Power supply connection box of high-voltage motor

A technology of power wiring and high-voltage electricity, which is applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of high product cost, inability to guarantee the minimum electrical clearance and minimum creepage distance of exposed charged bodies, and cable skewing, etc., to achieve The effect of low product cost, few parts and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

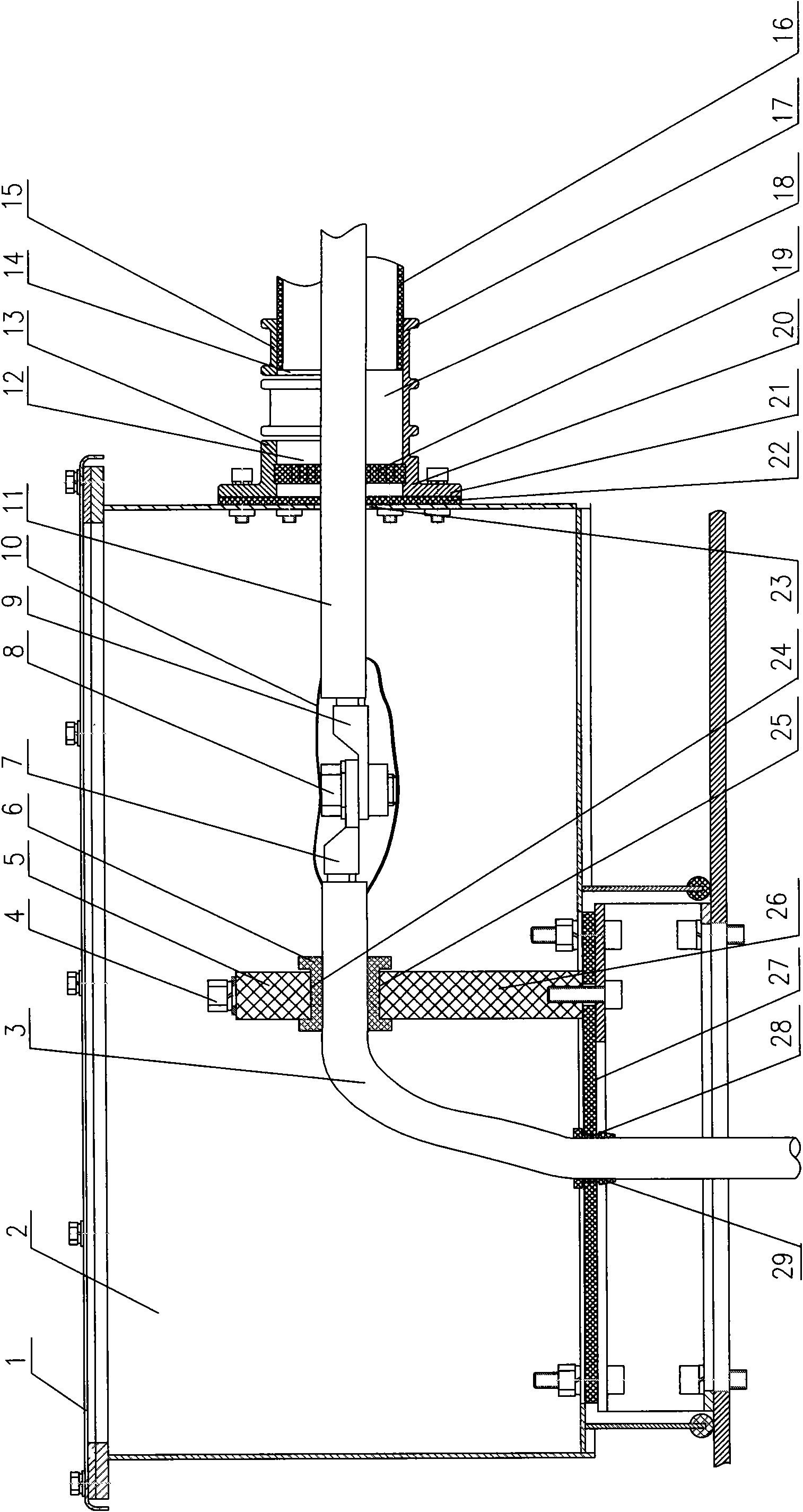

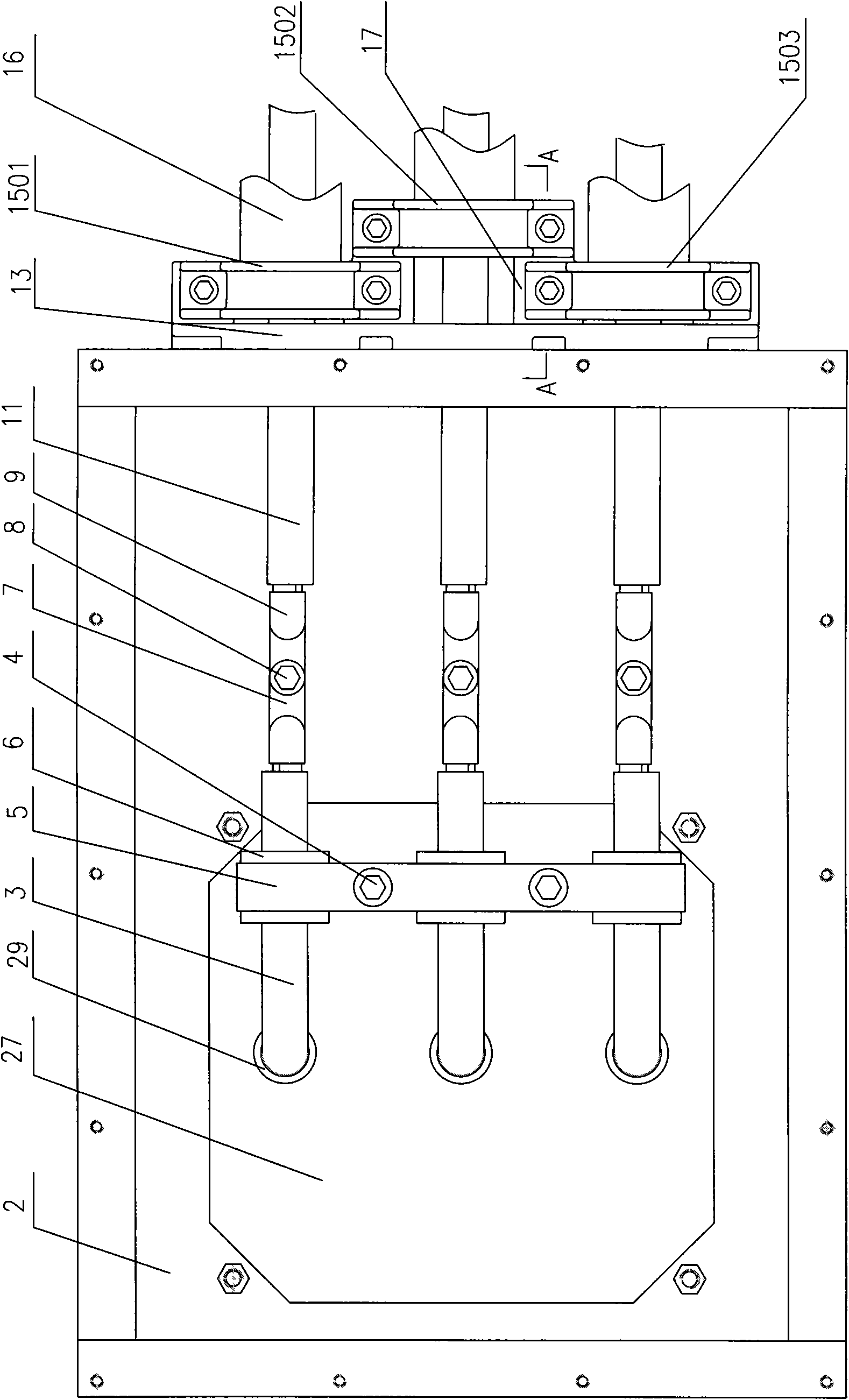

