame-retardant unsaturated polyester resin, the chopped glass fiber, the accelerant and the curing agent, preferably selecting the additive amount of each component, and combining an automatic spraying process, so that the floor paint is easy to construct and form, low in cost, stable in high-temperature performance of a paint film, safe and environment-friendly; and the paint has good corrosion resistance, scratch resistance, flame retardance and weather resistance.

Owner:广东晨宝复合材料股份有限公司

A skin-core structural fiber with both infrared and radar stealth and its preparation method and application

ActiveCN113249821BIncrease loadWell formedCamouflage devicesProtective buildings/sheltersElectromagnetic wave absorberSpinning

The invention discloses a skin-core structural fiber with both infrared and radar stealth and its preparation method and application. The skin-core structural fiber comprises the following raw materials in parts by weight: 1-5 parts of paraffin, 1-5 parts of electromagnetic wave absorber , 1 to 5 parts of high molecular polymer, polyacrylonitrile, N,N-dimethylacetamide, wherein the electromagnetic wave absorber is ferric oxide intercalated graphene oxide, nano ferric oxide, carbon black one or more of them. The invention uses the skin-core spinning technology to prepare the phase change material and the electromagnetic wave absorbing material into a fiber material with a skin-core structure, which solves the disadvantage that the stealth material only has a single infrared stealth or radar stealth, and at the same time, the fiber material has various molding methods and is easy to use .

Owner:NANTONG UNIVERSITY

a srnb-containing 6 o 16 Phase titanate and niobate composite low dielectric loss glass ceramics and preparation method

The present invention relates to providing a kind of SrNb 6 o 16 Phase Na 2 CO 3 -K 2 CO 3 -Nb 2 o 5 -SrCO 3 -TiO 2 ‑SiO2 2 -H 3 BO 3 -CeO 2 The system glass ceramic material and its preparation method, the glass-ceramic material is prepared by mixing glass phase and crystal phase, melting, cooling forming, annealing and crystallization heat treatment. Among them, Na in molar percentage (1‑x) (43.75:6.25:50):x (50:50) 2 CO 3 、K 2 CO 3 , Nb 2 o 5 , SrCO 3 and TiO 2 (x=0.05), SiO 2 with H 3 BO 3 The molar ratio is 25:75, CeO 2 It is 2mol. The dielectric loss of the glass-ceramic material prepared by the present invention is low, and the CeO added by the present invention 2 , not only promotes the crystallization process to a certain extent, but also obtains a high energy storage density glass-ceramic material with a uniform microstructure.

Owner:SHAANXI UNIV OF SCI & TECH

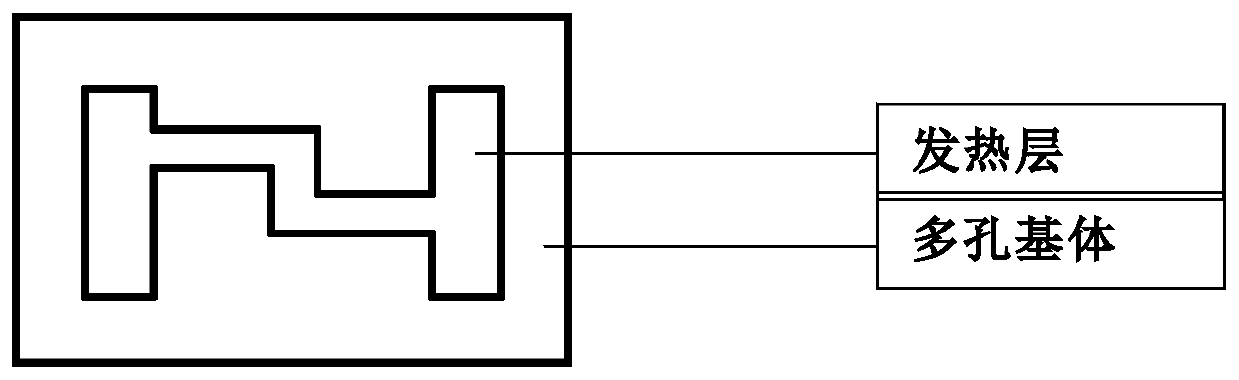

Preparation method of an easy-to-assemble self-heating porous titanium-based drug delivery atomizer core

The invention relates to a preparation method of a self-heating porous titanium-based drug delivery atomizing core which is easy to assemble, and belongs to the field of porous functional materials. The present invention adopts a slot-type structure to realize the assembly of the porous titanium-based drug atomization core, and increases the resistivity of the porous titanium-based drug atomizer core by adding alloy elements to realize self-heating of the drug atomizer core. Molding and gel injection molding techniques are used to manufacture self-heating porous titanium-based drug delivery atomizer cores. In the present invention, aiming at the problem of difficult assembly of traditional atomizing cores, it is proposed to use a slotted structure to realize the assembly of porous titanium-based drug atomizing cores, which saves the use of traditional heating resistance layer materials and avoids the high temperature sintering process of resistance wires. Oxidation, brittleness and other problems occur in the drug delivery atomization core; in order to realize the self-heating of the drug delivery atomization core, the resistivity of the porous titanium-based drug delivery atomization core is improved by adding alloy elements, and the functions of drug storage and heating drug oil are integrated, which is convenient for installation , greatly reduce the cost of manual assembly, facilitate the realization of automated production lines, and have the advantages of high applicability.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com