Patents

Literature

40results about How to "No discharge phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

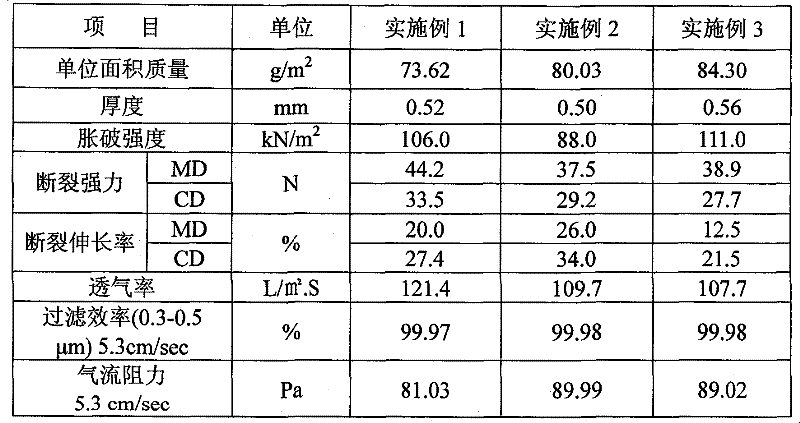

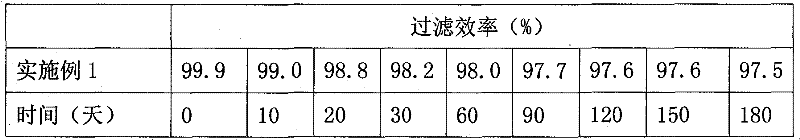

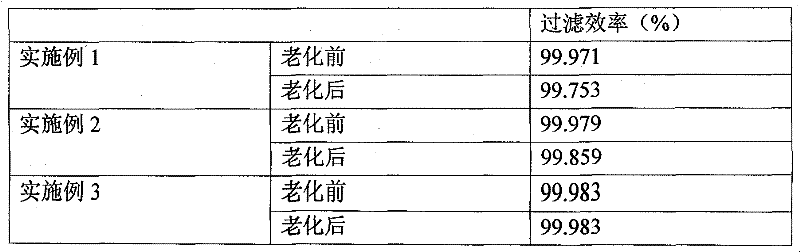

Method for preparing melt-blown polypropylene electret filter material

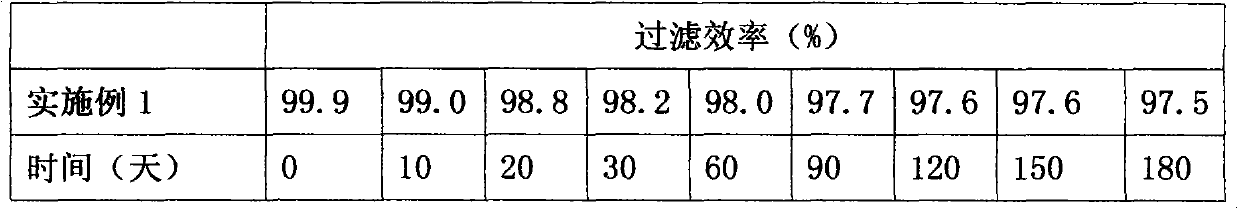

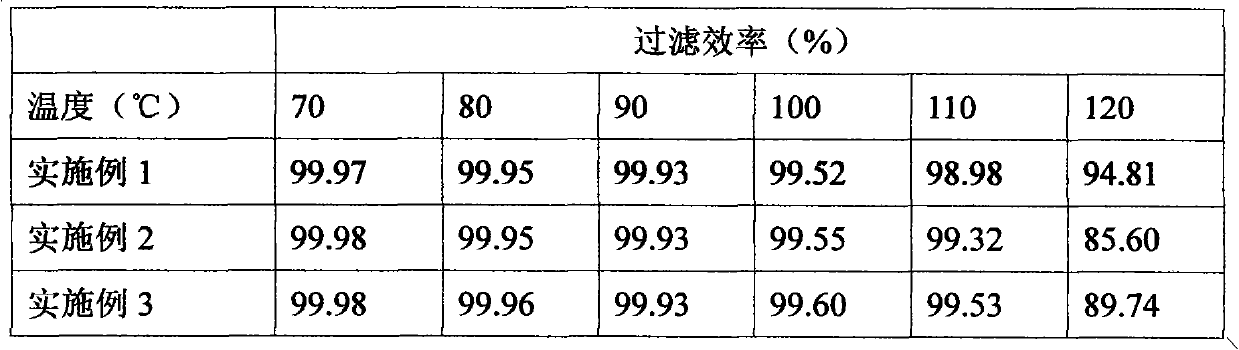

The invention relates to a method for preparing a melt-blown polypropylene electret filter material. The method comprises the following steps of: 1) modification of polypropylene: melting the raw material, polypropylene, and mixing the melt with an additive to obtain modified polypropylene; 2) melt-blown preparation process: a) in a molten state, feeding the modified polypropylene melt into a spinneret plate by using a metering pump; b) extruding the modified polypropylene melt from a spinneret orifice; and c) blowing the melt extruded out from the spinneret orifice into ultrafine fibers by using high-speed hot air to make the fibers fly to a condenser net curtain to form a fiber net through cooling and bonding; and 3), preparation process of an electret: passing the fiber net obtained in step (2) through an electrode of a corona discharge device and obtaining the electret through the discharging of the electrode. The melt-blown electret high-efficiency filter material obtained by the method has the advantages of very high electret charge stability, excellent filtering efficiency, very low pressure loss, long service life and optimal economic benefit.

Owner:HANGZHOU DIANZI UNIV +1

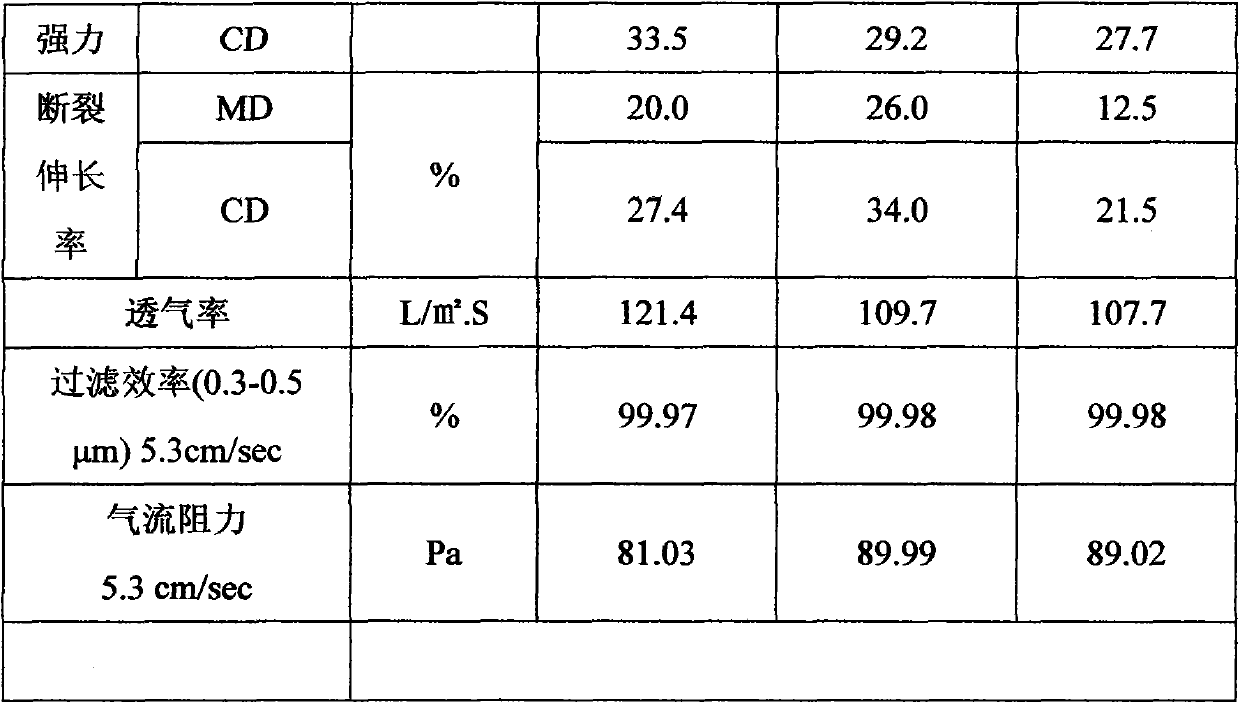

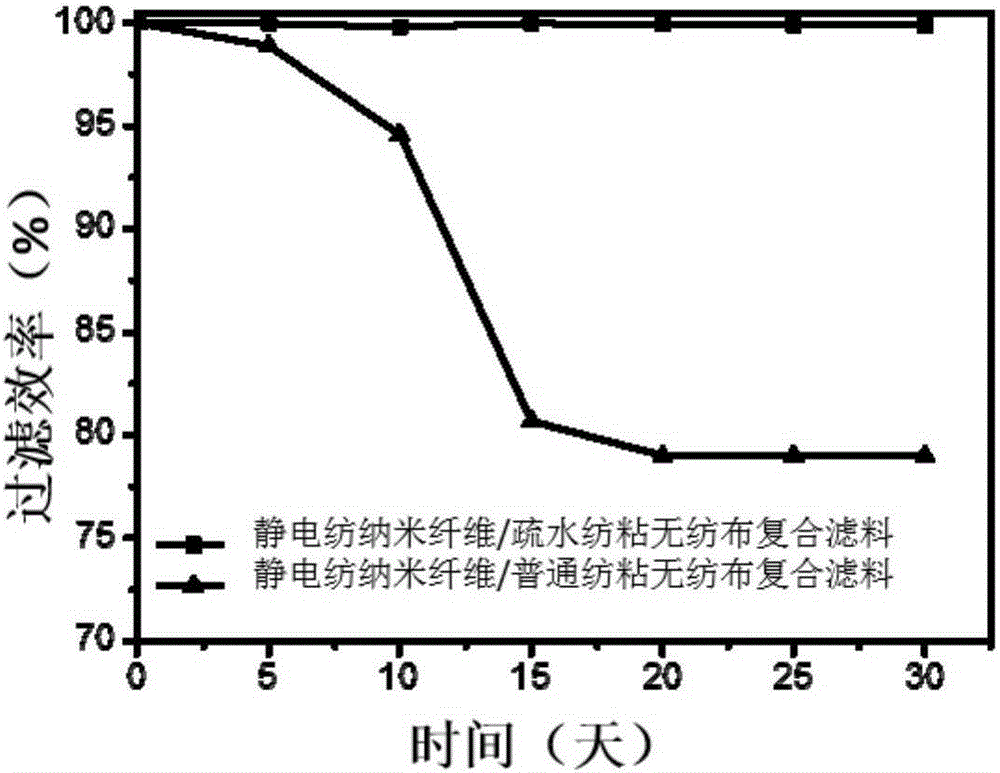

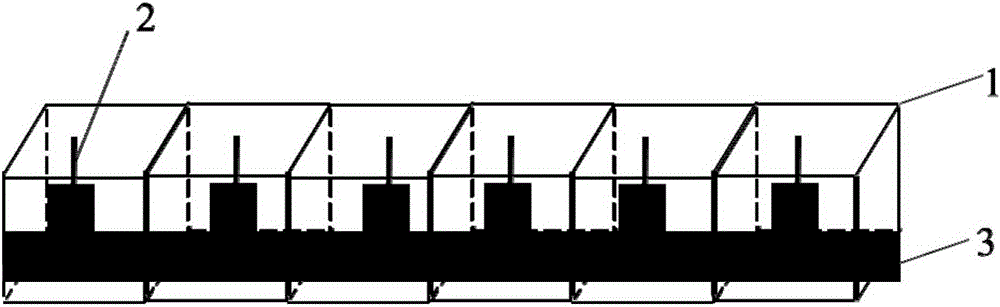

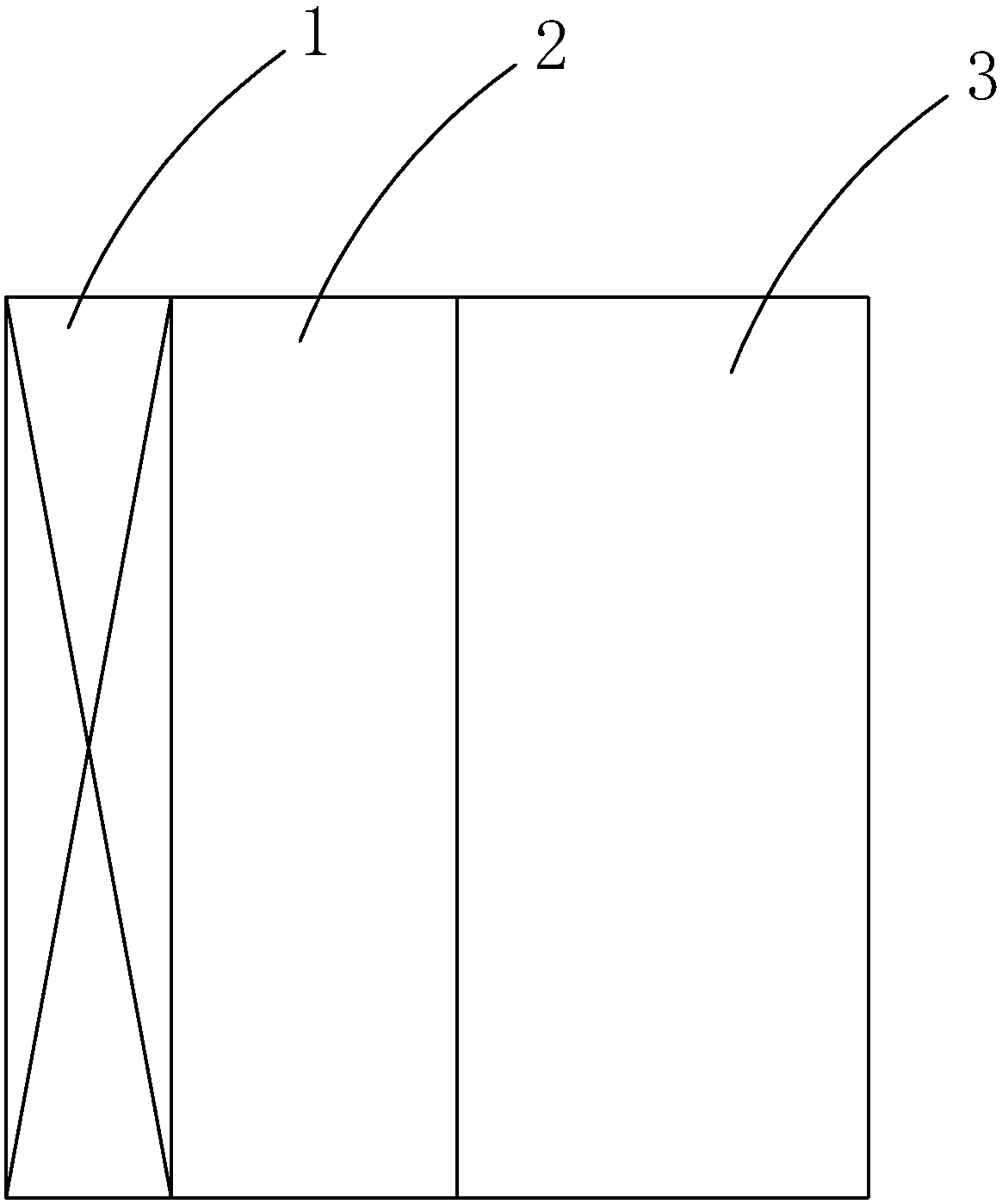

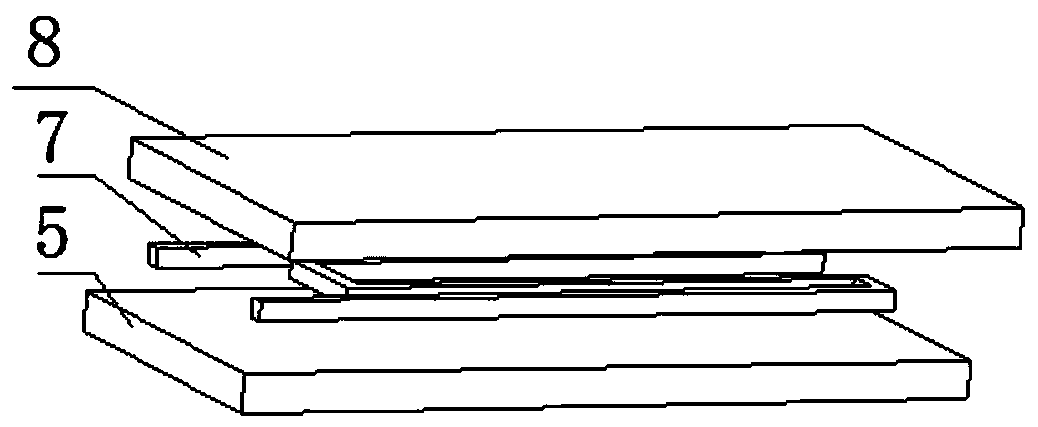

Electrostatic spinning method and nanometer fiber/anti-sticking non-woven fabric composite filter material prepared through electrostatic spinning method

ActiveCN105200539AImprove uniformityElectric field interference weakenedFilament/thread formingFiltration separationWoven fabric compositeElectrospinning

The invention relates to an electrostatic spinning method and a nanometer fiber / anti-sticking non-woven fabric composite filter material prepared through the electrostatic spinning method. Multi-needle electrostatic spinning is adopted in the electrostatic spinning method, and needles of multi-needle electrostatic spinning are insulated from one another. The prepared nanometer fiber / anti-sticking non-woven fabric composite filter material is formed by overlapping and compositing materials for overlapping from bottom to top according to the low-to-high sequence of filtering efficiency of a filtering material, the face, with electrostatic spinning fiber, of each layer of material for overlapping faces upwards, the uppermost layer of material for overlapping is covered with anti-sticking non-woven fabric, and therefore it is ensured that the top layer and the bottommost layer are both anti-sticking non-woven fabric layers; of every two adjacent layers of materials for overlapping, the filtering efficiency value for particles with grain size of 0.02 micron to 10 microns of the upper layer is 1.03-1.3 times that of the lower layer, the number of overlapping layers of the materials for overlapping ranges from 2 to 6, the anti-sticking non-woven fabric and the interlayer structure with electret effect nanometer fibers arrayed at intervals are formed, and the nanometer fiber / anti-sticking non-woven fabric composite filter material is formed; the filtering efficiency of the nanometer fiber / anti-sticking non-woven fabric composite filter material for particles with grain size of 0.02 micron to 10 microns reaches 99.999% or higher, and the pressure resistance is kept between 10 Pa and 30 Pa.

Owner:DONGHUA UNIV

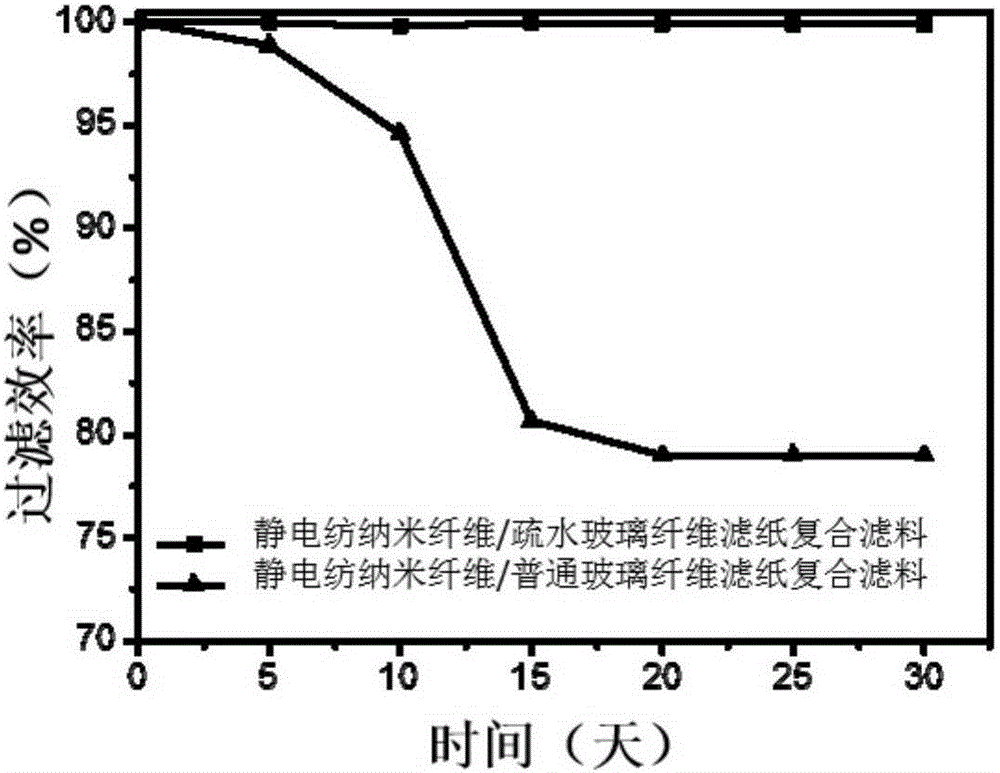

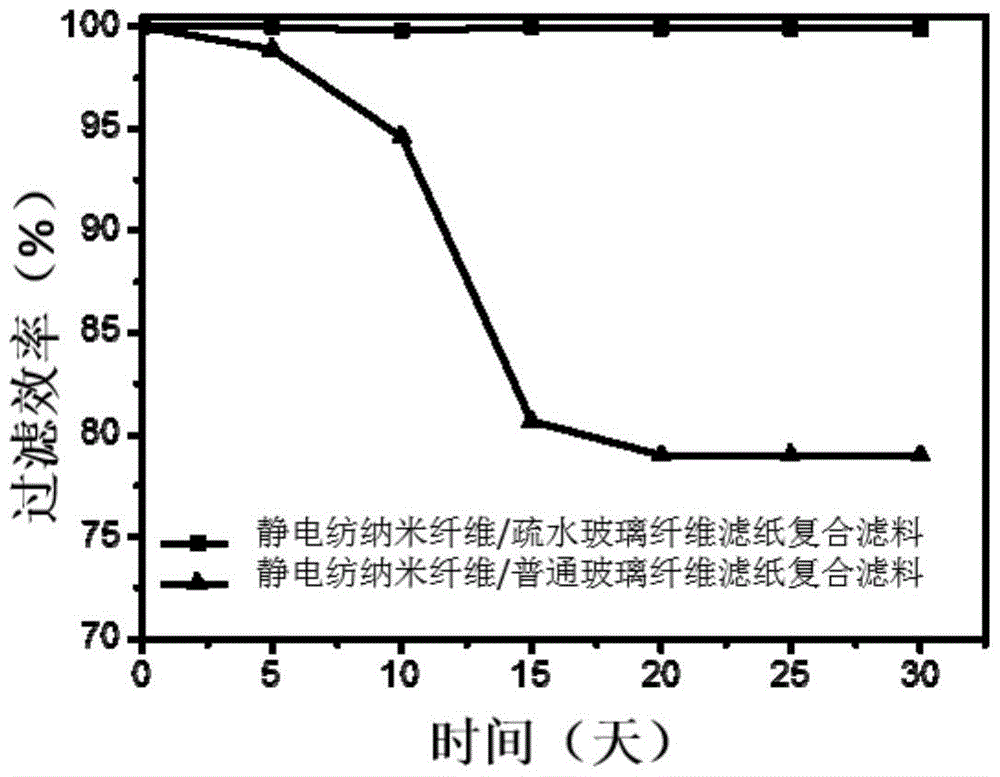

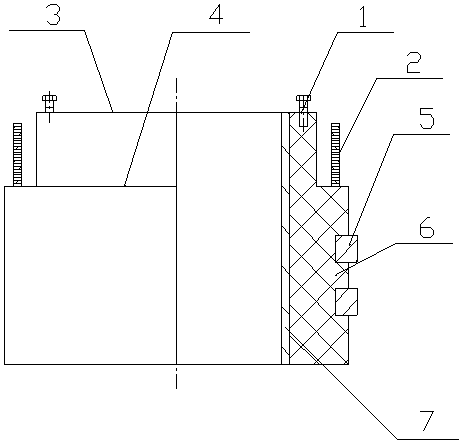

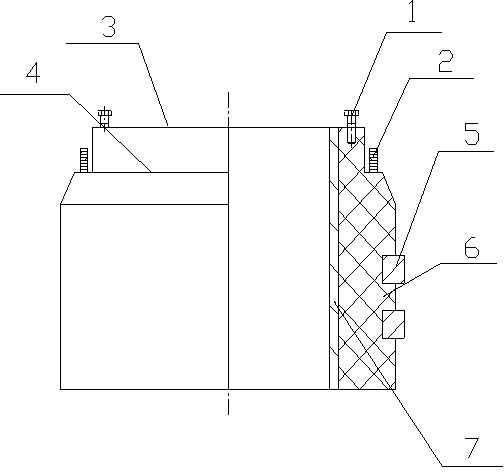

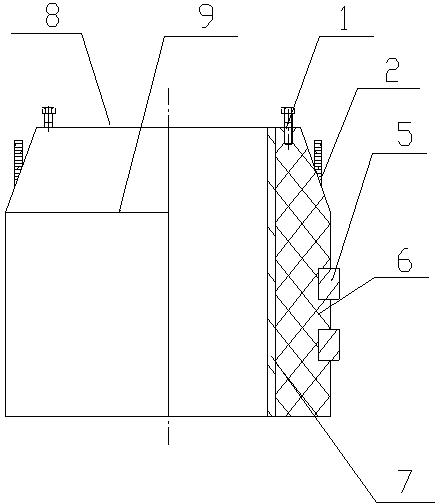

Static spinning method and nano fiber/glass fiber composite filter material prepared by same

ActiveCN105233568AImprove uniformityElectric field interference weakenedFilament/thread formingFiltration separationGlass fiberFiber

The invention relates to a static spinning method and a nano fiber / glass fiber composite filter material prepared by the same. According to the static spinning method, multiple needles are used to carry out static spinning, and the needles are insulated to each other. The nano fiber / glass fiber composite filter material is prepared by laminating and combining different filter materials together from bottom to top, wherein the filter efficiency of filter materials increases from bottom to top; the side, which is provided with static spun fibers, of each filter material layer is upward, the surface of the top layer is covered by glass fiber filter paper to ensure that the top layer and bottom layer of the filter material are both made of glass fiber filter paper. For two neighbored filter material layers, the filter efficiency of the upper layer on particles with a size of 0.02 to 10 [mu]m is 1.03 to 1.3 times higher than that of the lower layer. The composite filter material comprises two to six filter material layers, and has an sandwich structure, wherein in the sandwich structure, glass fiber filter paper and nano fiber with an electret effect are arranged alternately. The nano fiber / glass fiber composite filter material has a filter efficiency of 99.999% or more on particles with a size of 0.02 to 10 [mu]m, and the pressure resistance is maintained at 10 to 30 Pa.

