Electrostatic precipitator

An electrostatic dust collector and electrostatic dust collection technology, applied in the field of air purification, can solve problems such as short circuit of adjacent dust collection plates, easy water storage in spacers, and burning of spacers, and achieve various molding methods and overcome dust collection efficiency Low, reduce the effect of electromagnetic radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

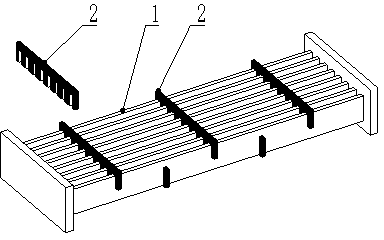

[0019] figure 1 Shown is a typical structure of a dust collection unit of a traditional electrostatic precipitator. The dust collection plate 1 is a metal plate, and the spacer 2 is a comb-shaped rack made of insulating plastic. The spacer 2 is stuck between the dust collection plates, so that Each dust collecting plate keeps equal distance. In order to avoid air discharge between adjacent dust collecting plates, the distance between the dust collecting plates 1 is generally 5-10 mm.

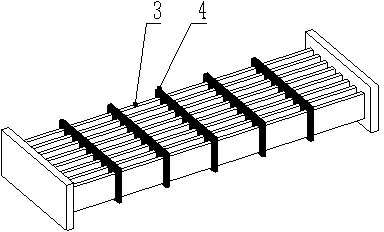

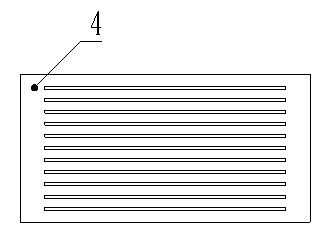

[0020] Such as figure 2 As shown, it is a schematic structural diagram of an electrostatic dust collection unit according to an embodiment of the present invention, and the surface of the dust collection plate 3 is covered with an insulating material. The spacer 4 is made of metal, and its shape is as follows: image 3 As shown, there are several long slits with a width of 0.5 mm on the metal plate for passing the dust collecting plates 3 and keeping the adjacent dust collecting plates at an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com