a collector ring

A technology of collector rings and copper rings, applied in the field of collector rings, can solve the problems of finding no way out of the wire, increasing the difficulty of actual assembly operations, etc., and achieving the effect of preventing fires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention is further described below in conjunction with preferred embodiments:

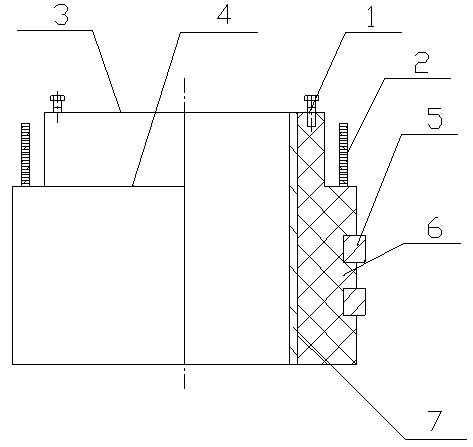

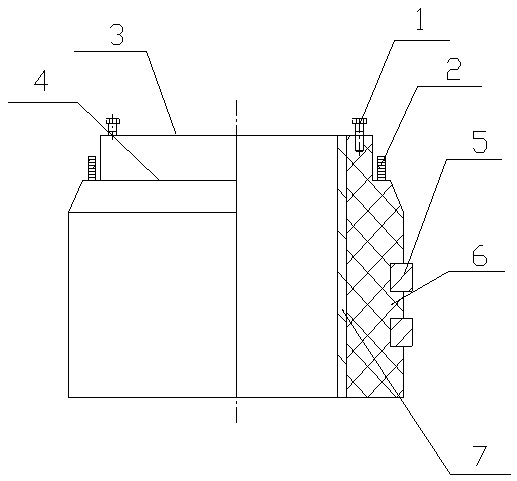

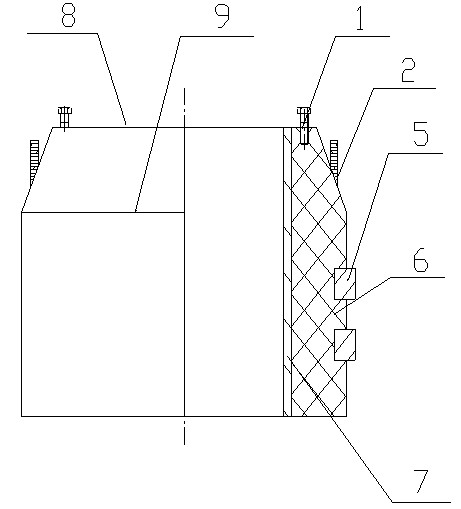

[0030] to combine figure 1 , a collector ring, which is set as a structure in which a copper ring 5 and a resin 6 are poured into one body, and one end of the collector ring is provided with a step, and the step is divided into an upper end surface 3 and a lower end surface 4; the copper ring and the copper busbar 2 are formed from The interior of the pouring body is fixed, and an insulating layer is set between the copper busbar and the unconnected copper ring, and the outlet end of the copper busbar is located at 4 places on the lower end surface of the step of the collector ring. Bolts 1 are provided on the upper end surface of the stepped end of the collector ring to facilitate connection with other equipment; according to actual needs, the bolts can be evenly distributed on the upper end surface or set according to the situation. The collector ring is provided with a steel plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com