High-strength non-discharge current transformer housing main tube

A current transformer, high-strength technology, applied in the direction of transformer/inductor casing, inductor, circuit, etc., can solve the problems of easy discharge and affecting the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Hereinafter, the present invention will be further explained based on the drawings and the embodiments.

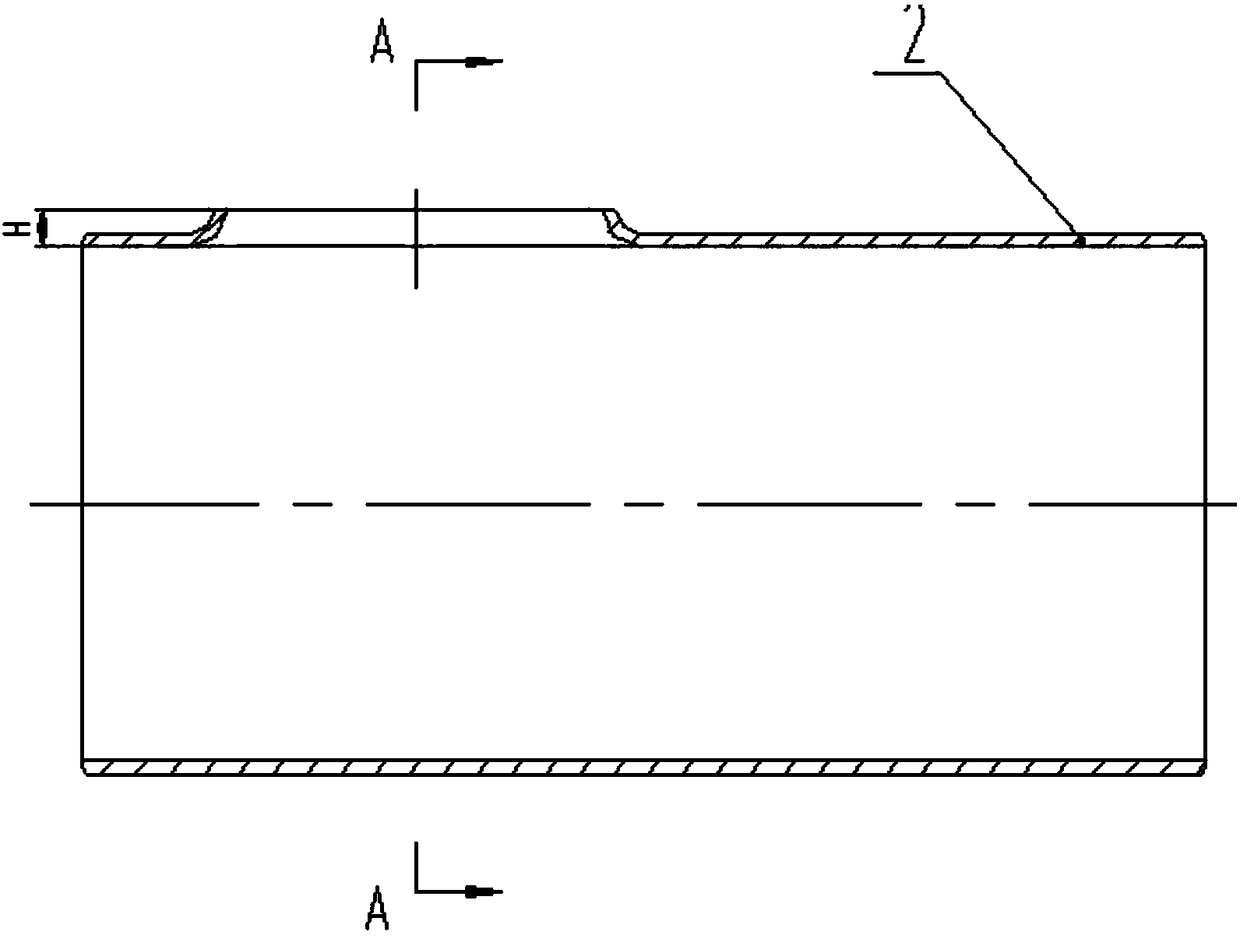

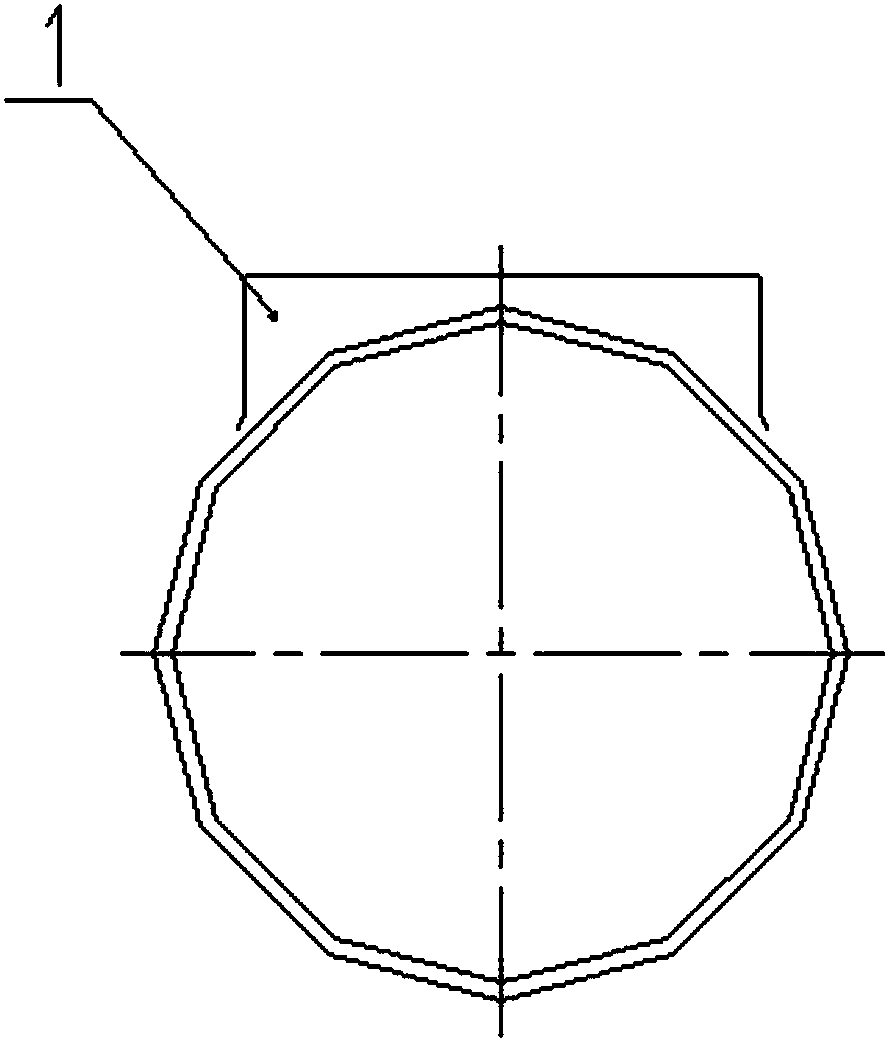

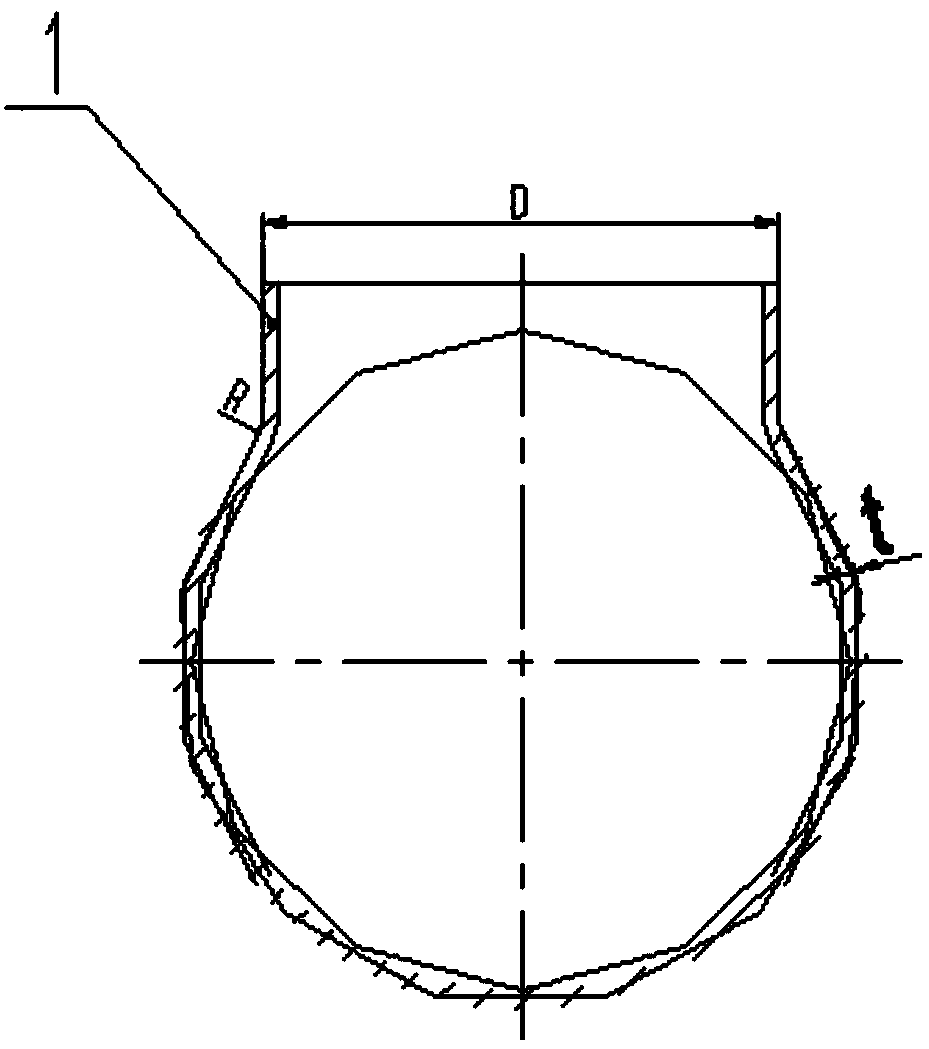

[0014] The main cylinder of the high-strength non-discharge current transformer housing shown in the figure includes a cylinder body 2, a support cylinder 1. The support cylinder 1 is formed by an opening on the side wall of the cylinder body 2 and flanged outwards. The cylinder body 2 and the support cylinder 1 intersect At the arc transition connection.

[0015] The arc fillet at the intersection of the cylinder body 2 and the branch cylinder 1 is R≥1+1.5t (t is the wall thickness of the cylinder body 2), the flange height H ≤(Dt)(1-K) / 2+0.43R+0.72t (D is the outer diameter of the support cylinder 1 and K is the flanging coefficient). In this embodiment, the wall thickness t of the cylinder 2 is 8mm, the outer diameter D of the support cylinder 1 is 200 mm, the material is aluminum alloy, and the flanging coefficient K is 0.7, the arc fillet R at the intersection of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com