Owner:上海迅江科技有限公司

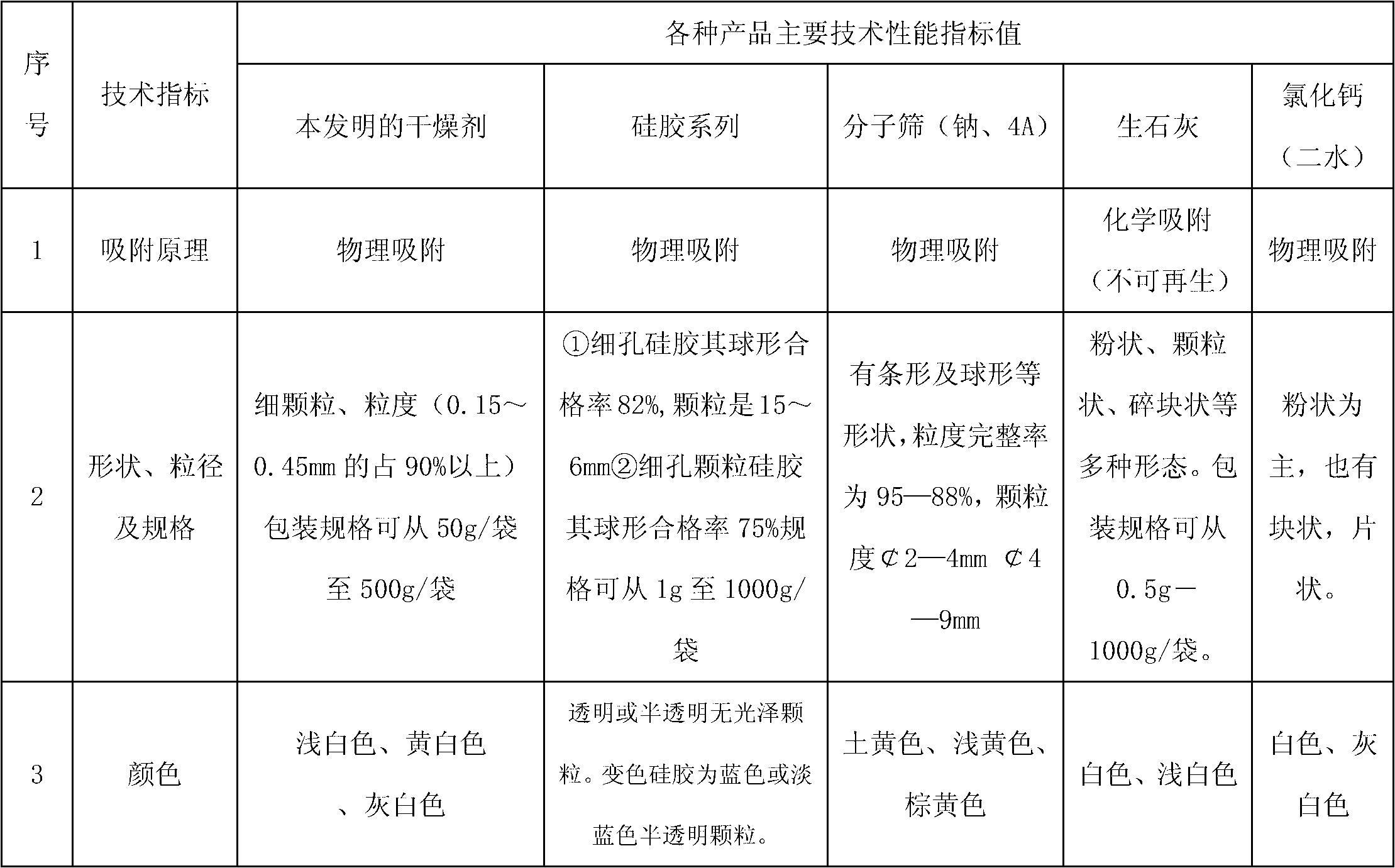

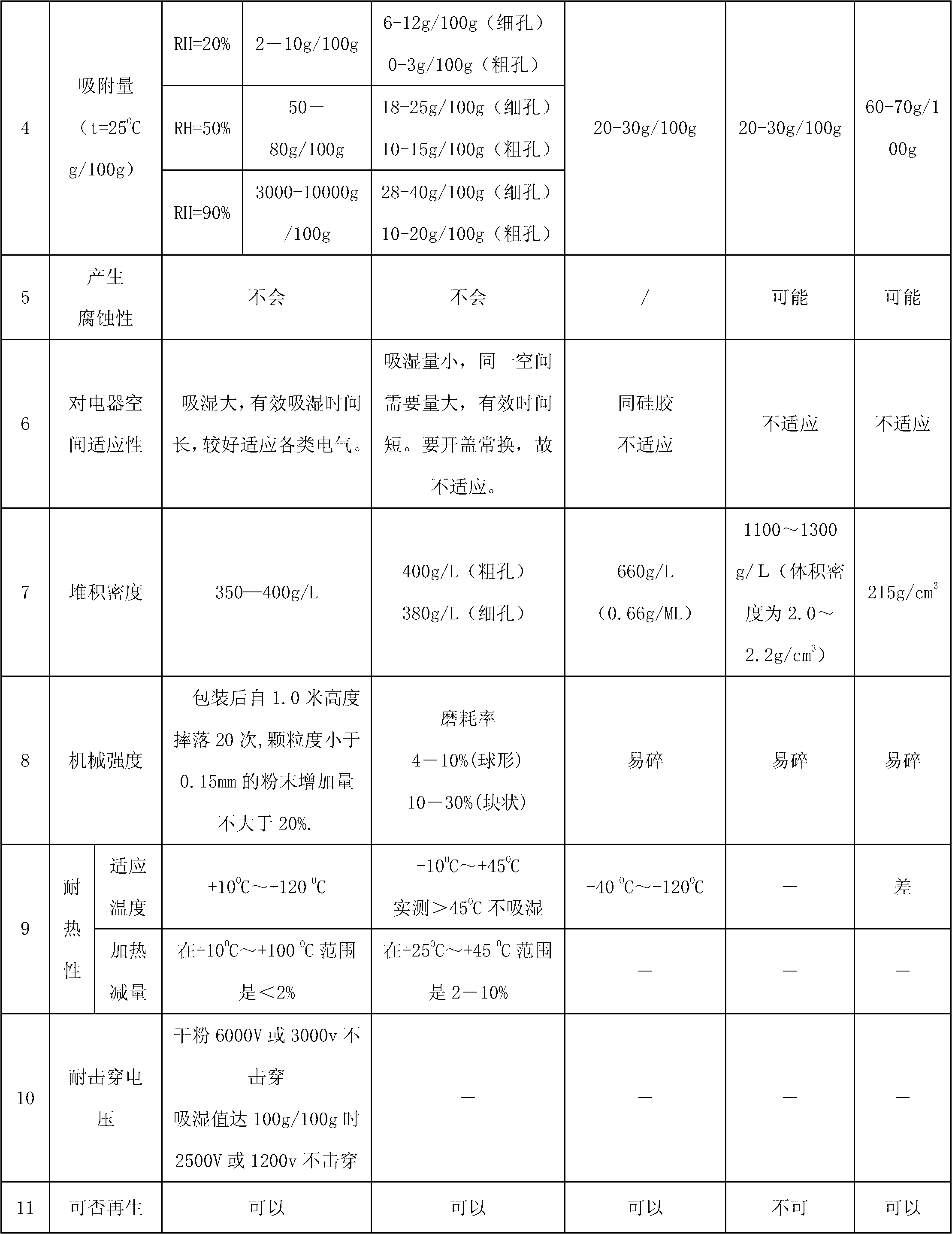

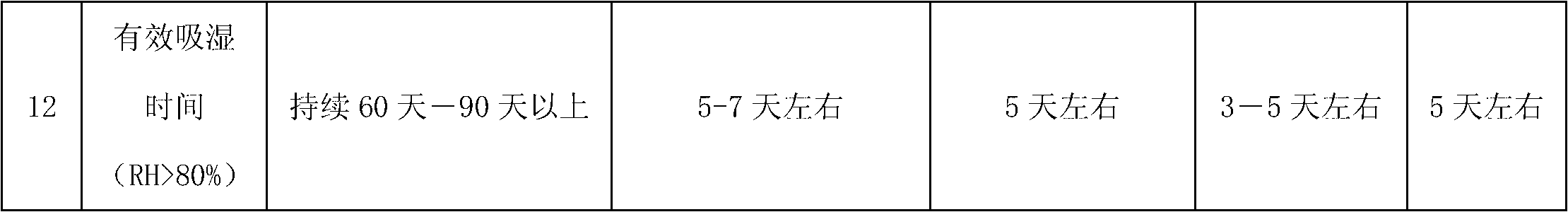

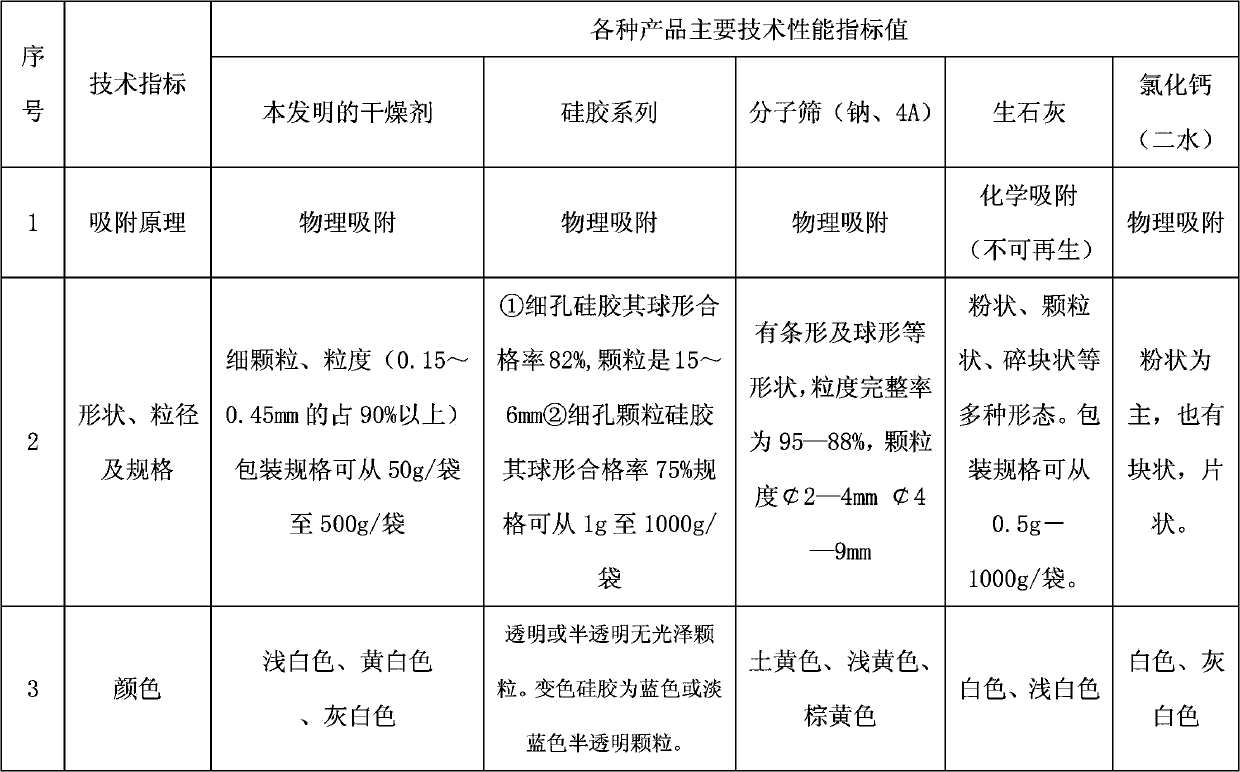

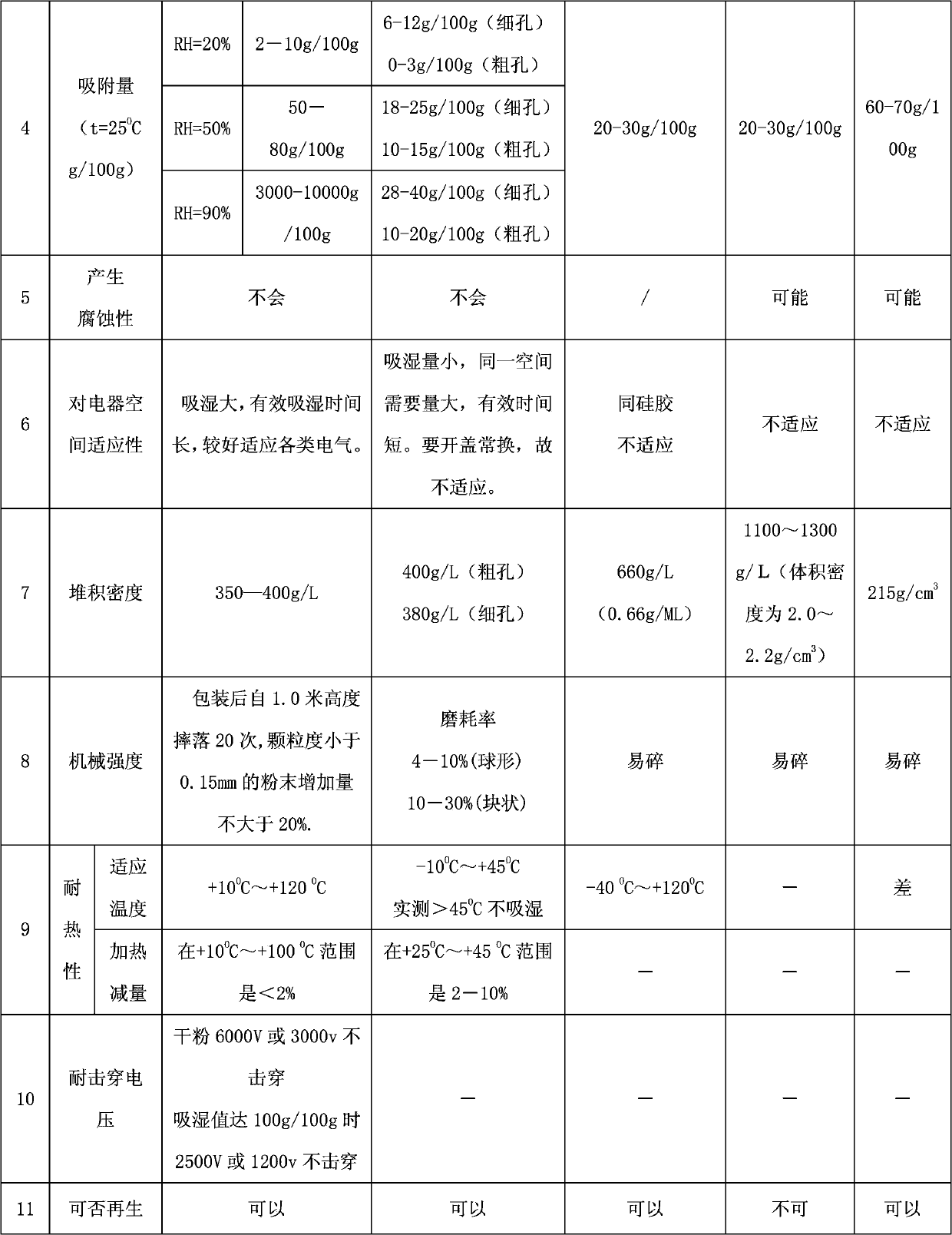

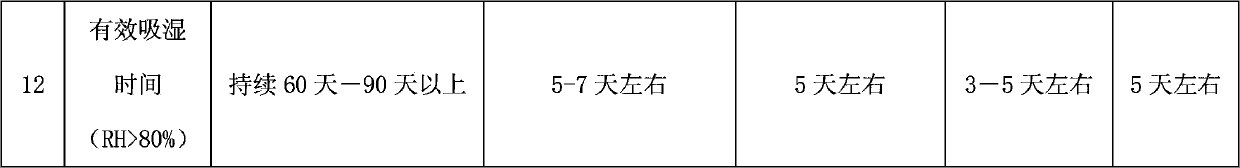

Drying agent for mine underground electric apparatus and preparation method thereof

ActiveCN102698573ANot corrosiveNo tendency to explodeDispersed particle separationLow voltageAlkali metal halide

The invention discloses a drying agent for an mine underground electric apparatus and a preparation method of the drying agent, belonging to the field of drying agent, wherein macromolecule water absorbent, compound of silicon or calcium and alkali halide or modified starch are mixed so as to prepare the powdery draying agent according to part by weight; the macromolecule water absorbent is 35-70 parts; the compound of silicon or calcium is 25-55 parts; the alkali halide or a mixture of the alkali halide and the modified starch is 10-15 parts; the grain size of the macromolecule water absorbent is 0.20-0.40mm; and the drying agent is powdery. According to the invention, raw material is wide in source and is purchased easily on the market; the drying agent is used for high / low-voltage power supply appliances worked on a mine underground high-humidity condition (RH=80-100%); the dry powder resists 6000V voltage or does not be broken down under voltage of 3000V; when moisture rate reaches to 1g / g, the dry powder resists 2500V voltage or does not be broken down under voltage of 1200V.