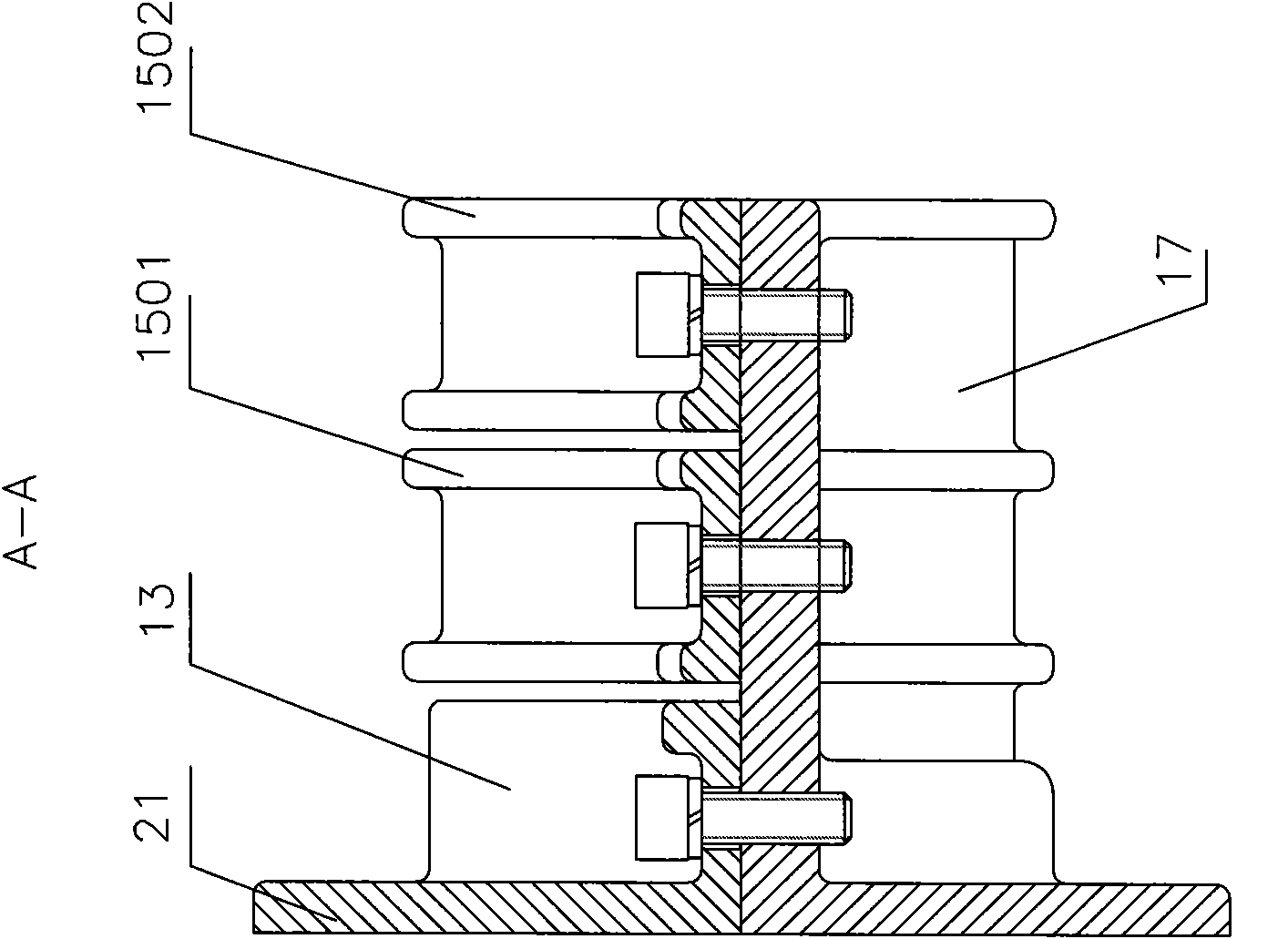

[0017] exist figure 1 Among them, a power connection device for a high-voltage motor, including a junction box cover 1 , a junction box seat 2 , a motor stator outlet cable 3 , a power supply cable 11 and a fixed connection assembly 20 . The junction box cover 1 and the junction box base 2 are mated and connected by connecting screws at the mating position. The power supply cable 11 is fixed between the fixed connection assembly 20 and the junction box seat 2, and extends into the box seat through the wire inlet hole 23 on the side wall of the box seat.

[0018] Such as figure 1 , figure 2 As shown, an insulating outlet plate 27 is installed on the bottom of the junction box seat 2 through its four-corner connecting bolts and nuts. The outlet plate 27 is made of epoxy glass cloth plate 3240. Drill φ30 outlet holes 28 on the outlet plate 27 according to the number of motor stator outlet cables. There are usually three outlet cables for the stator of a high-voltage motor, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com