Discharging unit used for ozone generator

A technology of ozone generator and discharge unit, which is applied in the field of ozone generator, can solve the problems of non-replacement, failure of discharge unit, high processing technology requirements and high manufacturing cost, and achieve convenient installation and replacement, small dielectric loss and good heat dissipation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

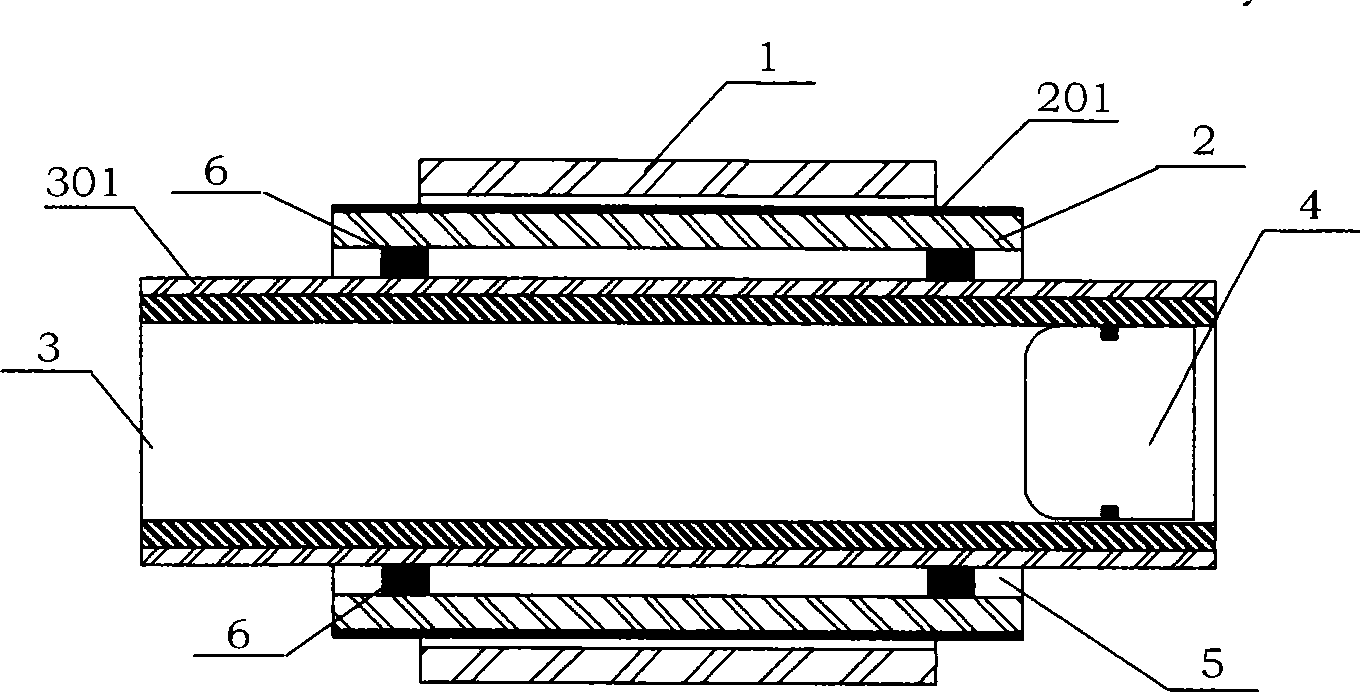

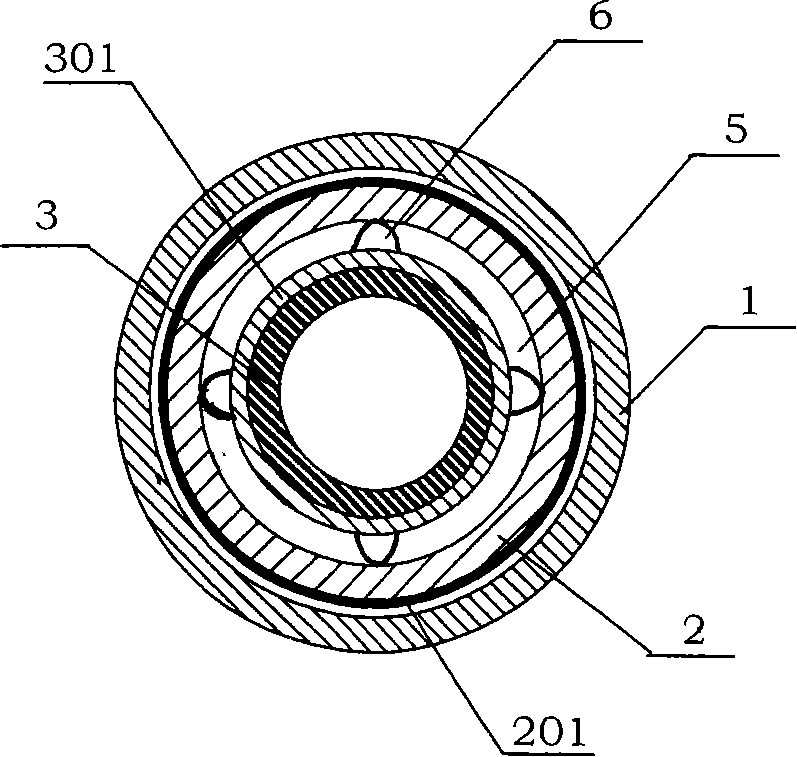

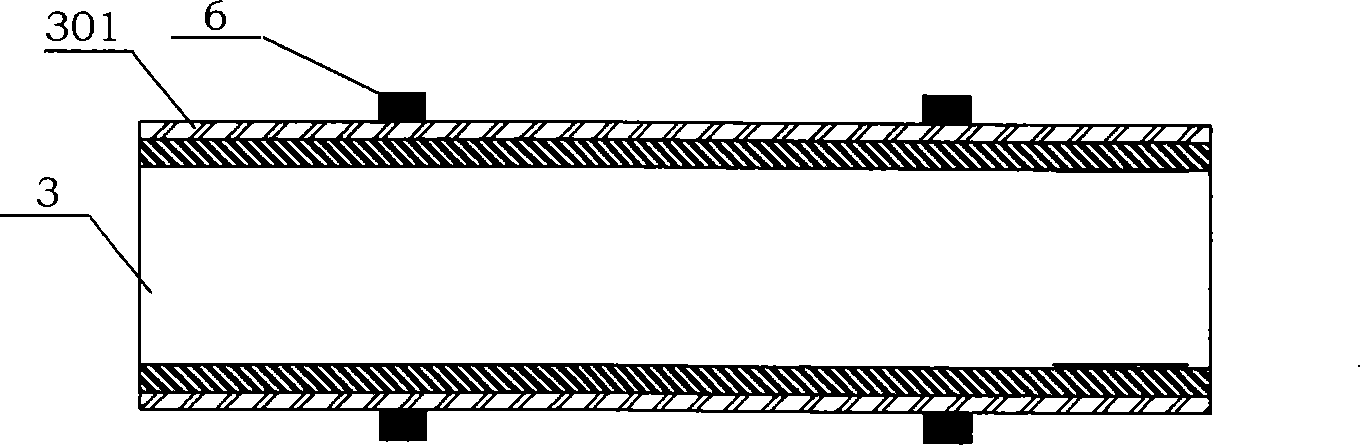

[0019] Such as Figure 1-3 As shown, the discharge unit for the ozone generator provided by the present invention includes a ground electrode 1, an insulating tube 2 and a high-voltage electrode 3 each installed in a phase sleeve. The high-voltage electrode 3, the insulating tube, and the ground electrode 2 are arranged in order from the inside to the outside. 1. The ground electrode 1 is grounded, and the discharge gap 5 is set between the high-voltage electrode 3 and the insulating tube 2. The ground electrode 1 and the insulating tube 2 are two components that are closely matched but separated from each other. The outer surface of the insulating tube 2 is covered. There is a conductive metal layer 201. The conductive metal layer 201 on the outer surface of the insulating tube 2 and the ground electrode 1 are both grounded. The high-voltage electrode 3 is made of ozone-resistant conductive material stainless steel 316L, and its outer surface is covered with a metal oxide film 301...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com