Owner:徐州意创化工科技有限公司

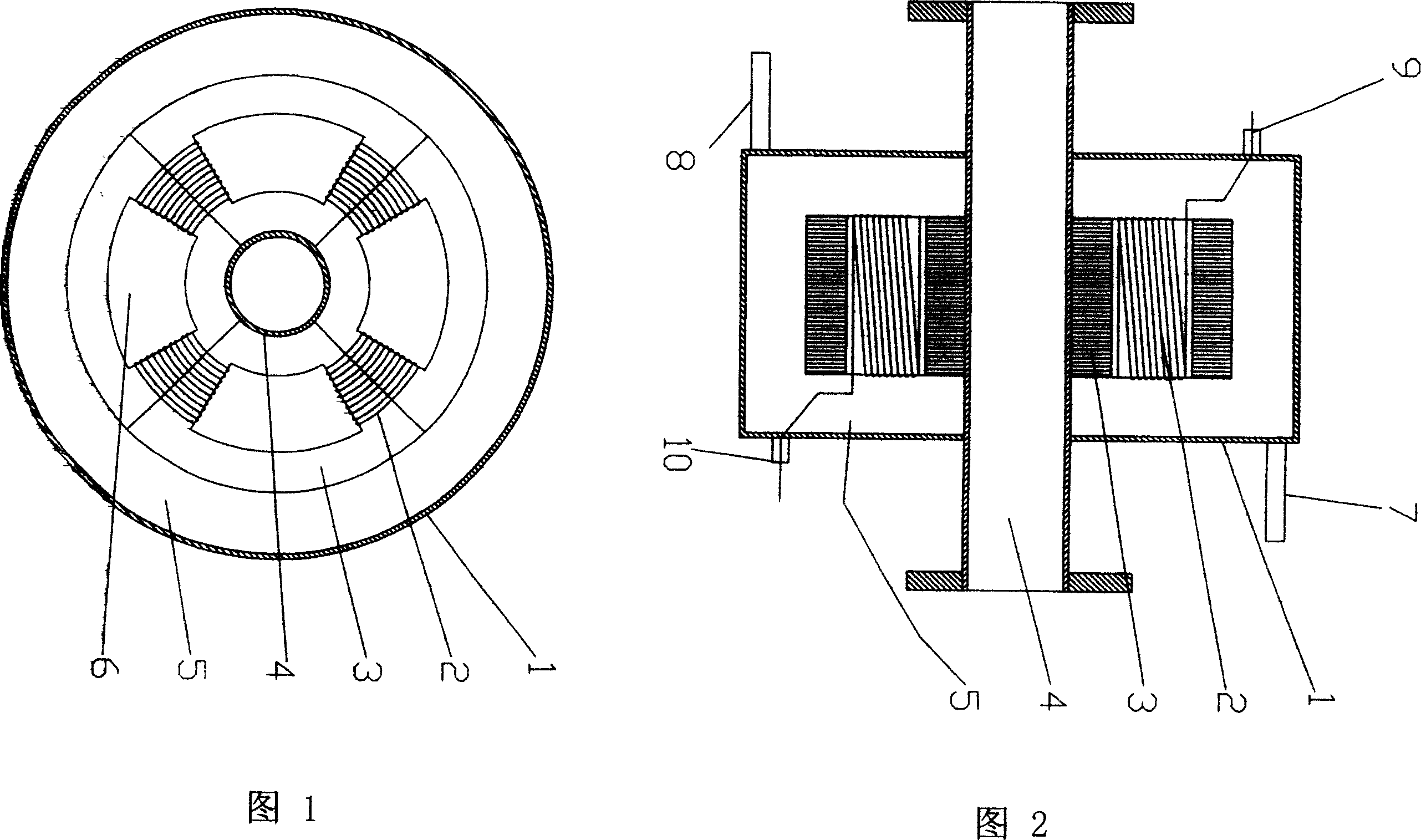

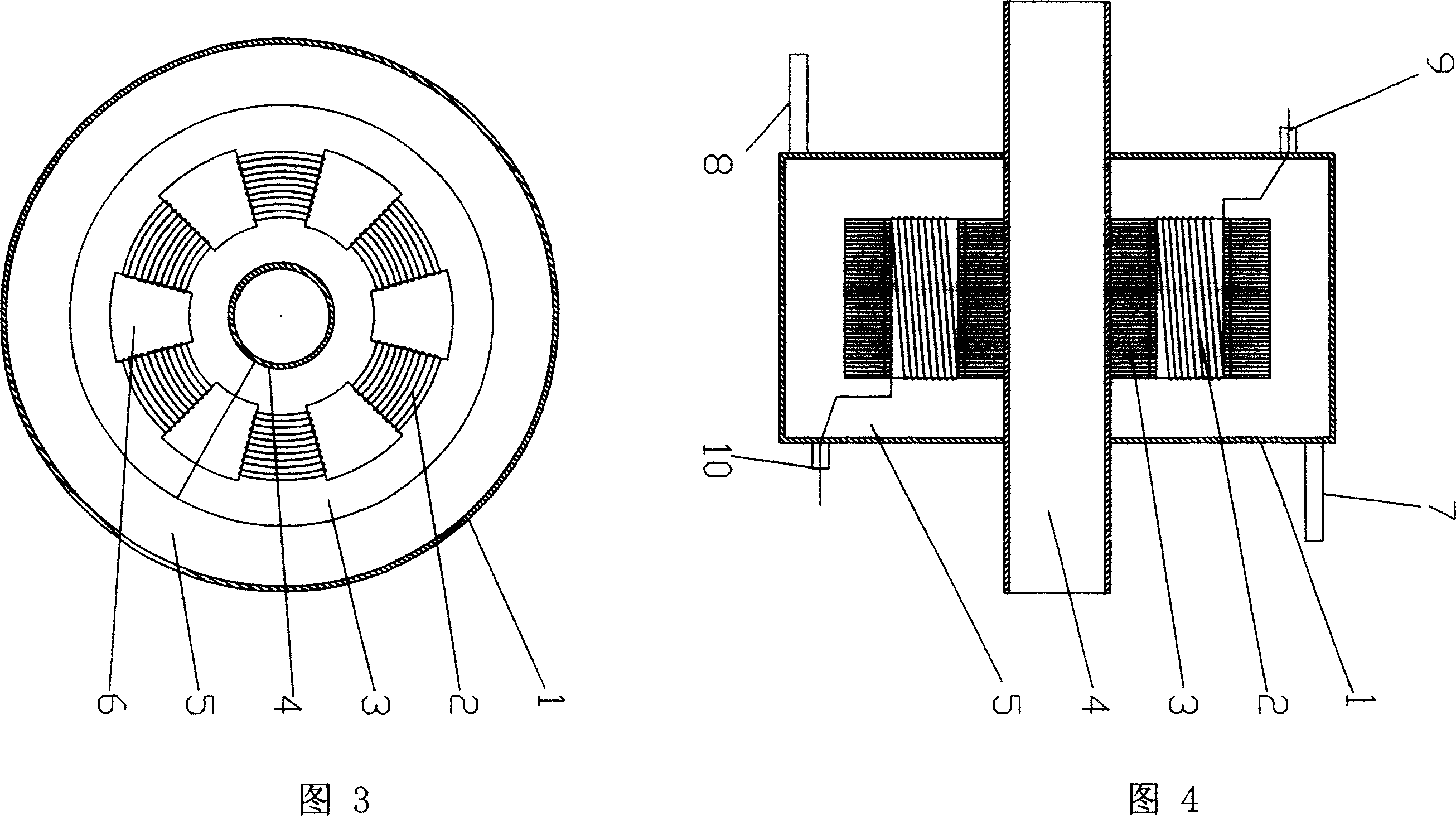

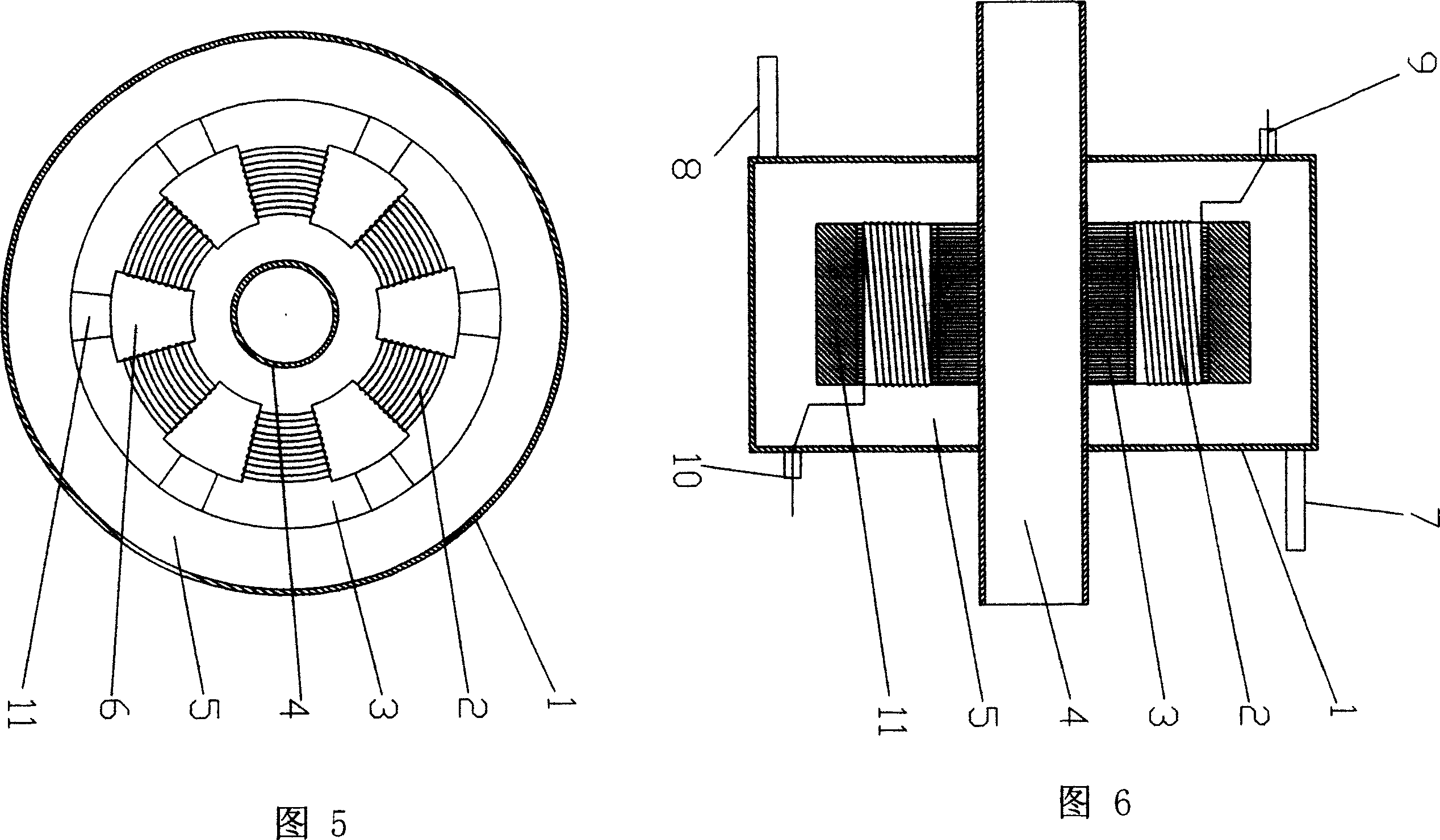

Circular center focusing high power supersonic transducer

InactiveCN101005717AImprove adaptabilityReduce the driving voltagePiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive transducersUltrasonic sensorTransducer

The invention comprises: a magnetostriction component, a central pipe eradiator, a driving coil, a closed case, a cooling media channel, a bias magnet, a forced cooling mechanism. A group of magnetostriction materials is laminated to form ring-shaped or sector-shaped driving component; on the lamination there is a sector-shaped or hole-shaped window opened; the central pipe eradiator is connected to the radiating face of the magnetostriction component; the driving coil for generating magnetic field is located on the group of laminations; on the closed case there are an entrance and outlet of cooling media and a connector of magnet field power.

Owner:BEIJING IN POWER ELECTRIC

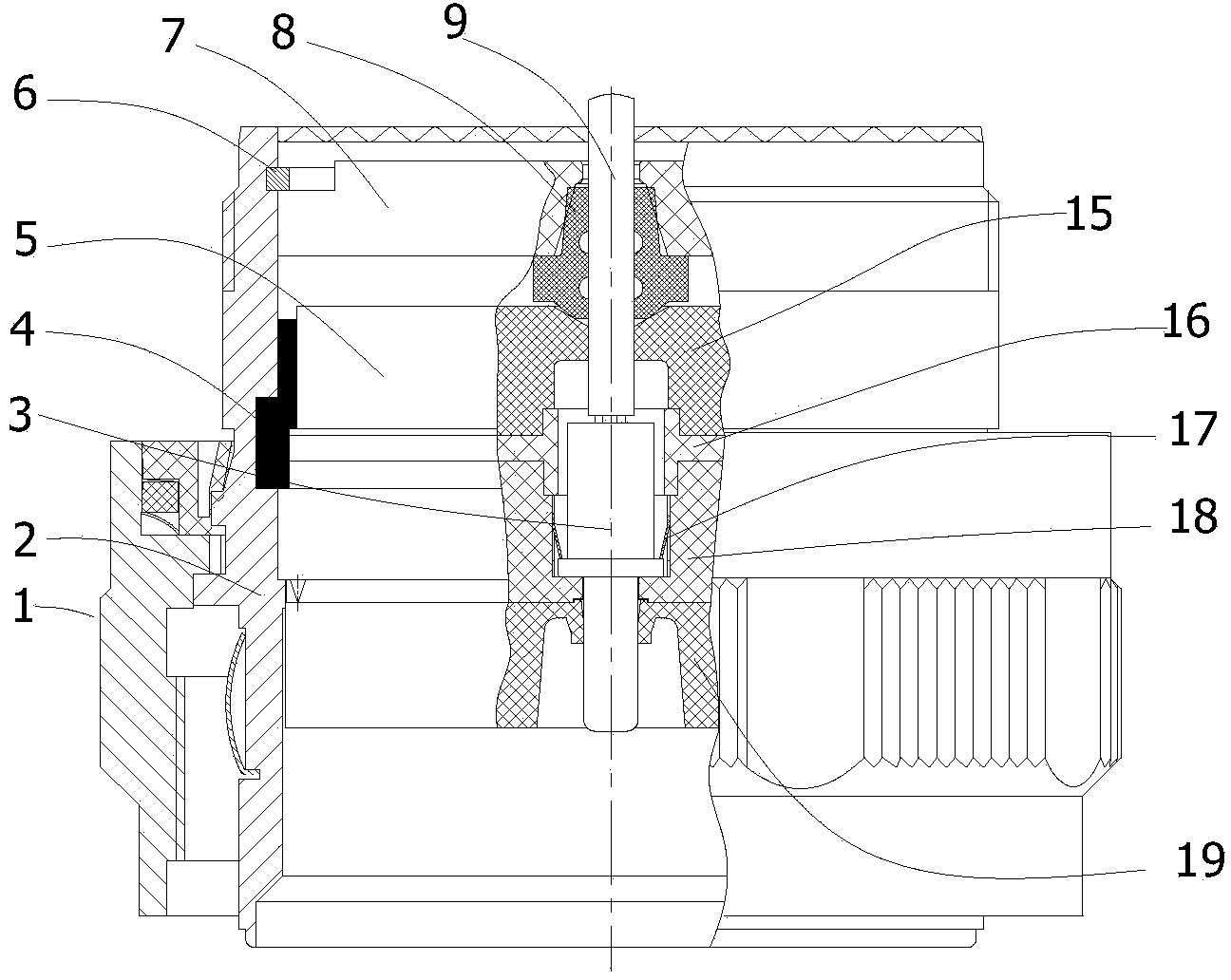

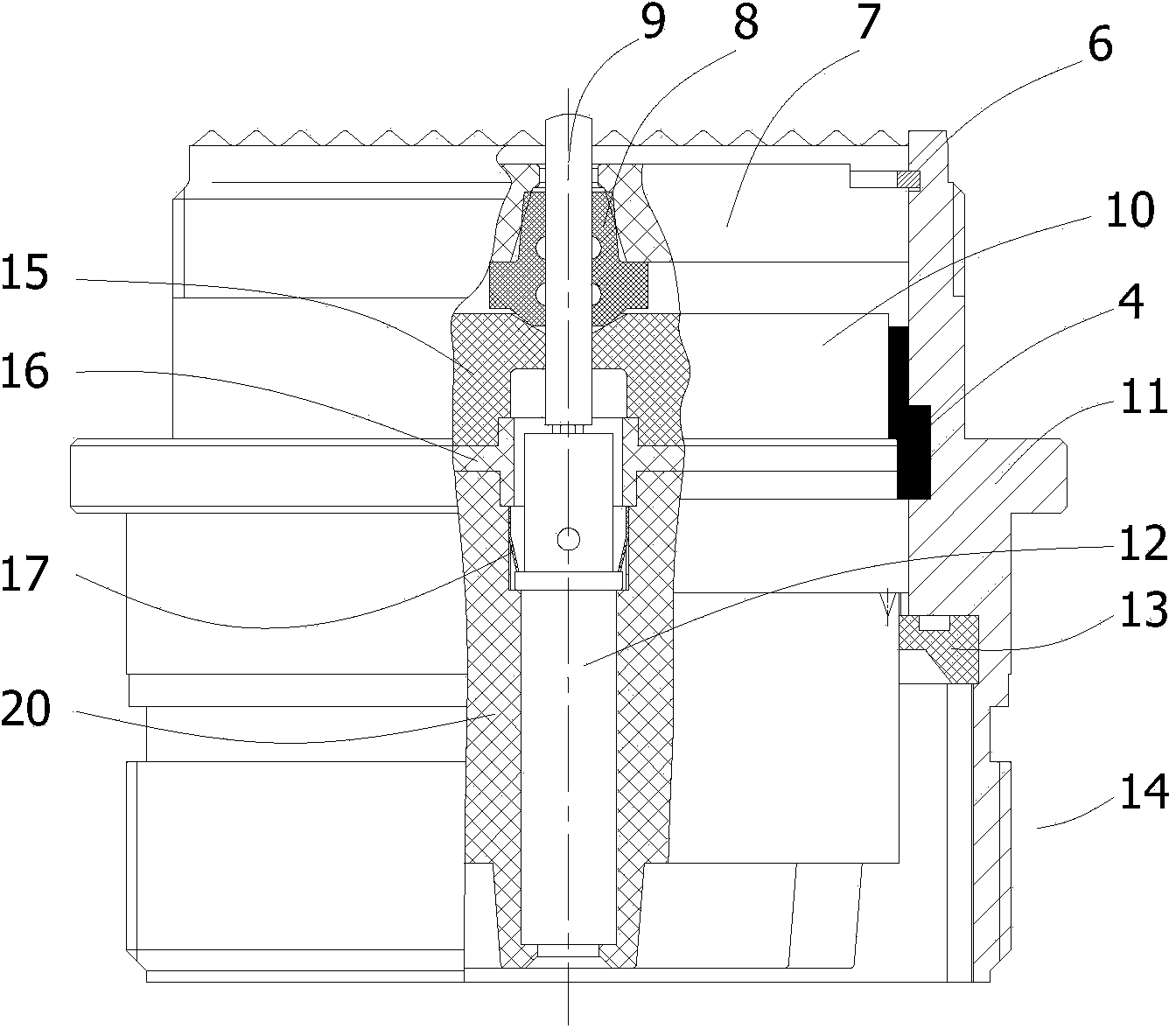

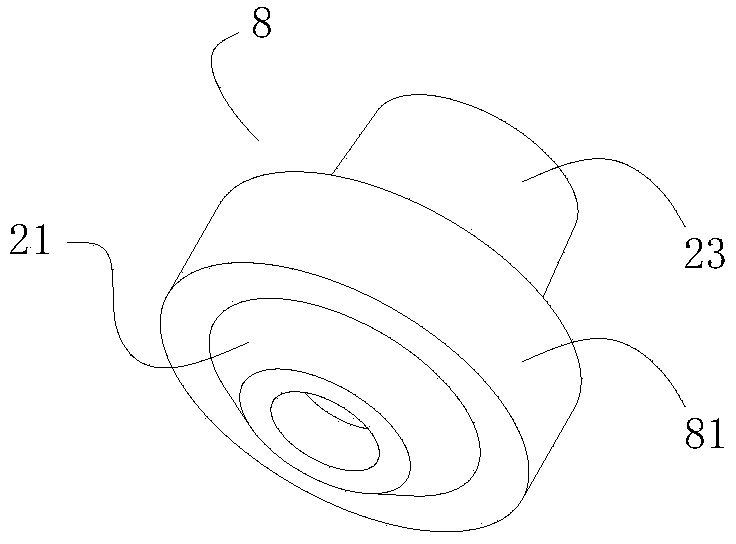

Sealing type high voltage resisting electric connector

ActiveCN104167632AExcellent environmental resistanceStrong vibration resistanceCouplings bases/casesSpatially adaptiveElectricity

A sealing type high voltage resisting electric connector is provided with a tail high voltage resisting device which comprises a sealing sleeve (8) and a cover board (7). The sealing sleeve (8) and the cover board (7) isolate adjacent wires (9) in a sealing mode and / or isolate a wire (9) from a connector shell in a sealing mode jointly. The cover board (7) is fixed to the connector shell. The cover board (7) is made of materials harder than materials of which the sealing sleeve (8) is made. The sealing sleeve (8) is made of elastic flexible materials. Each wire (9) with an insulating layer penetrates through and is sealed in an inner hole of the corresponding sealing sleeve (8), and penetrates through an inner hole of the cover board (7) at the same time. The sealing sleeve (8) is installed between the cover board (7) and a contact installation board in an extrusion mode. The sealing type high voltage resisting electric connector has the stability of high voltage resistance and good space adaptability.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

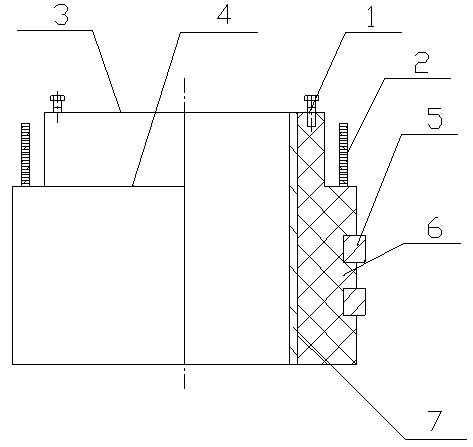

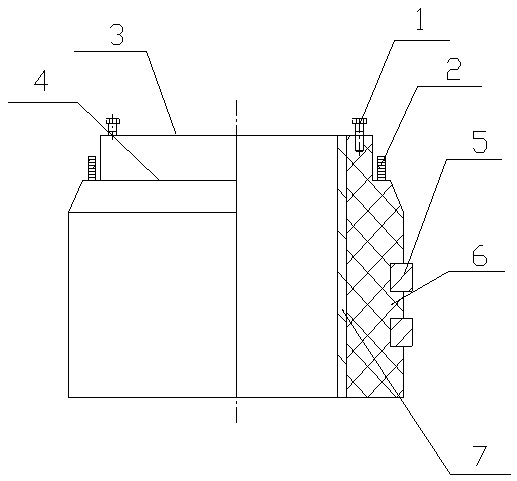

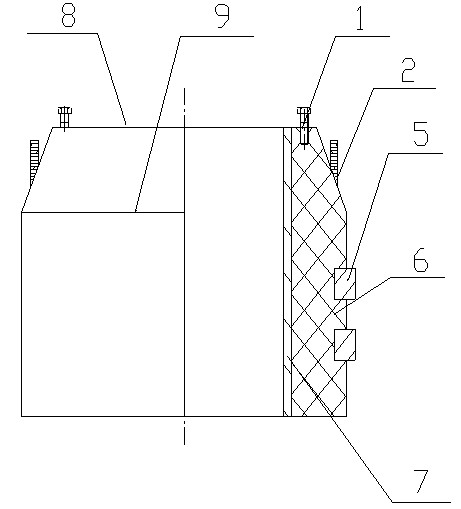

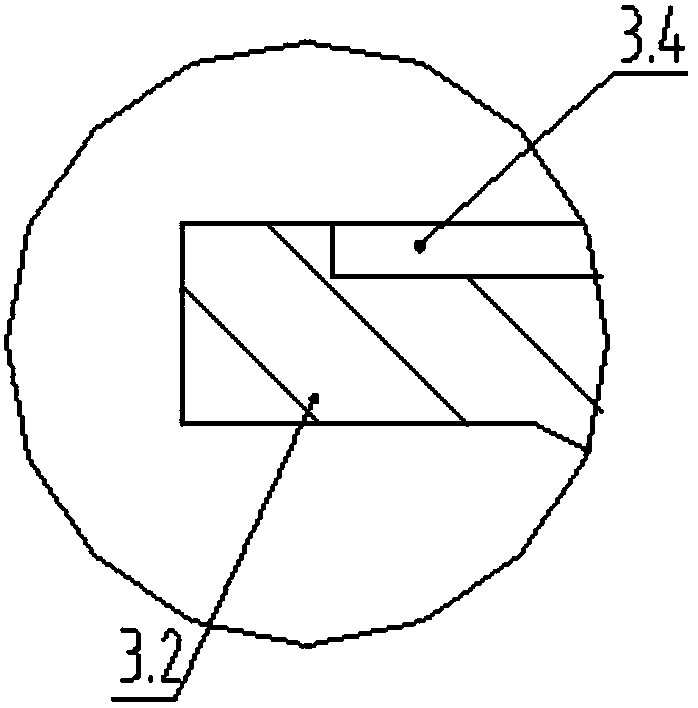

Power supply connection box of high-voltage motor

InactiveCN101588107ANo discharge phenomenonGuaranteed safe operationSupports/enclosures/casingsHigh pressureHigh voltage

The invention discloses a power supply connecting box of a high-voltage motor, which comprises involutedly connected connection box covers, a box base, a stator lead cable, a power supply cable and a fixedly connecting assembly, wherein the power supply cable is fixed with the box base through the fixedly connecting assembly and extends into the box base through a lead inlet on the wall of the box base. The power supply connection box is characterized in that the bottom of the connection box base is provided with an insulation lead board, the lead board is provided with a plurality of lead outlets, the stator lead cable extends into the box base through the lead outlets, the lead board is assembled with a fixed lead clamp, the top of a clamp body is provided with a clamp block, the fixed lead clamp body and the clamp block are provided with clamp grooves, the stator lead cable is clamped and fixed into the clamp grooves, and after the power supply cable and a connection lug which is connected to the end part of the stator lead cable are connected by adopting a connecting piece, the exposed electrified bodies are covered by an insulating piece. The least electric clearance and the creepage distance of the electrified bodies are ensured because positions among connection cables are fixed and the electrified bodies are insulated; and the invention has the advantages of reasonable design, simple structure and low product cost.

Owner:SHANDONG HUALI ELECTRIC MOTOR GRP

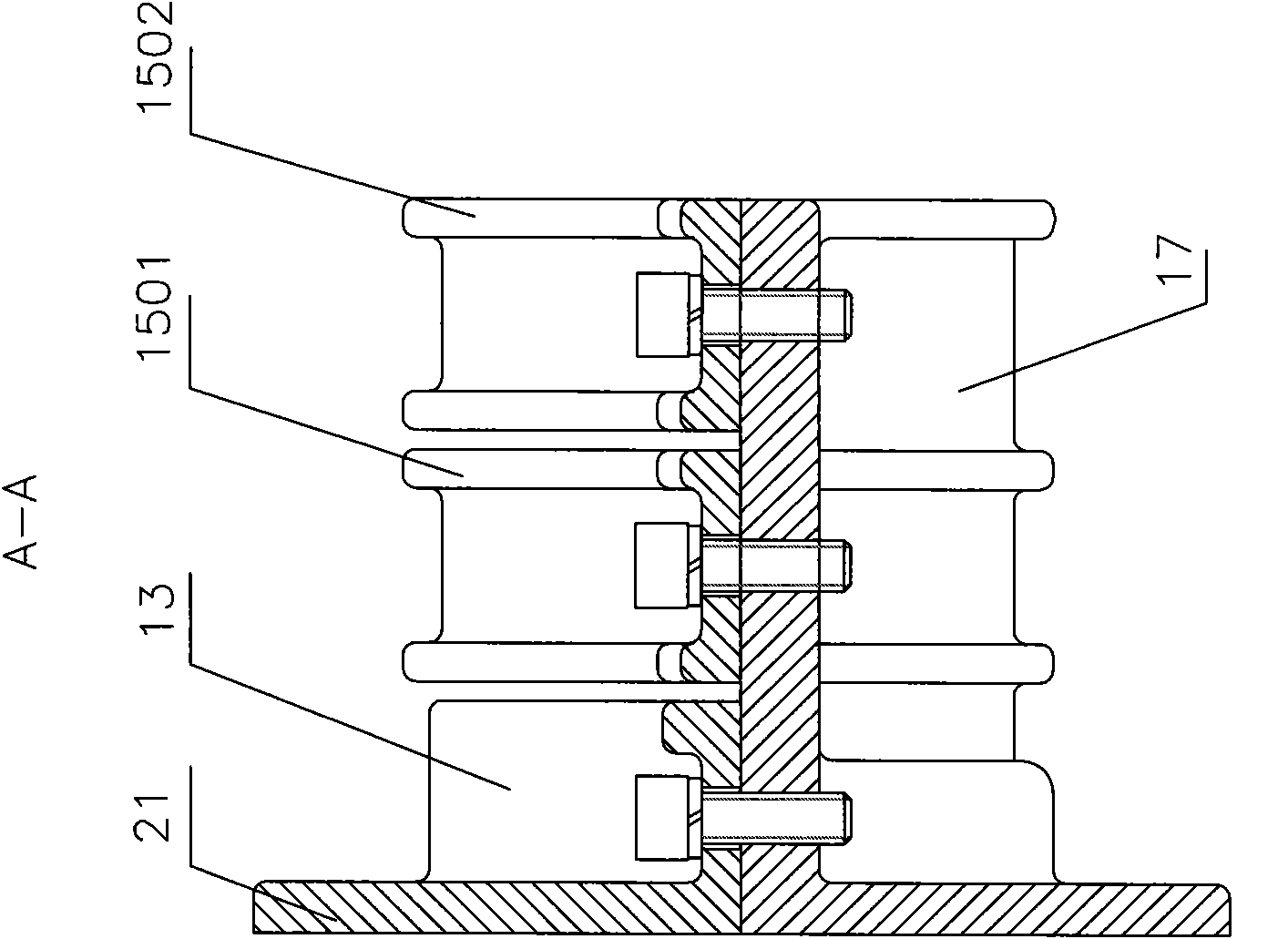

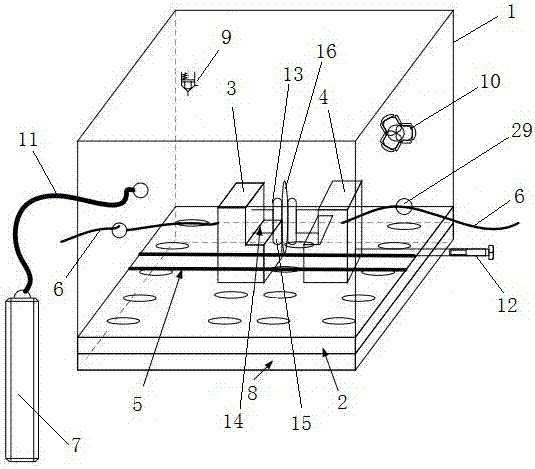

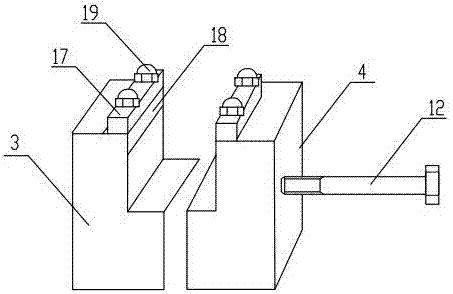

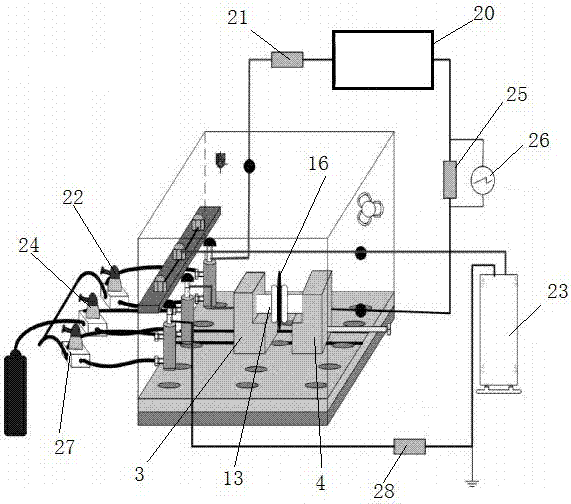

Electric field sensitive type insulation material static performance test device and system

ActiveCN106885976AGuaranteed operational safetyReduce the impact of coronaTesting dielectric strengthCurrent limitingTraining set

