DC cable terminal oil-air interface lifting device

A DC cable, oil-gas interface technology, applied in the direction of cable terminals, etc., can solve the problems of no air cavity, increased operating costs, increased product costs, etc., to achieve the effect of saving material costs, small size, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

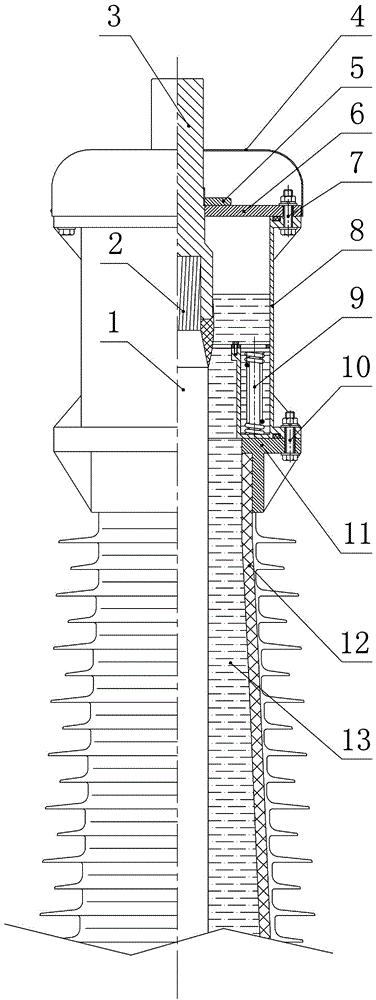

[0010] According to the accompanying drawings, the present invention is a DC cable terminal oil-gas interface lifting device, which is applied to DC cable terminals and can also be applied to UHV AC cable terminals, including cable 1, cable core 2, outlet rod 3, top cover 6, rain cover 4. Insulating bushing 12, insulating oil 13, bushing flange 11 and prefabricated oil tank 8. The prefabricated oil tank 8 has no bottom and no cover, one end of which is connected to the sleeve flange 11 by the second tightening bolt 10, and the other end is connected to the top cover 6 by the first tightening bolt 7, and is connected to the DC cable terminal through the insulating sleeve 12 Insulating oil 13 is poured into the cavity to lift the insulating oil interface upward until the interface height of the insulating oil 13 is raised to more than half of the height of the prefabricated oil tank 8, and the interface height of the insulating oil 13 exceeds the horizontal plane of the casing fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com