Method for preparing melt-blown polypropylene electret filter material

A technology of melt-blown polypropylene and filter materials, which is applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., and can solve the practical requirements of application limitations, single types of filter materials, and uniform electret electric field stability and other problems to achieve the effects of slow pressure loss, improved economic benefits, and excellent filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

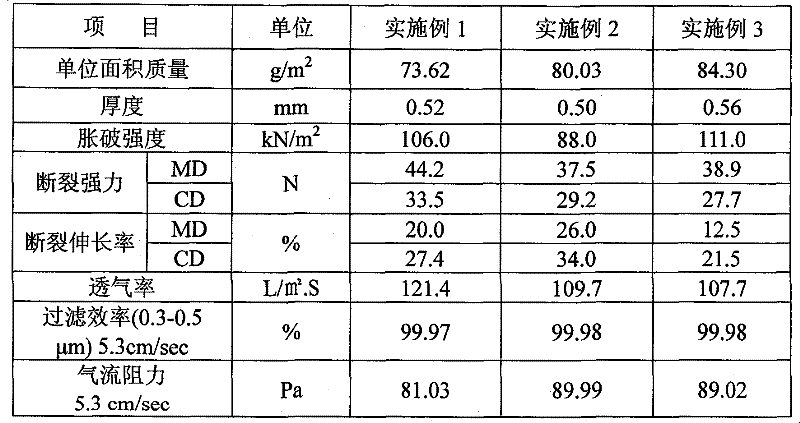

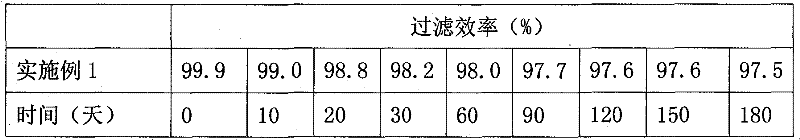

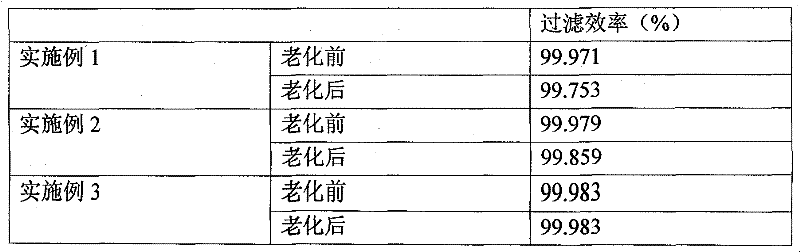

Embodiment 1

[0036] A preparation method of melt-blown polypropylene electret filter material, comprising the following steps:

[0037] 1) Modification of polypropylene: the raw polypropylene is melted, mixed with 4Wt% additives, and the melt index is controlled to 1200 to obtain modified polypropylene; the additives are modified rosin, stearate, ethylene distearate Amide blend.

[0038] 2) Meltblown preparation process:

[0039] a) Select a spinneret with an aperture diameter of 0.3 microns and an aspect ratio of 15, and in the molten state, feed the modified polypropylene melt into the spinneret with a metering pump;

[0040] b) The temperature of the extruder is controlled at 220°C, the temperature of the spinneret is controlled at 260°C, and the frequency of the metering pump is controlled at 25Hz, and the modified polypropylene melt is extruded from the spinneret hole.

[0041] c) Blow the melt extruded from the spinneret hole into ultra-fine fibers with high-speed hot air, make it fl...

Embodiment 2

[0045] A preparation method of melt-blown polypropylene electret filter material, comprising the following steps:

[0046] 1) Modification of polypropylene: the raw polypropylene is melted, mixed with 3Wt% additives, and the melt index is controlled to 1100 to obtain modified polypropylene; the additives are modified rosin, stearate, ethylene distearate Amide blend.

[0047] 2) Meltblown preparation process:

[0048] a) Select a spinneret with an aperture diameter of 0.2 microns and an aspect ratio of 12, and in the molten state, feed the modified polypropylene melt into the spinneret with a metering pump;

[0049] b) The temperature of the extruder is controlled at 230°C, the temperature of the spinneret is controlled at 270°C, and the frequency of the metering pump is controlled at 25Hz, and the modified polypropylene melt is extruded from the spinneret hole.

[0050] c) Blow the melt extruded from the spinneret hole into ultra-fine fibers with high-speed hot air, make it ...

Embodiment 3

[0054] A preparation method of melt-blown polypropylene electret filter material, comprising the following steps:

[0055] 1) Modification of polypropylene: the raw polypropylene is melted, mixed with 4.5Wt% additives, and the melt index is controlled to 1300 to obtain modified polypropylene; the additives are modified rosin, stearate, ethylene bihard Fatty amide blend.

[0056] 2) Meltblown preparation process:

[0057] a) Select a spinneret with an aperture diameter of 0.2 microns and an aspect ratio of 16, and feed the modified polypropylene melt into the spinneret with a metering pump in a molten state;

[0058] b) The temperature of the extruder is controlled at 210°C, the temperature of the spinneret is controlled at 250°C, the frequency of the metering pump is controlled at 25Hz, and the modified polypropylene melt is extruded from the spinneret hole.

[0059] c) Blow the melt extruded from the spinneret into ultra-fine fibers with high-speed hot air, make it fly to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com