The present invention discloses an electric field sensitive type insulation material static performance test device and system and belongs to the technical field in which electric, electrochemical or magnetic methods are adopted to test and analyze materials. The test system comprises an electric field sensitive type insulation material static performance test device. The test system further comprises a high-voltage direct-current power source, a current limiting resistor, a first pneumatic time delay high-voltage switch K1, a high-voltage non-inductive capacitor, a second pneumatic time delay high-voltage switch K2, a sampling resistor, an oscilloscope, a third pneumatic time delay high-voltage switch K3 and a discharge resistor. According to the test system, capacitor charging and discharging design is utilized, and therefore, damage to a power source caused by the change of the performance of a tested insulation material can be avoided, and the power source can be protected; and the postposition discharging resistor in the test system can fully discharge the residual electric quantity of the capacitor at the end of testing, and the safety of operation can be ensured.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

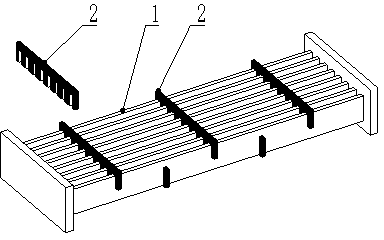

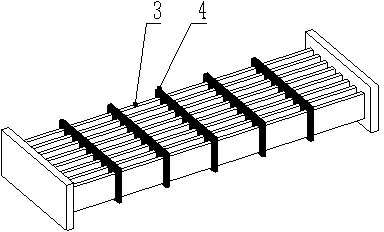

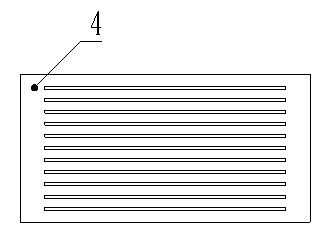

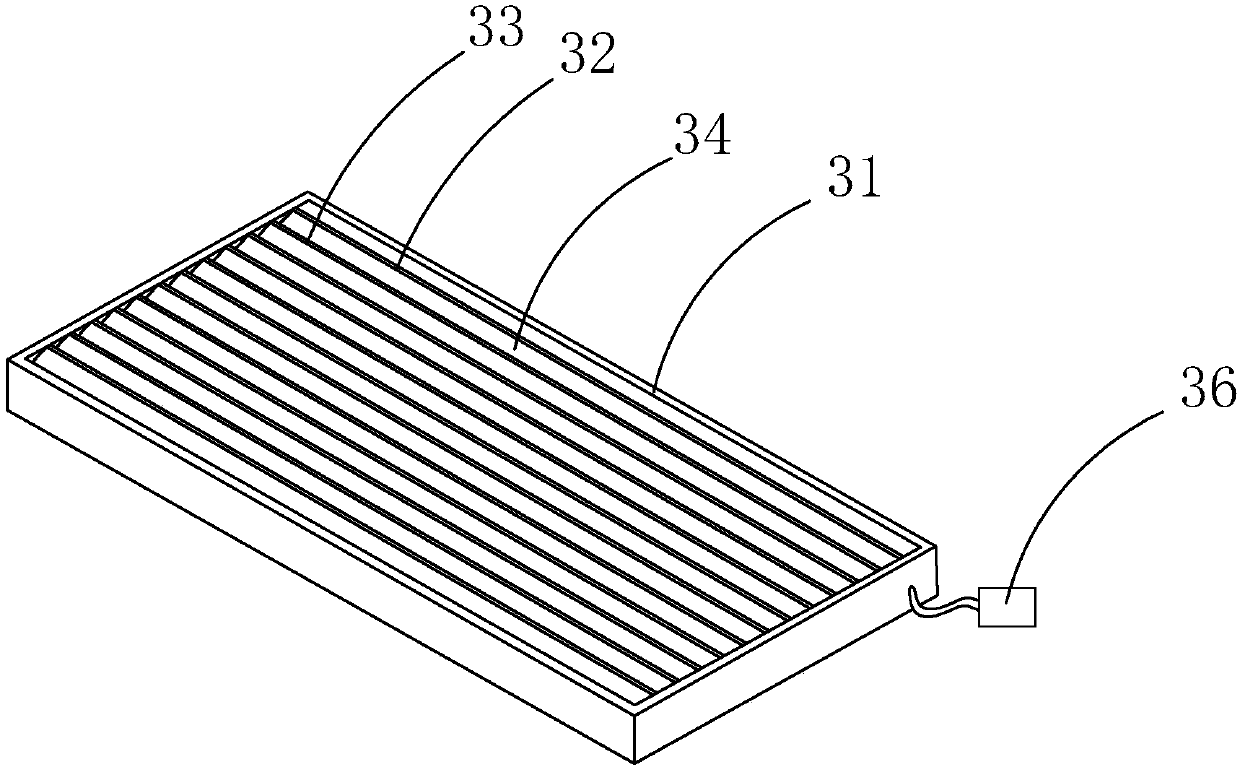

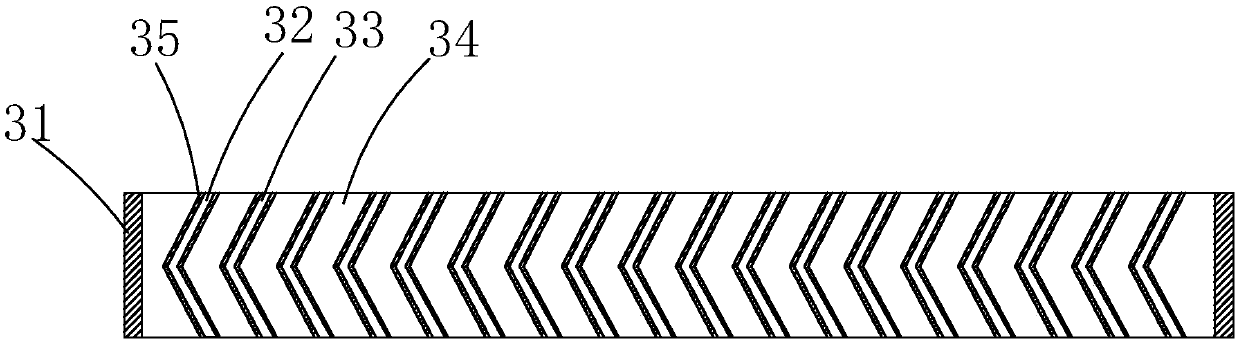

Electrostatic precipitator

InactiveCN104785371ANo discharge phenomenonVarious molding methodsElectrostatic separation detailsElectricityDie casting

The present invention provides an electrostatic precipitator, comprising an electrically charged unit and an electrostatic dust collection unit, and the electrostatic precipitator is characterized in that: the electrostatic dust collection unit adopts a spacer made from a metal material or an inorganic conductive material to keep a certain distance between dust collection plates and sheets. The air contact surface of the dust collection plates and sheets is made from an insulation material, so that adjacent dust collection plates and sheets may not be conducted. The spacer can be prepared by stamping molding of a metal plate such as an aluminum plate and a copper plate, also can be prepared by die-cast molding, metal bar pressing molding, and other manners, and an inorganic conductive material also can be used. Compared with a traditional electrostatic precipitator, electrostatic precipitator has the advantages of high efficiency, no arc discharge, low ozone and higher security.

Owner:QUALITY AIR SHENZHEN TECH CO LTD

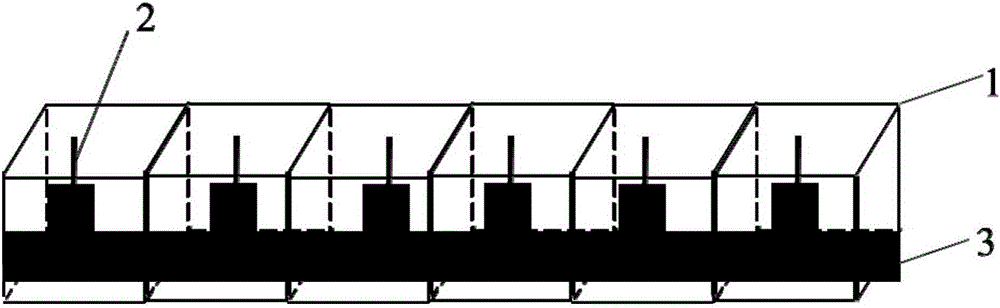

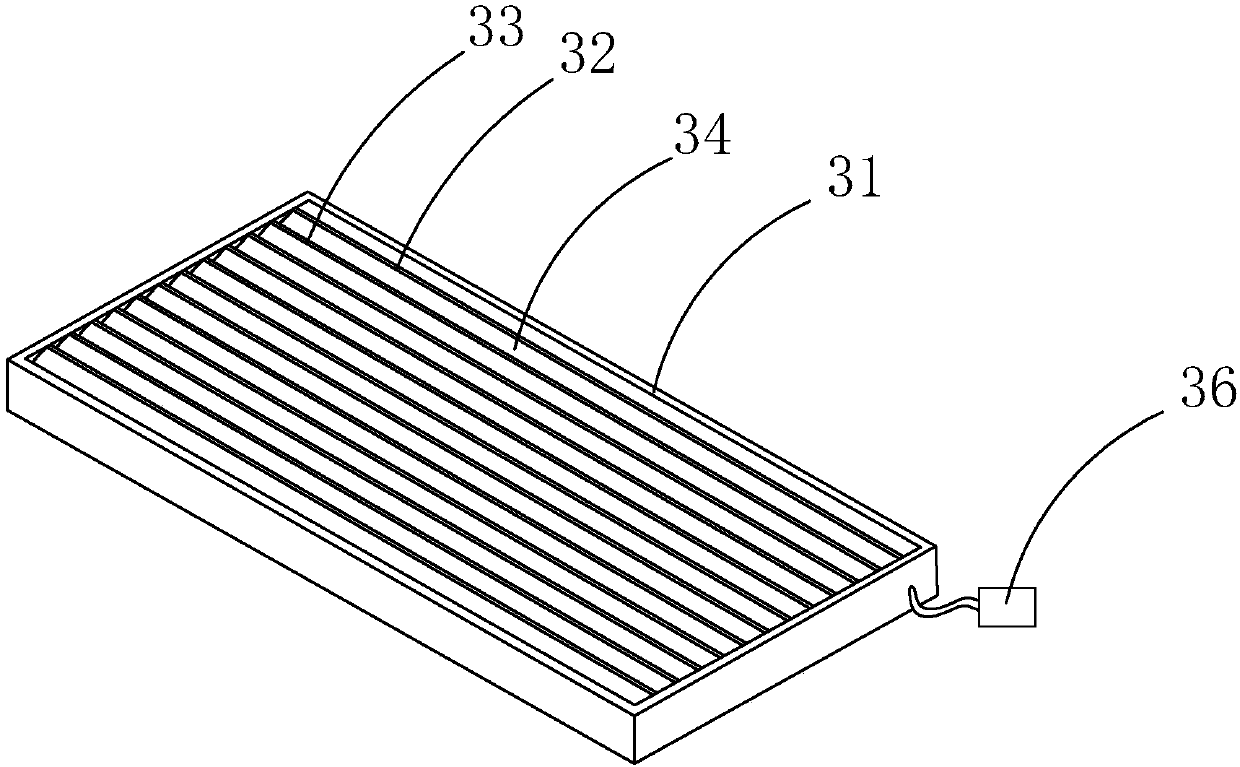

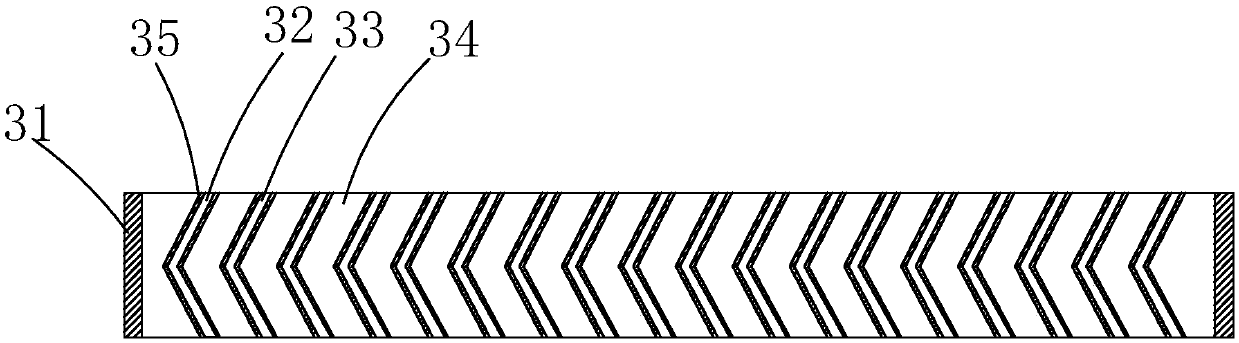

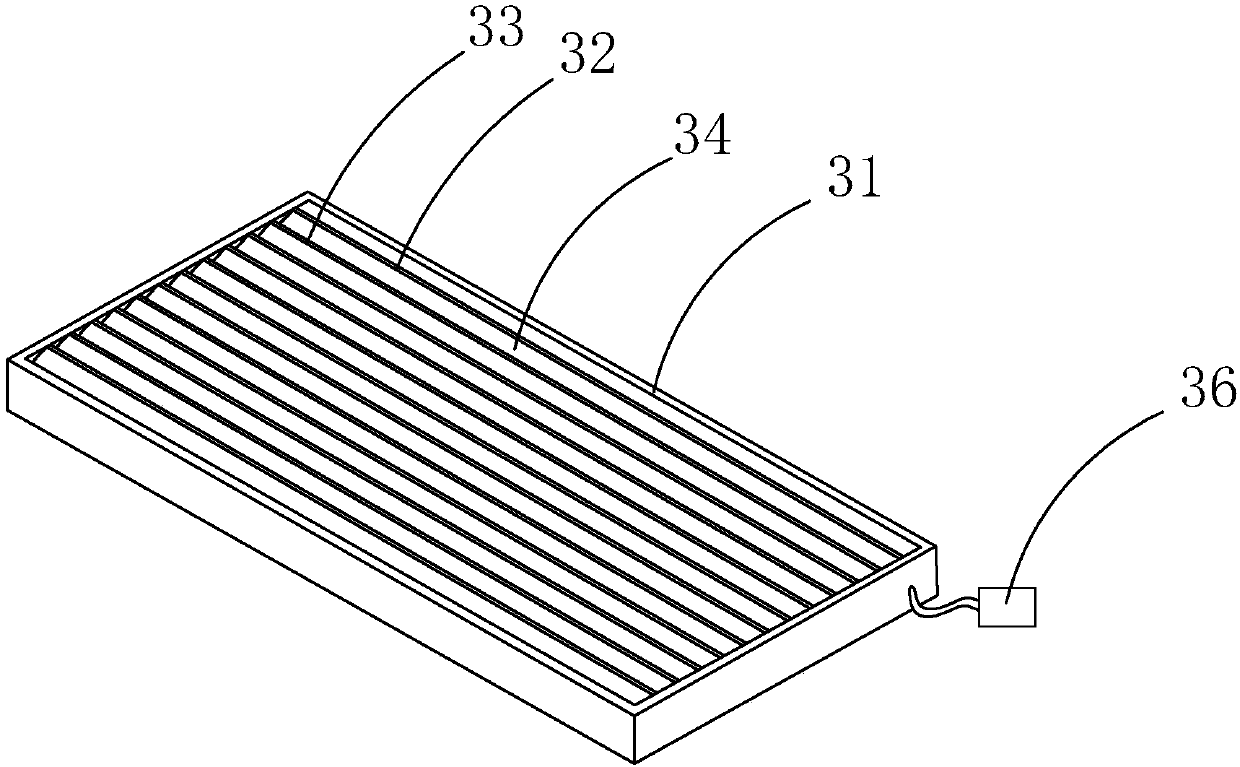

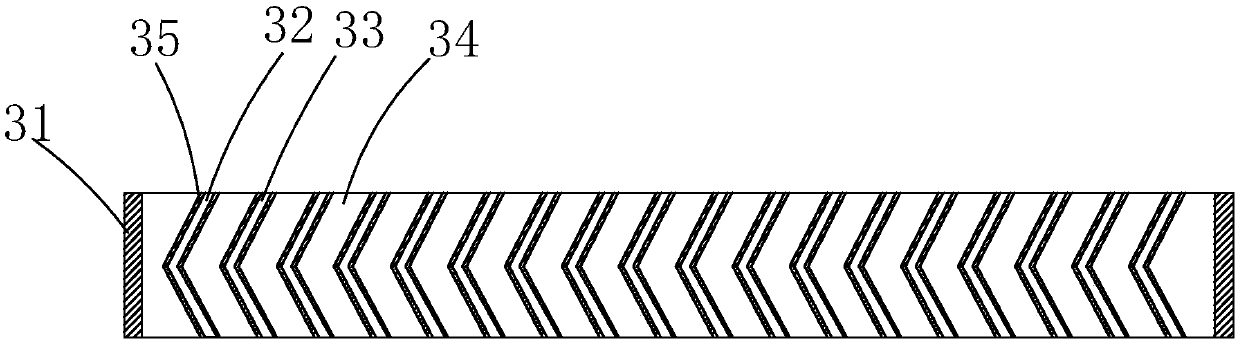

Dust collecting device applicable to machine room

InactiveCN107855220AExtended filter pathNo discharge phenomenonElectric supply techniquesInsulation layerAir filter

The invention discloses a dust collecting device applicable to a machine room. The dust collecting device comprises a shell, wherein an air inlet and an air outlet are formed in the shell; an exhaustfan, a polarizer and an electrostatic dust collector are sequentially arranged from the air inlet to the air outlet; the electrostatic dust collector comprises a frame, a positive plate and a negativeplate, wherein the positive plate and the negative plate are arranged on the inner side of the frame; the positive plate and the negative plate are arranged at an interval; a passage is left betweenthe two adjacent plates and is a bend passage; and insulation layers are coated on surfaces of the positive plate and the negative plate. The electrostatic dust collector is adopted for collecting dust, so that during work, dusty gas is electrically separated when passing through a high-voltage electrostatic field, dust is adsorbed on the plates, and a dust collecting effect is achieved; and withthe bend passage, an air filter path can be prolonged favorably, so that a dust collecting effect is better.

Owner:广东信通建设工程有限公司

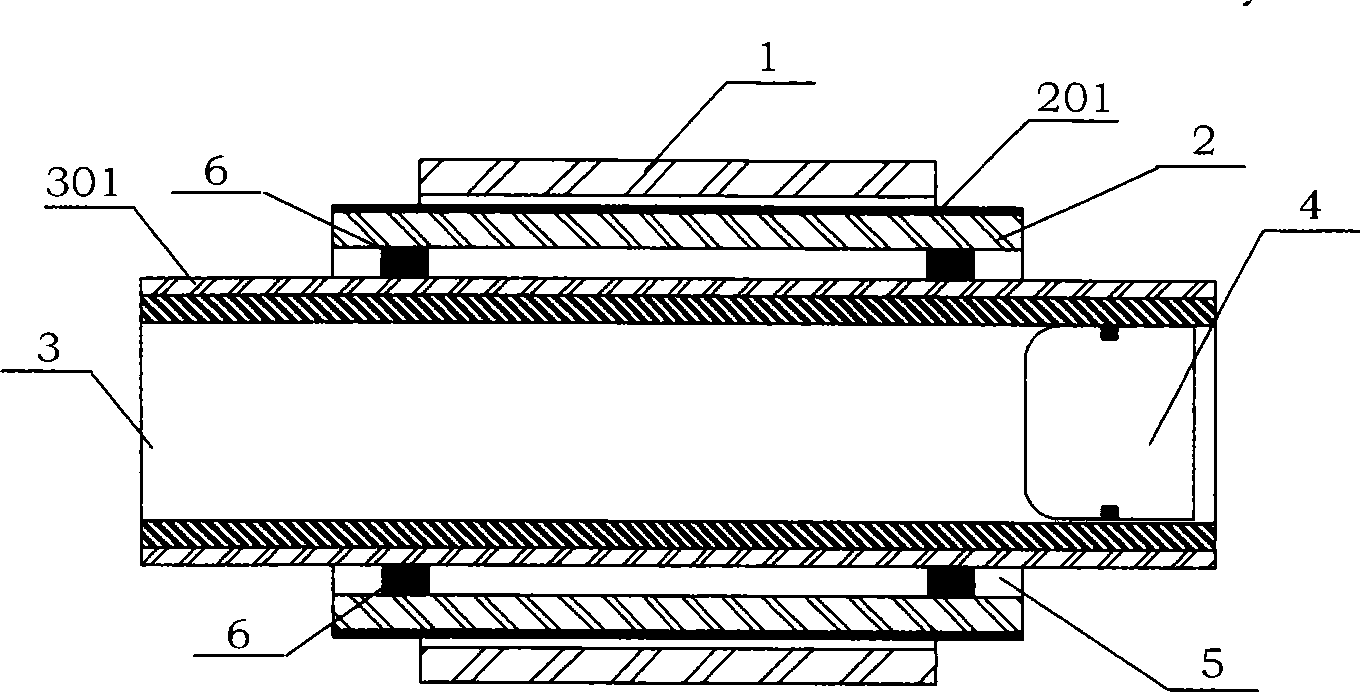

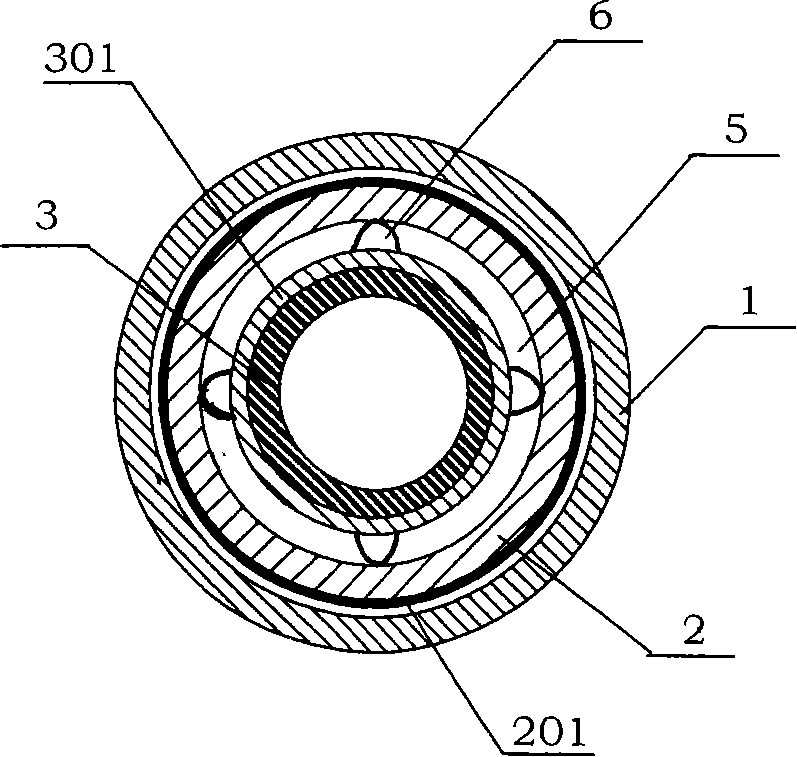

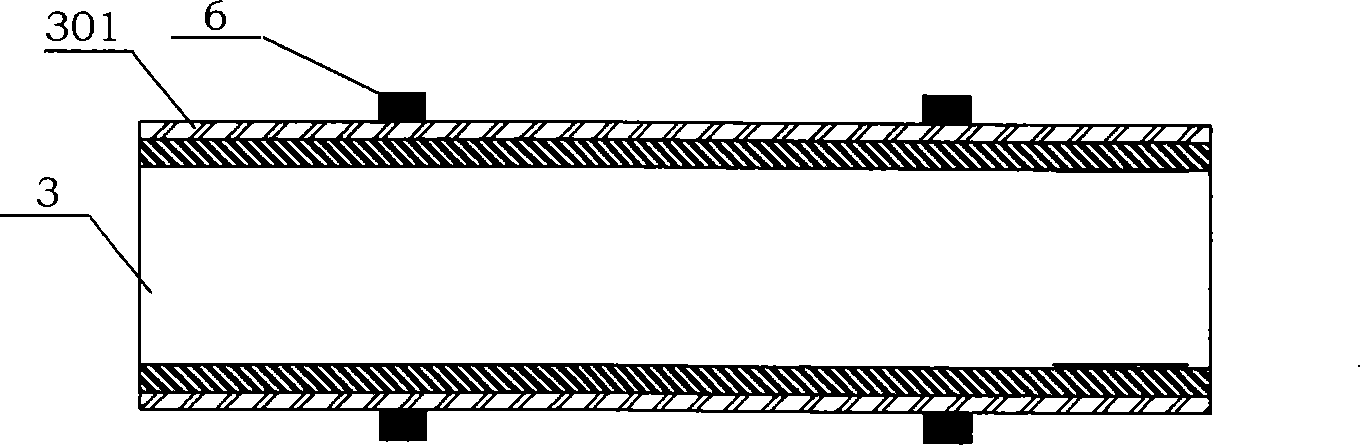

a collector ring

The invention discloses a collector ring, which relates to a low voltage electrical appliance and aims to eliminate the restrictions of an outlet position in the assembly of the conventional collector ring and other equipment. The collector ring specifically has a structure formed by pouring copper rings (5) and resin (6) into a whole. One end of the collector ring is provided with a step. The copper ring (5) and a copper bus (2) are fixedly connected in a poured body. An insulating layer is arranged between the copper bus (2) and the copper ring (5) which is not connected with the copper bus (2). An outlet terminal of the copper bus (2) is positioned at the lower end face (4) of the step of the collector ring. Bolts (1) are arranged at the upper end face (3) of the step of the collector ring. The outside outlet of the collector ring can provide a rational outlet position for rotating equipment without a central outlet position so as to eliminate the restrictions of the outlet position in the assembly of the collector ring and the other equipment.

Owner:洛阳聚科特种工程机械有限公司

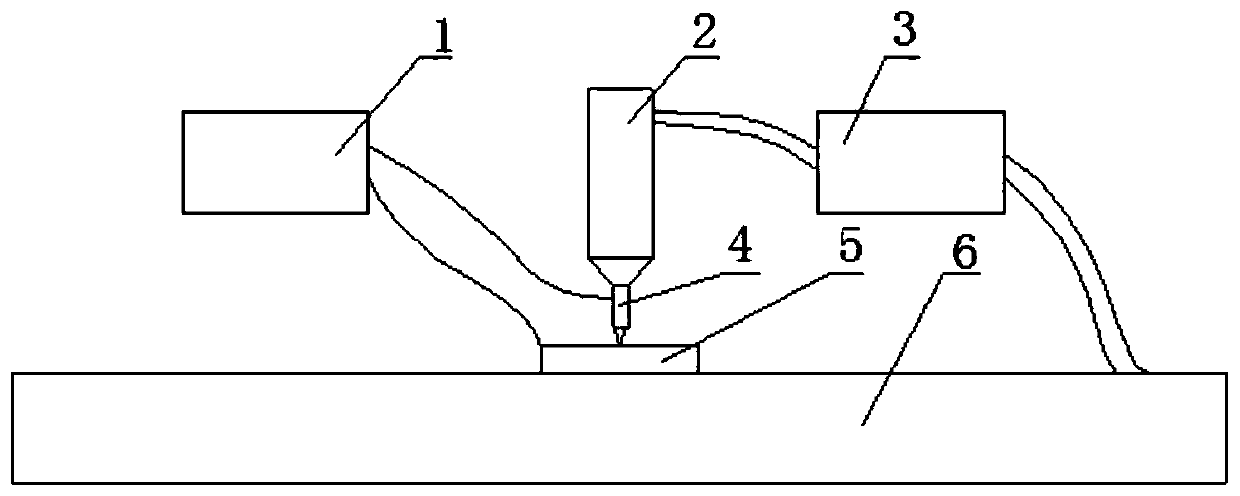

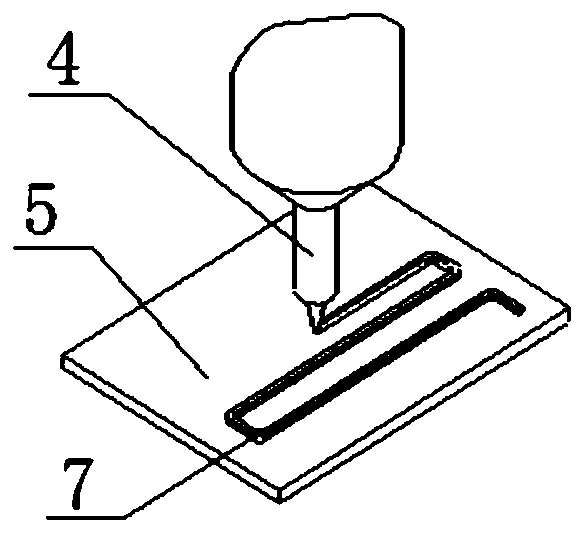

Near-field direct-writing technology-based micronano resistor strain gauge fabrication method and strain gauge

InactiveCN110793683AOmit productionSave pasteForce measurementElectrical/magnetic solid deformation measurementEpoxySilver paste

The invention relates to the field of strain gauges, in particular to a near-field direct-writing technology-based micronano resistor strain gauge fabrication method and a strain gauge. The method comprises the following steps of 1) placing a strain gauge substrate on a mobile platform; 2) inputting a sensitive gate shape of the strain gauge by a direct-writing device, and generating a mobile platform control code by a system; 3) injecting nanometer silver paste into an injector, connecting a high-voltage power supply, connecting a negative voltage to a metal pin, and allowing the strain gaugesubstrate to be connected with ground or connecting a positive voltage to the strain gauge substrate; 4) taking the written strain gauge substrate out of the mobile platform, drying the strain gaugesubstrate in a drying oven for 5 hours, taking out and observing morphology, and testing a resistance value; 5) fixing the tested strain gauge by a binding agent, and covering an upper layer with an epoxy resin film; and 6) welding a leading-out line after the binding agent is dried. By the method, an individual micronano strain gauge can be made according to a demand, the process is flexible, moreover, the two processes of alloy foil fabrication and pasting are omitted, and the cost is low.

Owner:JIHUA LAB

Dust removal device for communication machine room

InactiveCN107649292AExtended filter pathNo discharge phenomenonParticle charging/ionising stationsElectrode constructionsElectricityAir filter

The invention discloses a dust removal device for a communication machine room. The dust removal device comprises a shell. An air inlet and an air outlet are formed in the shell. An exhaust fan, a polarization device and an electrostatic precipitator are sequentially arranged from the air inlet to the air outlet. The electrostatic precipitator comprises a frame, a positive pole plate and a negative pole plate, wherein the positive pole plate and the negative pole plate are arranged on the inner side of the frame. The positive pole plate and the negative pole plate are spaced, and a passage isreserved between the adjacent pole plates. The passage is a bent passage. The surface of the positive pole plate and the surface of the negative pole plate are coated with insulating layers. Dust removal is performed by the adoption of the electrostatic precipitator, when the electrostatic precipitator operates, gas containing dust is electrically separated when passing through a high-voltage electrostatic field in work, the dust is adsorbed to the pole plates, and the dust removal effect is achieved; the air filtering path can be extended due to the bent passage, and the dust removal effect is better; furthermore, through covering of the insulating layers, no discharging phenomenon is generated between the positive pole plate and the negative pole plate, and therefore ozone generation isavoided; and the structure is safe, practical, stable and reliable.

Owner:江门市中讯通信技术有限公司

Communication machine room with electrostatic dust removing function

InactiveCN107930852AExtended air filtration pathGood dust removal effectElectric supply techniquesElectrode constructionsElectrostatic adsorptionElectrostatic attraction

The invention discloses a communication machine room with electrostatic dust removal. From the air inlet to the air outlet, there are exhaust fans, polarizers and electrostatic adsorbers in sequence. The communication room uses a dust removal device to filter the air. There are channels between adjacent plates in the electrostatic adsorber and the channels are curved channels. When the dust-containing gas passes through the high-voltage electrostatic field, it is electrically separated, and the dust is adsorbed on the electrode plate to achieve the dust removal effect. The curved channel is conducive to extending the air filtration path, and the dust removal effect is better; in addition, through the covering of the insulating layer, the positive plate and negative electrode There will be no discharge phenomenon between the plates, so as to avoid the generation of ozone, and the structure is safe, practical, stable and reliable.

Owner:广东信通建设工程有限公司

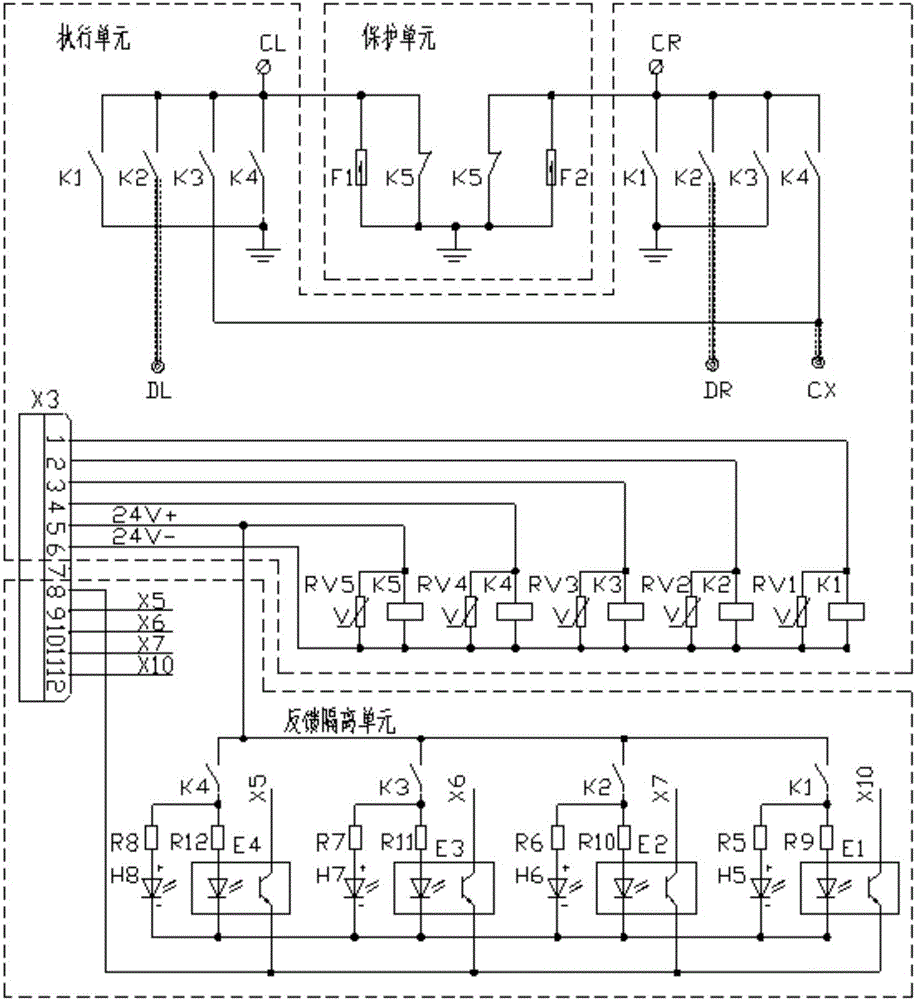

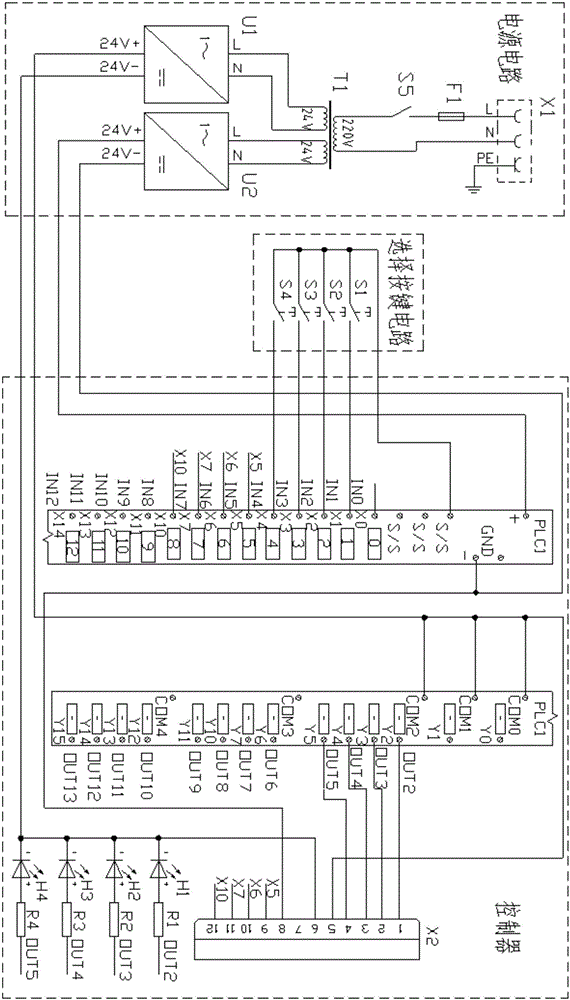

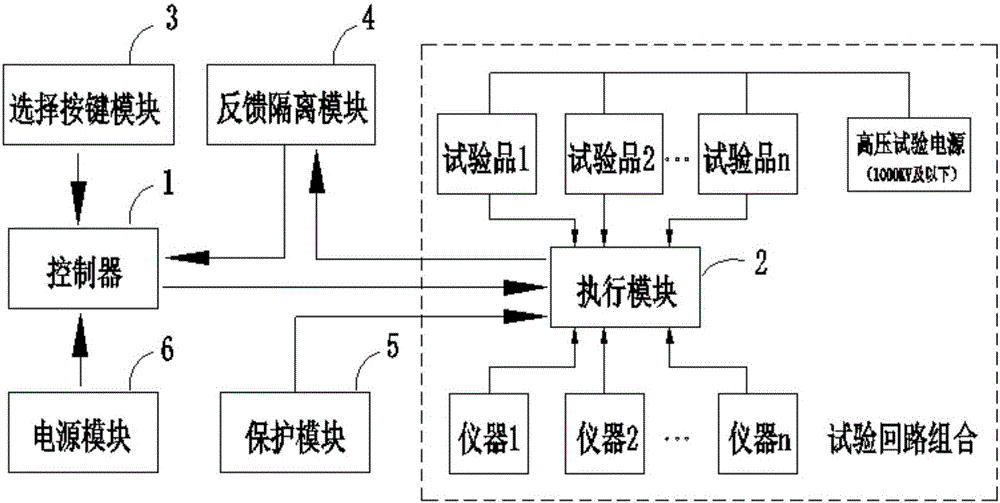

Electrifying wire-switching device and running method

ActiveCN106153989AReduce labor intensityNo discharge phenomenonMeasurement instrument housingTest efficiencyControl signal

The invention relates to an electrifying wire-switching device and a running method. The device comprises a controller and an executing module, wherein the controller is used for generating a wire-switching control signal and the executing module is used for connecting a test loop of a plurality of test loops, switching the connecting to the selected another test loop for test according to the wire-switching control signal, and delaying the disconnecting of the previous test loop which is connected. Compared with the prior art, the electrifying wire-switching device has the advantages that the test wiring is switched under the electrifying condition; no discharging phenomenon happens in a switching process; the test operation program is simplified; the test efficiency and safety are effectively increased; the labor intensity of the tester and the loss of test equipment are reduced.

Owner:GUILIN POWER CAPACITOR

High-insulation and high-voltage GIS (gas insulated switchgear) casing

InactiveCN108233245AProtect the sealing surfaceImprove structural strengthSwitchgear arrangementsEngineeringPulp and paper industry

The invention discloses a high-insulation and high-voltage GIS (gas insulated switchgear) casing. The casing comprises a main cylinder, main cylinder flanges and branch cylinder assemblies, wherein female ends of the main cylinder flanges are nested on the main cylinder at an interval and fixedly connected through welding; each branch cylinder assembly comprises a branch cylinder II and a branch cylinder flange; the outward end surfaces of the main cylinder flanges concave inwards to form round grooves I; further improvement is characterized in that the outward end surfaces of the branch cylinder flanges concave inwards to form round grooves II; holes are formed in the side wall of the main cylinder, openings of the holes extend outwards to form the branch cylinders I, and the intersections of the main cylinder and the branch cylinders I are in circular arc transition connection; the branch cylinder I is welded and fixedly connected with the end part of the branch cylinder II of the branch cylinder assembly; the diameter of an inner hole of each main cylinder flange is equal to that of an inner hole of the main cylinder, and a joint between the inner end surface of the female end of each main cylinder flange and each inner groove of the main cylinder is ground flush; insulated coatings are arranged on the inner walls of the inner holes of the main cylinder and the walls of theinner holes of the main cylinder flanges. The sealing surfaces of the main cylinder flanges and the branch cylinder flanges can be effectively protected, the insulation performance is good, and no discharge phenomenon can be caused.

Owner:JIANGSU HAIDA ELECTRIC

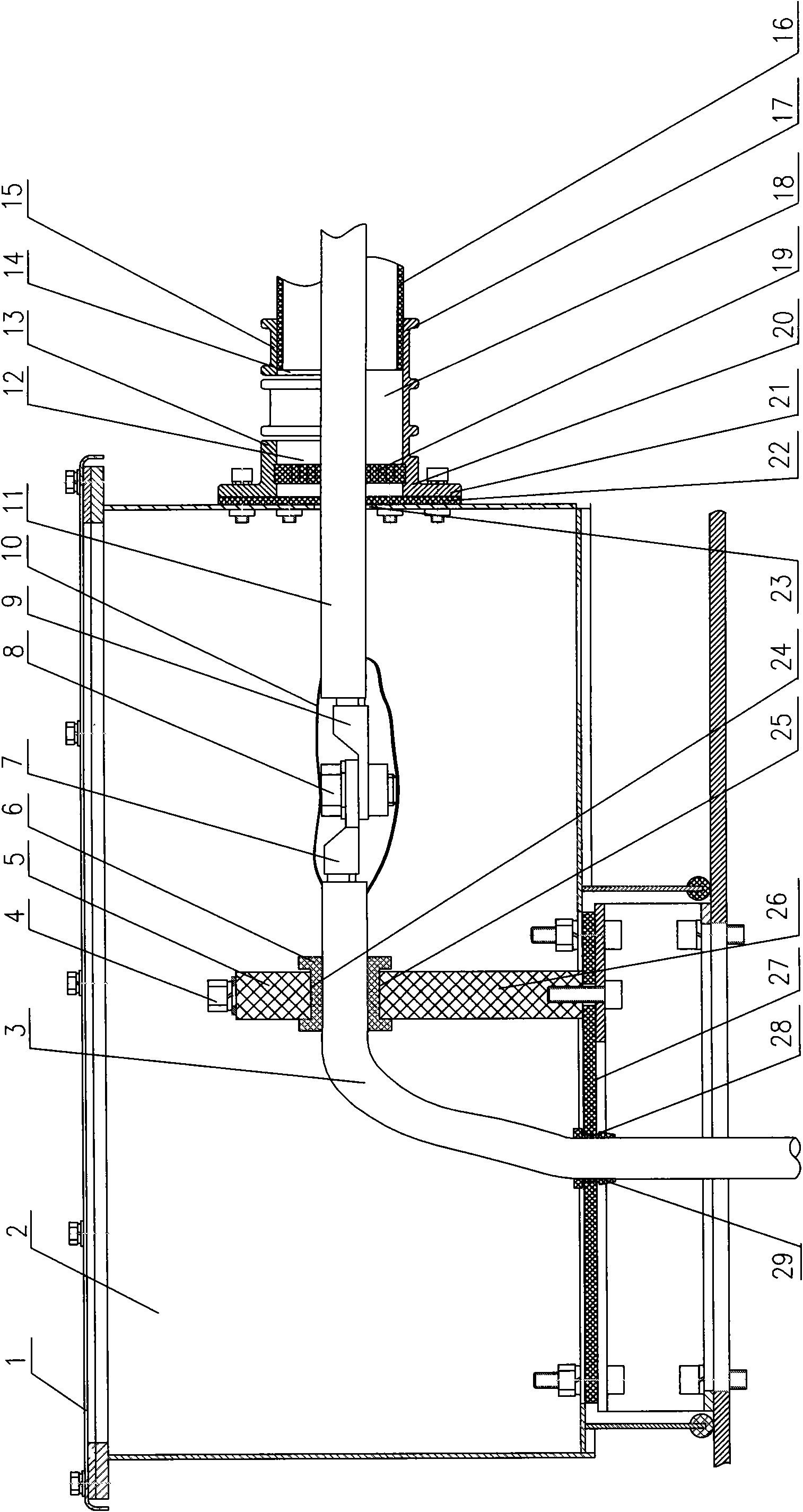

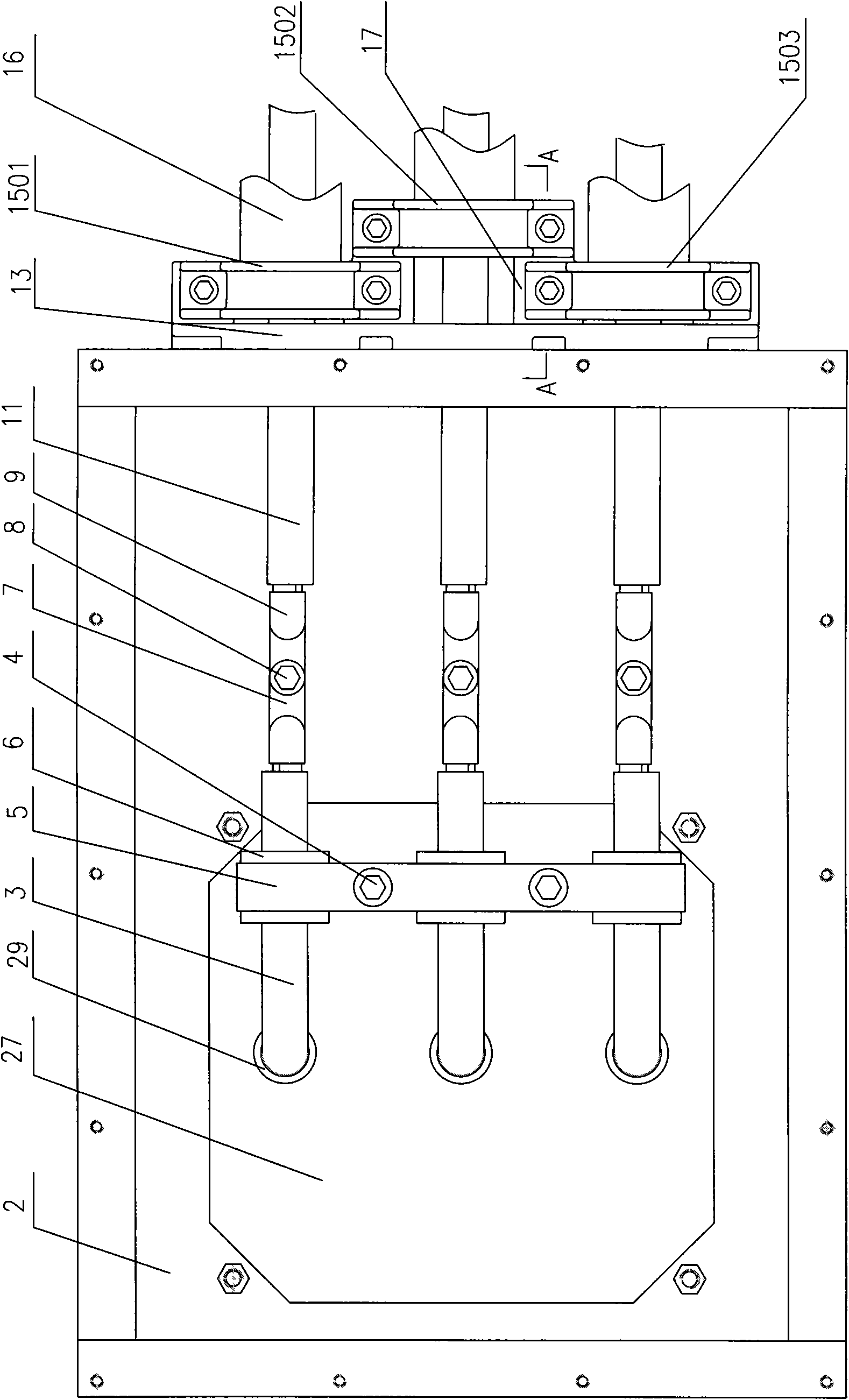

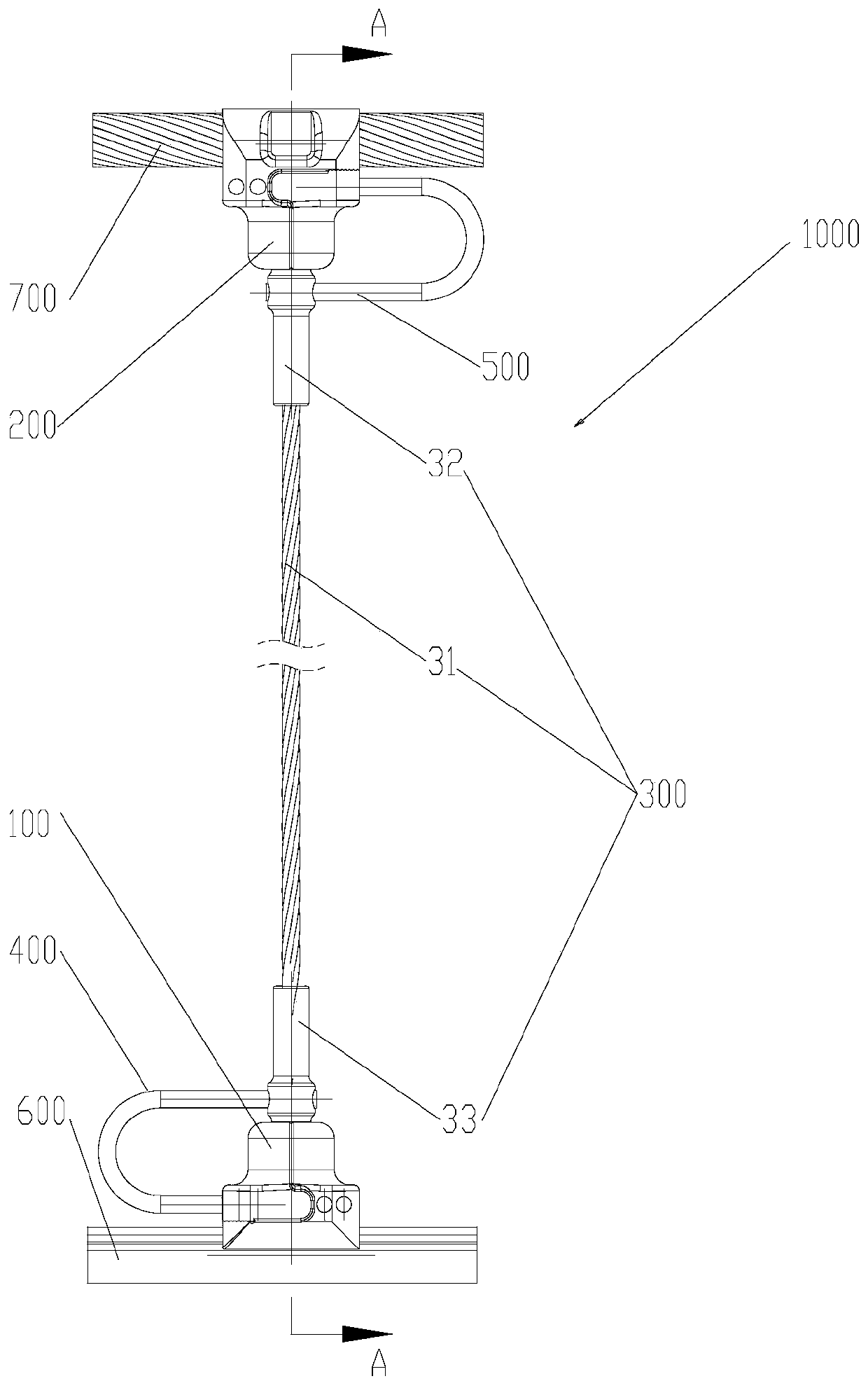

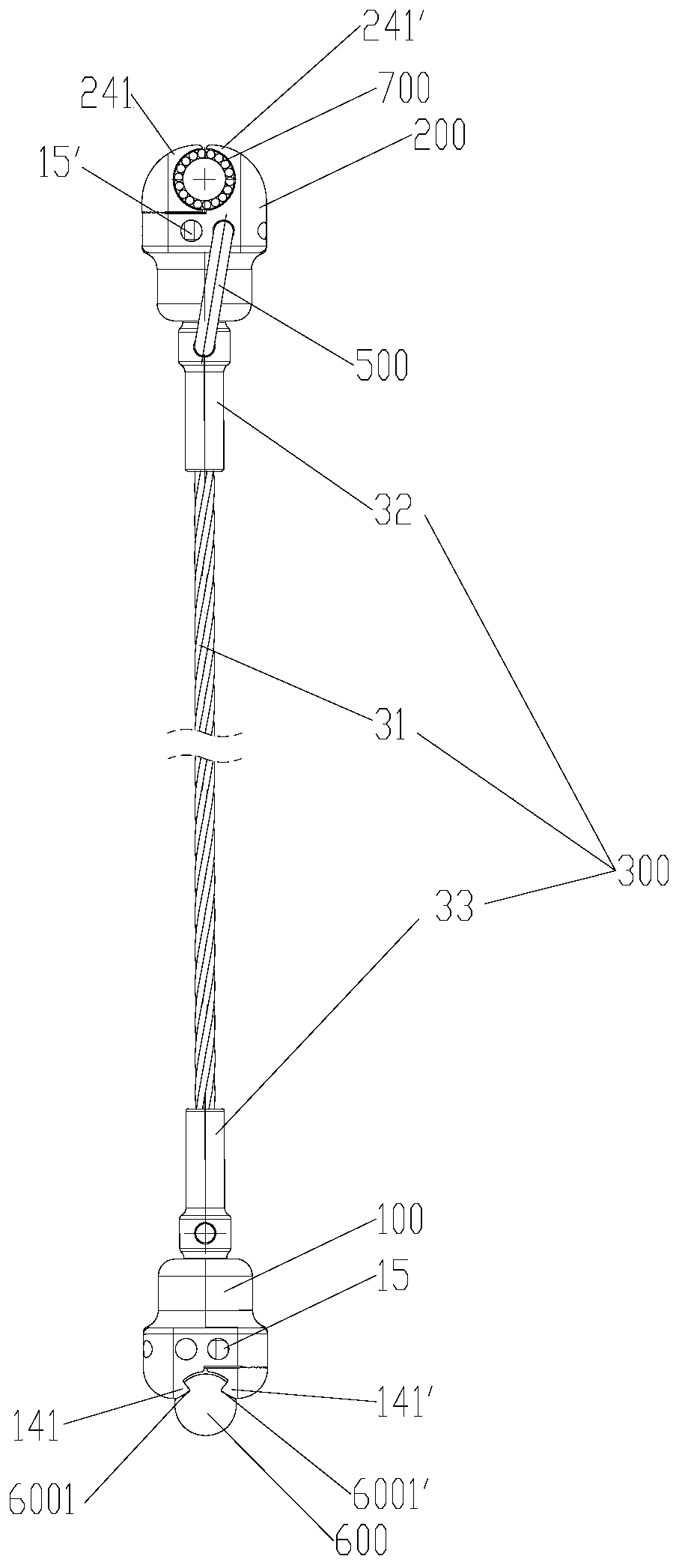

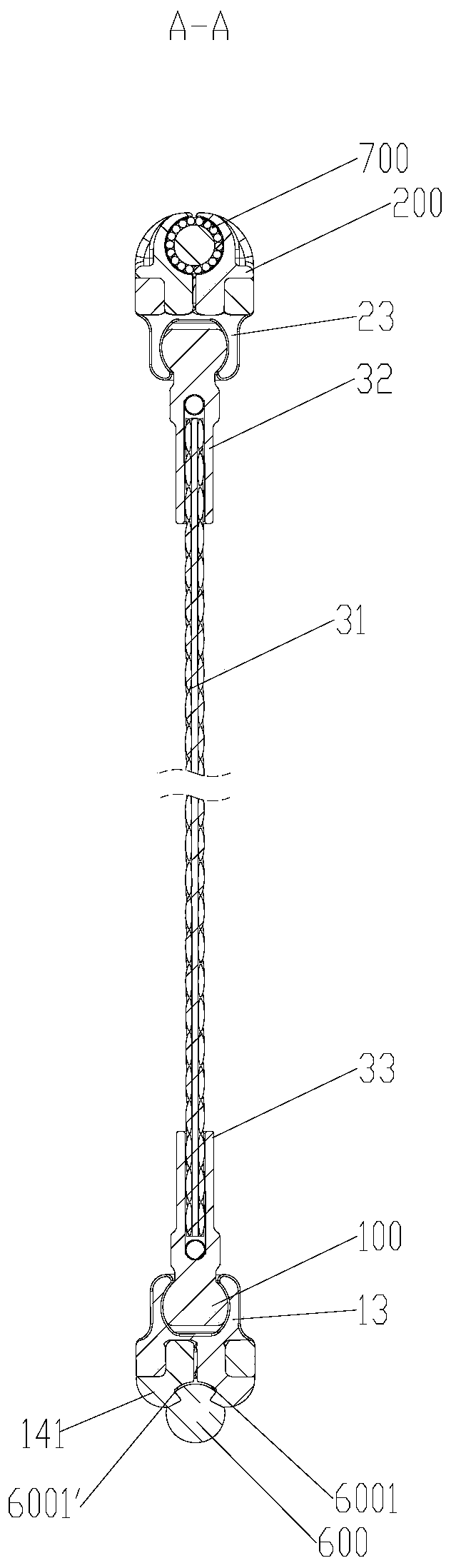

Boltless contact wire dropper wire clip, boltless carrier cable dropper wire clip, dropper wire and integrated dropper device

The invention discloses a boltless contact wire dropper wire clip, a boltless carrier cable dropper wire clip, a dropper wire and an integrated dropper device, and relates to an electrified railway contact net erecting device. The integrated dropper device comprises the dropper wire, and further comprises the boltless contact wire dropper wire clip and the boltless carrier cable dropper wire clipwhich are rotatably connected at two ends of the dropper wire, wherein the boltless contact wire dropper wire clip is composed of a demountable contact wire left half dropper wire clip and a demountable contact wire right half dropper wire clip which are of the same structure, and are assembled together in a plug-in mode by using the vertical axis as the symmetrical axis through a positioning clamping device and an anti-loosing device, and the carrier cable dropper wire clip is composed of a demountable carrier cable left half dropper wire clip and a demountable carrier cable right half dropper wire clip which are of the same structure, and are assembled together in a plug-in mode by using the vertical axis as the symmetrical axis through a carrier cable clamping positioning device and ananti-loosing device. The integrated dropper device does not need a bolt when connected with a contact wire and a carrier cable, and is quick and convenient to construct.

Owner:西安远航专用装备制造有限公司

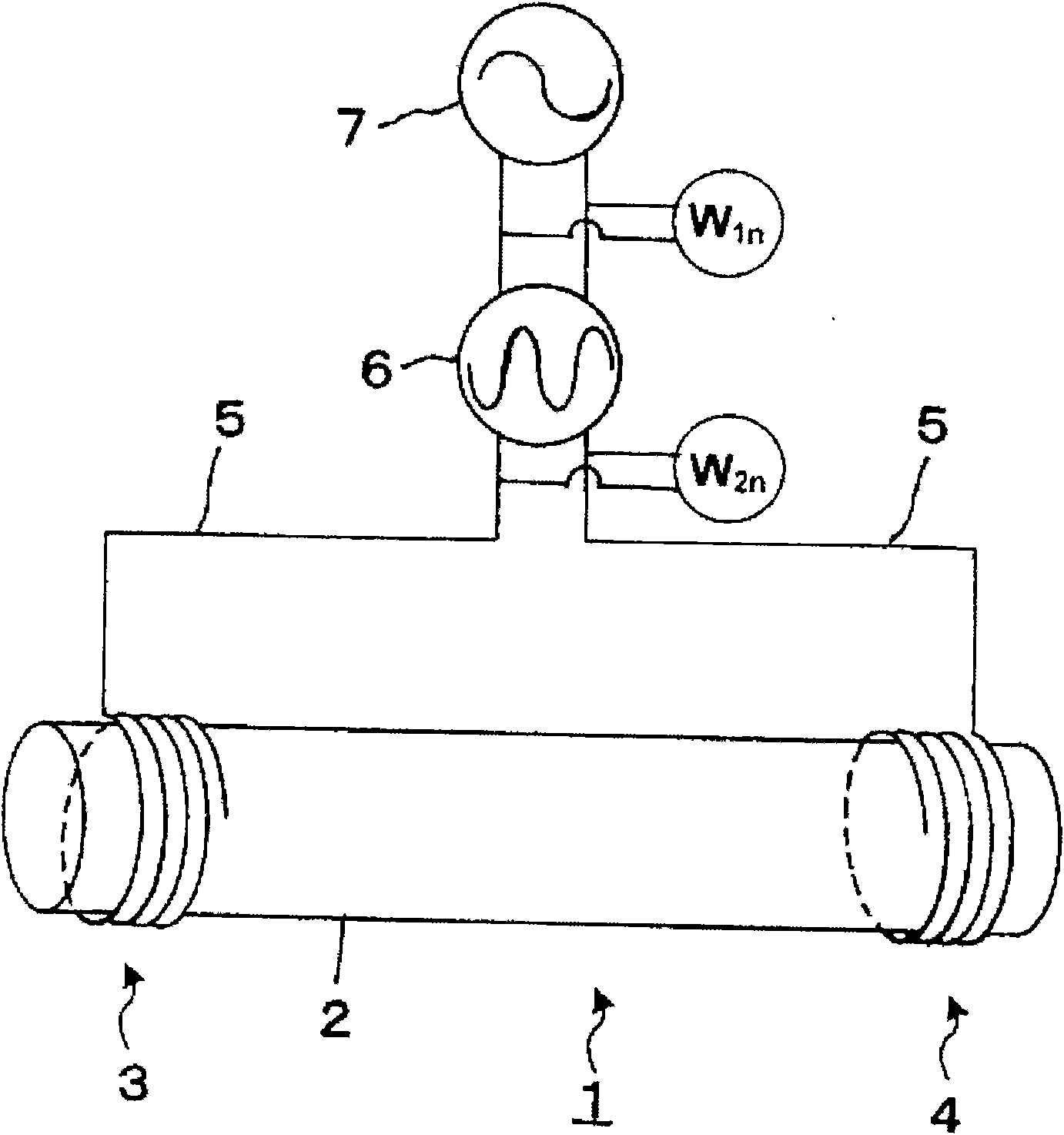

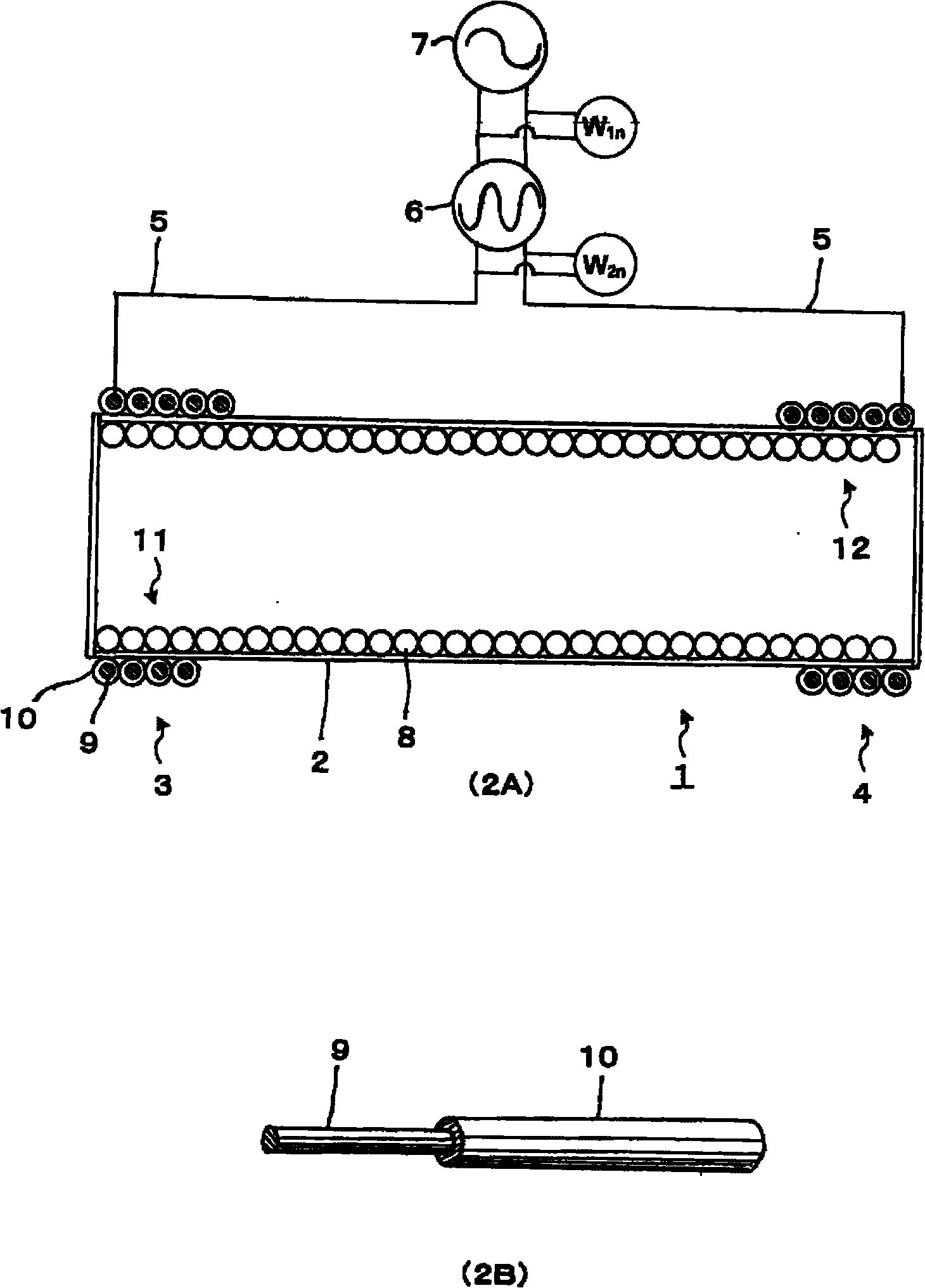

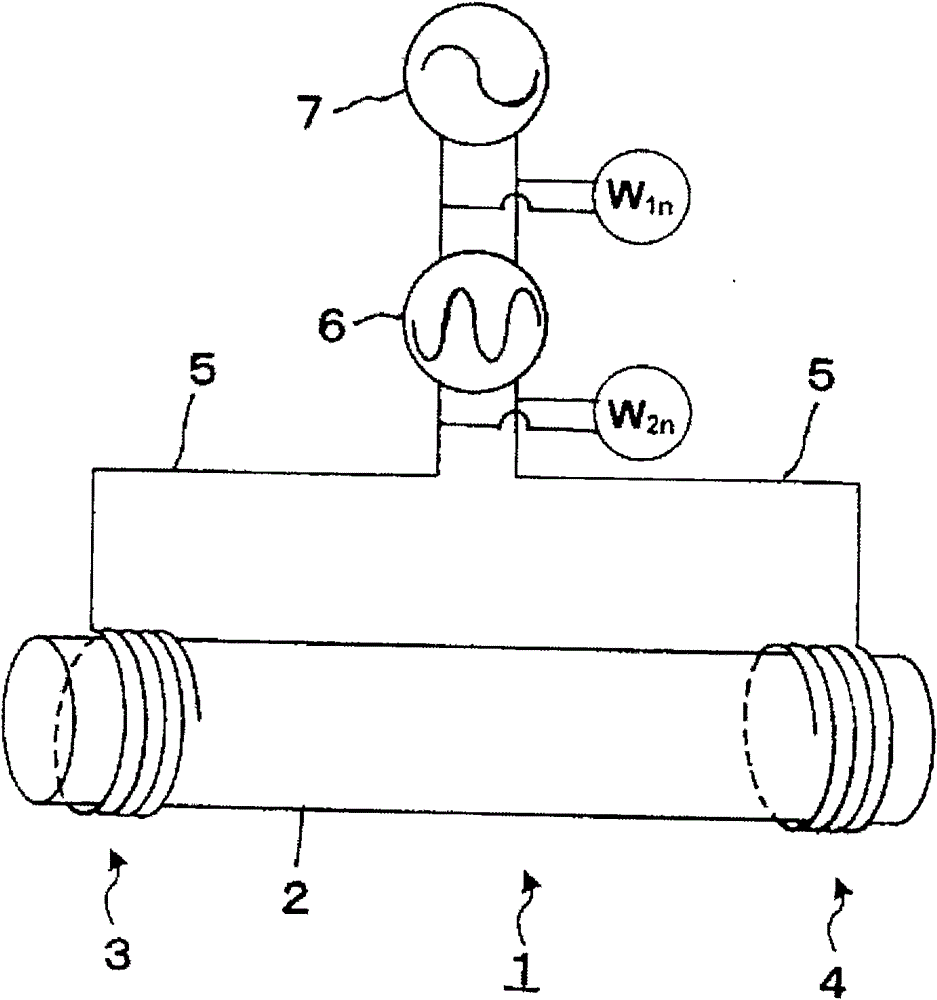

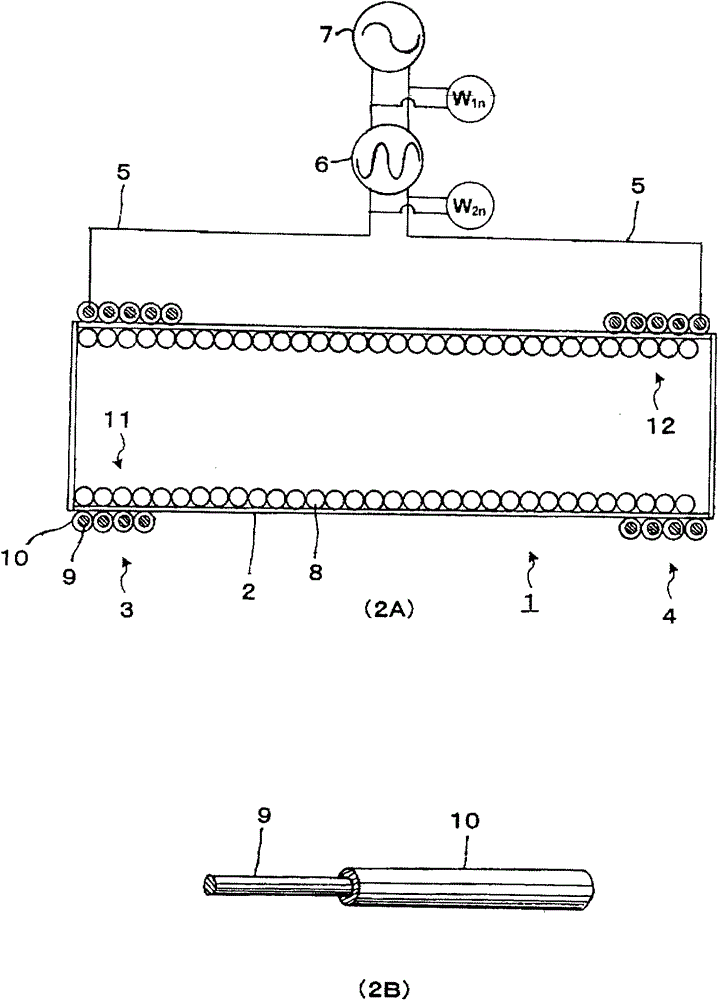

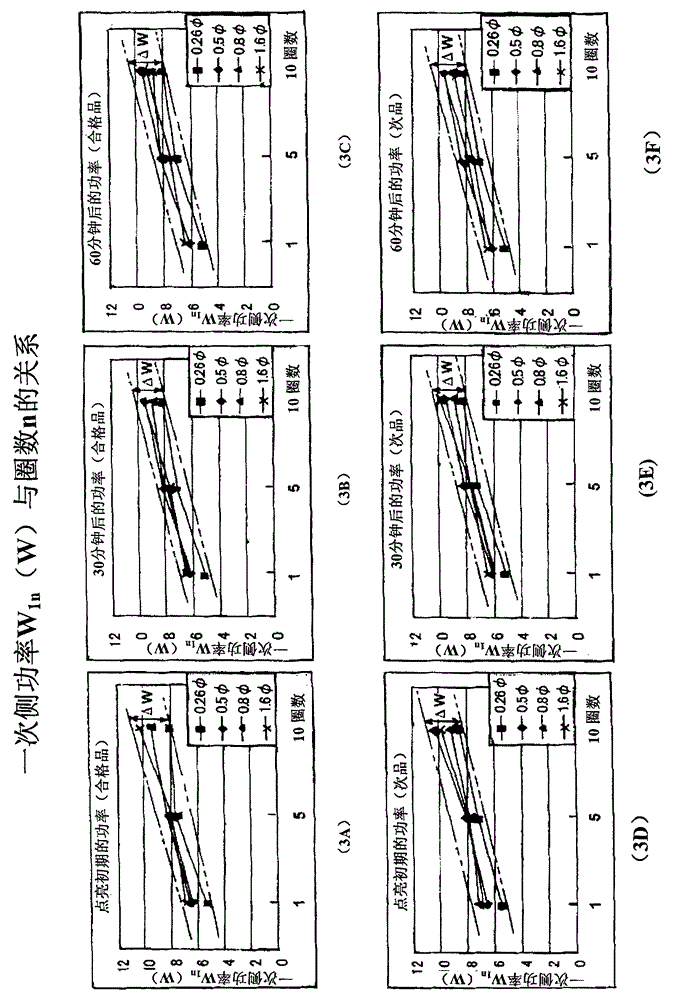

Coil electrode fluorescent electric-discharge lamp pipe

ActiveCN102067276AExtend your lifeNo discharge phenomenonPoint-like light sourceMultiple discharge path lampsElectric dischargeFluorescence

In a coil electrode fluorescent electric-discharge lamp pipe (1), a fluorescent film (8) is formed on the inner surface of a glass pipe (2) on positions to which coil electrodes (3, 4) are opposed. The pipe (1) can use the entire glass pipe (2) as a fluorescent electric-discharge region. The pipe (1) can provide illumination with high light intensity. The coil electrodes (3, 4) are constituted by forming an insulating coating electric wire in which the periphery of an electric wire (9) is covered with an insulating layer (10) in the shape of a winding, and consequently the electric wire (9) for the electrode is wounded on the glass pipe (2) via the insulating layer (10) and an electric-discharge phenomenon never occurs between the electric wire (9) and the surface of the glass pipe (2). This prevents reduction in the life of the fluorescent electric-discharge lamp pipe caused by a pinhole formed by the electric-discharge phenomenon. Thus, the long life of the fluorescent electric-discharge lamp pipe can be achieved. Further, the long life is achieved since an illumination efficiency is not deteriorated, and significant power saving can be realized under efficient power consumption.

Owner:北京千树万树互联网科技有限公司

Method for preparing melt-blown polypropylene electret filter material

The invention relates to a method for preparing a melt-blown polypropylene electret filter material. The method comprises the following steps of: 1) modification of polypropylene: melting the raw material, polypropylene, and mixing the melt with an additive to obtain modified polypropylene; 2) melt-blown preparation process: a) in a molten state, feeding the modified polypropylene melt into a spinneret plate by using a metering pump; b) extruding the modified polypropylene melt from a spinneret orifice; and c) blowing the melt extruded out from the spinneret orifice into ultrafine fibers by using high-speed hot air to make the fibers fly to a condenser net curtain to form a fiber net through cooling and bonding; and 3), preparation process of an electret: passing the fiber net obtained instep (2) through an electrode of a corona discharge device and obtaining the electret through the discharging of the electrode. The melt-blown electret high-efficiency filter material obtained by themethod has the advantages of very high electret charge stability, excellent filtering efficiency, very low pressure loss, long service life and optimal economic benefit.

Owner:HANGZHOU DIANZI UNIV +1

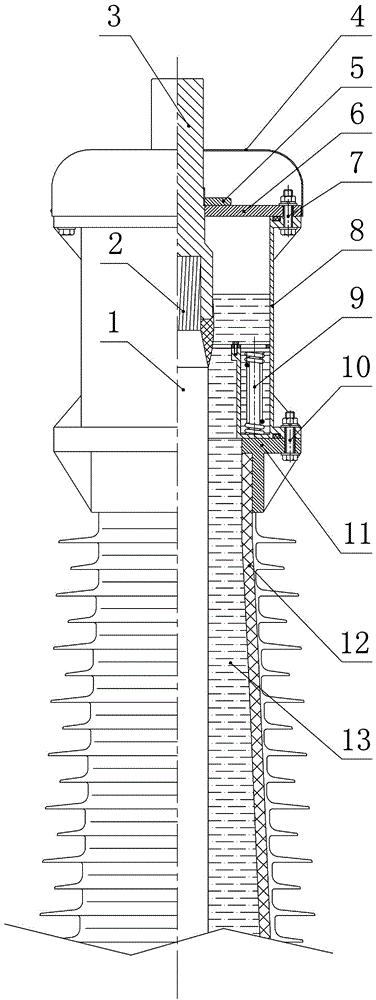

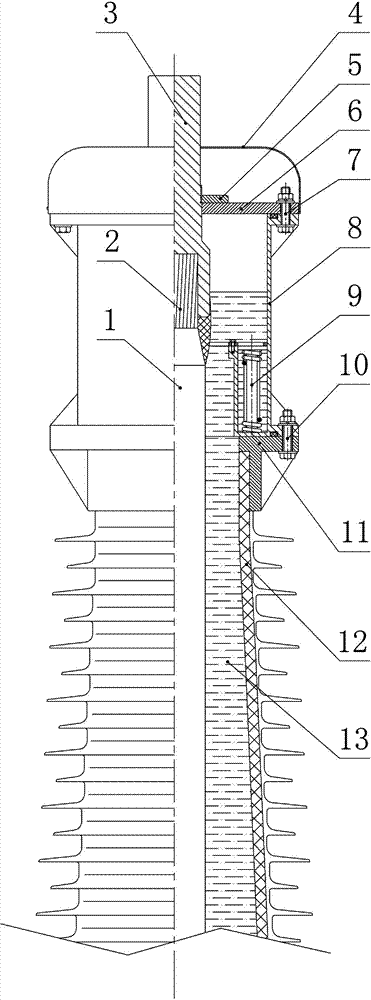

DC cable terminal oil-air interface lifting device

ActiveCN103887757BPlay a protective effectNo discharge phenomenonCable terminationsAir interfaceFuel tank

The invention discloses a direct-current electric cable terminal oil-gas interface lifting device which comprises an electric cable, an electric cable wire core, a wire-out rod, a top cover, a rain cover, an insulation sleeve pipe, insulation oil and a sleeve pipe flange. The direct-current electric cable terminal oil-gas interface lifting device is characterized in that a prefabricated oil tank is further included, one end of the prefabricated oil tank is connected to the sleeve pipe flange through a screwing bolt, the other end of the prefabricated oil tank is connected with the top cover through the screwing bolt, a cavity of the insulation sleeve pipe of a direct-current electric cable terminal is filled with the insulation oil, so that the insulation oil interface is lifted until the height of the insulation oil interface is lifted to more than 1 / 2 of the height of the prefabricated oil tank, the height of the insulation oil interface exceeds the horizontal face of the sleeve pipe flange, a Faraday cage is formed on the sleeve pipe of the direct-current electric cable terminal, the direct-current electric cable terminal is protected, and the discharging phenomenon generated on the air interface of the direct-current electric cable terminal under the effect of a direct-current electric field or an extra-high-voltage alternating-current electric field is avoided.

Owner:上海三原电缆附件有限公司

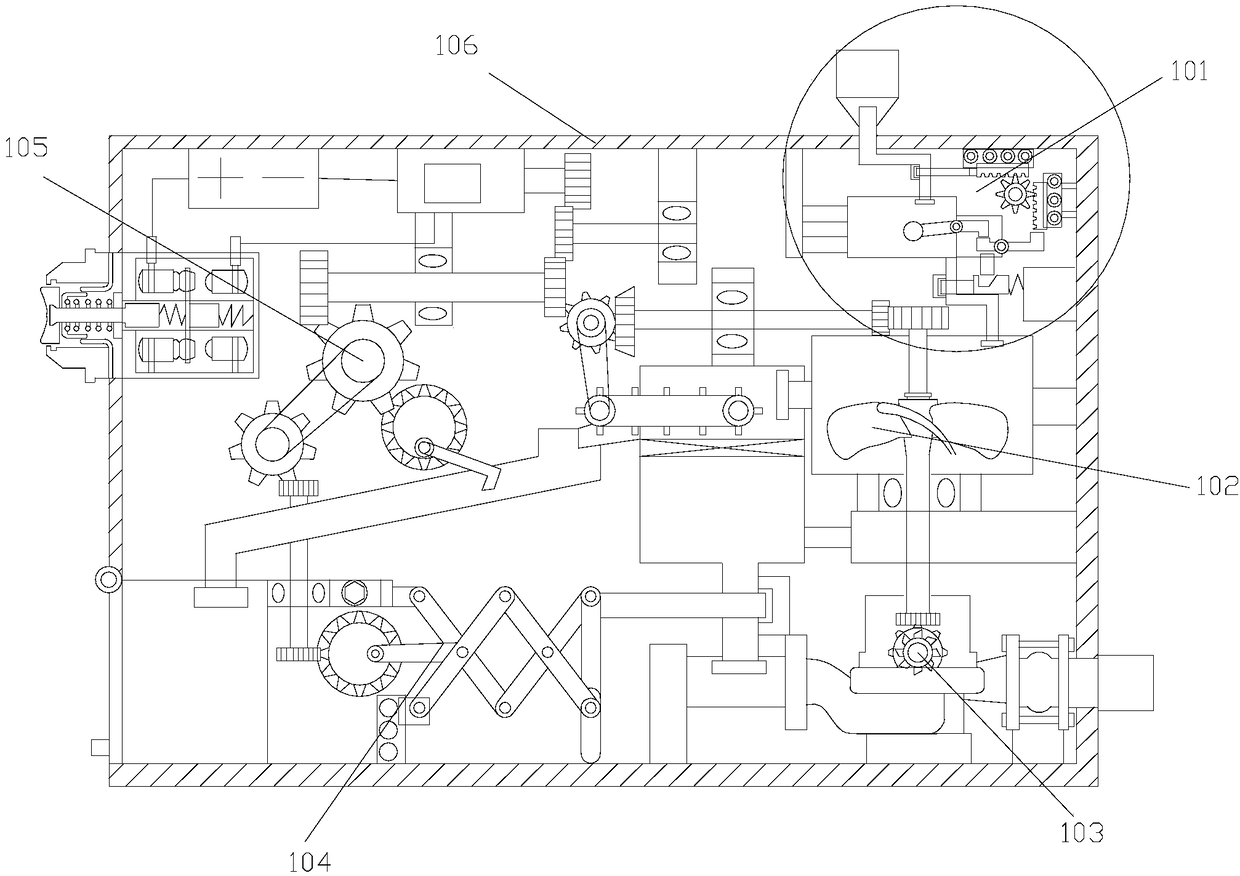

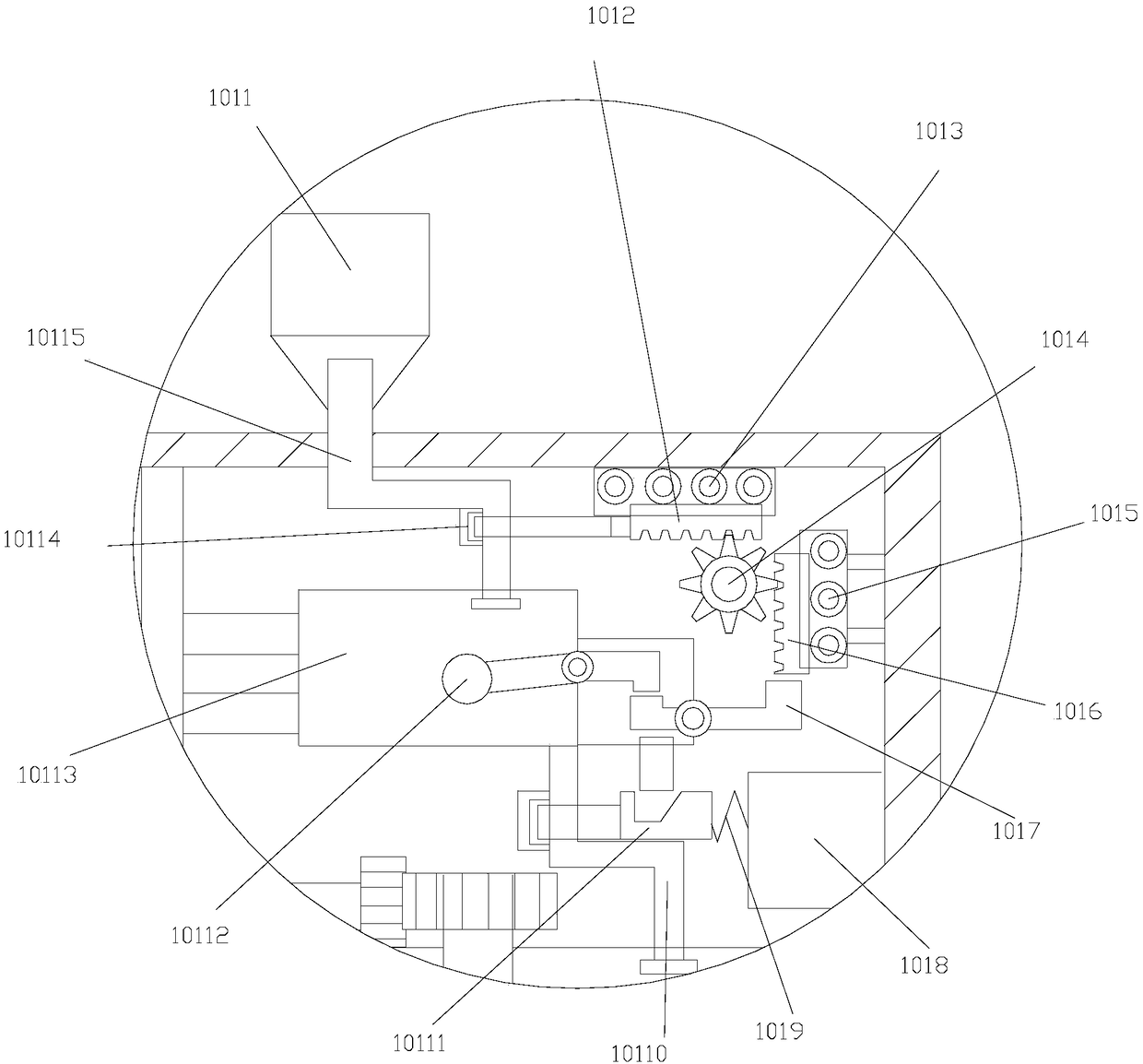

Discharging unit used for ozone generator

The invention provides a discharge unit used for an ozonizer, which includes an earth electrode, an insulating tube and a high voltage electrode, wherein, the high voltage electrode adopts conductive material and the earth electrode is earthed; the discharge unit also contains a discharging gap and is characterized in that: the discharge gap is between the high voltage electrode and the insulating tube, the outer surface of the insulating tube is covered with a layer of conductive metal and the conductive metal layer is earthed.

Owner:FUJIAN NEWLAND ENTECH CO LTD

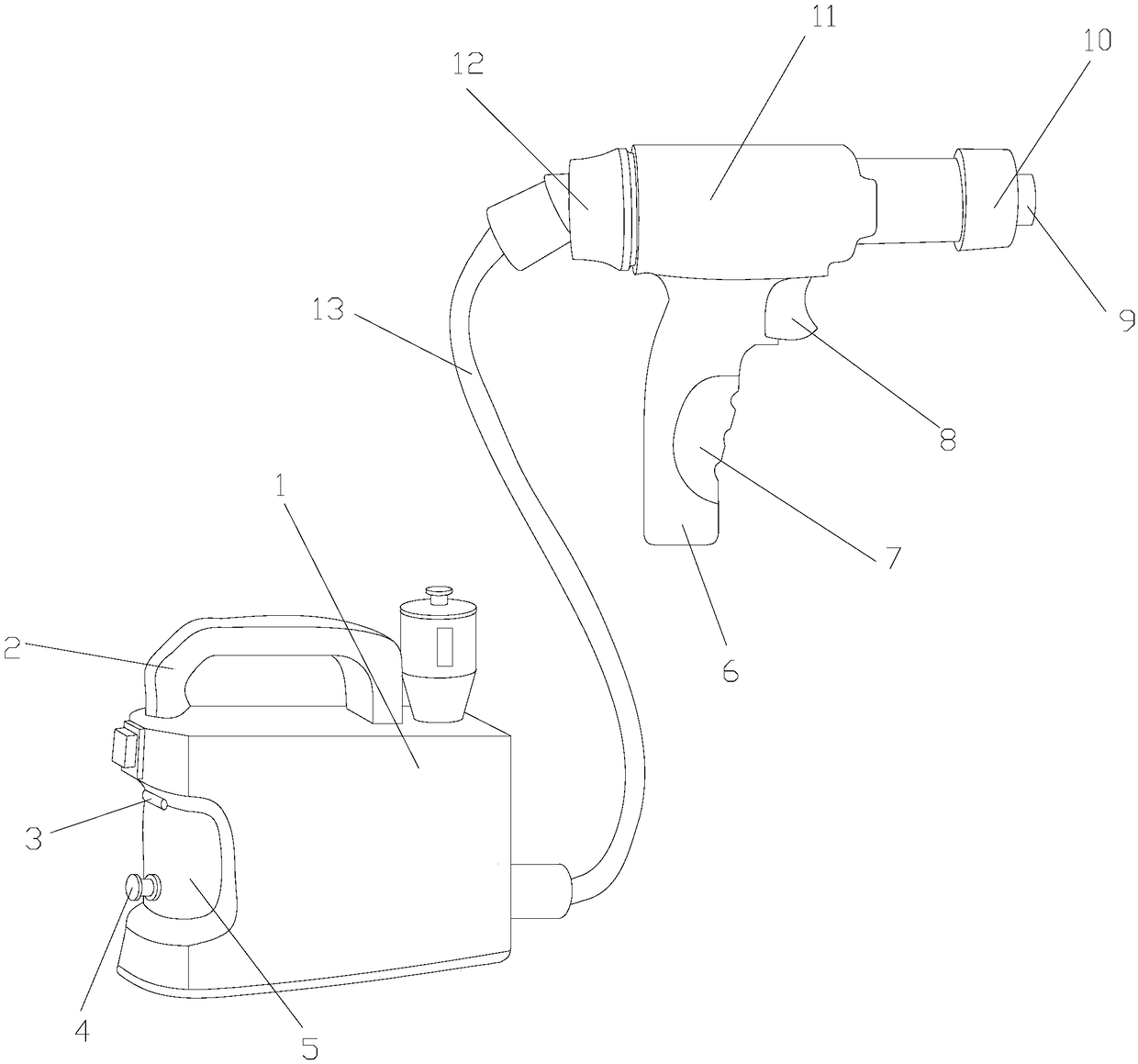

Coating structure on equipment for producing leather products

The invention discloses a coating structure on equipment for producing leather products. The coating structure comprises a spraying device, a handle, a hinge, a ring handle, a box door, a hand grip, an antiskid pad, a switch button, a nozzle, a nozzle fixing base, a spray gun, a hose connecting base and a hose, and the bottom of the handle is fixedly connected to the top of the spraying device byscrews; the right end of the box door is welded with an inner ring of the hinge, and attached to the left end of the spraying device; the top of the hand grip and the bottom of the spray gun are of anintegrated structure, and the right end of the hand grip is bonded with the left end of the antiskid pad; and the right side of the upper end of the hand grip is connected to the left end of the switch button in a slot manner. According to the coating structure on the equipment for producing the leather products, the structure is provided with the spraying device, and the vacuum problem is solvedthrough the device effectively; the blocking phenomenon due to the air pressure problem does not occur, and the wear and tear of internal parts is reduced; the service life is prolonged, and meanwhile the interior automatic filtering is achieved, so that the spraying effect is better; and impurities are not generated easily.

Owner:莆田市多迪贸易有限公司

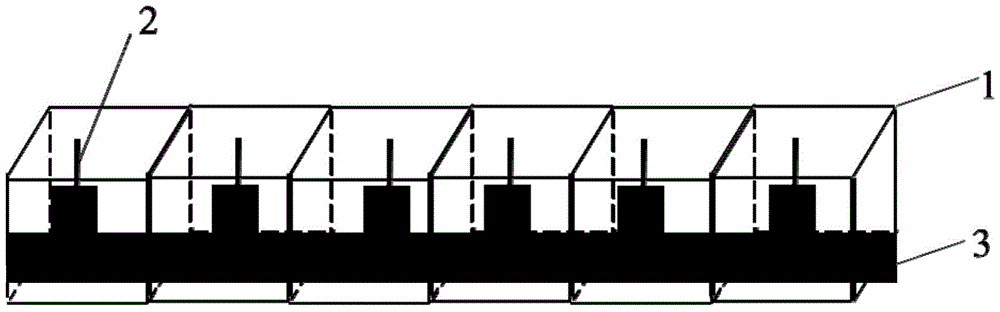

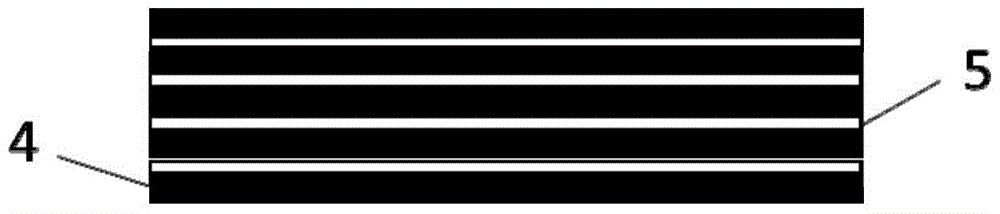

Coil electrode fluorescent electric-discharge lamp pipe

ActiveCN102067276BExtend your lifeNo discharge phenomenonPoint-like light sourceMultiple discharge path lampsElectric dischargeConductor Coil

In a coil electrode fluorescent electric-discharge lamp pipe (1), a fluorescent film (8) is formed on the inner surface of a glass pipe (2) on positions to which coil electrodes (3, 4) are opposed. The pipe (1) can use the entire glass pipe (2) as a fluorescent electric-discharge region. The pipe (1) can provide illumination with high light intensity. The coil electrodes (3, 4) are constituted byforming an insulating coating electric wire in which the periphery of an electric wire (9) is covered with an insulating layer (10) in the shape of a winding, and consequently the electric wire (9) for the electrode is wounded on the glass pipe (2) via the insulating layer (10) and an electric-discharge phenomenon never occurs between the electric wire (9) and the surface of the glass pipe (2). This prevents reduction in the life of the fluorescent electric-discharge lamp pipe caused by a pinhole formed by the electric-discharge phenomenon. Thus, the long life of the fluorescent electric-discharge lamp pipe can be achieved. Further, the long life is achieved since an illumination efficiency is not deteriorated, and significant power saving can be realized under efficient power consumption.

Owner:北京千树万树互联网科技有限公司

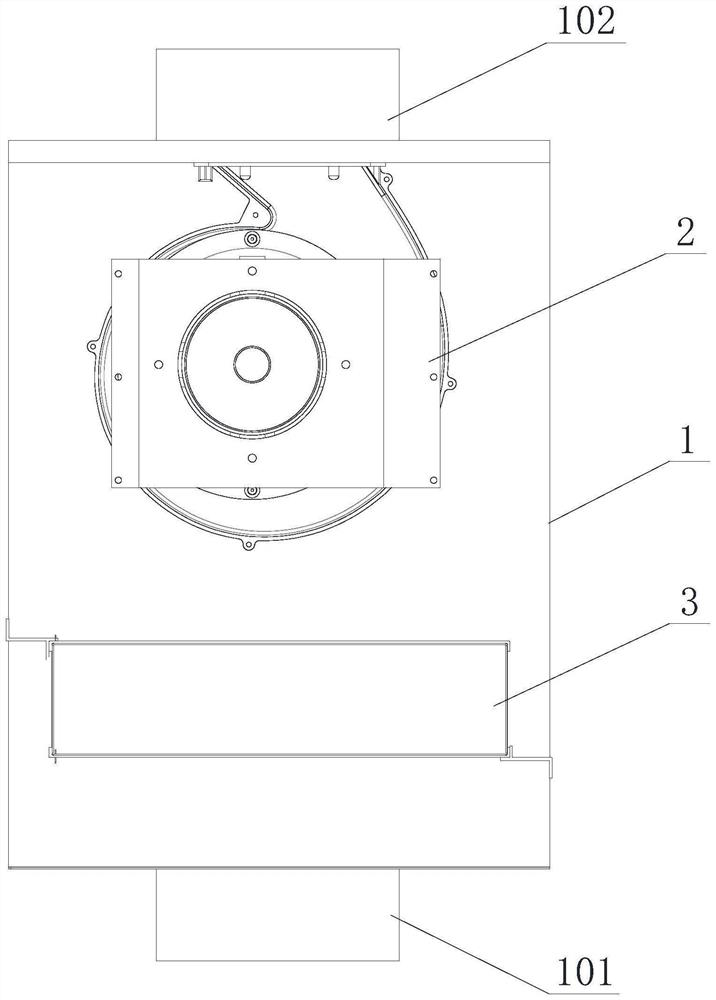

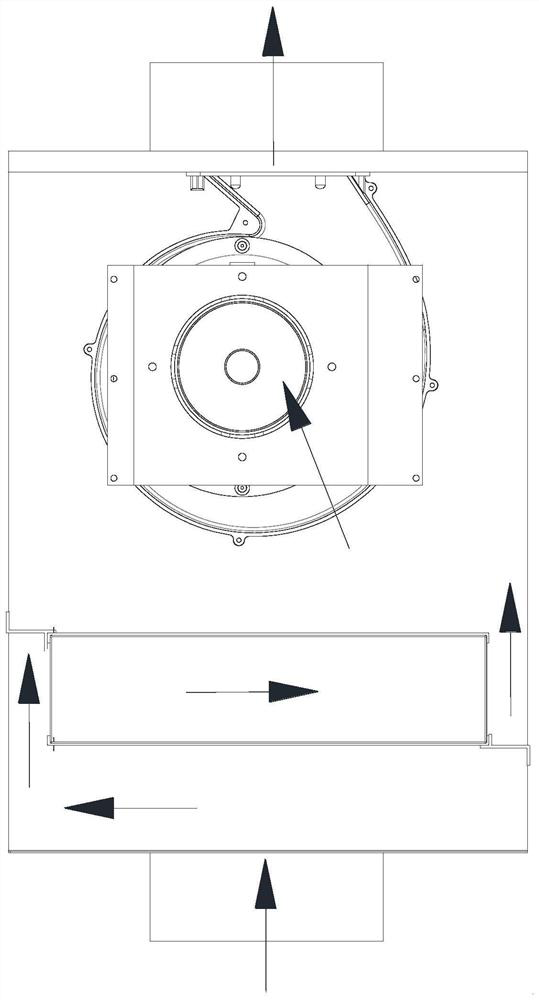

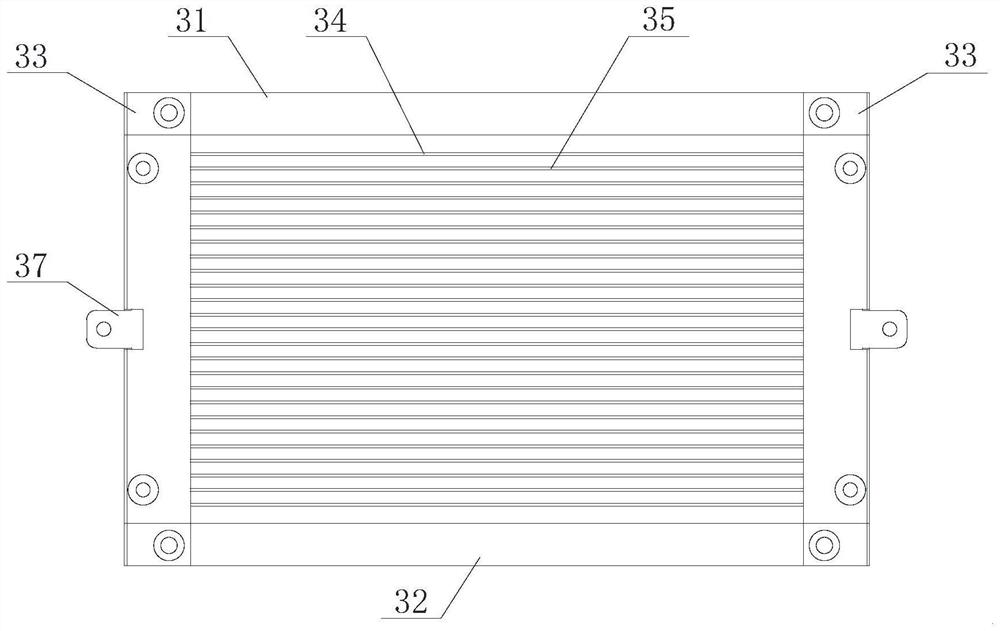

Fresh air ventilator with electrostatic dust collection device and electrostatic dust collection device for fresh air ventilator

InactiveCN113457846AHigh capacity storageLarge storage capacityExternal electric electrostatic seperatorElectric supply techniquesFiltrationFresh air

The invention discloses a fresh air ventilator with an electrostatic dust collection device. The fresh air ventilator comprises a shell, wherein an air inlet and an air outlet are formed in the shell; a centrifugal fan is arranged in the shell corresponding to the air outlet, and an electrostatic dust collection device is arranged in the shell corresponding to the air inlet; the electrostatic dust collection device comprises a top plate, a bottom plate and two side plates arranged between the top plate and the bottom plate; positive plates and negative plates are arranged between the two side plates; the positive plates and the negative plates are alternately arranged at intervals, and a channel is reserved between every two adjacent plates; and the length direction of the side plates is perpendicular to the air inlet direction of the fresh air ventilator. According to the fresh air ventilator, the air inlet direction of the electrostatic dust collection device in the fresh air ventilator is perpendicular to the air inlet direction of the fresh air ventilator, that is, fresh air enters from the side portion of the electrostatic dust collection device for dust collection and filtration, the magnetic field area is large, the purification efficiency is high, and the size of the needed fresh air ventilator is small. Correspondingly, the invention further provides an electrostatic dust collection device for the fresh air ventilator.

Owner:台州德备环境设备科技有限公司

Nanofiber/glass fiber composite filter material prepared by a kind of electrospinning method and the same

ActiveCN105233568BImprove uniformityElectric field interference weakenedFilament/thread formingFiltration separationGlass fiberFiber

The invention relates to a static spinning method and a nano fiber / glass fiber composite filter material prepared by the same. According to the static spinning method, multiple needles are used to carry out static spinning, and the needles are insulated to each other. The nano fiber / glass fiber composite filter material is prepared by laminating and combining different filter materials together from bottom to top, wherein the filter efficiency of filter materials increases from bottom to top; the side, which is provided with static spun fibers, of each filter material layer is upward, the surface of the top layer is covered by glass fiber filter paper to ensure that the top layer and bottom layer of the filter material are both made of glass fiber filter paper. For two neighbored filter material layers, the filter efficiency of the upper layer on particles with a size of 0.02 to 10 [mu]m is 1.03 to 1.3 times higher than that of the lower layer. The composite filter material comprises two to six filter material layers, and has an sandwich structure, wherein in the sandwich structure, glass fiber filter paper and nano fiber with an electret effect are arranged alternately. The nano fiber / glass fiber composite filter material has a filter efficiency of 99.999% or more on particles with a size of 0.02 to 10 [mu]m, and the pressure resistance is maintained at 10 to 30 Pa.

Owner:SHANGHAI XUNJIANG TECH CO LTD

Collector ring

The invention discloses a collector ring, which relates to a low voltage electrical appliance and aims to eliminate the restrictions of an outlet position in the assembly of the conventional collector ring and other equipment. The collector ring specifically has a structure formed by pouring copper rings (5) and resin (6) into a whole. One end of the collector ring is provided with a step. The copper ring (5) and a copper bus (2) are fixedly connected in a poured body. An insulating layer is arranged between the copper bus (2) and the copper ring (5) which is not connected with the copper bus (2). An outlet terminal of the copper bus (2) is positioned at the lower end face (4) of the step of the collector ring. Bolts (1) are arranged at the upper end face (3) of the step of the collector ring. The outside outlet of the collector ring can provide a rational outlet position for rotating equipment without a central outlet position so as to eliminate the restrictions of the outlet position in the assembly of the collector ring and the other equipment.

Owner:洛阳聚科特种工程机械有限公司

Drying agent for mine underground electric apparatus and preparation method thereof

ActiveCN102698573BSolve the problem of moisture absorption and dehumidificationPrevent accidents such as sudden power outagesDispersed particle separationLow voltageAlkali metal halide

The invention discloses a drying agent for an mine underground electric apparatus and a preparation method of the drying agent, belonging to the field of drying agent, wherein macromolecule water absorbent, compound of silicon or calcium and alkali halide or modified starch are mixed so as to prepare the powdery draying agent according to part by weight; the macromolecule water absorbent is 35-70 parts; the compound of silicon or calcium is 25-55 parts; the alkali halide or a mixture of the alkali halide and the modified starch is 10-15 parts; the grain size of the macromolecule water absorbent is 0.20-0.40mm; and the drying agent is powdery. According to the invention, raw material is wide in source and is purchased easily on the market; the drying agent is used for high / low-voltage power supply appliances worked on a mine underground high-humidity condition (RH=80-100%); the dry powder resists 6000V voltage or does not be broken down under voltage of 3000V; when moisture rate reaches to 1g / g, the dry powder resists 2500V voltage or does not be broken down under voltage of 1200V.

Owner:徐州意创化工科技有限公司

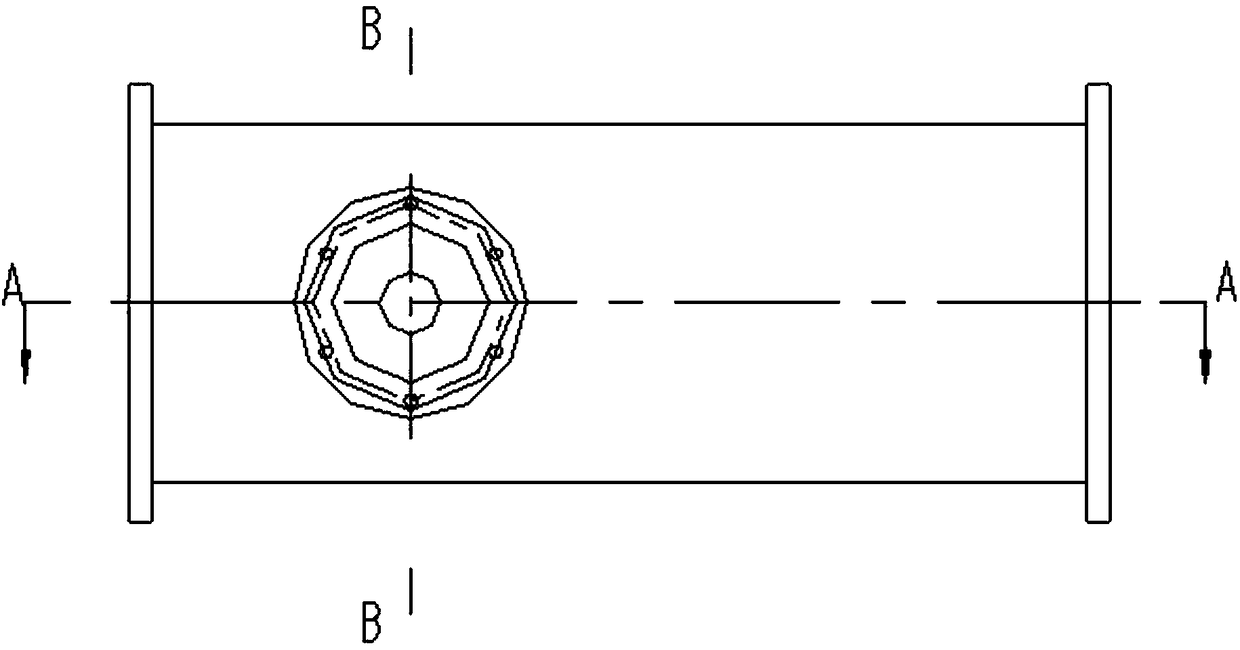

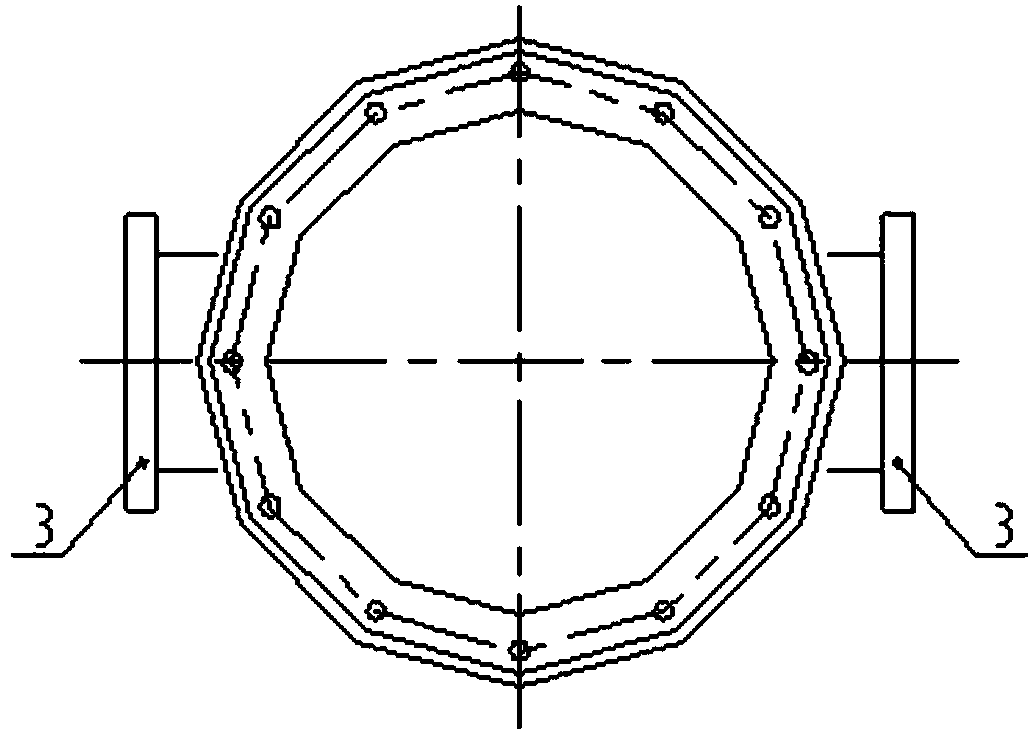

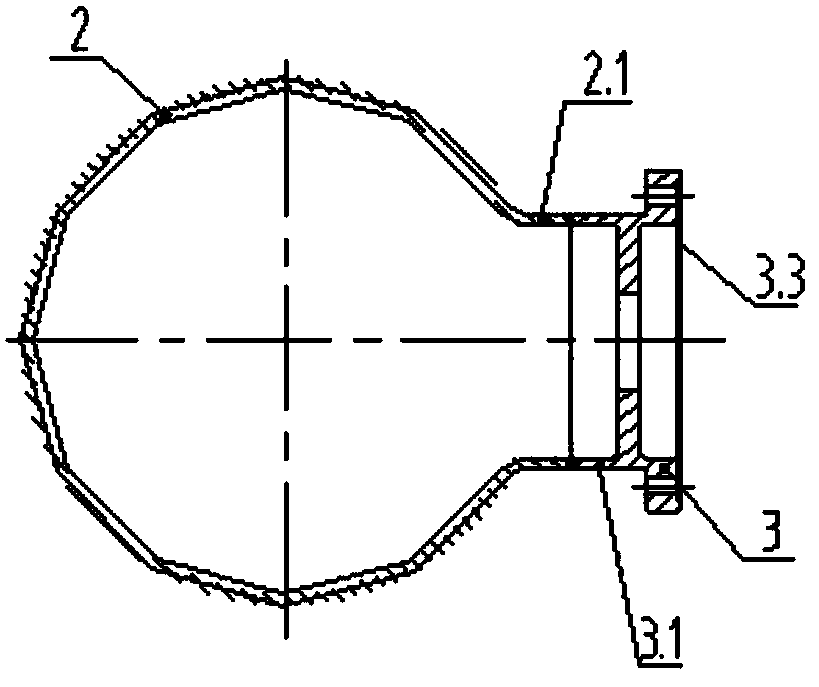

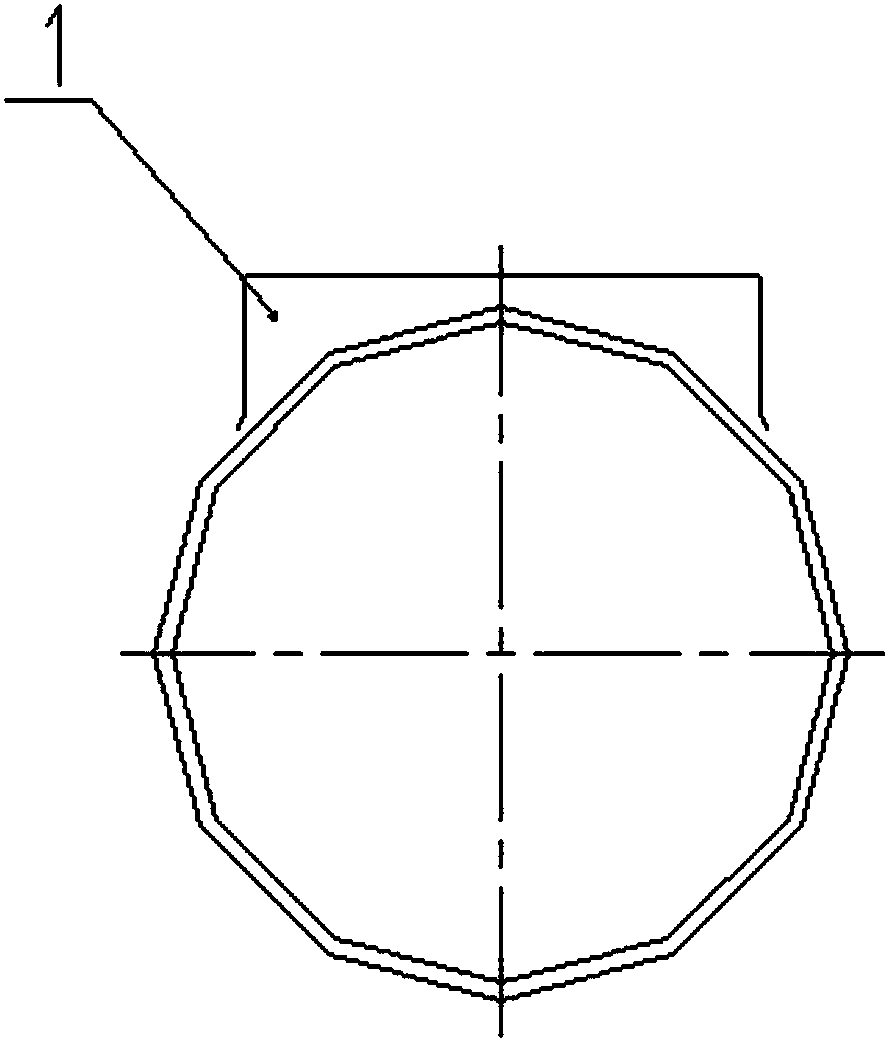

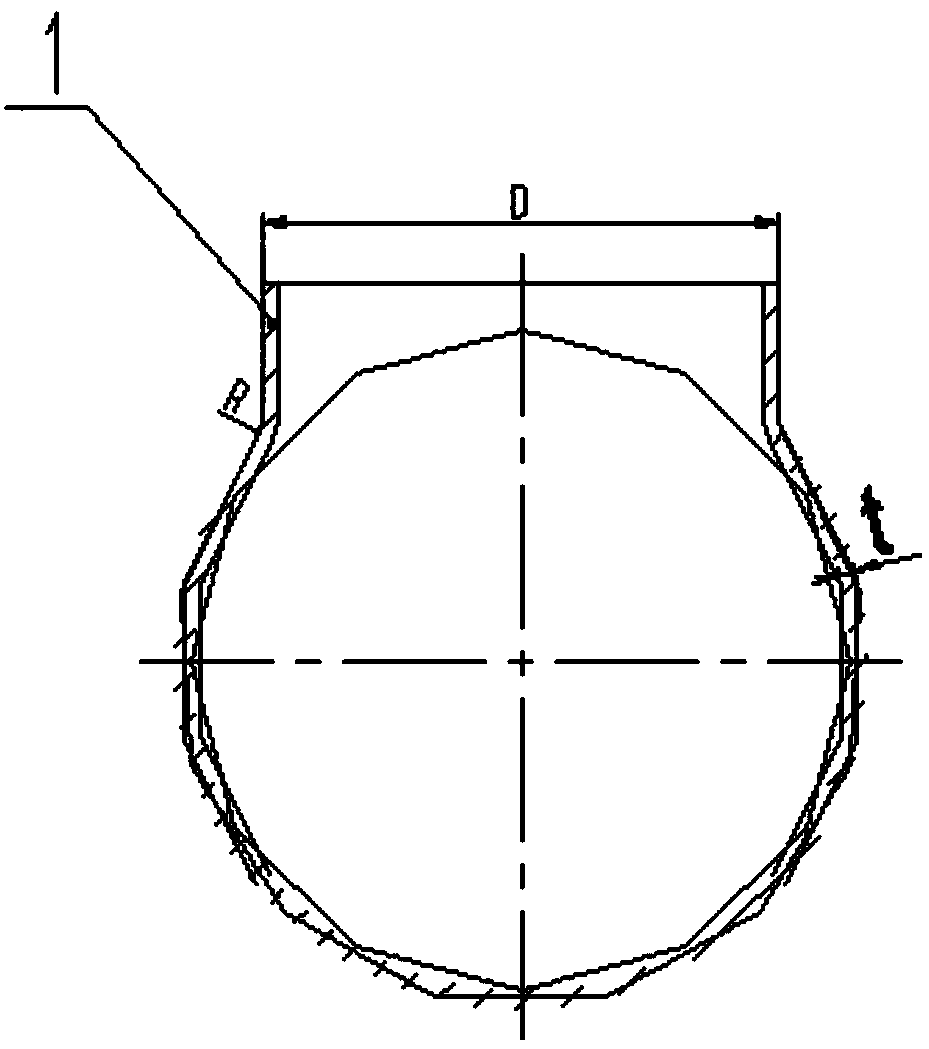

High-strength non-discharge current transformer housing main tube

InactiveCN108172387AImprove structural strengthReduce stress concentrationTransformersTransformers/inductances casingsStress concentrationElectric discharge

The invention discloses a high-strength non-discharge current transformer housing main tube. The main tube comprises a tube body and a secondary tube, the secondary tube is formed by outward flangingof a side wall opening of the tube body, and arch transition connection is adopted at the position where the tube body and the secondary tube joint; the main tube is further characterized in that an arch circular angle at the position where the tube body and the secondary tube joint is R>=1+1.5t (t is the thickness of the wall of the tube body), and flanging height is H<=(D-t)(1-K) / 2+0.43R+0.72t (D is the outer radius of the secondary tube and K is flanging coefficient). According to the main tube, the tube body and the secondary tube are of an integrated structure, structural strength is high, arch transition connection is adopted at the position where the tube body and the secondary tube joint, stress concentration is less, and electric discharge phenomena do not occur when the main tubeis used.

Owner:JIANGSU HAIDA ELECTRIC

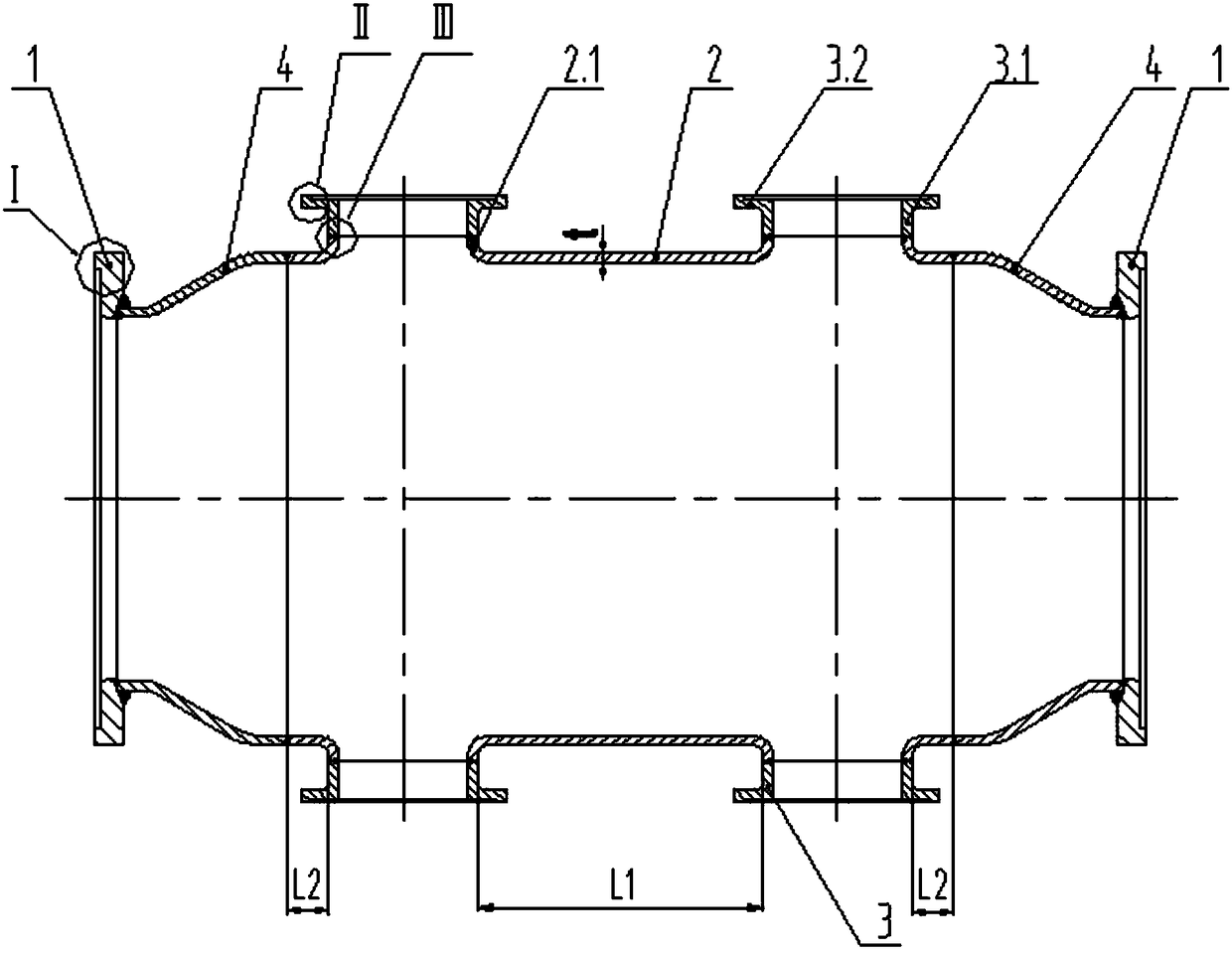

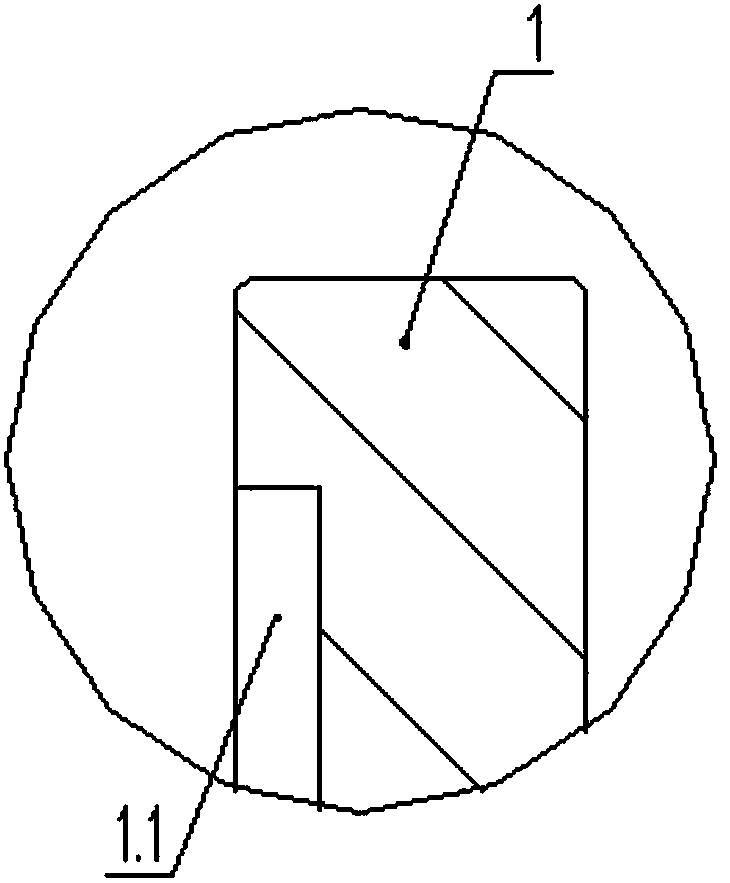

High-insulation linear disconnecting switch casing

InactiveCN108320982ANot easy to bruiseProtect the sealing surfaceAir-break switch detailsEngineeringWelding deformation

The invention discloses a high-insulation linear disconnecting switch casing which comprises a main cylinder, a main cylinder flange, a diameter variable cylinder and branch cylinder assemblies; eachbranch cylinder assembly is composed of a second branch cylinder and a branch cylinder flange, and each second branch cylinder is welded and fixedly connected to a corresponding first branch cylinderin the side surface of the main cylinder; the outward end surfaces of the main cylinder flange and the branch cylinder flanges are concaved to form first and second grooves respectively; further, holes are formed in the sidewall of the main cylinder, the holes extend outwardly to form the first branch cylinders respectively, and the position where the main cylinder is intersected with the first branch cylinders are in arched smooth connection; the minimal distance L1 between flanges of the adjacent first branch cylinders is greater than or equivalent to 7t (t represents the wall thickness of the main cylinder); the minimal distance L2 between the flange of the first cylinder and the end surface of the main cylinder is greater than or equivalent to 5t; and the hole walls in the main cylinder, the main cylinder flange, the diameter variable cylinder and the branch cylinder assemblies are coated with insulating coatings respectively. Thus, the sealing surfaces of the outward end surfacesof the main and branch cylinder branches are protected effectively, welding deformation is low, a discharging phenomenon does not occur, the insulating performance is high, and use is safe and reliable.

Owner:JIANGSU HAIDA ELECTRIC

Direct-current electric cable terminal oil-gas interface lifting device

ActiveCN103887757APlay a protective effectNo discharge phenomenonCable terminationsAir interfaceFuel tank

The invention discloses a direct-current electric cable terminal oil-gas interface lifting device which comprises an electric cable, an electric cable wire core, a wire-out rod, a top cover, a rain cover, an insulation sleeve pipe, insulation oil and a sleeve pipe flange. The direct-current electric cable terminal oil-gas interface lifting device is characterized in that a prefabricated oil tank is further included, one end of the prefabricated oil tank is connected to the sleeve pipe flange through a screwing bolt, the other end of the prefabricated oil tank is connected with the top cover through the screwing bolt, a cavity of the insulation sleeve pipe of a direct-current electric cable terminal is filled with the insulation oil, so that the insulation oil interface is lifted until the height of the insulation oil interface is lifted to more than 1 / 2 of the height of the prefabricated oil tank, the height of the insulation oil interface exceeds the horizontal face of the sleeve pipe flange, a Faraday cage is formed on the sleeve pipe of the direct-current electric cable terminal, the direct-current electric cable terminal is protected, and the discharging phenomenon generated on the air interface of the direct-current electric cable terminal under the effect of a direct-current electric field or an extra-high-voltage alternating-current electric field is avoided.

Owner:上海三原电缆附件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com